Servo-motor acceleration-deceleration control method for servo pressure machine

An acceleration and deceleration control, servo press technology, applied in the direction of motor generator control, motor control, electronic commutation motor control, etc., can solve the control flexibility limit, can not effectively use the constant and maximum output torque, can not give full play Servo motor performance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

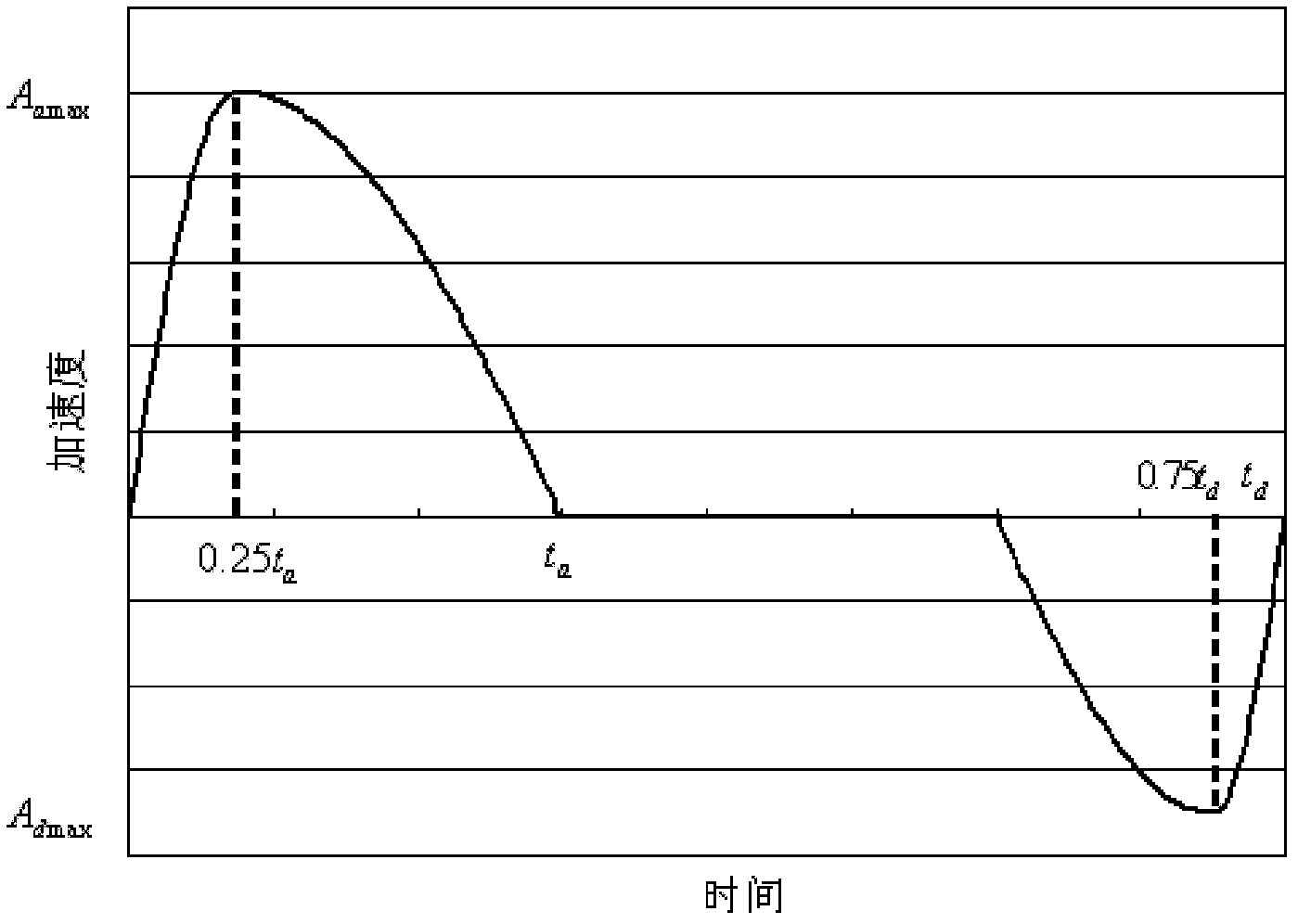

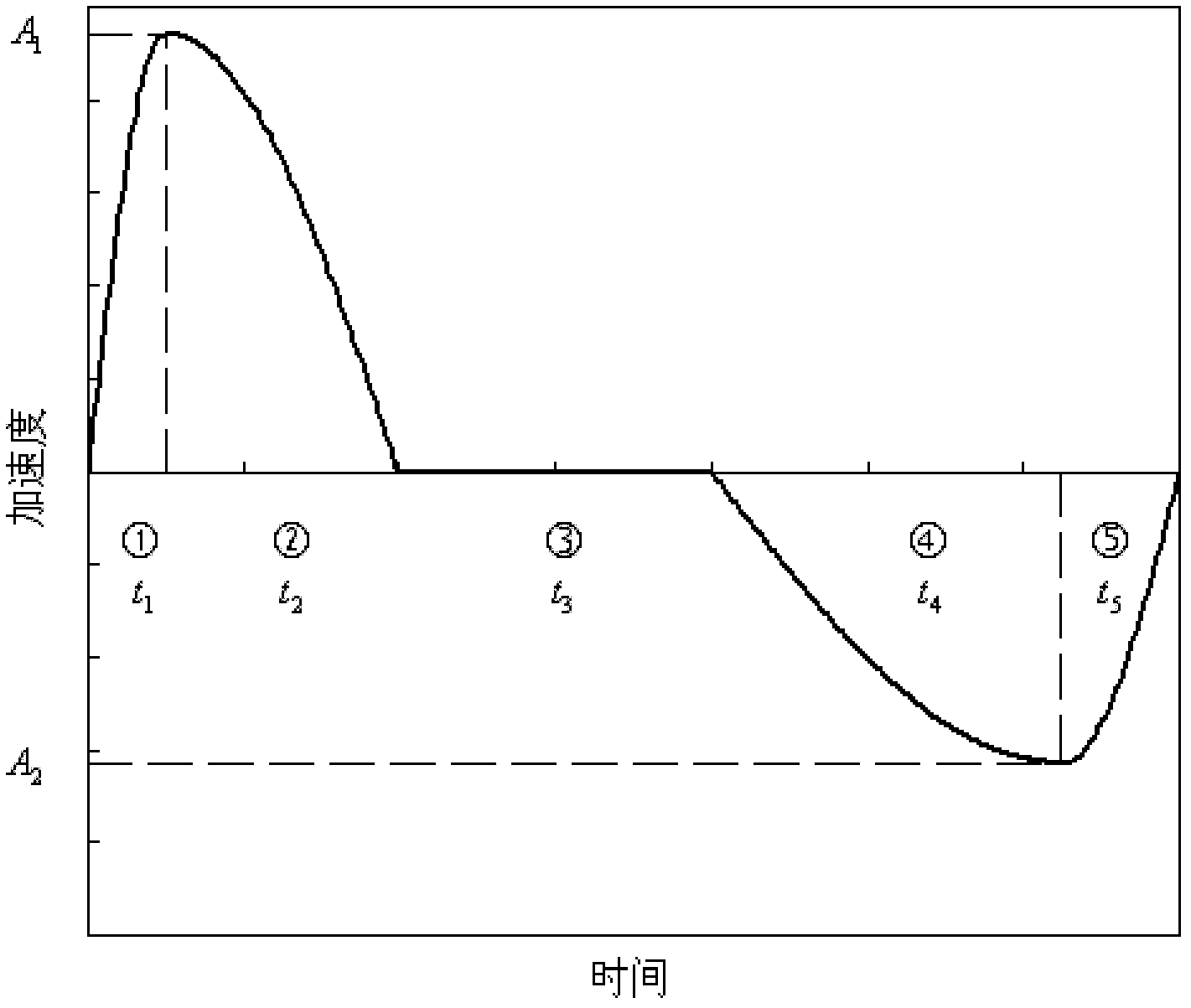

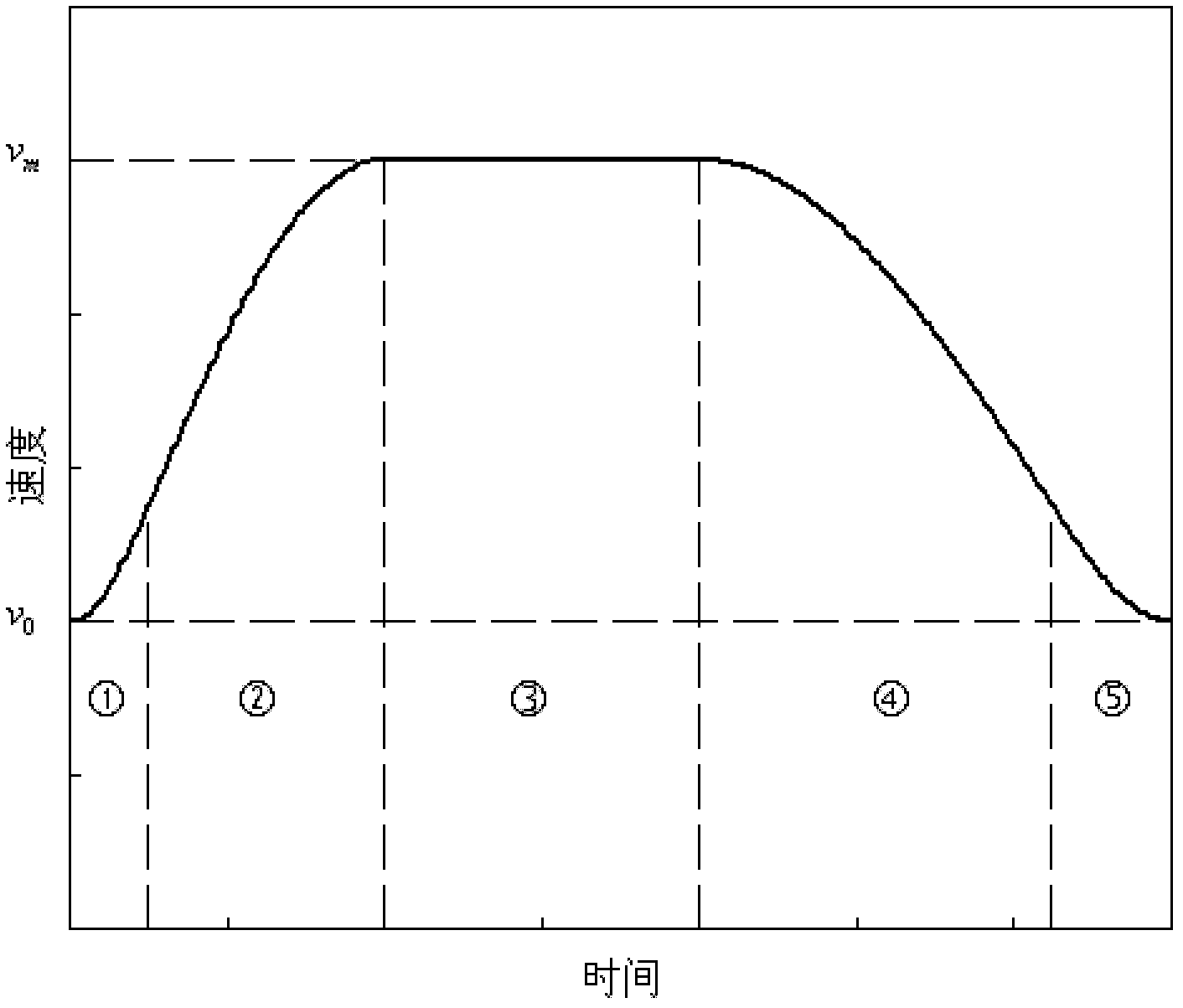

[0040] The principle of acceleration and deceleration of the servo motor of the present invention is as follows: figure 1 As shown, the acceleration phase is divided into two time periods, in [0, 0.25t a ] In the time period, the cycle is T=t a The trigonometric function constructs the acceleration curve, in [0.25t a , t a ] In the time period, the cycle is T=3t a The trigonometric function constructs the acceleration curve, the maximum acceleration is A amax . Divide the deceleration interval into two stages, in [0, 0.75t d ] In the time period, the cycle is T=3t d The trigonometric function constructs the acceleration curve, in [0.75t d , t d ] In the time period, the cycle is T=t d The trigonometric function constructs the acceleration curve, the maximum acceleration is A dmax .

[0041] According to the acceleration and deceleration capabilit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com