Sludge, excrement and kitchen waste synergistic anaerobic digestion process

A technology of kitchen waste and anaerobic digestion, applied in sludge treatment, biological sludge treatment, pyrolysis treatment of sludge, etc., can solve the problems of high cost, secondary pollution, poor effect, etc. and harmless treatment, reducing external emissions, and improving the effect of material dewatering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

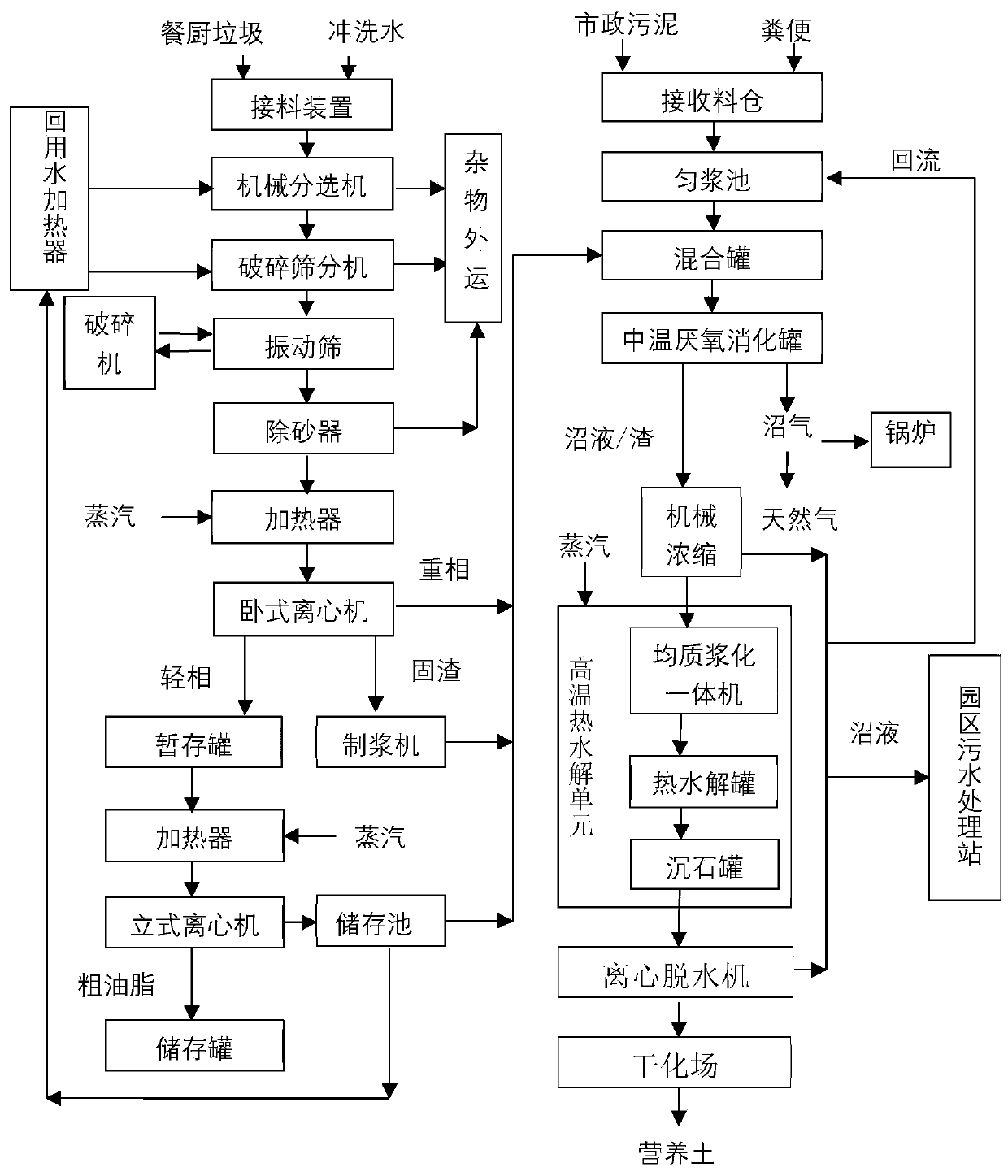

[0023] The technology and detailed description of the present invention will be described below in conjunction with the accompanying drawings, but this does not constitute a limitation to the protection scope of the present invention.

[0024] Process flow of the present invention such as figure 1 shown. The process includes food waste pretreatment, sludge and manure pretreatment, and main treatment.

[0025] 1. Food waste pretreatment

[0026] Food waste pretreatment includes: unloading and feeding, multi-stage screening and crushing, oil-water separation and pulping.

[0027] (1) Unloading and feeding

[0028] After the vehicle loaded with food waste is weighed by the floor scale, it drives to the unloading hall, and dumps the food waste into the receiving hopper of the material receiving device. The shaftless screw conveyor with draining function at the bottom of the receiving hopper transports the food waste to the machine. sorting machine.

[0029] In order to reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com