Treatment device and method for slag obtained after overhauling aluminum electrolysis cell

A treatment method and technology of a treatment system, which is applied in the field of the treatment system of aluminum electrolytic overhaul slag, can solve problems such as shutdown, huge environmental fines of production units, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

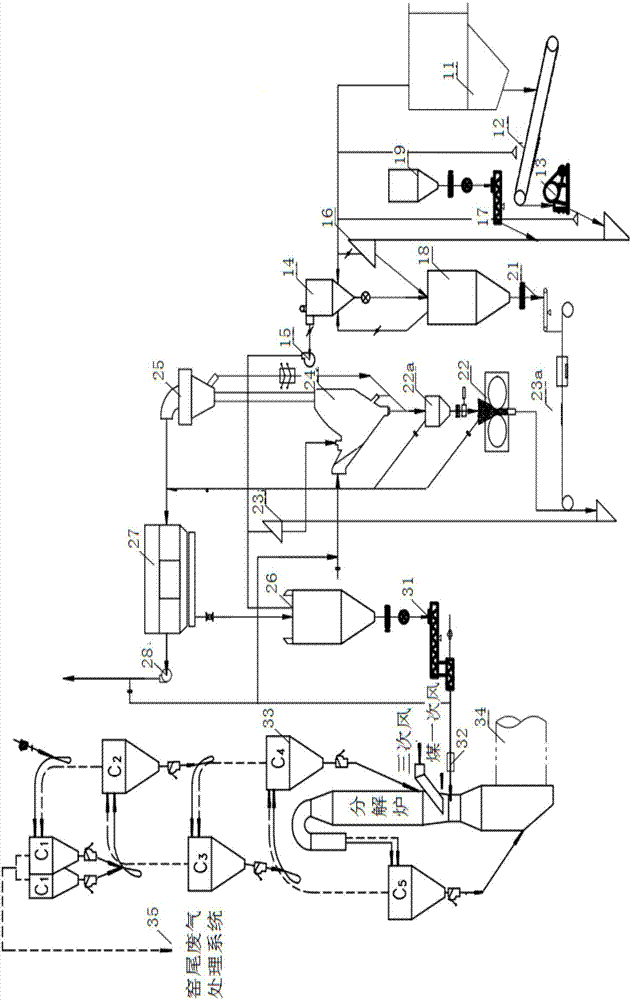

[0087] like figure 1 As shown, the present invention provides a treatment system for overhaul slag of an aluminum electrolytic cell, including a pretreatment station, a grinding station, a cement kiln incineration treatment furnace system and a waste gas treatment system;

[0088] Described waste gas treatment system comprises the first suction machine 15, the second suction machine 28, the first bag dust collector 14, the second bag dust collector 27 and kiln tail waste gas treatment system 35; The second suction machine 28 and The outlet gas of the first suction machine 15 is connected with the air inlet of the coal injection pipe 32 by pipeline;

[0089] The pretreatment station is provided with an automobile unloading pit 11, an apron feeder 12, a jaw crusher 13, a first bag dust collector 14, and a first suction machine 15; the apron feeder 12 is placed in an automobile The bottom of the unloading pit 11 is connected with the jaw crusher 13, which is used to crush the ov...

Embodiment 2

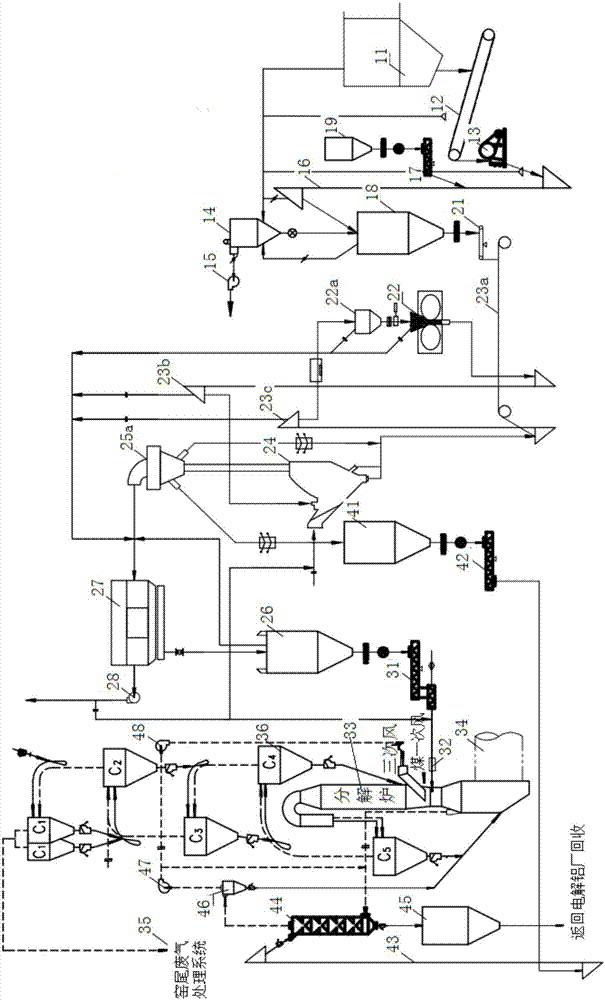

[0105] like figure 2 As shown, the present invention provides a treatment system for overhaul slag of an aluminum electrolytic cell, including a pretreatment station, a grinding station, a cement kiln incineration treatment furnace system, a waste gas treatment system and a HF removal system;

[0106] Described waste gas treatment system comprises the first suction machine 15, the second suction machine 28, the first bag dust collector 14, the second bag dust collector 27 and kiln tail waste gas treatment system 35; The second suction machine 28 and The outlet gas of the first suction machine 15 is connected with the air inlet of the coal injection pipe 32 by pipeline;

[0107] The HF removal system includes a heavy powder bin 41, a vertical evaporator 44, a cyclone dust collector 46 and a circulating fan 47;

[0108] The pretreatment station is provided with an automobile unloading pit 11, an apron feeder 12, a jaw crusher 13, a first bag dust collector 14, and a first suct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com