Environment-friendly type continuous feeding device and method of smelting furnace

A technology of feeding device and melting furnace, applied in the direction of furnace types, furnaces, crucible furnaces, etc., can solve the problems of increasing energy consumption of melting furnaces, harsh working environment, and reducing combustion temperature, so as to improve the working environment of the workshop and improve the operability The effect of improving the sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

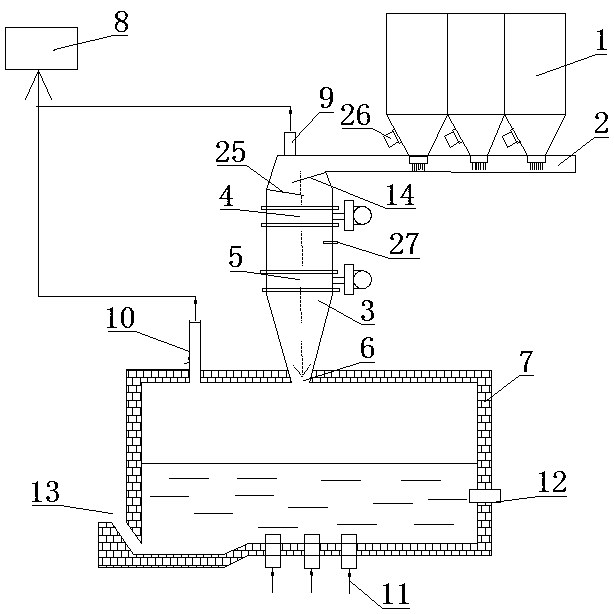

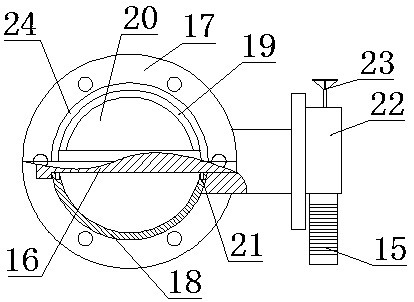

[0037] An environment-friendly continuous feeding device for a smelting furnace, such as Figure 1-2 As shown, it includes the steady flow bin 1, the airtight conveyor belt 2, the feeder 3 and the smelting furnace 7 which are connected in sequence; A vibrating motor 26 is provided on the outside of the lower part of the warehouse, and the outlet at the bottom of the steady flow warehouse 1 is located above the head end of the airtight conveyor belt 2; A baffle structure 4 and a second baffle structure 5, a material level gauge 27 is arranged above the second baffle structure 5; a feeder inlet is provided on the feeder 3, and the feeder inlet is arranged at the lower end of the airtight conveyor belt 2 , the inlet of the feeder 3 is provided with deflectors 14 matched with the airtight conveyor belt 2, and buffer plates 25 are arranged staggeredly below the deflectors 14; The tuyere 9 and the exhaust outlet 9 are provided with an exhaust fan; the top of the smelting furnace 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com