Ac motor system and method for controlling same, and related power conversion device

A technology of power conversion device and electric motor, applied in the direction of AC motor control, control system, electrical components, etc., can solve the problems of DC voltage fluctuation, uneconomical, inconsistent power, etc., and achieve the effect of increasing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

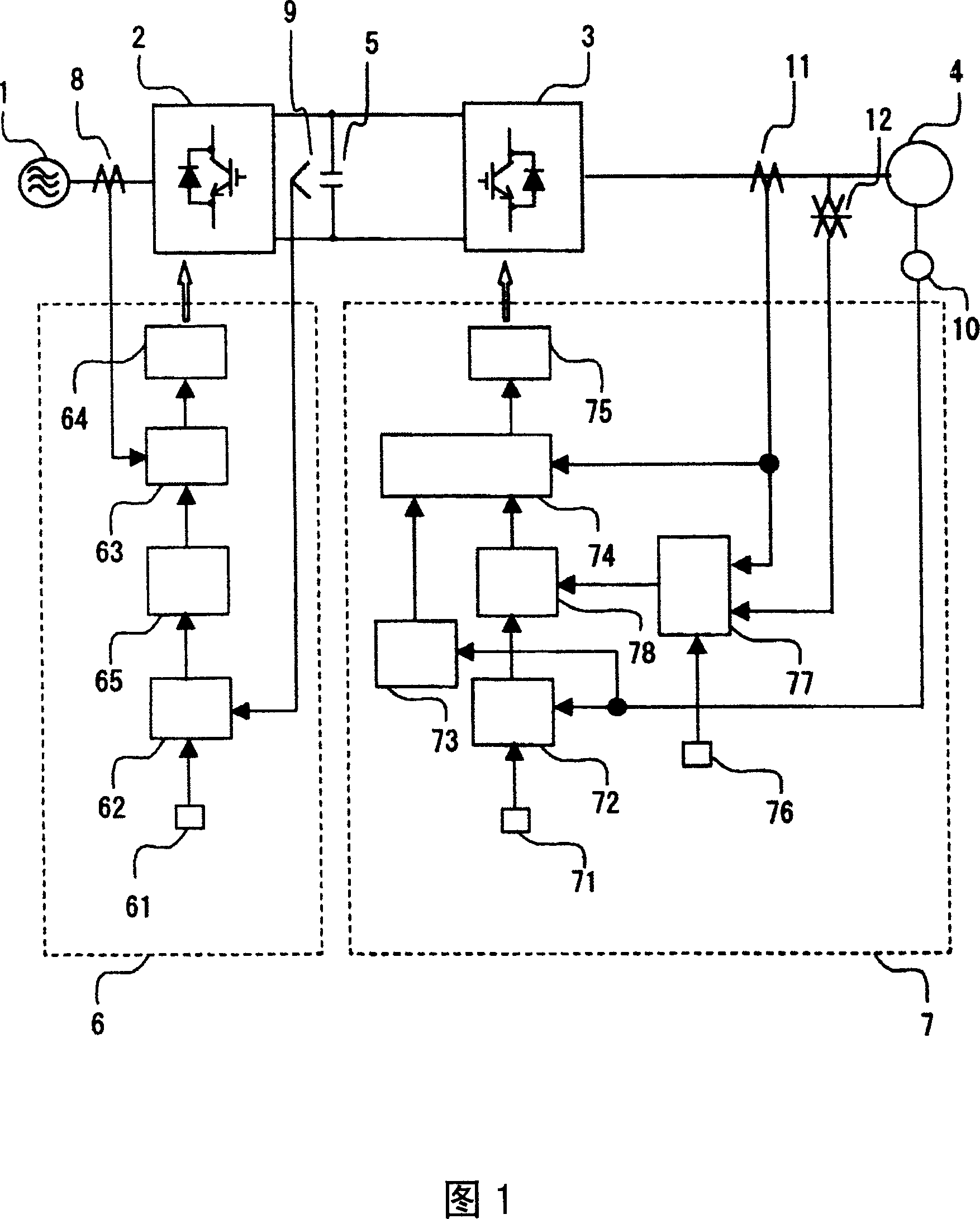

[0020] Fig. 1 is an overall configuration diagram of the present invention. 1 is an AC power supply, 2 is a rectifier that converts the AC power of the AC power supply 1 into DC power, 3 is an inverter that converts the DC power output by the rectifier 2 into desired power, and 4 is the above-mentioned An AC motor driven by the power output from the inverter 3, 5 is a smoothing capacitor provided between the rectifier and the inverter, and 6 is a rectifier control device that operates the rectifier 2 so that the DC voltage becomes a predetermined value , 7 is an inverter control device that operates the inverter 3 so that the output torque and speed of the electric motor 4 meet desired characteristics. 8 is a current detector, which detects and outputs the output current of the rectifier 2 . 9 is a voltage detector, which detects and outputs the voltage across the smoothing capacitor 5, that is, the DC voltage. 10 is a speed detector directly connected to the motor 4, which ...

Embodiment 2

[0036] Fig. 5 is another embodiment of the device of the present invention, instead of the power limit value setter 76, a power limit set value calculator 79 and a power supply voltage fluctuation detector 80 that detects the fluctuation amount of the AC power supply 1 are set, and detects The power supply voltage fluctuation amount is input to the power limit set value calculator 79, and the power limit set value is calculated in the power limit set value calculator 79 according to the power supply voltage fluctuation amount, and the calculated set value is input to The power limit computing unit 77 is different from FIG. 1 in this point. In FIG. 1 , the maximum inverter output power determined by the control capability of the rectifier is set as a fixed value in the power limit value setter 76 , but the control capability of the rectifier varies according to the operating conditions of the rectifier. For example, when the AC power supply voltage drops, the rectifier current ...

Embodiment 3

[0039] 6 is another embodiment of the device of the present invention. In the current command limiter 65 on the rectifier side, the margin of the output rectifier current command relative to the rectifier current limit value is input to the power limiter set value calculator 79 . The power limit set value calculator 79 is different from FIG. 5 in that the power limit set value is calculated based on the margin of the rectifier current command, and the calculated set value is input to the power limit calculator 77 . In FIG. 5 , only fluctuations in the rectification control capability are defined as power supply voltage fluctuations. However, although the influence of the power supply voltage fluctuation is large, other various factors such as the efficiency fluctuation of the transformer and the DC voltage fluctuation also cause the control capability to fluctuate. Therefore, due to fluctuations in the control capability of the rectifier due to these influences, the power limi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com