Ion implantation system and method

An ion implantation system and ion implantation technology, applied in the field of ion implantation systems, can solve problems such as the difficulty of applying ion implantation to large-sized wafer workpieces, and achieve the effects of improving dose uniformity, saving costs, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

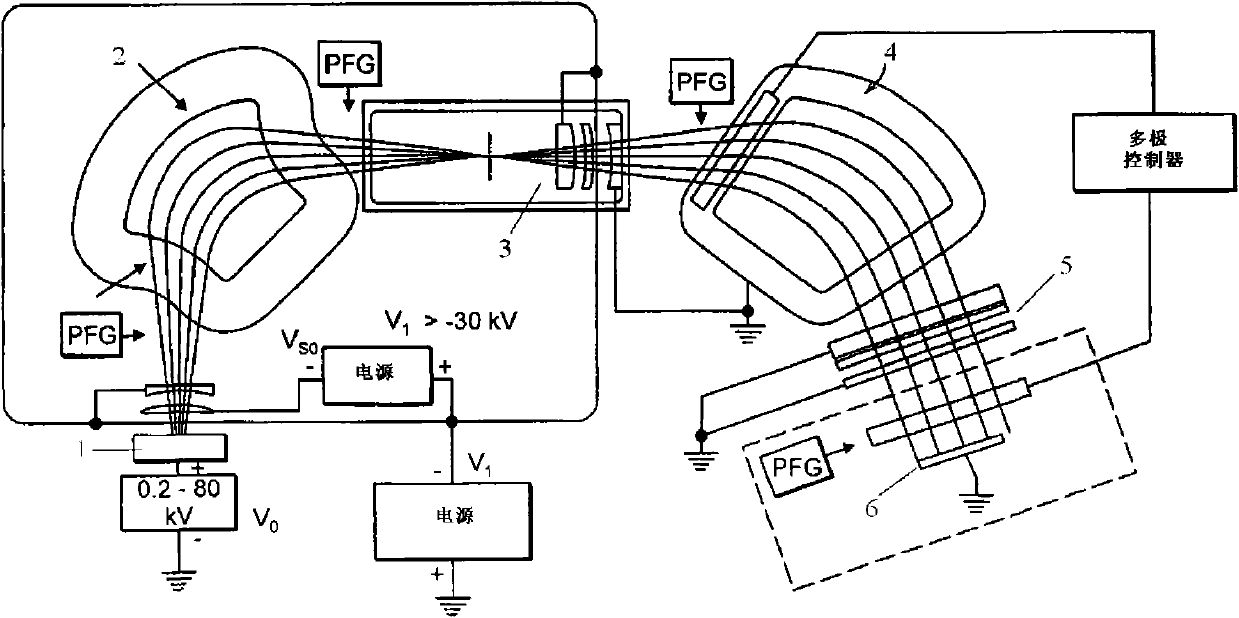

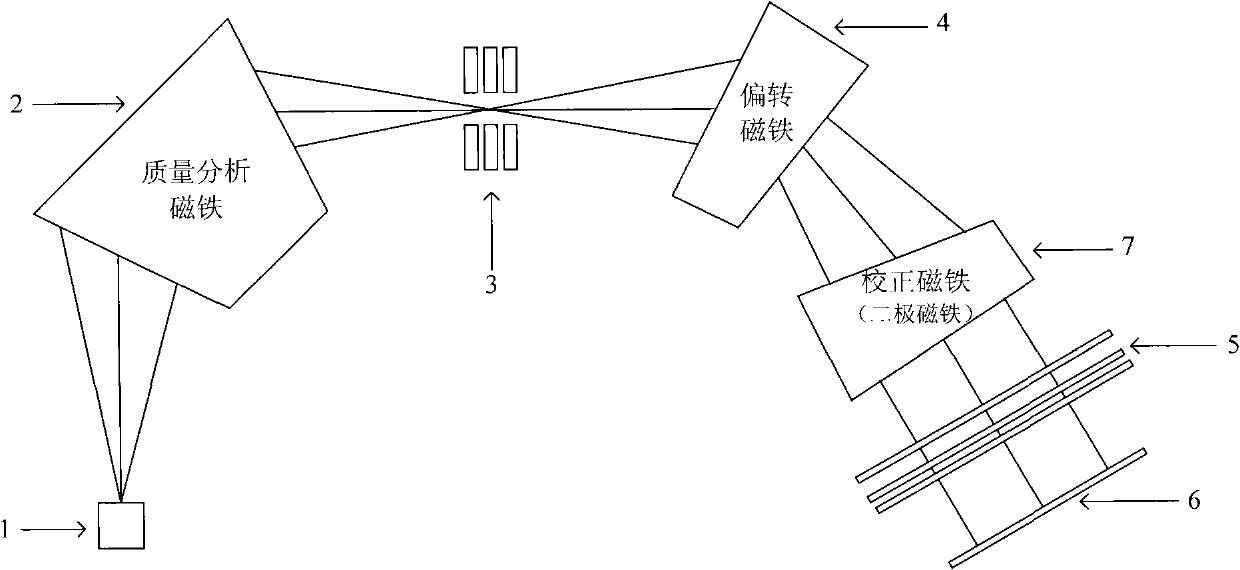

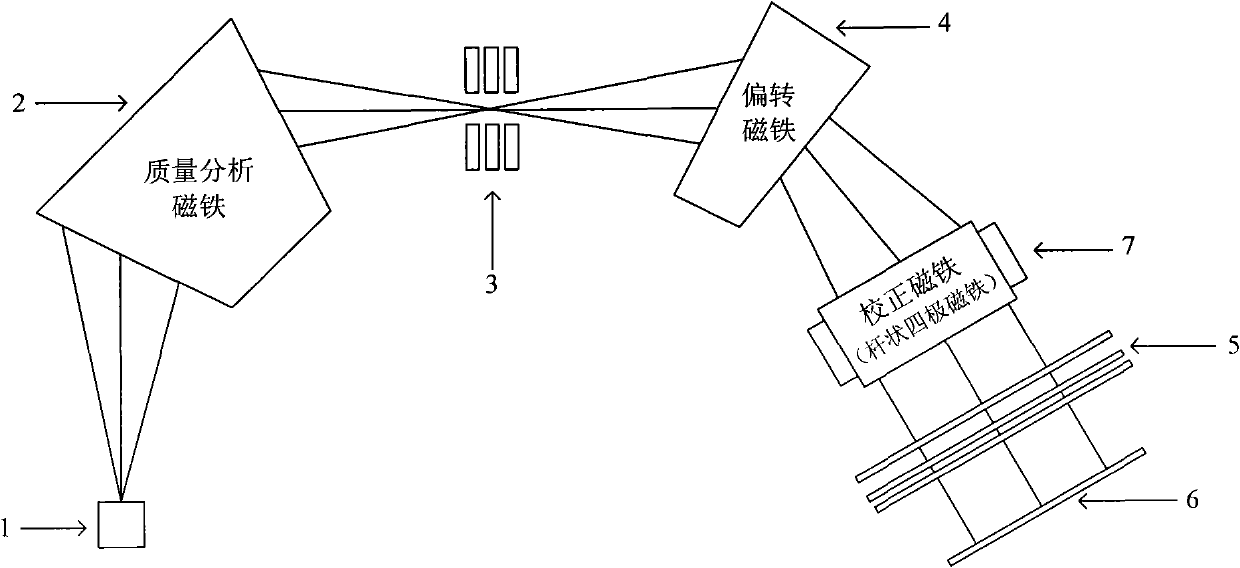

[0024] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0025] Such as figure 2 and image 3 As shown, similar to the existing system, the ion implantation system of the present invention includes an ion source and an extraction device 1 for extracting an ion beam from the ion source. On the transmission path of the ion beam, the ion implantation system of the present invention is also sequentially provided with: a mass analysis magnet 2, which is used to deflect the beam current by about 90°, so as to select the ion beam within a preset charge-to-mass ratio range. In addition, a group of small magnetic poles driven by a motor can also be preferably set in the mass analysis magnet 2, and by adjusting the position of the group of small magnetic poles, the beam current passing through the mass analysis magnet 2 can be controlled. Fine-tuning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com