Patents

Literature

74results about How to "Good for secondary use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Treatment device and method for slag obtained after overhauling aluminum electrolysis cell

ActiveCN107401746ALose toxicityEliminate hazardsClinker productionIncinerator apparatusElectrolysisSlag

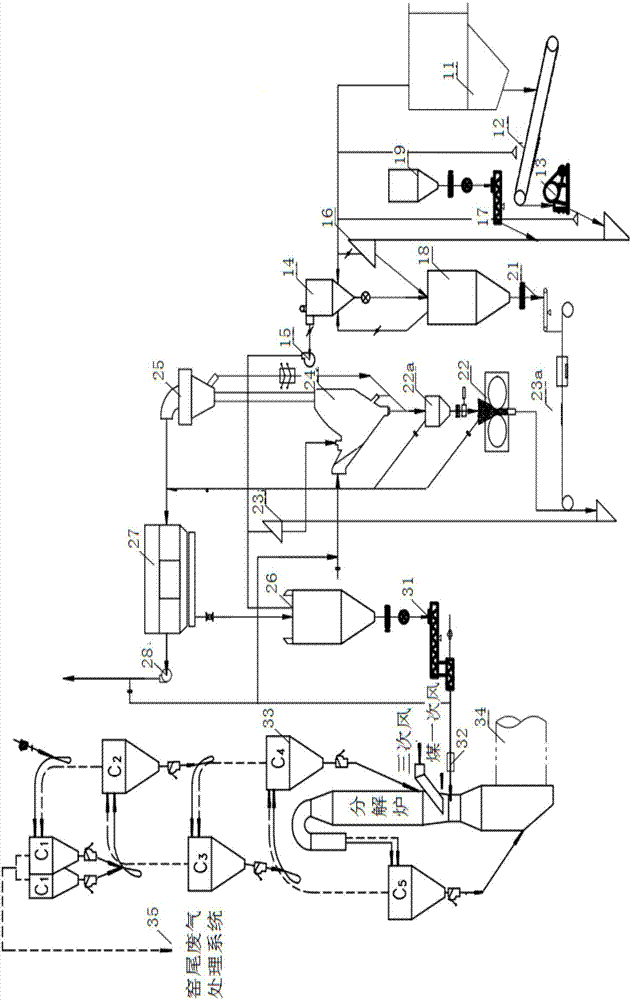

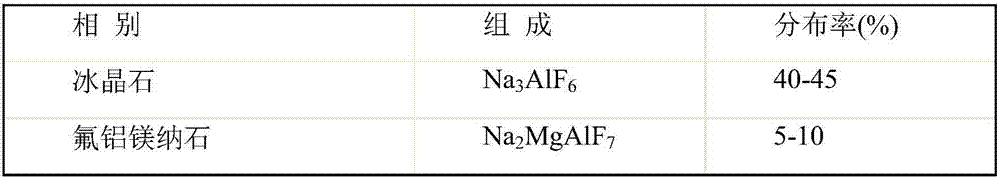

The invention provides a treatment device and method for slag obtained after overhauling an aluminum electrolysis cell. The treatment method comprises the following steps: crushing the slag obtained after overhauling the aluminum electrolysis cell, mixing the crushed slag with a lime fluoride retention additive, grinding the mixture, performing powder selection circulation to obtain powder, and combusting the powder in a cement kiln, so as to completely eliminate hazards and enable the aluminum electrolysis cell to completely lose toxicity. According to the treatment device and method for slag obtained after overhauling the aluminum electrolysis cell, the overall treatment process is carried out in a sealing environment, exhaust gas generated is basically dry gas and finally discharged after being combusted, so that the clean emission is realized, and the secondary atmospheric pollution is avoided; besides, residue generated is used as a cement clinker and can be effectively reutilized, the risk of secondary pollution is completely eliminated, and the environment and production safety is also realized.

Owner:长沙中硅环保科技有限公司

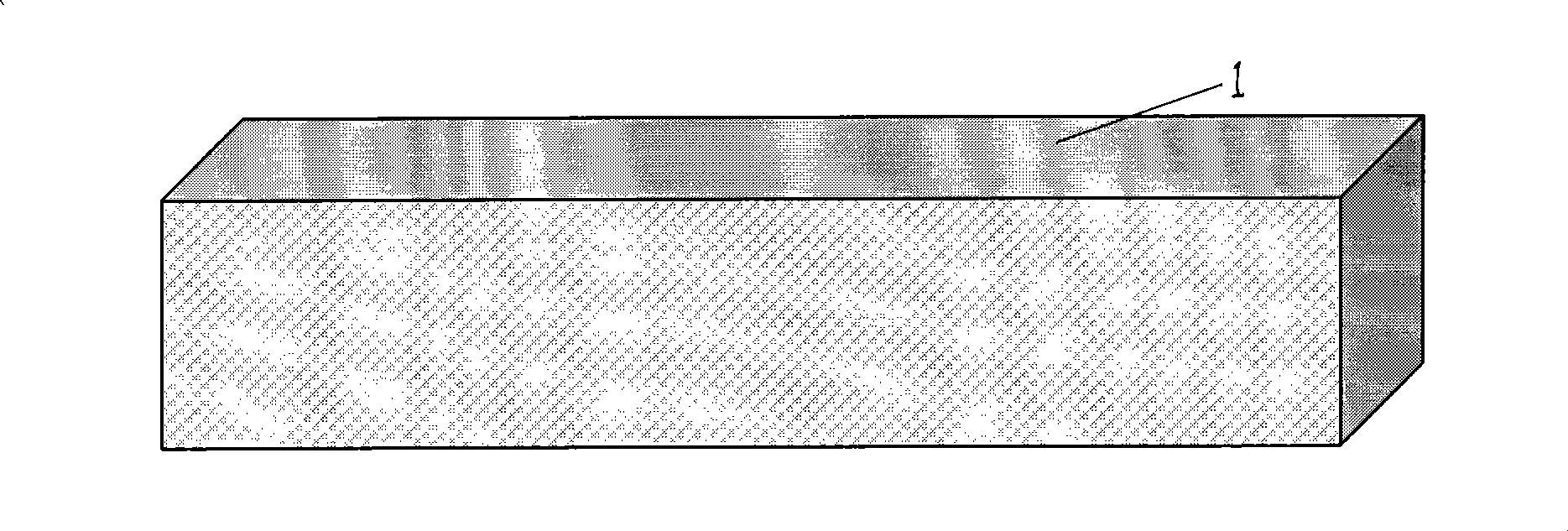

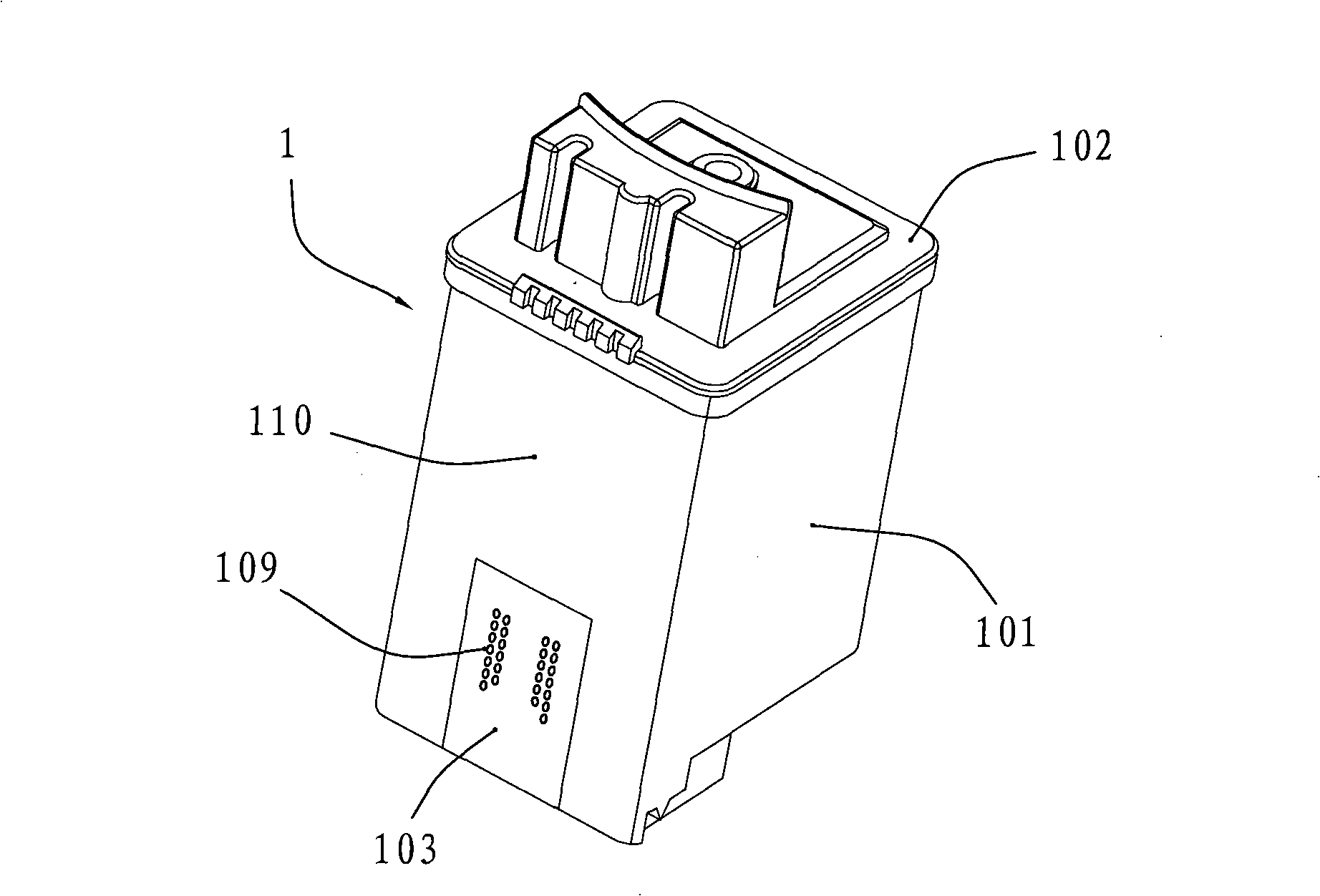

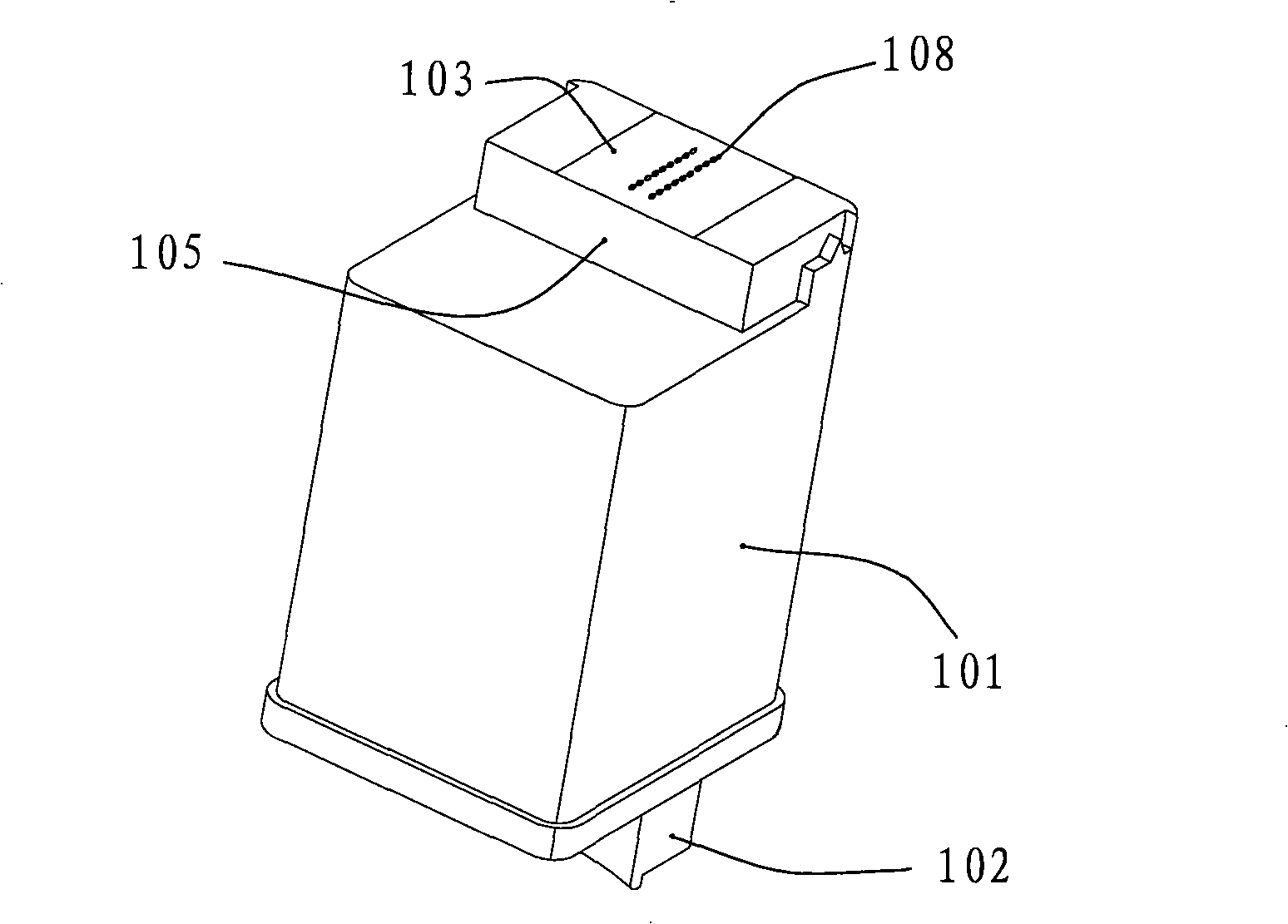

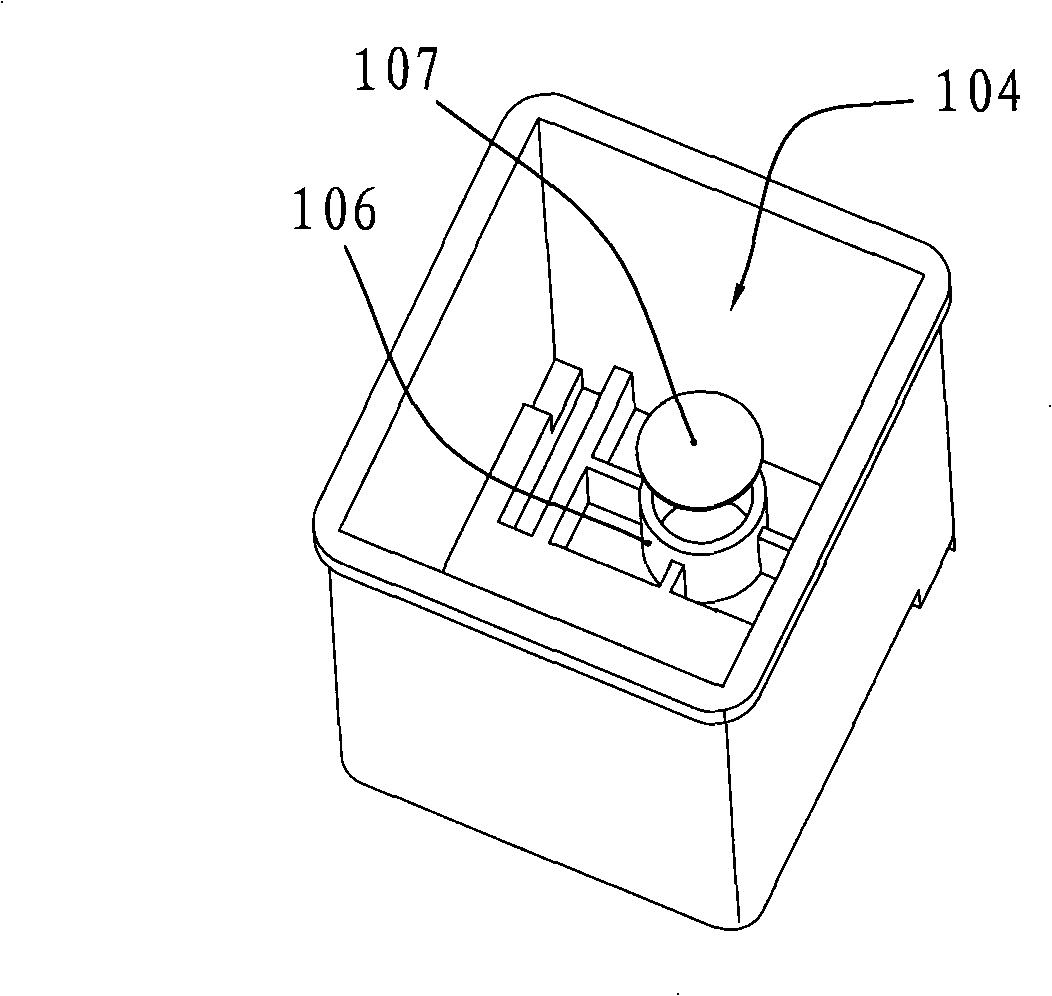

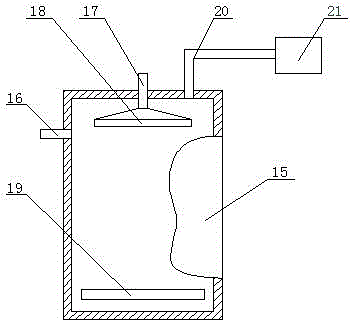

Environment-friendly dish washing machine

InactiveCN106889964AEasy to cleanGood for secondary useTableware washing/rinsing machine detailsWater storage tankWater resources

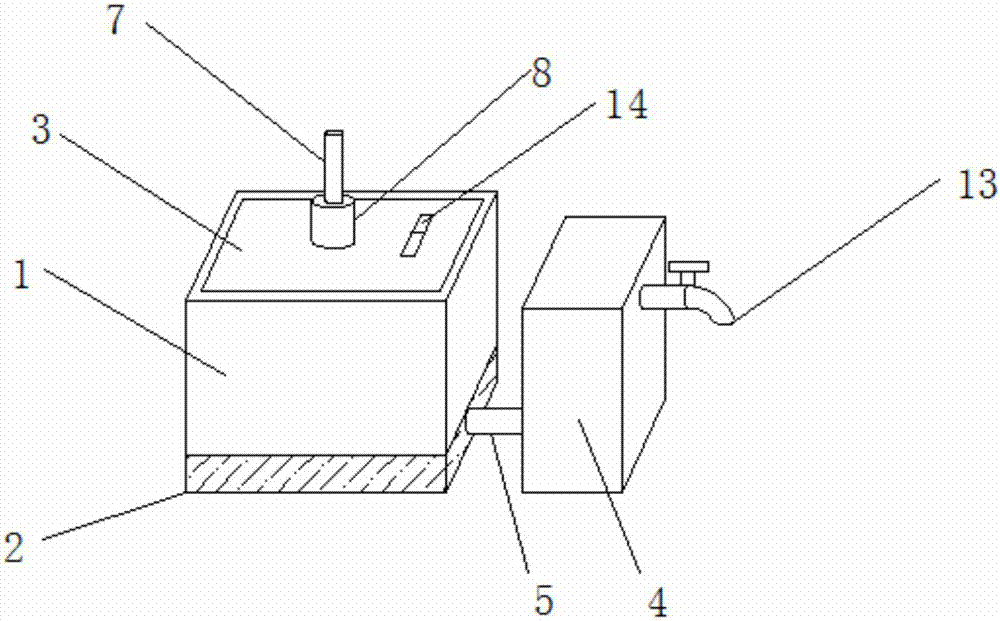

The invention discloses an environment-friendly dish washing machine. The environment-friendly dish washing machine comprises a dish washing machine body, a first water storage tank, a second water storage tank and a sewage purifier. The first water storage tank is arranged on the lower surface of the dish washing machine body and communicated with the same through a plurality of drain pipes, and the drain pipes are provided with switch valves respectively. The second water storage tank is communicated with the first water storage tank through the sewage purifier, and the lateral side of the second water storage tank is provided with a water tap. A spraying mechanism is arranged at the upper end of the dish washing machine body, and a placement rack is arranged in the dish washing machine body. By the environment-friendly dish washing machine, the problem that in the prior art, dish washing machines which are effective in dish cleaning fail to meet international advocated requirements on water resources due to serious water resource waste caused by direct discharging of sewage after cleaning is solved.

Owner:卫祥

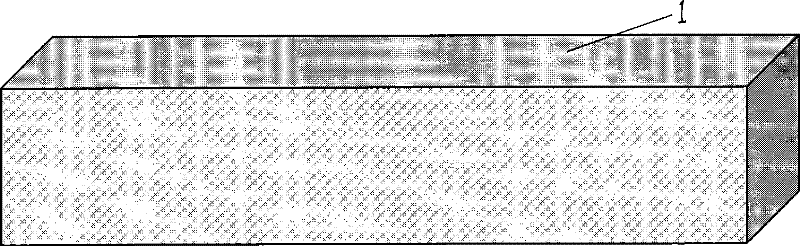

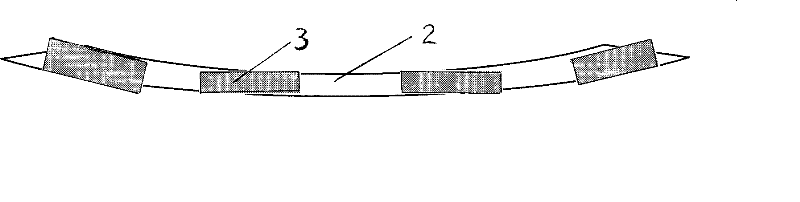

Plant breeding substrate and production method thereof

InactiveCN101361454ALight in massHigh courageCultivating equipmentsSoilless cultivationGreeningPlant cultivation

The invention relates to plant cultivation. A plant cultivation substrate is made into a whole by wooden fragments, a soil conditioner and a nutrient particle body. Compared with the like products, the cultivation substrate has the advantages of light self mass, high courage performance and high moister retention: the invention has the best sealing environment to the plant, and does not need the technology experience of the specialists, therefore, the invention not only can realize the greening of roofs, etc., save labor force, and reduce cost, but also is in fixed base type, and can effectively avoid sealing lost and dispersion caused by heavy rain and strong wind.

Owner:大连染谷绿业科技有限公司 +2

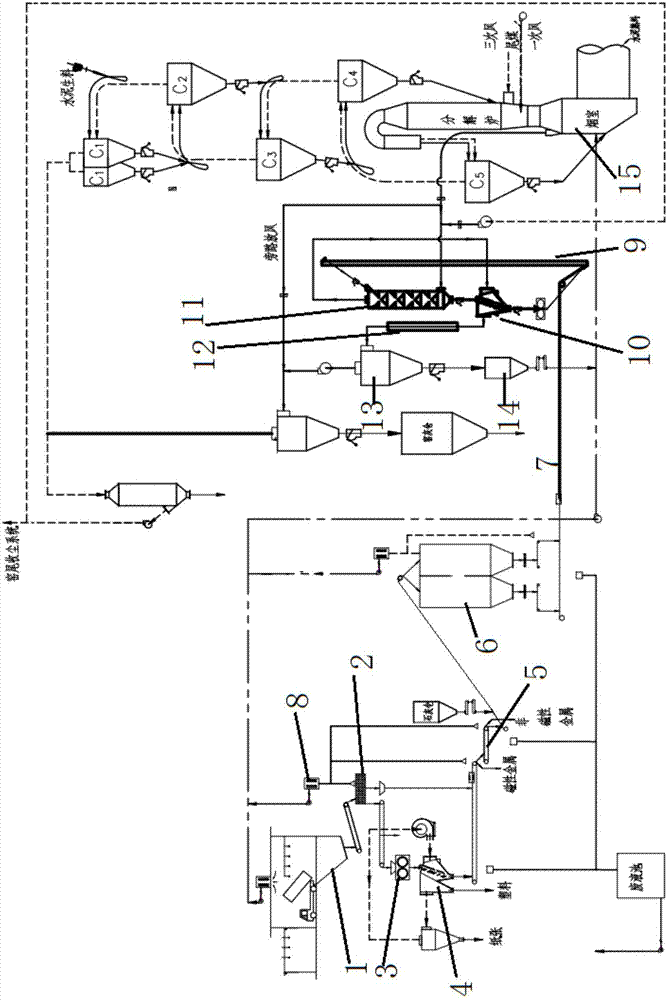

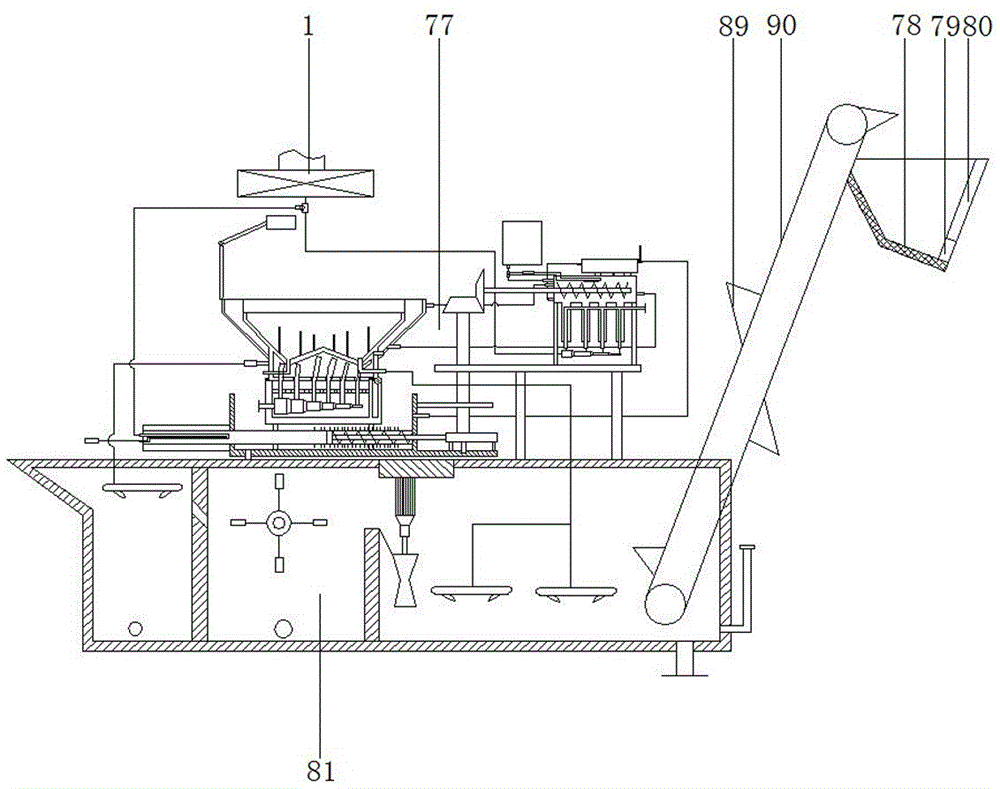

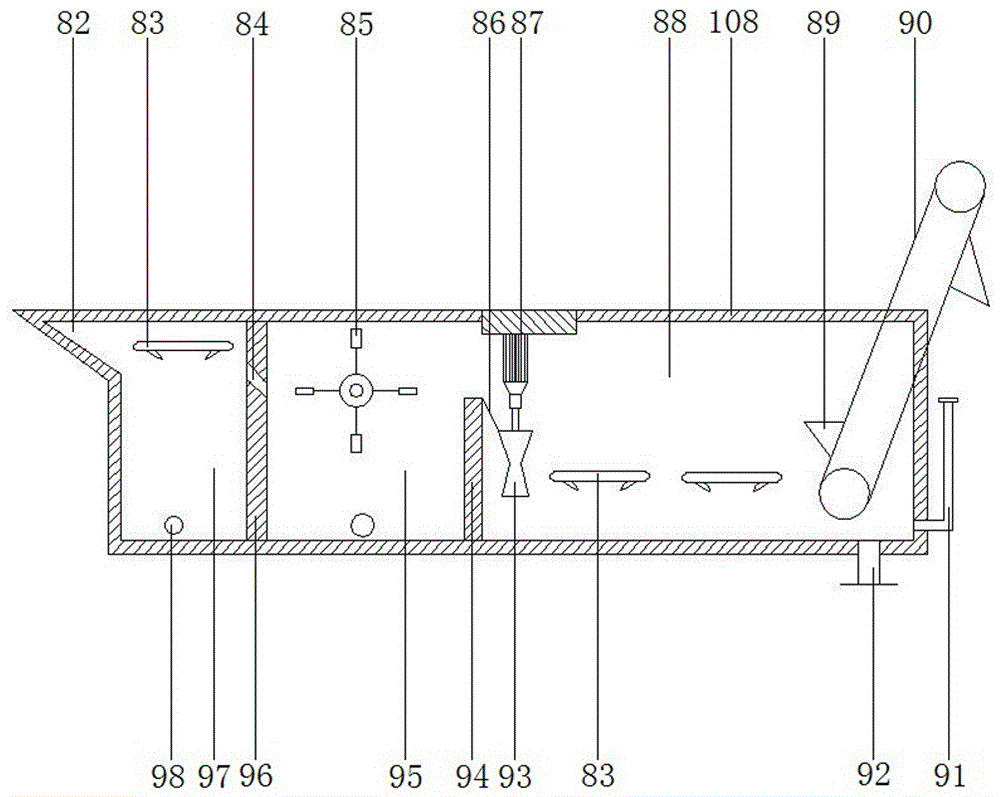

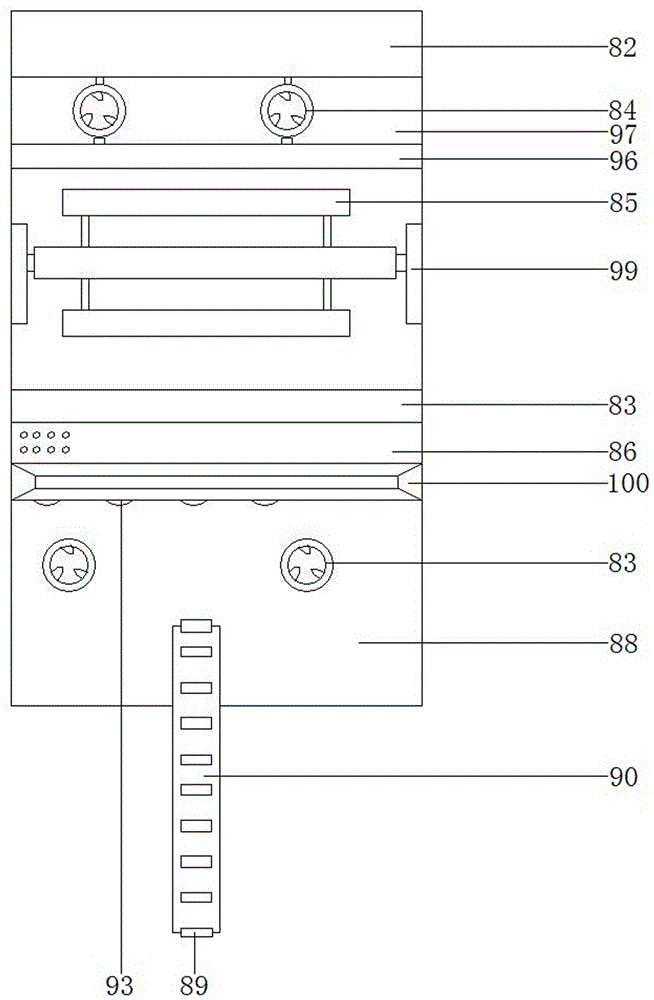

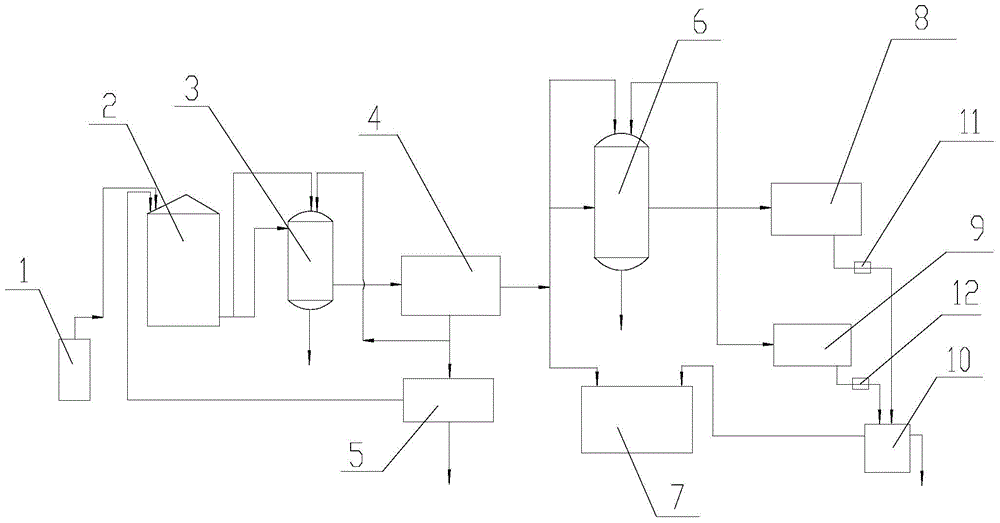

Household garbage treatment method and treatment system

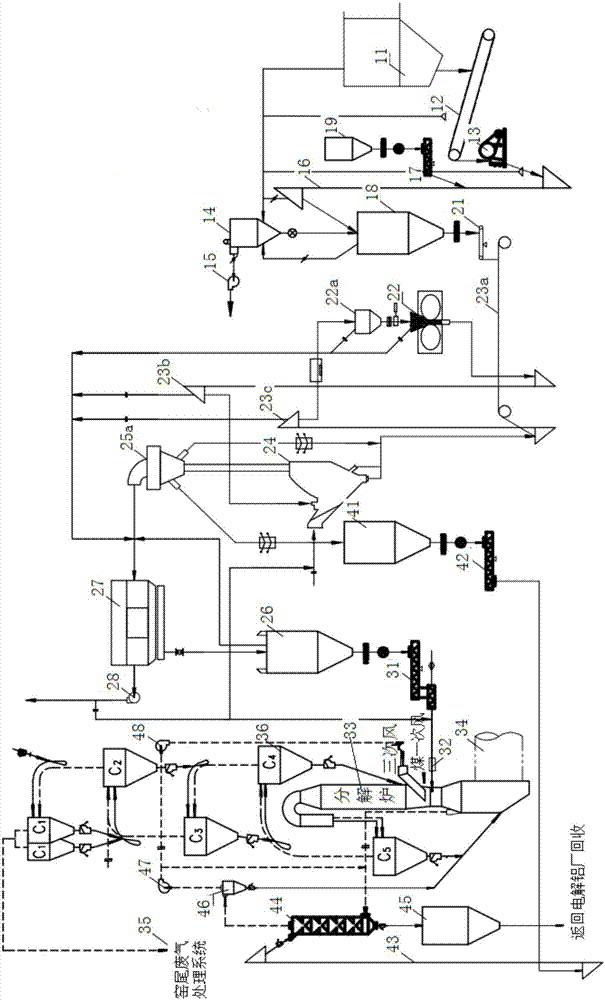

The invention provides a household garbage treatment method and treatment system. According to the treatment method, household garbage is broken, recoverable garbage is sorted out, and an anti-corrosion modifier is added to be stored; the stored garbage is subject to breaking, and hot air drying and grinding of a cement kiln, powder selection is carried out, and granule matter is burnt. In the process, the garbage is subject to drying and grinding and then is burnt, the side effect of garbage water or garbage waste gas on safety operation of a cement kiln system can be reduced as far as possible, the secondary pollution is reduced, harmless, low-cost and low-investment treatment of household garbage is ensured, and the method and system meet the sustainable development circular economy direction. According to the treatment system, the special advantage of the cement kiln is sufficiently used, in combination with the garbage system, the capital investment is reduced, the garbage treatment capacity is improved, garbage applicability is improved, and the system is a harmless, recycling and low-cost treatment system.

Owner:长沙中硅环保科技有限公司

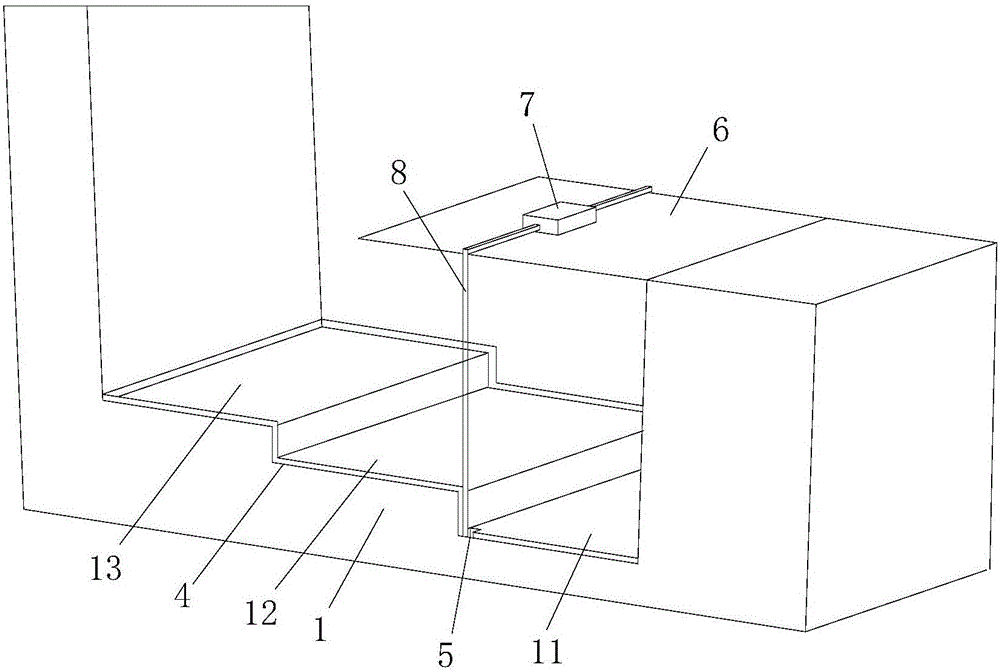

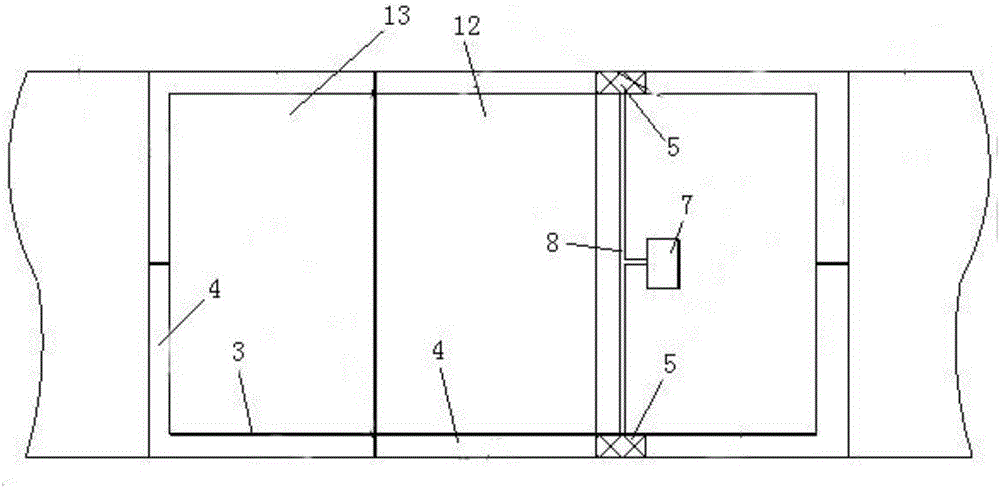

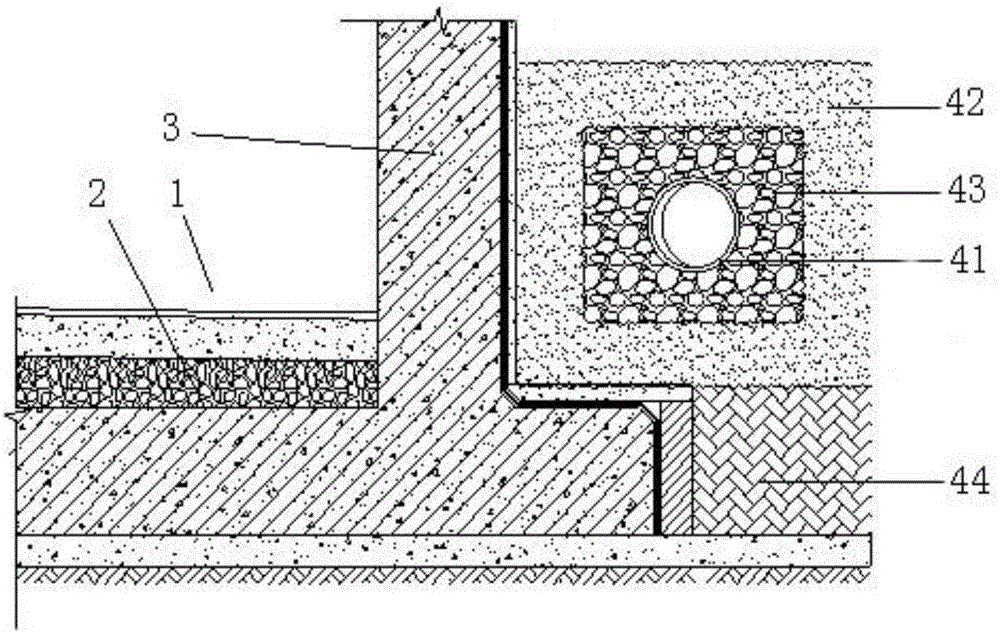

Karst region step-type basement water drainage structure and construction method thereof

InactiveCN106592756APromote the concept of sustainable developmentGood for secondary useCellarsFoundation engineeringBasementWater storage

The invention provides a Karst region step-type basement water drainage structure and a construction method thereof. A base distributed in a step form is arranged at the bottom of a basement, a bottom plate is laid in the position of the base, at least one water drainage blind ditch with a water drainage slope is arranged along the outer side of an external wall of the basement, water-collecting wells are arranged in a bottom layer step of the base, the lower ends of water pipes extend into the water-collecting wells, the other ends of the water pipes extend into a water storage basin formed in a basement positive and negative zero top plate surface, and self-priming pumps are arranged in the water-collecting wells correspondingly. The problem that economical efficiency or an effective water drainage effect cannot be achieved through a traditional base water drainage method is solved. The Karst region step-type basement water drainage structure and the construction method thereof belong to the technical field of building construction.

Owner:CHINA CONSTR FOURTH ENG DIV

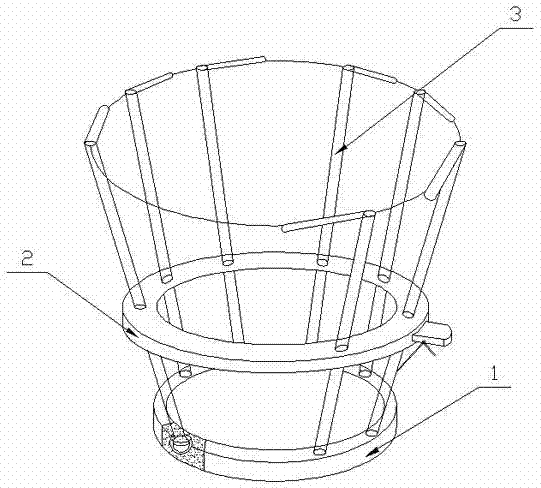

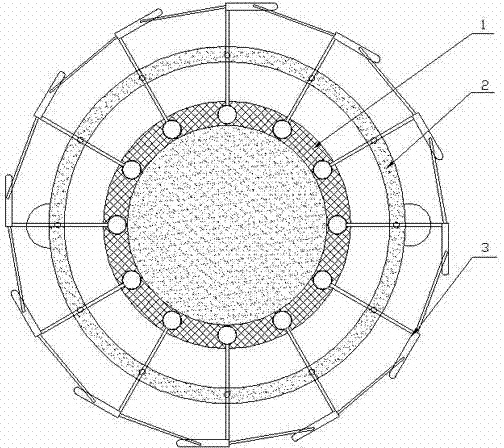

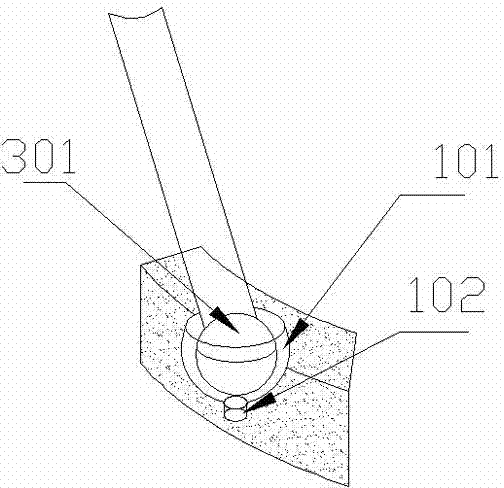

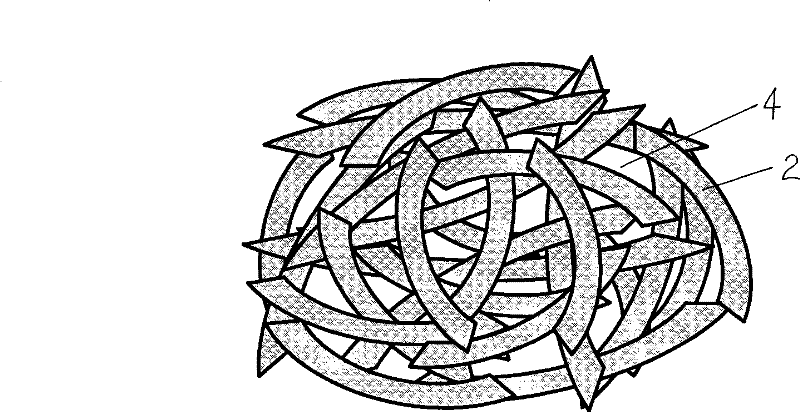

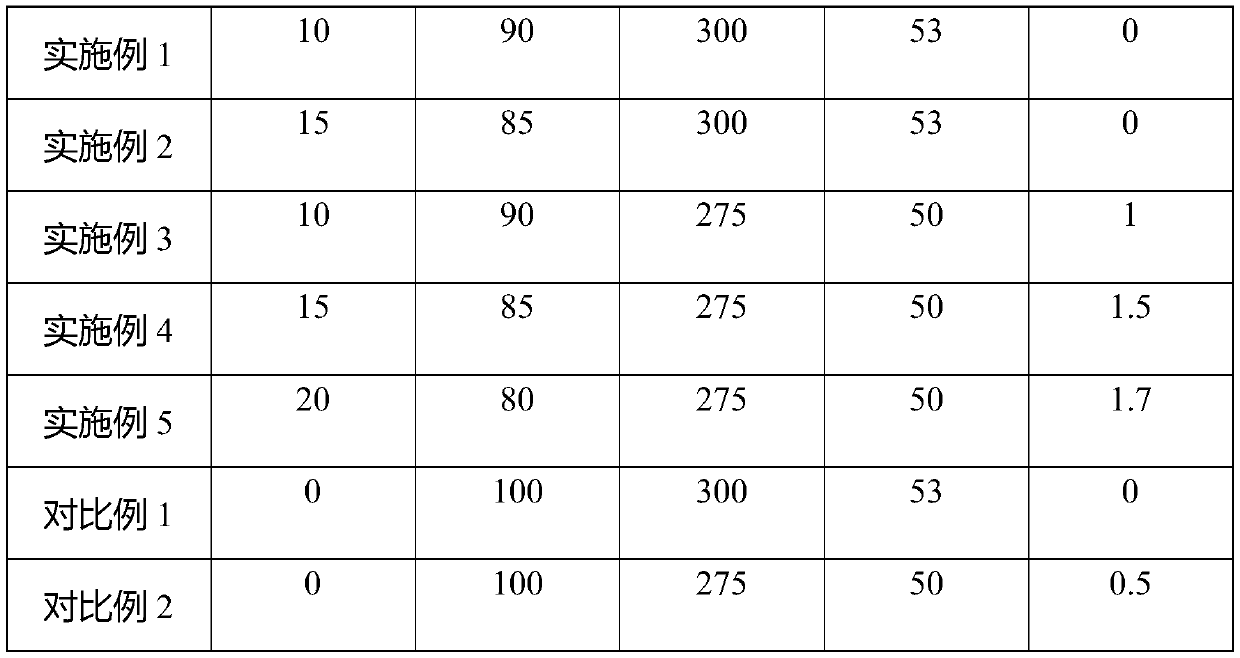

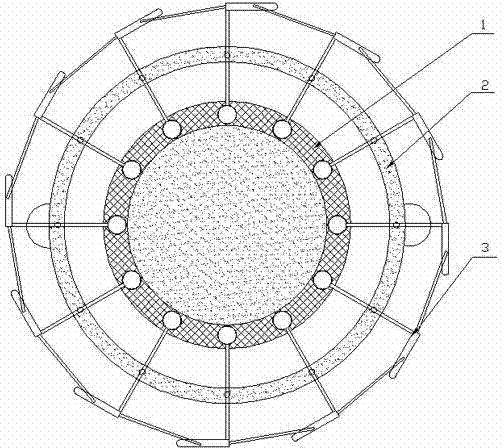

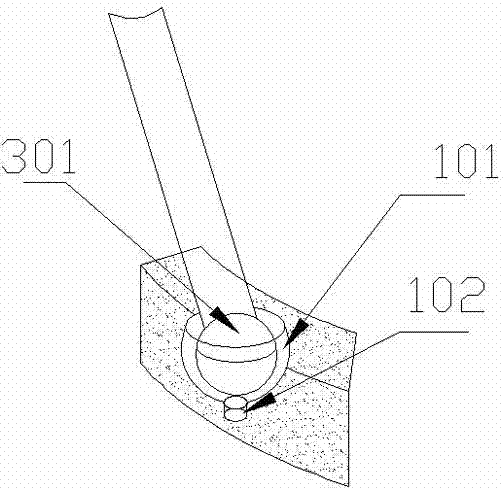

Trash can with adjustable caliber

The invention discloses a trash can with the adjustable caliber. The trash can comprises a bottom disc and multiple spherical holes distributed in the circumference of the upper edge of the bottom disc. Each spherical hole covers a spherical head arranged at one end of a spoke so that a hinge mechanism can be formed, the other end of each spoke penetrates through a through hole formed in a restraining ring, and the restraining ring is located between the two ends of each spoke all the time. Each spoke independently distributed on the edge of the bottom disc penetrates through the restraining ring so that a trash can body of an integrated structure can be formed. The restraining ring is further provided with spring clips used for limiting movement of the restraining ring. In the state when the spring clips are loosened, the restraining ring is made to move in the length direction of the spokes, so that the caliber is adjusted and the size of the trash can is changed. According to the trash can with the adjustable caliber, the size of the caliber of the trash can is changed by changing the vertical position of the restraining ring, trash cans with different calibers can be suitable for different plastic bags, the abandoned plastic bags in daily life can be effectively recycled, resources are saved, white pollution is reduced, and environment friendliness is achieved.

Owner:HENAN UNIV OF SCI & TECH

Natural rubber microbial deodorization processing technology

The invention discloses a natural rubber microbial deodorization processing technology, which consists of crushing, extrusion crushing, pressing ruckling, deodorization symbiotic microbial bacterial liquid cleaning, granulation, drying and packaging. The technology is characterized in that during deodorization symbiotic microbial bacterial liquid cleaning, a symbiotic flora cleaning solution well cultured in a corresponding structure of a deodorization cleaning pool is injected into the corresponding structure in the deodorization cleaning pool to conduct cleaning and deodorization on the ruckled natural rubber, so that re-processed odorless natural rubber can be finally obtained through the step. The technology can perform secondary processing deodorization treatment on already processed natural rubber so as to obtain a low odor or odorless natural rubber finished product, and especially for inferior quality natural rubber processed by small rubber processing plants in remote areas, the technology also can enhance the physical and chemical properties of the processed natural rubber by secondary processing.

Owner:昆明珩森科技有限公司

Improvement method for ink ribbon cartridge for ink-jet typewriter

The invention provides an improved method used for the ink box of an ink jet printer, comprising: detecting a printing head circuit, removing a box cover, removing porous fibre material and convex blocks on the external wall of an ink storage chamber, cleaning a printing head, filling new porous fibre material and filling ink water into the ink storage chamber, test-running the gained ink box subsequently, removing the secondarily filled porous fibre material of the ink box which is qualified by the test-running; subsequently sealing the opening by a matched top cover, and detecting the airtightness of the printing head to reach a state without air leakage so as to gain the improved product. The method of the invention is beneficial to reducing the usage cost of the existing wide-width recording medium printer and realizes good environmental protection effect by one-off use of the ink box.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

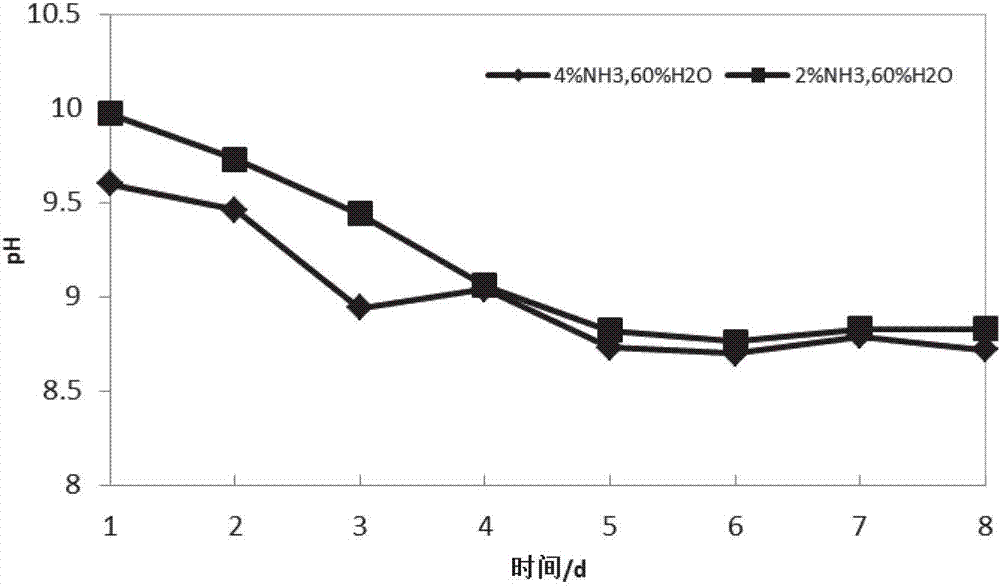

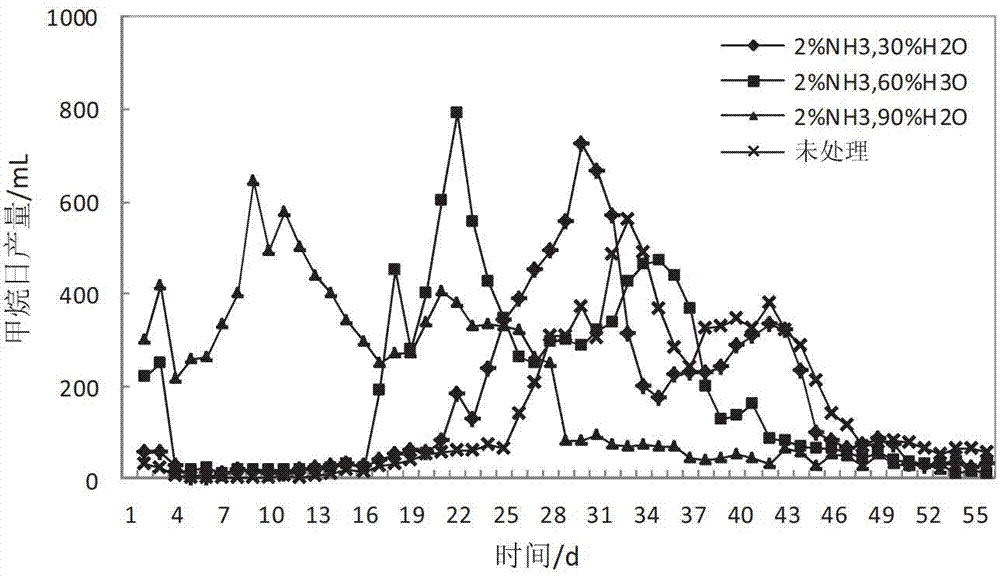

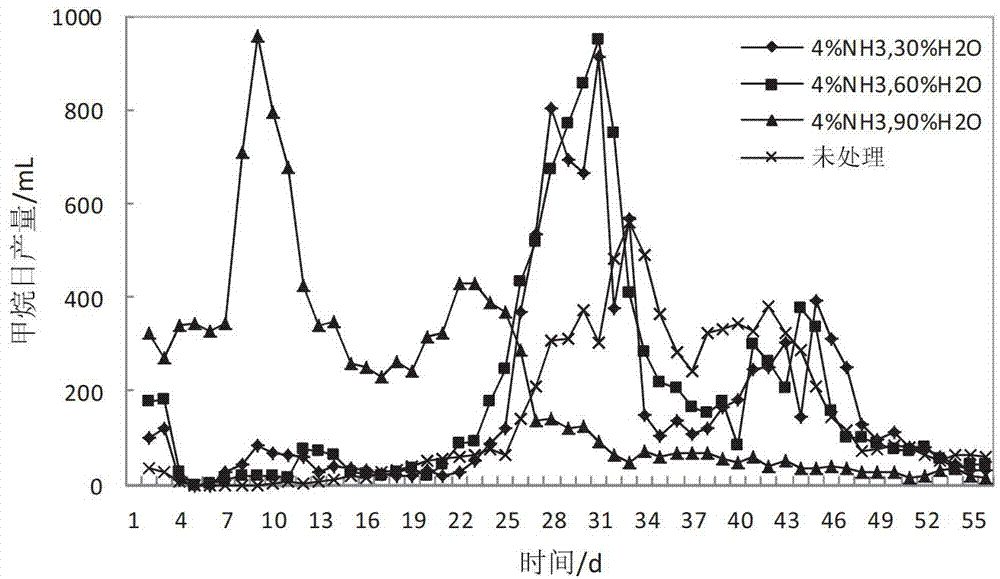

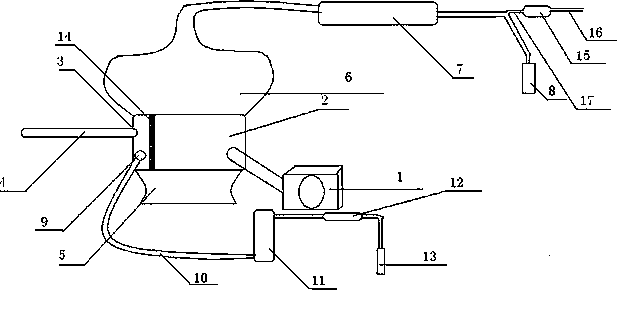

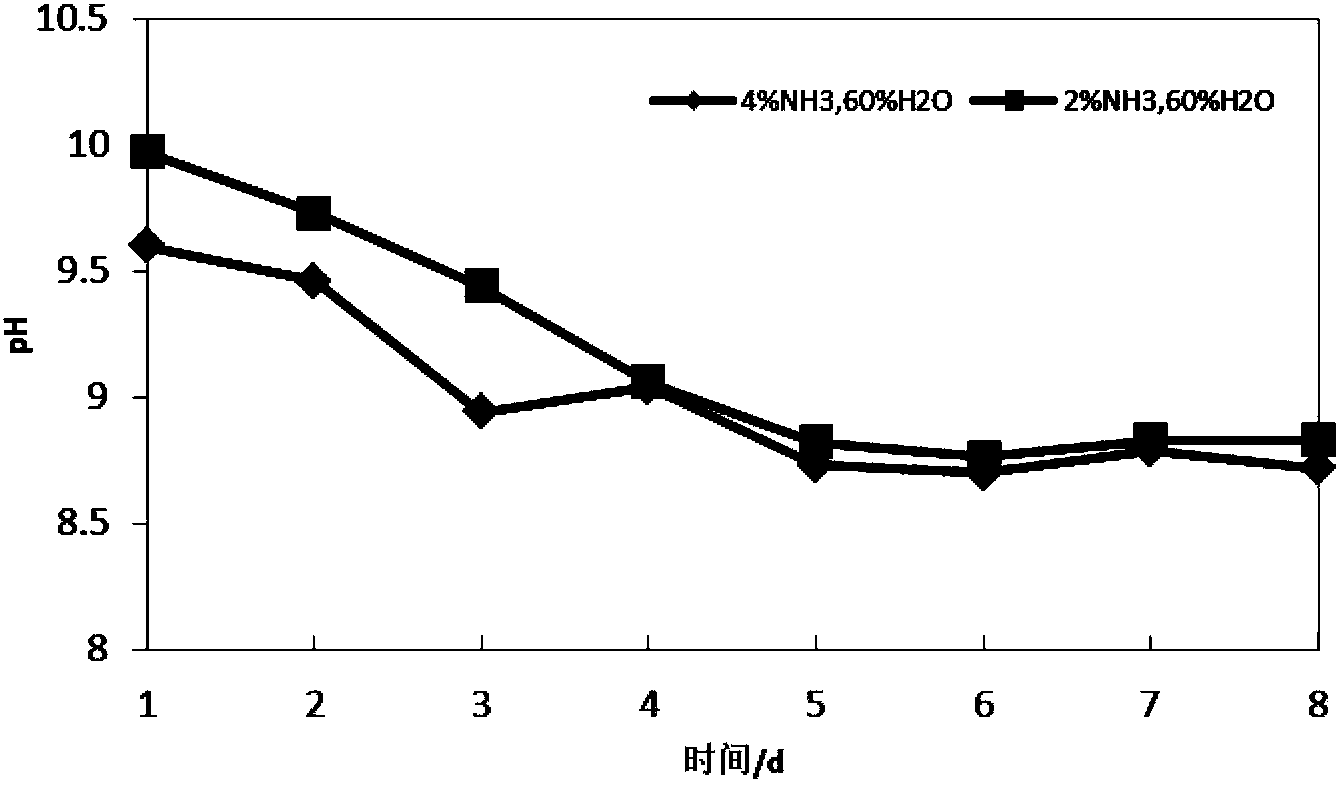

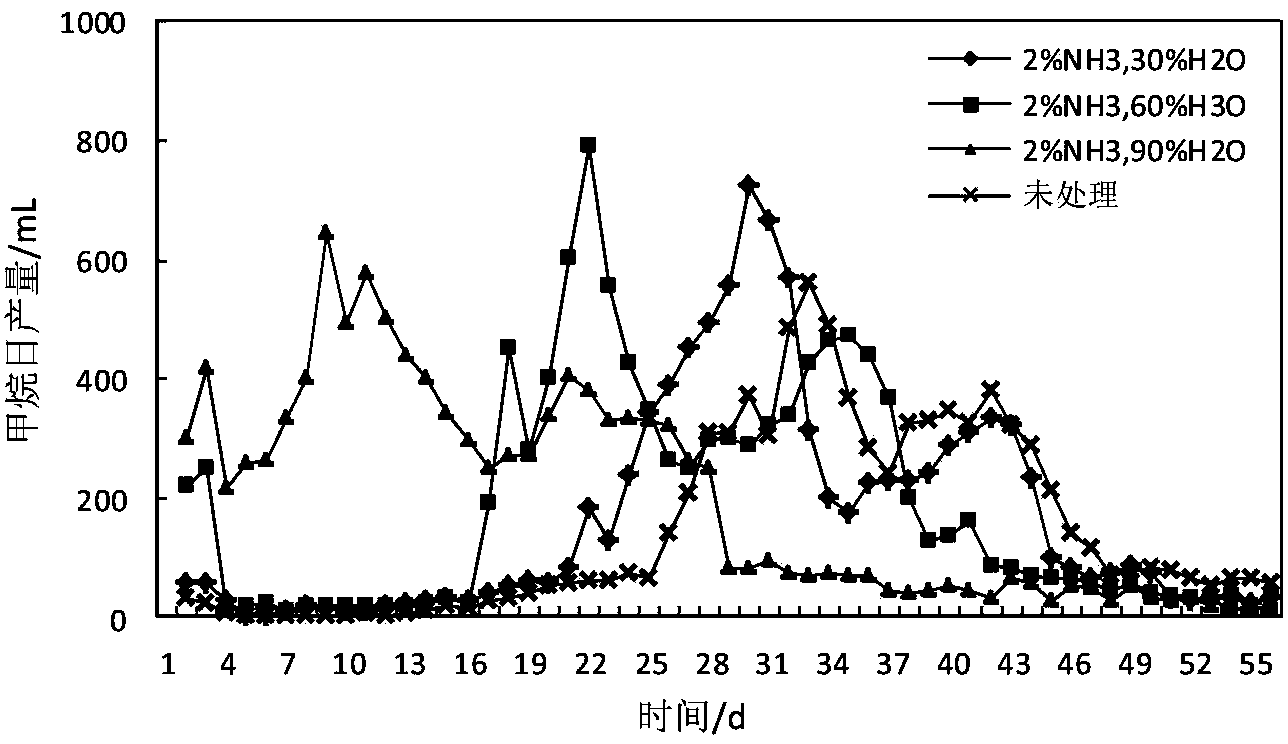

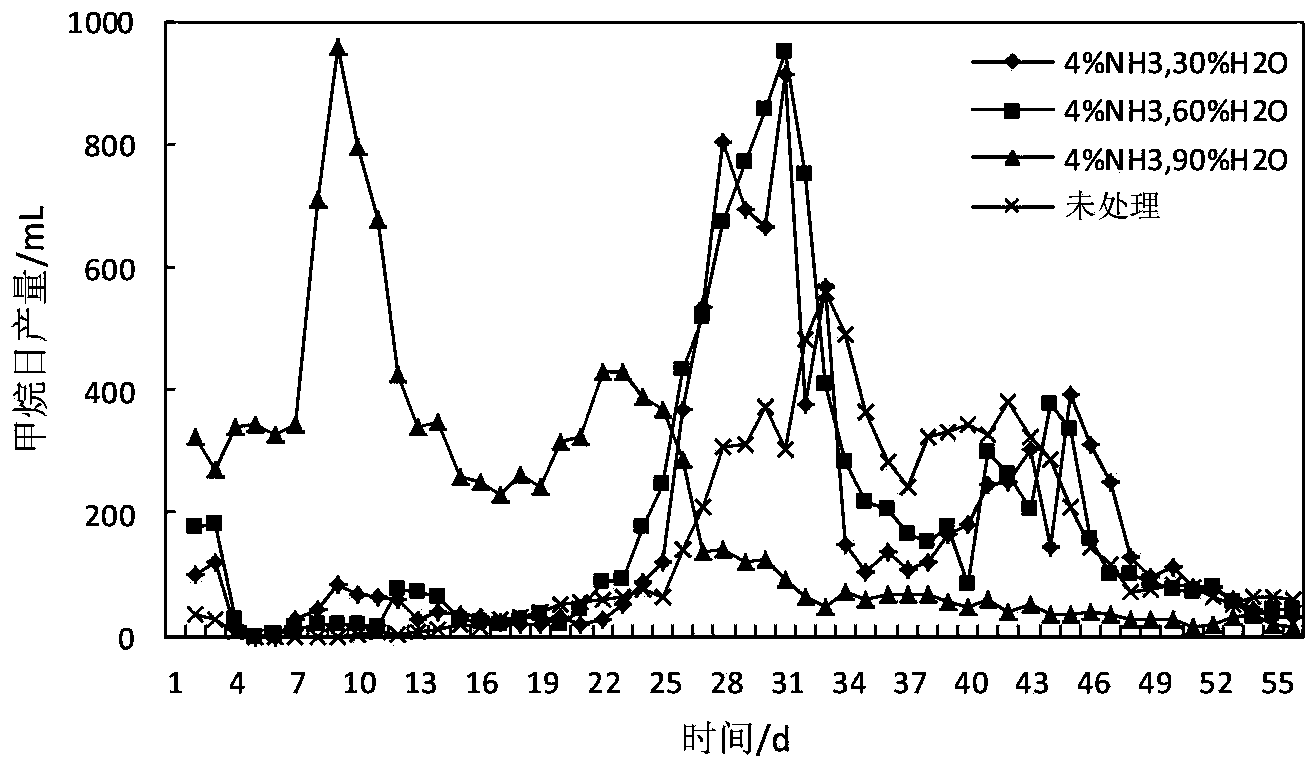

Method for improving straw methane yield through pure ammonia wet process soaking normal temperature pretreatment

ActiveCN102827879AReduce preprocessing timeEasy to produceWaste based fuelFermentationMethane yieldPre treatment

The invention discloses a method for improving the straw methane yield through straw pretreatment. According to the method, ammonia water and water are mixed and are uniformly sprayed onto straws placed in a sealed bag so that the straws are in a wet soaking state, and the pretreatment is carried out for 90 hours to 110 hours under the normal temperature condition. The pretreatment effect is improved through regulating different moisture contents in the wet type soaking state, and in addition, the methane content in the methane is obviously improved in the anaerobic fermentation process. Results show that the straws pretreated under the condition of 60 to 90 percent of moisture content at the normal temperature can fast enter the methane production peak period, and in addition, the anaerobic fermentation period is effectively shortened. When the pure ammonia concentration is 2 to 6 percent, when the moisture content is 60 to 90 percent, T80 is shortened by 23.23 to 50.1 percent, 9.30 to 50.1 percent and 9.30 to 25.5 percent through being compared with that of 43 days without the treatment. When the result is applied to the practical engineering, the engineering scale can be reduced by one time, and the investment cost is greatly reduced. Meanwhile, through being compared with that of straws which are not pretreated, the unit VS methane yield is respectively improved by 5.09 to 14.63 times, 1 to 16.1 times and 1.6 to 10.15 times.

Owner:BEIJING UNIV OF CHEM TECH

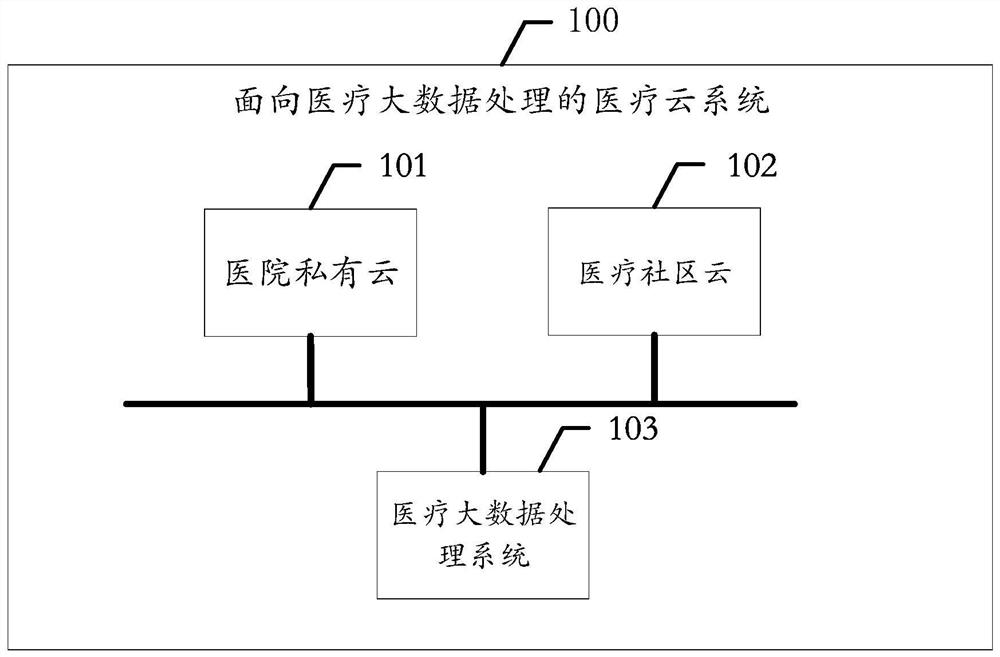

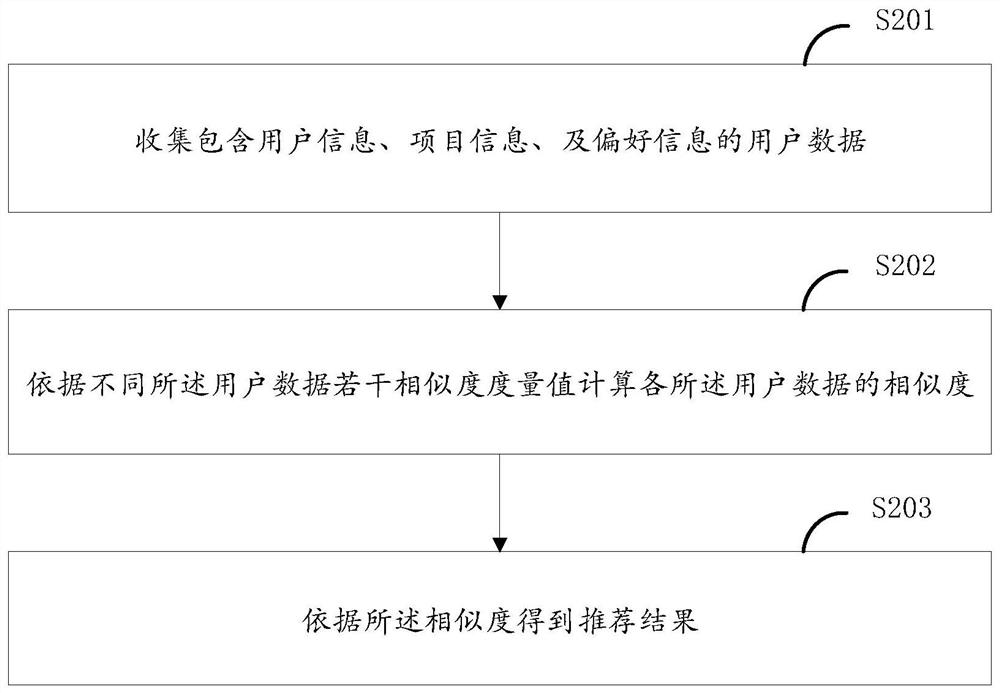

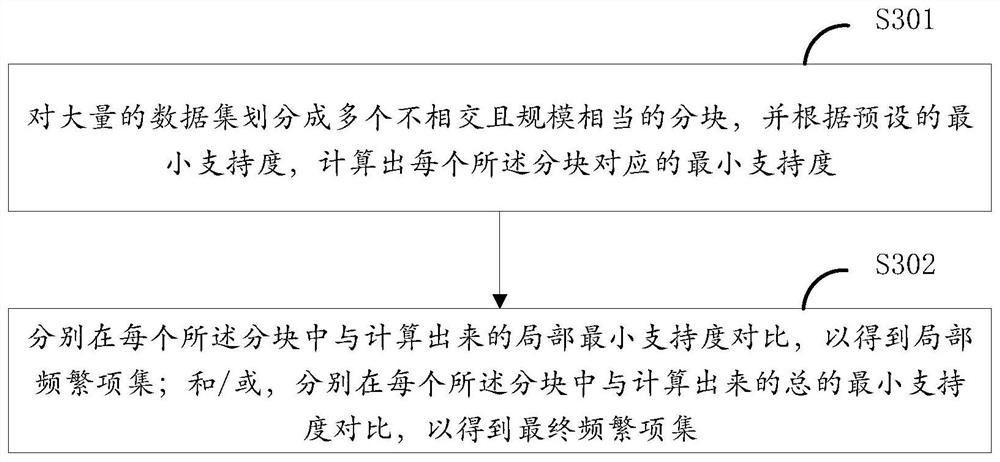

Medical cloud system, method and system for medical big data processing and medium

PendingCN111951935ALow costIncrease profitHealthcare resources and facilitiesVirtual desktopVirtualization

The invention provides a medical cloud system, method and system for medical big data processing and a medim. IT resources of a hospital are pooled through a virtualization technology, on the basis ofhospital private cloud, a virtual desktop architecture is adopted to be upgraded into medical community cloud, and through a medical big data processing system based on Hadoop, a distributed computing mode is used for solving the problems of medical big data collection, storage and analysis. An Apriori algorithm oriented to the medical big data in a cloud environment is provided, a transaction database is converted into a Boolean matrix by utilizing a matrix thought, a transaction storage mode and matrix rows and columns are compressed and improved, algorithm end conditions are optimized, andthe data is transplanted to a Hadoop medical big data platform to realize MapReduce parallel processing. According to the method, the database scanning frequency is effectively reduced, and the problems of algorithm serialization, low efficiency of generating frequent item sets and the like are solved.

Owner:SHANGHAI ENG RES CENT FOR BROADBAND TECH & APPL

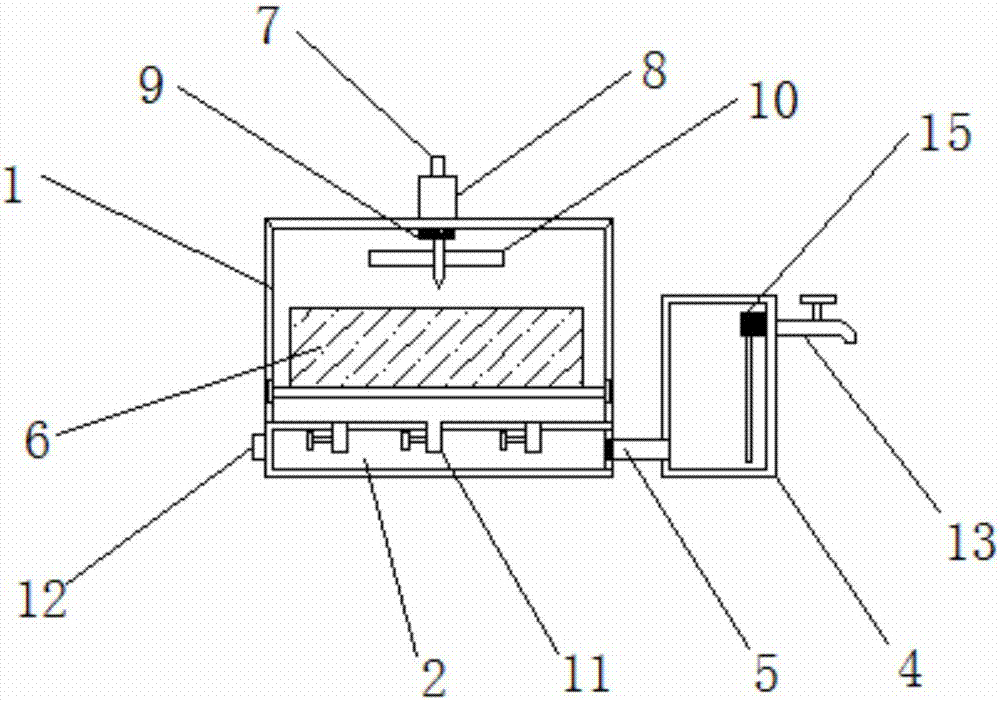

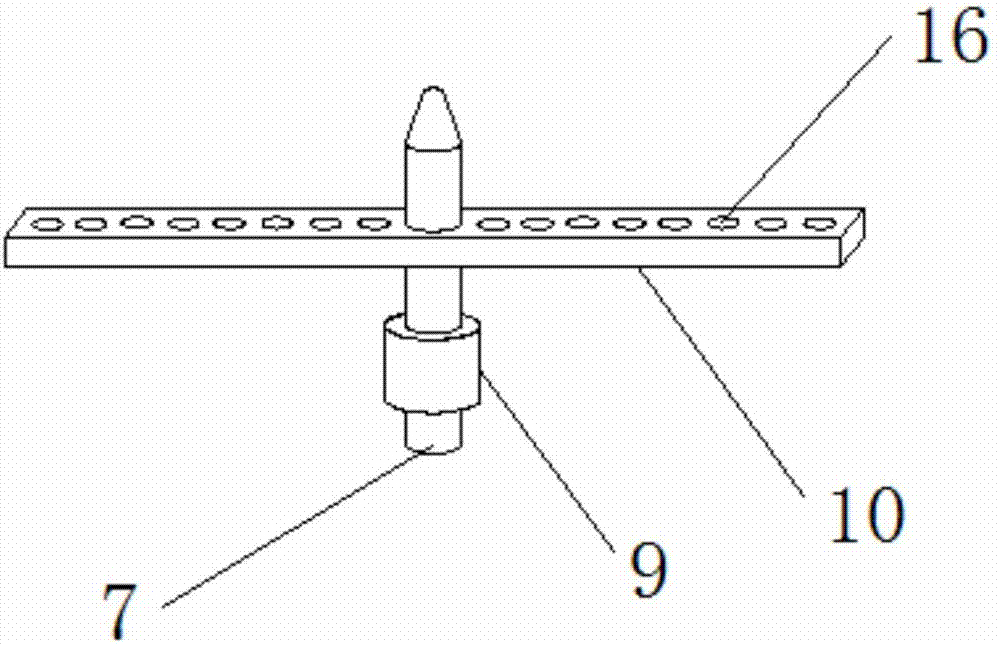

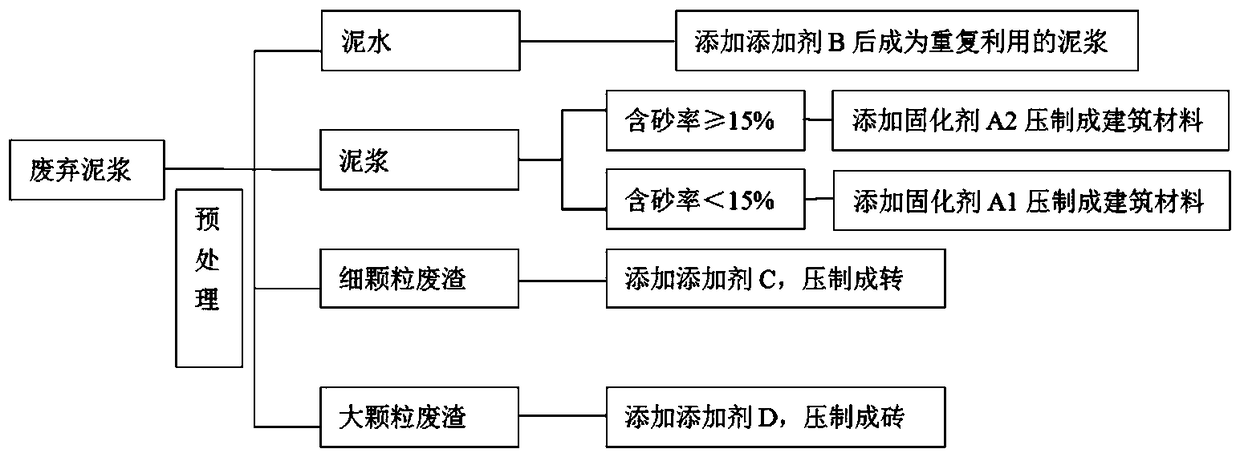

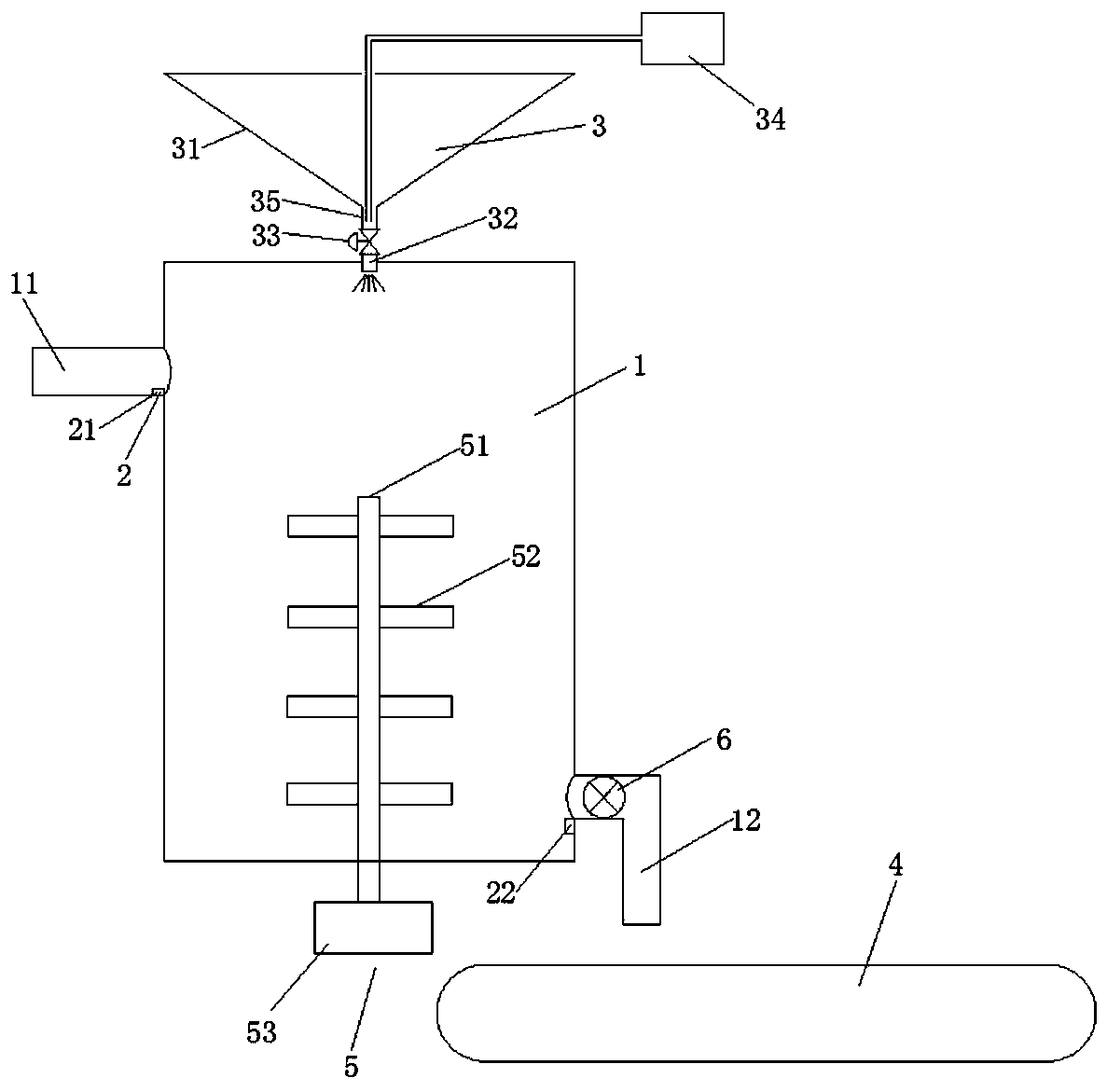

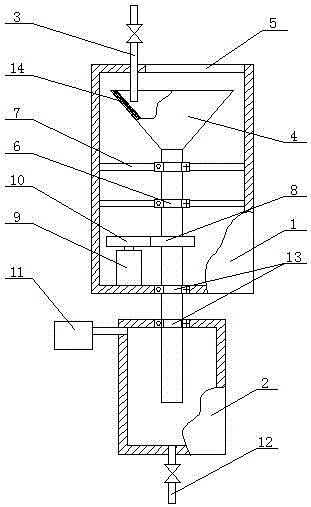

Comprehensive treatment method for shield waste mud and mixing material-adding device

ActiveCN108358491AGood for secondary useSimple structureSolid waste managementDischarging apparatusBrickFirming agent

The invention provides a comprehensive treatment method for shield waste mud. The method comprises the following steps: (1) pretreating the waste mud to obtain muddy water, mud and granular waste residues; (2) measuring the sand content of the mud obtained in the step (1), when the sand content is >= 15%, adding a sandy soil curing agent A2 by adopting a mixing material-adding device for consolidation, performing stirring, and performing pressing to prepare a building material; and when the sand content is < 15%, adding a clay curing agent A1 by adopting the mixing material-adding device for consolidation, performing stirring, and performing pressing to prepare a building material; and (3) adding a curing agent into the granular waste residues obtained in the step (1) by adopting the mixing material-adding device, performing stirring, and performing pressing to form a brick. The invention also provides the mixing material-adding device. The method provided by the invention can reduce problems of pollution and land occupation of the waste mud, makes the waste mud obtain secondary utilization, and achieves purposes of having certain economic benefits, saving energy and reducing emission.

Owner:湖南垚森信息科技有限公司

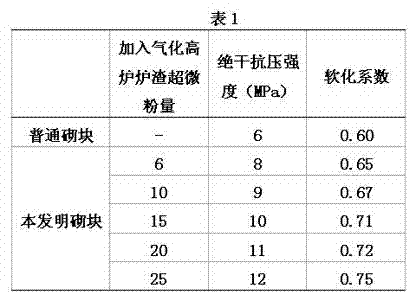

Ardealite modified and strengthened damp-proof gypsum block

The invention discloses an ardealite modified and strengthened damp-proof gypsum block which is mainly prepared by hemihydrate gypsum, vaporized slag ultra-fine powder, an activator and water. The strength of the block can be improved, the sound insulation, damp proofing and fire proofing effects are good, and meanwhile environmental pollution caused by chemical reaction can be avoided.

Owner:贵州友仁建材科技开发有限公司

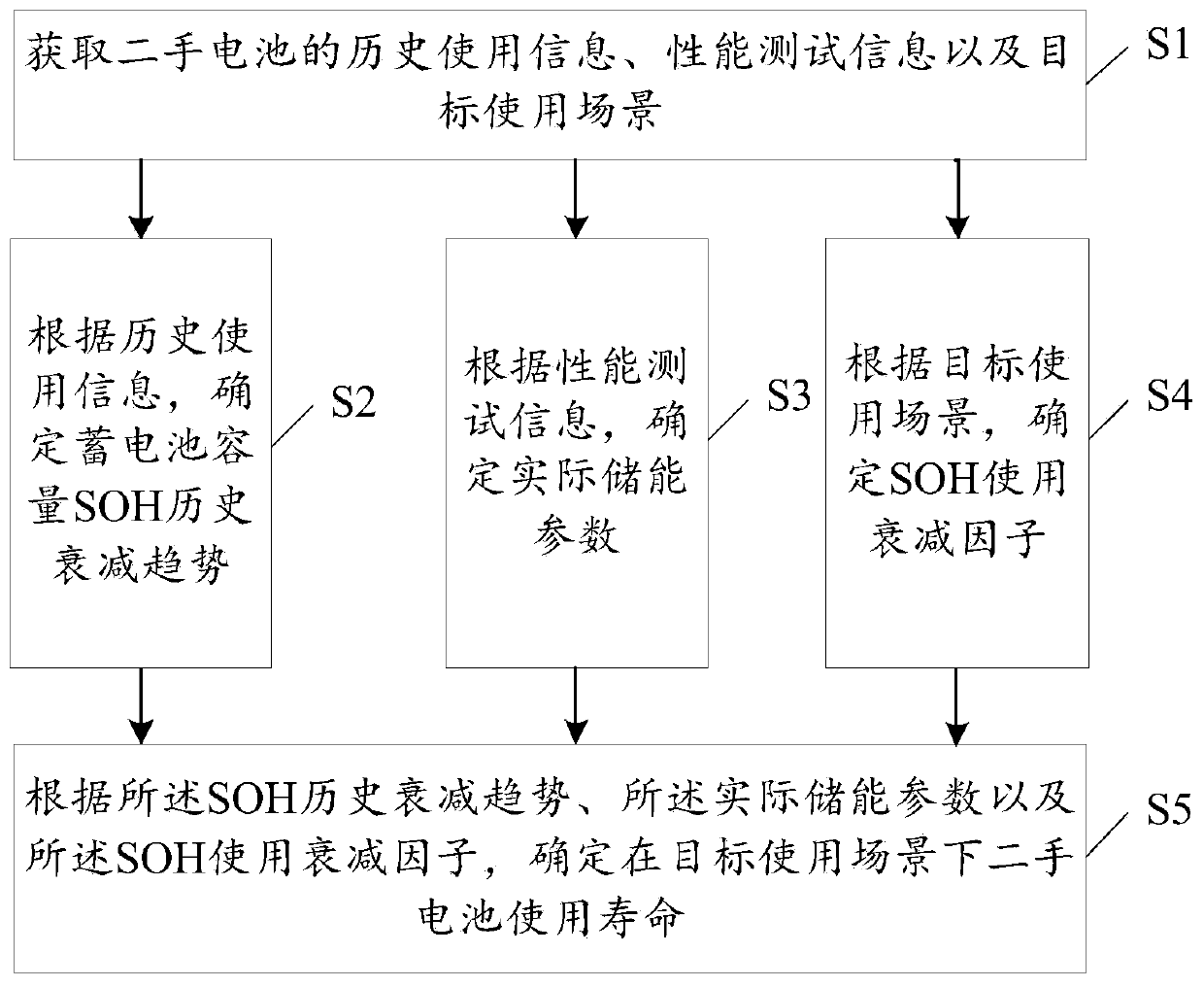

Method and device for predicting service lifetime of second-hand battery

The invention discloses a method and device for predicting the service lifetime of a second-hand battery. The method comprises the following steps: acquiring historical use information, performance test information and a target use scene of the second-hand battery; determining an SOH historical attenuation trend, an actual energy storage parameter and an SOH usage attenuation factor according to the historical usage information, the performance test information and the target usage scenario; determining the service lifetime of the second-hand battery in the target usage scenario according to the SOH historical attenuation trend, the actual energy storage parameter and the SOH usage attenuation factor. The SOH historical attenuation trend, the actual energy storage parameter and the SOH usage attenuation factor are important parameters influencing the service lifetime of the second-hand battery, and therefore, when the service lifetime of the second-hand battery is determined accordingto the SOH historical attenuation trend, the actual energy storage parameter and the SOH usage attenuation factor, the service lifetime of the second-hand battery in the target use scene can be accurately predicted, so that the second-hand battery can be effectively reutilized.

Owner:NEUSOFT REACH AUTOMOBILE TECH (SHENYANG) CO LTD

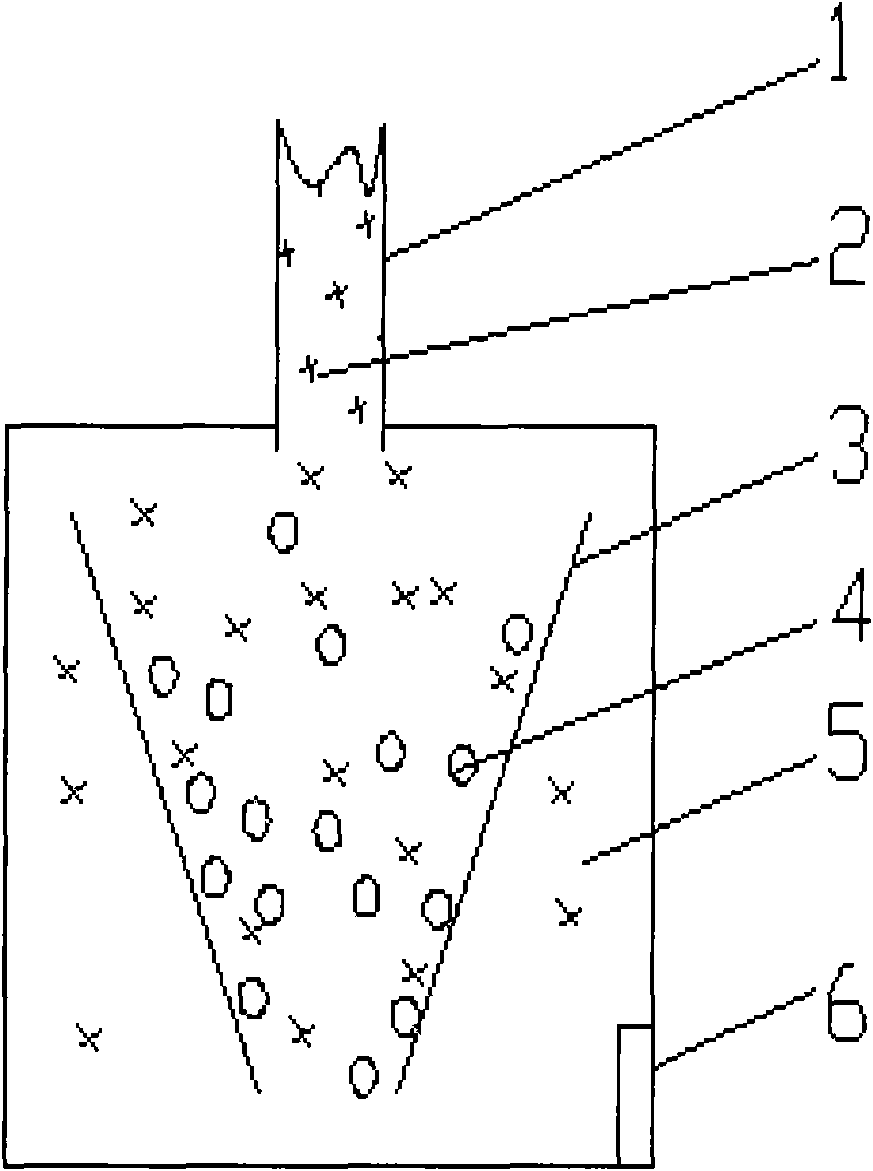

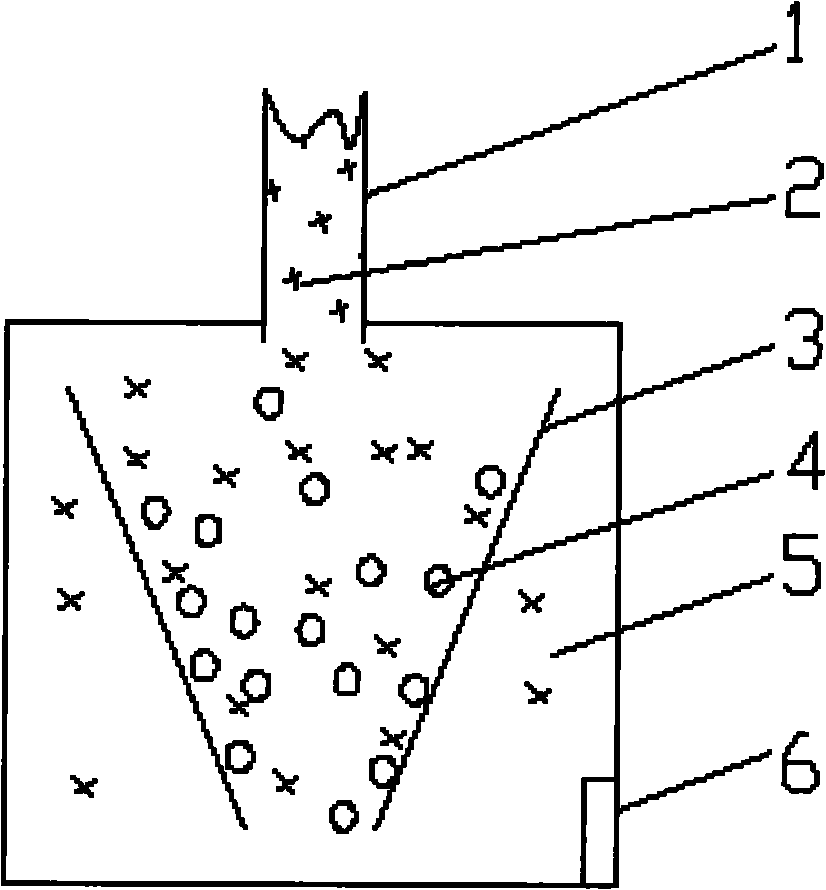

Settling chamber for reclaiming residual naphthalene in synthesizing process of high-efficiency water reducing agent

InactiveCN101912695AIncrease profitGood for secondary useOrganic chemistrySublimationFlue gasSuperplasticizer

The invention relates to the field of naphthalene high-efficiency water reducing agents used in cement concrete, in particular to a settling chamber for reclaiming residual naphthalene in a synthesizing process of a high-efficiency water reducing agent. At present, the main problem is that in a production process, when melted naphthalene is sulfonated at a relatively high temperature, the naphthalene cannot be completely melted or the naphthalene is not completely reacted in a sulfonation process, so the naphthalene resource is wasted, and when discharged into the air through an escape pipe, causes pollution to atmosphere, blockage of flue gas pipelines, damage to a reclaiming kettle and the like. The invention provides the settling chamber for reclaiming the residual naphthalene in the synthesizing process of the high-efficiency water reducing agent, which can reclaim the naphthalene remaining after the naphthalene is melted and a sulfonated in the production process of the high-efficiency water reducing agent, absorb uncombined naphthalene steam in the product at the same time and increase the quality of the water reducing agent. The settling chamber can reduce the production cost. By the settling chamber, the utilization rate of raw materials is improved by about 6 percent and the utilization of environmental pollutants is realized.

Owner:大连市铭源全科技开发有限公司

Method for producing ammonium bifluoride through fluorine-containing waste etching liquid

InactiveCN106517244AGood for secondary useReduce pollutionGravity filtersAmmonium halidesLiquid wasteHydrofluoric acid

The invention discloses a method for producing ammonium bifluoride through fluorine-containing waste etching liquid. The method includes the following steps that (1) the fluorine-containing waste etching liquid is subjected to impurity removing through an impurity removing device, and sulfate ions, chloride ions and nitrate ions in the waste liquid are removed; (2) the waste liquid after impurity removing is added into a reaction kettle, liquid ammonia is led into the reaction kettle till new precipitate cannot be generated, heating is carried out, unreacted ammonia gas is discharged and recycled, liquid and the precipitate are added into a filter, filtered and separated, and filtered liquid and filtered residues are obtained; (3) hydrofluoric acid is added into the filtered liquid obtained in the step (2) till the pH value is not changed, the mixture is evaporated, crystallized, washed, dried and smashed, and the ammonium bifluoride product is obtained. The method is suitable for fluorine-containing waste etching liquid with the high fluorine content (the hydrofluoric acid content is larger than or equal to 5 wt%), the waste liquid after impurity removing is treated and recycled to obtain the ammonium bifluoride product; the fluorine-containing waste etching liquid is effectively subjected to secondary utilization, pollution of the waste liquid to the environment is reduced, and the industrial value is improved.

Owner:昆明培铭科技有限公司

Plant breeding substrate and production method thereof

InactiveCN101361454BLight in massImprove ventilationCultivating equipmentsSoilless cultivationEnvironment of AlbaniaGreening

The invention relates to plant cultivation. A plant cultivation substrate is made into a whole by wooden fragments, a soil conditioner and a nutrient particle body. Compared with the like products, the cultivation substrate has the advantages of light self mass, high ventilation performance and high moister retention: the invention has the best sealing environment to the plant, and does not need the technology experience of the specialists, therefore, the invention not only can realize the greening of roofs, etc., save labor force, and reduce cost, but also is in fixed base type, and can effectively avoid sealing lost and dispersion caused by heavy rain and strong wind.

Owner:大连染谷绿业科技有限公司 +2

Method for recycling molybdenum from waste slag of catalyst

InactiveCN106916974AGood for secondary useSimple processProcess efficiency improvementIndustrial wasteEnvironmental chemistry

The invention discloses a method for recycling molybdenum from waste slag of a catalyst. The method includes the following steps that A, a sodium hydroxide solution and a sodium carbonate solution are added into the waste slag of the aluminum-oxide-based catalyst and are mixed uniformly; B, after the mixed material is ground into slurry and heated, solid-liquid separation is performed, and a sodium aluminate-sodium molybdate mixed solution is obtained; C, molybdenum in the sodium aluminate-sodium molybdate mixed solution is adsorbed through resin to obtain a molybdenum solution; and D, after calcium chloride is added into the molybdenum solution, calcium molybdate is obtained through precipitation. According to the method for recycling the molybdenum from the waste slag of the catalyst, the molybdenum is recycled from the waste slag of the aluminum-oxide-based catalyst through an analytical method, the technological process is simple, the equipment cost is low, the recycling rate is high, secondary utilization of the industrial waste slag is effectively achieved, valuable mineral resources are saved, and the remarkable progressive significance is achieved.

Owner:SICHUAN DONGYU INFORMATION TECH

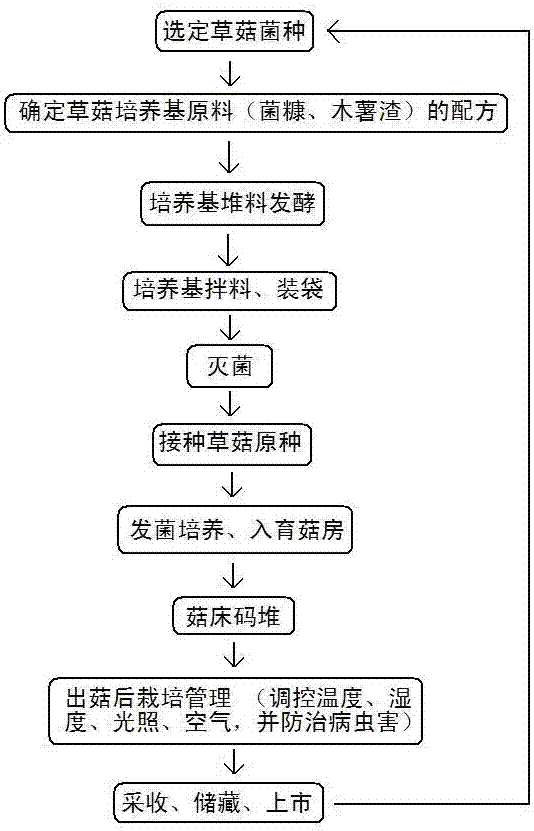

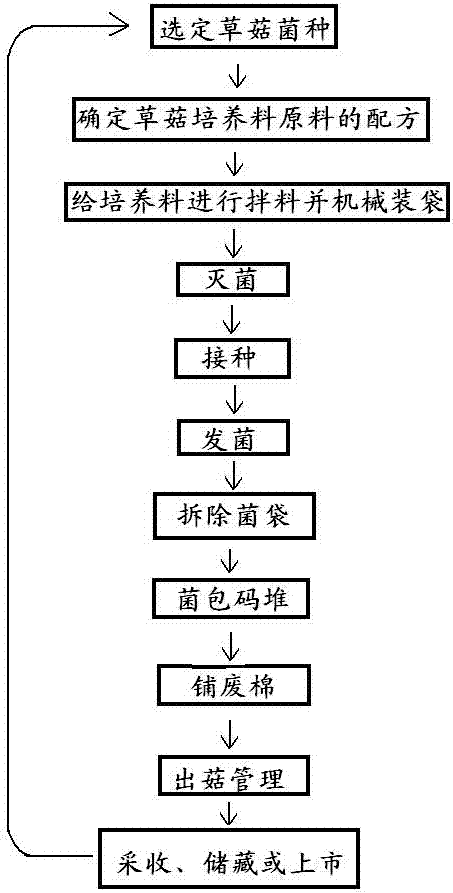

Mass production mode of bag cultured volvaria volvacea with spent substrate of pleurotus eryngii

InactiveCN107079708AGood for secondary useReduce manufacturing costCalcareous fertilisersBio-organic fraction processingCelluloseHypha

The invention belongs to a mass production mode of bag cultured volvaria volvacea with spent substrate of pleurotus eryngii, and relates to the field of planting of edible mushrooms and utilization of agricultural wastes. Waste spent substrate formed by annual production of the pleurotus eryngii forms a pollution source, and manioc wastes are added according to the characteristic that a part of cellulose of the spent substrate is decomposed into mycelium proteins by pleurotus eryngii hypha, so that a large amount of low-cost culture material obtained easily is manufactured. The traditional volvaria volvacea production mode is a bed type cultivation pattern, a lot of manpower is needed when fermentation raw materials are put on or off a shelf, and secondary fermentation is needed, so that time, labor and energy are consumed. The invention provides the mass production mode of the volvaria volvacea, which has the advantages that labor and energy consumption are reduced, the mushroom producing time is shortened, the yield is improved, and the cost is lowered. A technological process comprises the following steps: bagging the piled culture material after fermentation, sterilizing, inoculating and performing spawn running; after a bag is fully filled with the hypha, disinfecting, removing the bag, putting gymnobacteria on a culture frame for management of producing mushroom, and harvesting in a concentration manner. The mass production mode provided by the invention has the advantages that the secondary fermentation is not needed, so that manpower and energy consumption can be reduced, mushrooms can be produced in advance, and the cost is lowered.

Owner:GUANGXI POLYTECHNIC

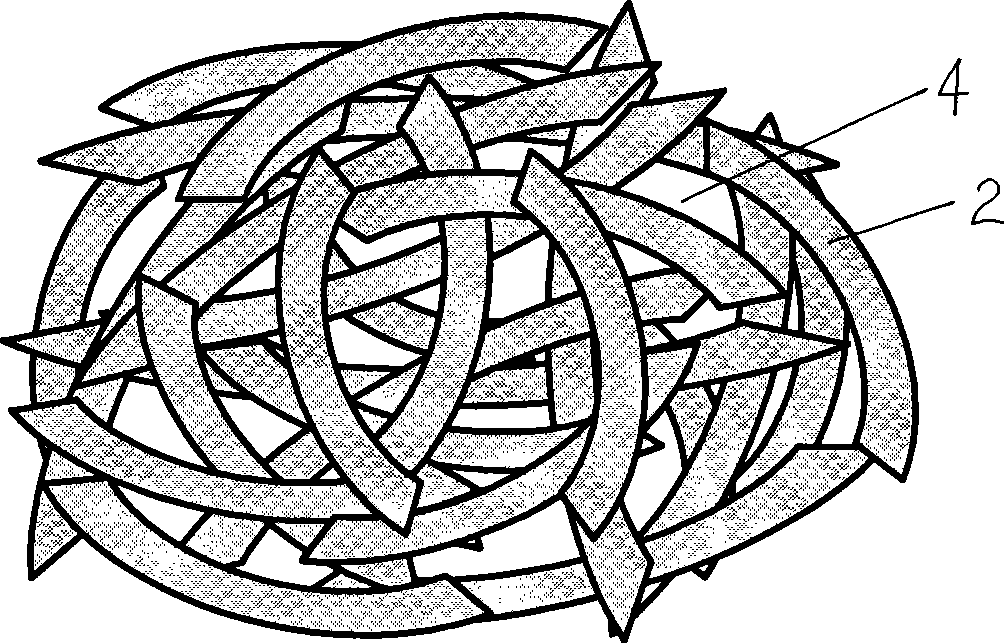

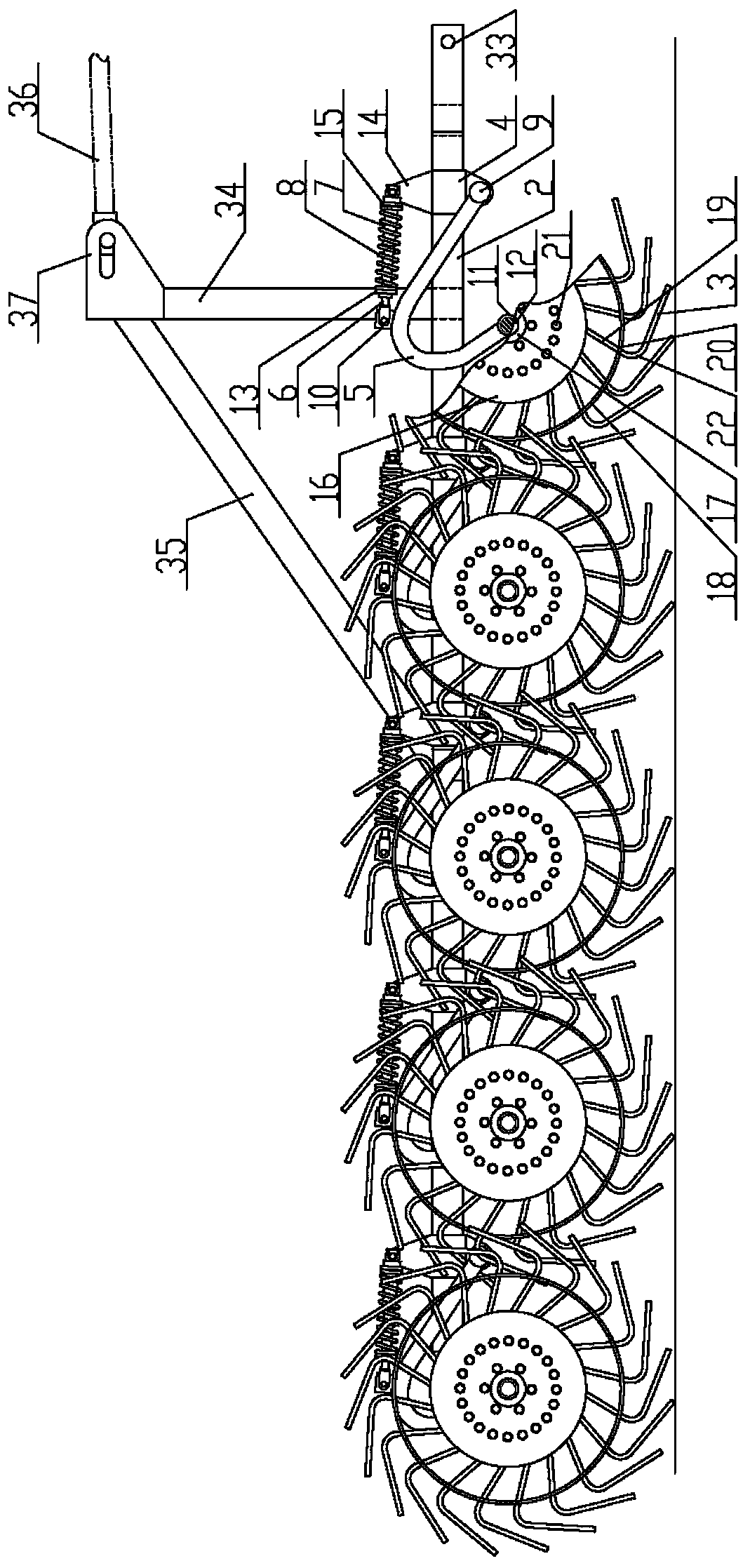

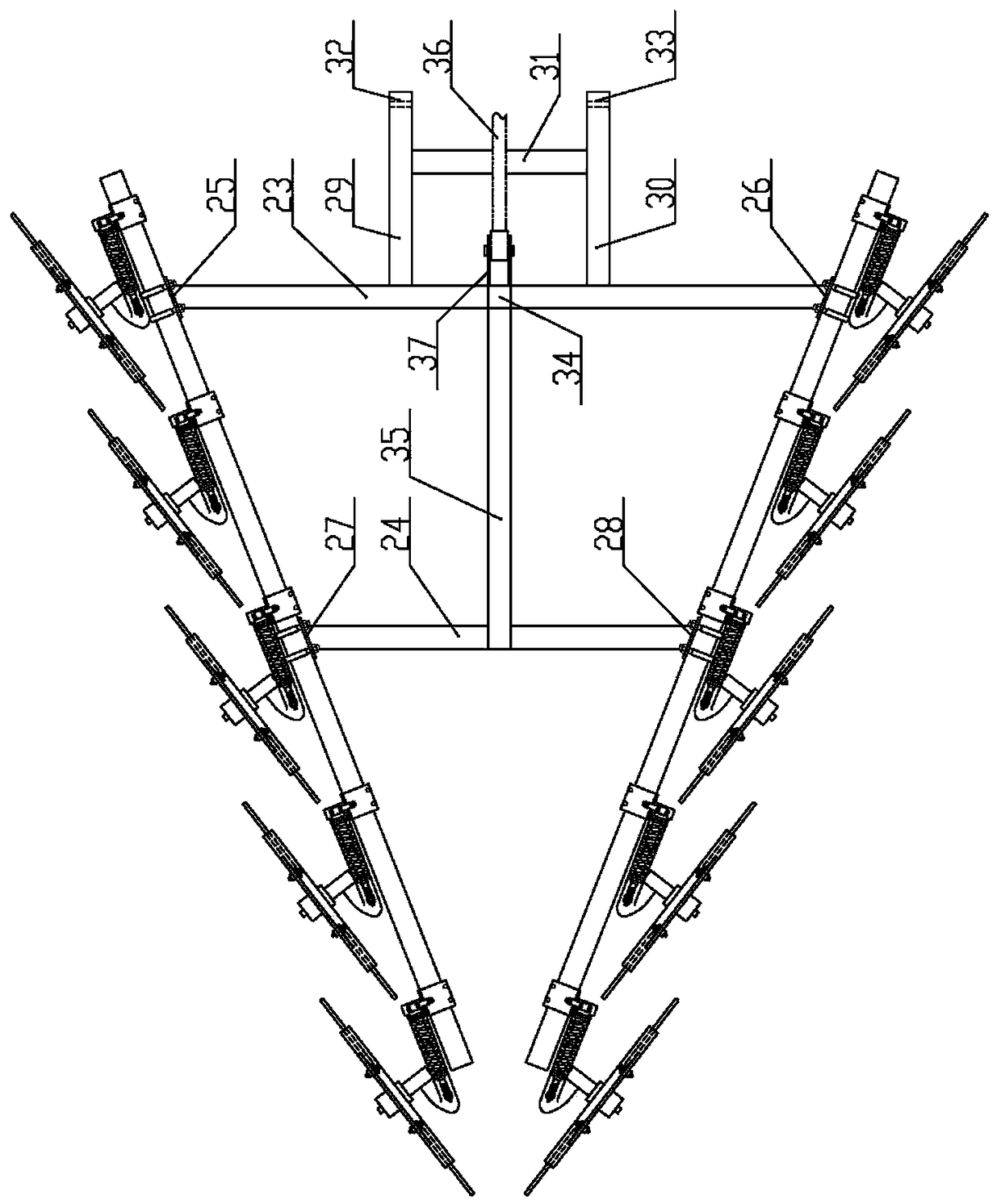

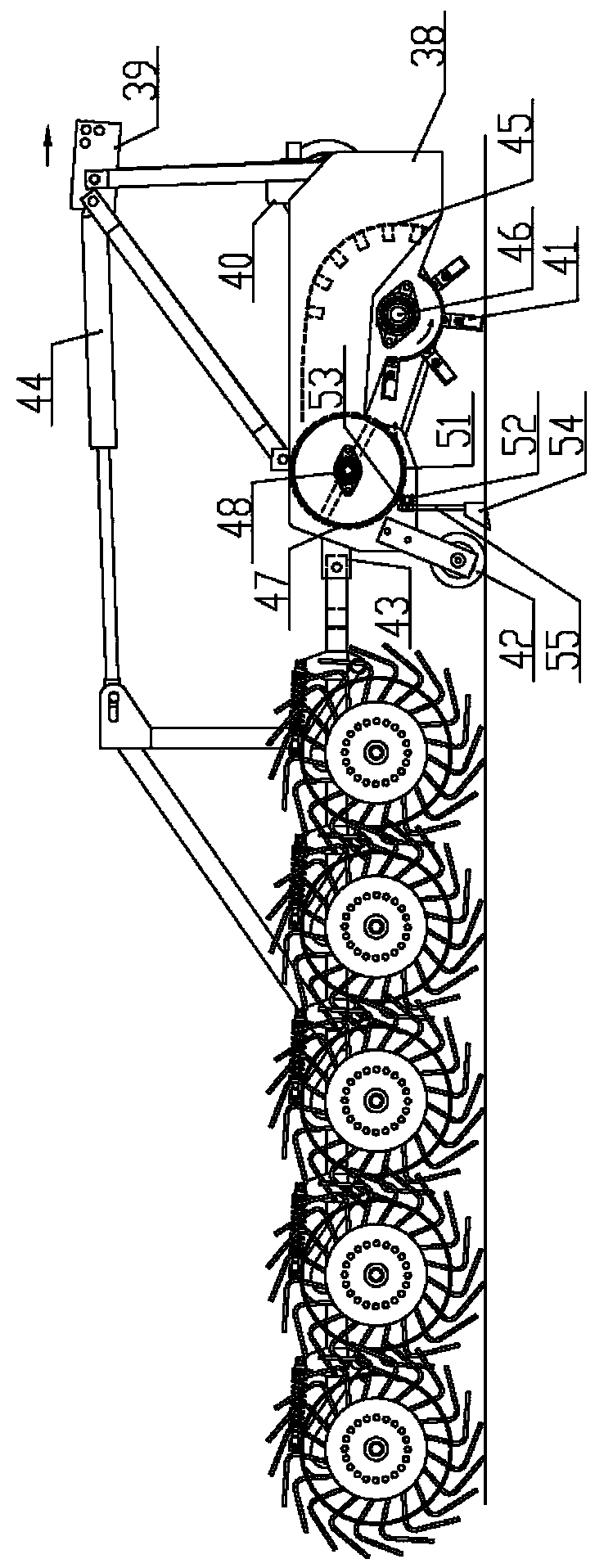

Wheel rake type mulching film strip collecting device and mulching film strip collecting type straw returning machine

PendingCN109328496AUnbreakableEasy to collect and packSpadesMowersAgricultural engineeringCantilever

The invention relates to the technical field of agricultural machinery, in particular to a wheel rake type mulching film strip collecting device and a mulching film strip collecting type straw returning machine. The wheel rake type mulching film strip collecting device comprises a strip collecting frame and at least one pair of rake wheel components, wherein strip collecting frame comprises a leftframe pole and a right frame pole, the rake wheel component comprises a rake wheel and a spring cantilever device. The mulching film strip collecting type straw returning machine comprises a returning machine frame, a straw crushing device, an auger device and a wheel rake type mulching film strip collecting device. The wheel rake type mulching film strip collecting device and the mulching film strip collecting type straw returning machine are reasonable and compact in structure and convenient to use. Arranged at the rear part of the straw crushing device capable of conveying crushed straws to two sides of a mulching film, the wheel rake type mulching film strip collecting device and the mulching film strip collecting type straw returning machine can pick up the mulching film by the rakewheels at the left side and the right side and furl the mulching film towards the middle part of a strip collecting interval, so that the mulching film is stacked into a strip shape. Through practicaltests, the collected mulching film contains less broken straws and other impurities, the mulching film is not lifted up in the collecting process and will not be scattered everywhere, meanwhile, themulching film is not easy to be broken, so subsequent packaging and collection and subsequent secondary utilization of the mulching film are easy.

Owner:张朝书

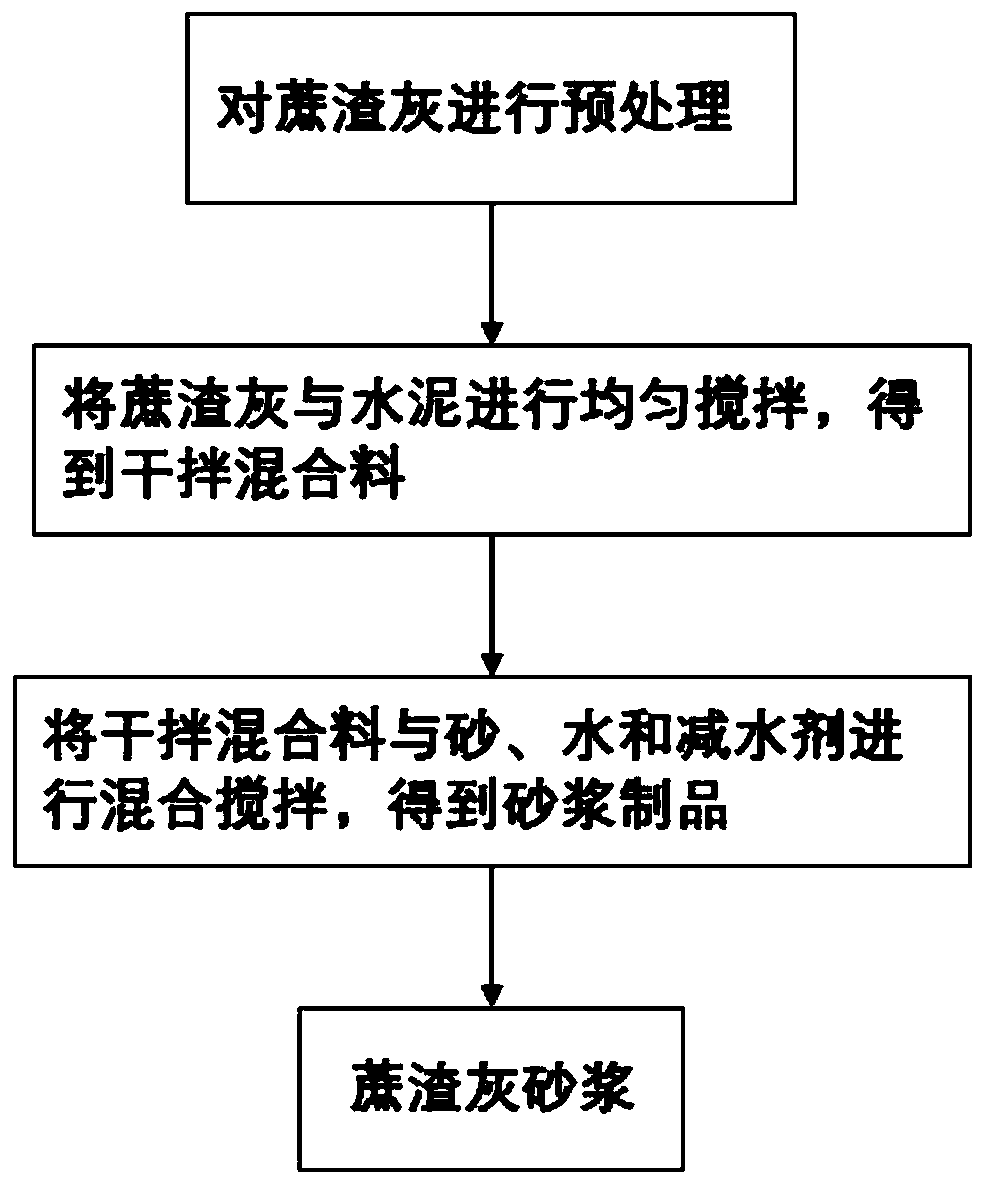

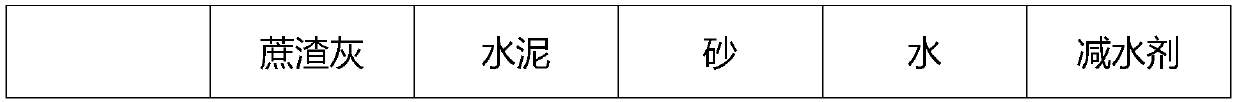

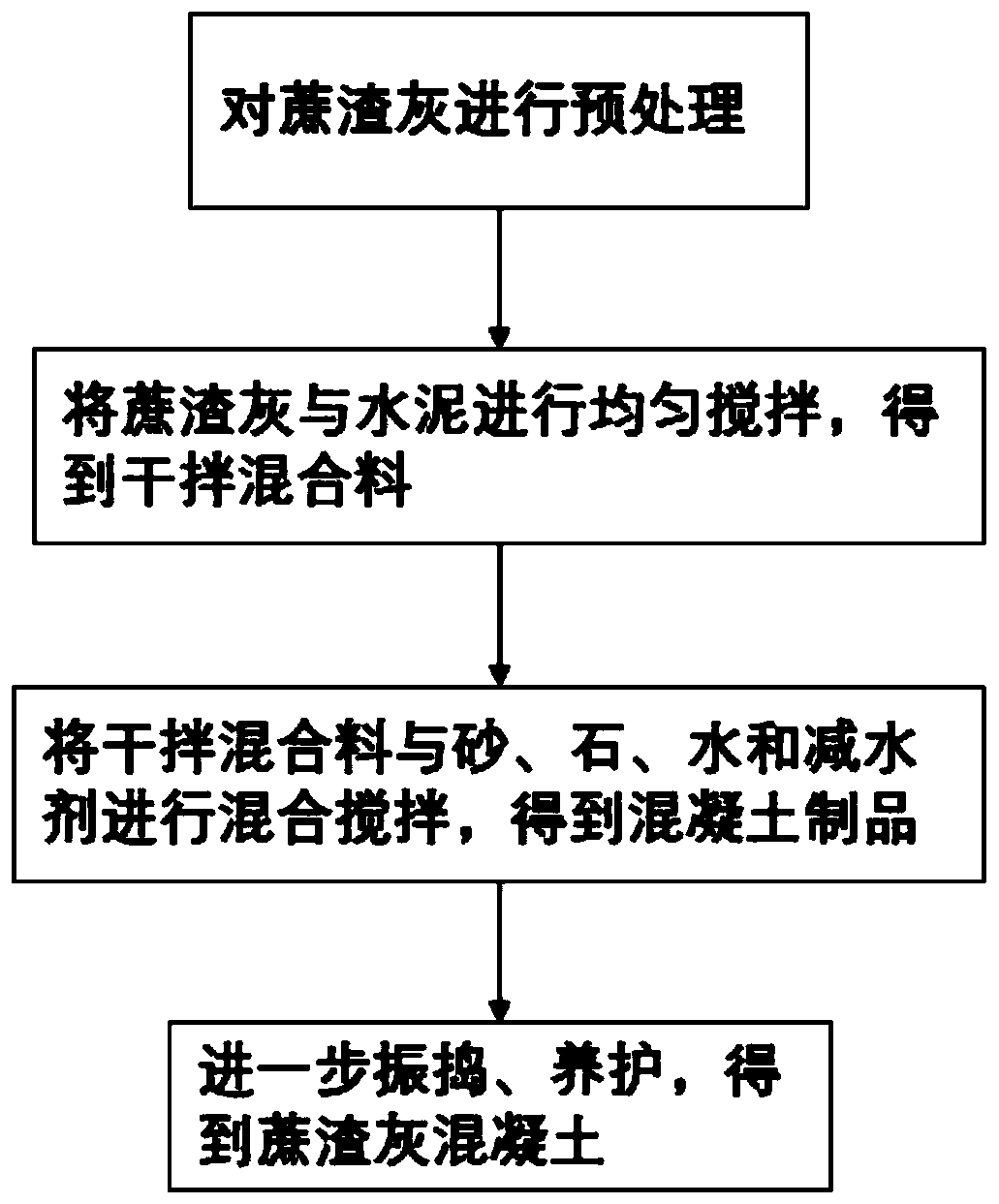

Preparation method for bagasse ash mortar

InactiveCN110282917AIncreased pozzolanic activityImprove compactnessSolid waste managementResource consumptionUltimate tensile strength

The invention discloses a preparation method for bagasse ash mortar. The preparation method comprises the following steps that bagasse ash discharged from a burning furnace of a sugar refinery is pretreated, so that the activity of the bagasse ash is improved; and the pretreated bagasse ash serves as a raw material for preparing the mortar, the pretreated bagasse ash, sand, water, cement and a water reducer are mixed, stirred, poured and vibrated so as to prepare a bagasse ash mortar product, and standard curing is further adopted. The bagasse ash mortar prepared through the preparation method has higher structural strength and durability. Compared with traditional mortar, the bagasse ash mortar prepared through the preparation method has the advantages that on the premise that the performance is improved, the bagasse ash can be fully reused, the resource consumption is reduced, and economical and environmentally-friendly production is facilitated.

Owner:GUANGXI UNIV +1

Trash can of adjustable size

The invention discloses a trash can of the adjustable size. The trash can comprises a bottom disc and multiple spherical holes distributed in the circumference of the upper edge of the bottom disc. Each spherical hole covers a spherical head arranged at one end of a spoke so that a hinge mechanism can be formed, the other end of each spoke penetrates through a through hole formed in a restraining ring, and the restraining ring is located between the two ends of each spoke all the time. Each spoke independently distributed on the edge of the bottom disc penetrates through the restraining ring so that a trash can body of an integrated structure can be formed. The restraining ring is further provided with fastener screws used for limiting movement of the restraining ring. In the state when the fastener screws are loosened, the restraining ring is made to move in the length direction of the spokes, so that the size of the trash can is adjusted. According to the trash can of the adjustable size, the size of the trash can is changed by changing the vertical position of the restraining ring, trash cans of different sizes can be suitable for different plastic bags, the abandoned plastic bags in daily life can be effectively recycled, resources are saved, white pollution is reduced, and environment friendliness is achieved.

Owner:HENAN UNIV OF SCI & TECH

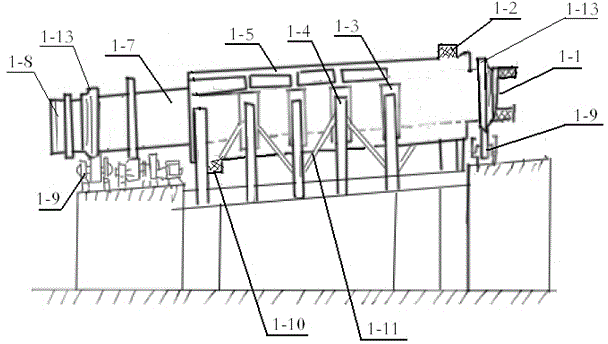

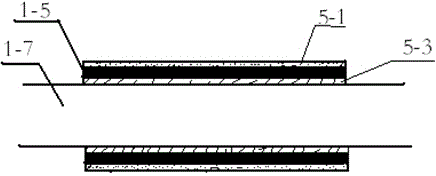

Petroleum coke material calcination cooling device

InactiveCN104697326AGood for secondary useIncrease profitRotary drum furnacesWaste heat treatmentThermodynamicsPetroleum coke

The invention discloses a petroleum coke material calcination cooling device. The device comprises a cylinder and rims, wherein a material inlet, a material outlet and the rims are arranged on the cylinder respectively, the material inlet and the material outlet are located at two ends of the cylinder respectively, one rim is arranged at each of two ends where the material inlet and the material outlet are located, the cylinder further comprises a cooling body connected with the material inlet, an air inlet and an air outlet are arranged on the cooling body, and the diameter of the cooling body is larger than that of the cylinder. With the adoption of the device, heat of a calcined waste coke material can be fully and effectively utilized secondarily, the energy utilization rate and the heat recovery efficiency are increased from traditionally about 20% to more than 30%, and energy is saved.

Owner:GUANGXI HONGDA BIO ENERGY TECH

Method and device for treating organic wastewater

InactiveCN103663585AReduce environmental pollutionGood for secondary useWater/sewage treatment by heatingExhaust fumesDistillation

The invention relates to a method and device for treating organic wastewater. In order to solve the problems of high cost, complex process and the like during the treatment of the organic wastewater at present, the invention provides the method for treating the organic wastewater, and the method comprises the steps of 1, collecting an organic waste liquid; 2, gradually heating the organic waste liquid, and performing distillation purification; and 3 collecting pure water, and burning organic waste gas. The method is simple, convenient and easy to operate, so that excessive manpower and material inputs are not needed, the treatment cost of the wastewater is saved, wastes are changed into treasures, and the organic liquid can be reused.

Owner:苏州工业园区七星电子有限公司

Method for improving straw methane yield through pure ammonia wet process soaking normal temperature pretreatment

ActiveCN102827879BReduce preprocessing timeEasy to produceWaste based fuelFermentationMethane yieldPre treatment

Owner:BEIJING UNIV OF CHEM TECH

Water-desalting-station multi-media-filter washing water saving system

InactiveCN105366829AGood for secondary useEmission reductionGeneral water supply conservationMultistage water/sewage treatmentSaline waterWater saving

The invention aims at providing a water-desalting-station multi-media-filter washing water saving system. According to the technical scheme, the water-desalting-station multi-media-filter washing water saving system is composed of a deep pool, a water storage tank, a multi-media filter, a primary reverse osmosis part, a secondary reverse osmosis part, a mixed bed, a dry absorption circulating pool, a boiler, an acid refining device and a collecting pool. A water outlet of the water storage tank is communicated with a water injection opening and a washing opening of the multi-media filter through pipes, a water outlet of the multi-media filter is communicated with a water injection opening of the primary reverse osmosis part through a pipe, and a low-pressure-side outlet of the primary reverse osmosis part is communicated with a water injection opening of the secondary reverse osmosis part and the washing opening of the multi-media filter through pipes. The water-desalting-station multi-media-filter washing water saving system has the advantages that drained concentrated water is effectively reused, sewage draining is reduced while water is saved, and the good environment-friendly effect and the good economical effect are achieved.

Owner:TIANJIN BODA SULFURIC ACID IND

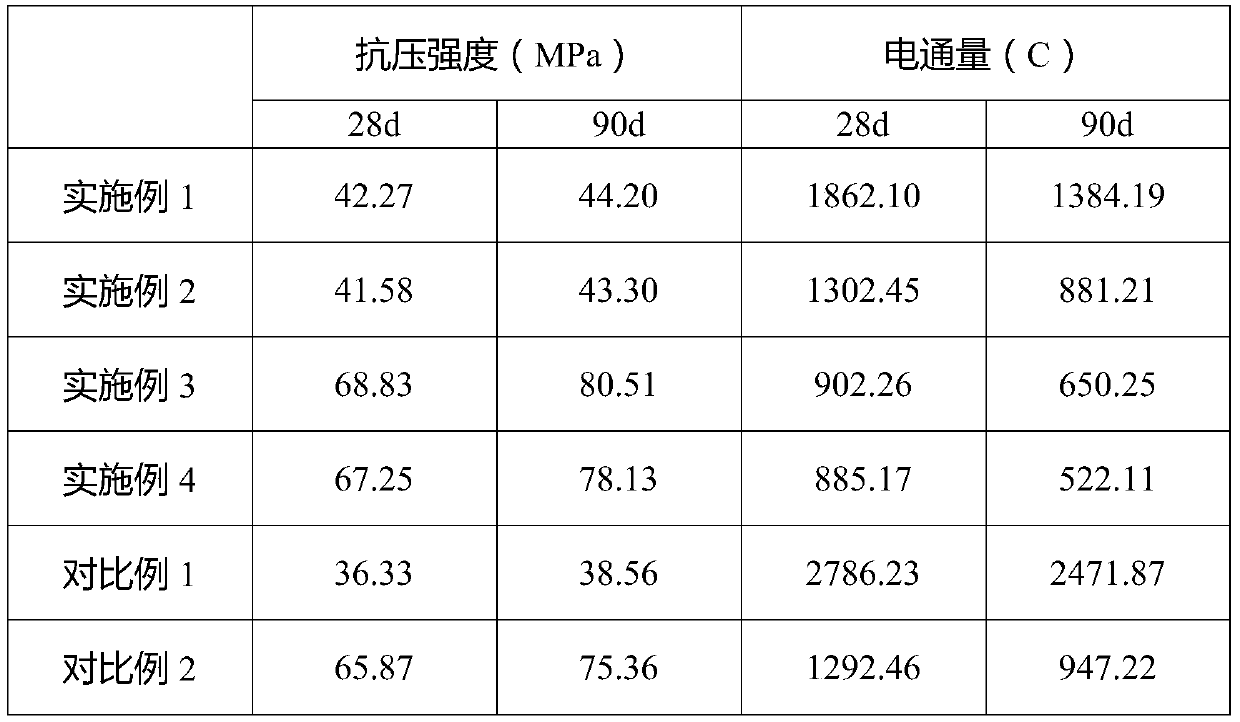

Bagasse ash concrete and preparation method thereof

InactiveCN110330281AIncreased pozzolanic activityImprove compactnessPulp and paper industryPre treatment

The invention discloses bagasse ash concrete and a preparation method thereof. The preparation method comprises the following steps: pretreating bagasse ash discharged from a furnace of a sugar refinery so that the activity of the bagasse ash is improved; taking the pretreated bagasse ash as a raw material for preparing concrete, mixing and stirring with sand, stone, water, cement and a water reducing agent, pouring and vibrating to prepare a bagasse ash concrete product, and further curing by one of standard curing and thermal curing. The prepared bagasse ash concrete has high structural strength and durability. Compared with traditional concrete, the bagasse ash concrete has the advantages that on the premise that the performance is improved, the bagasse ash can be fully reused, the resource consumption is reduced, and economic and environment-friendly production is facilitated.

Owner:GUANGXI UNIV +1

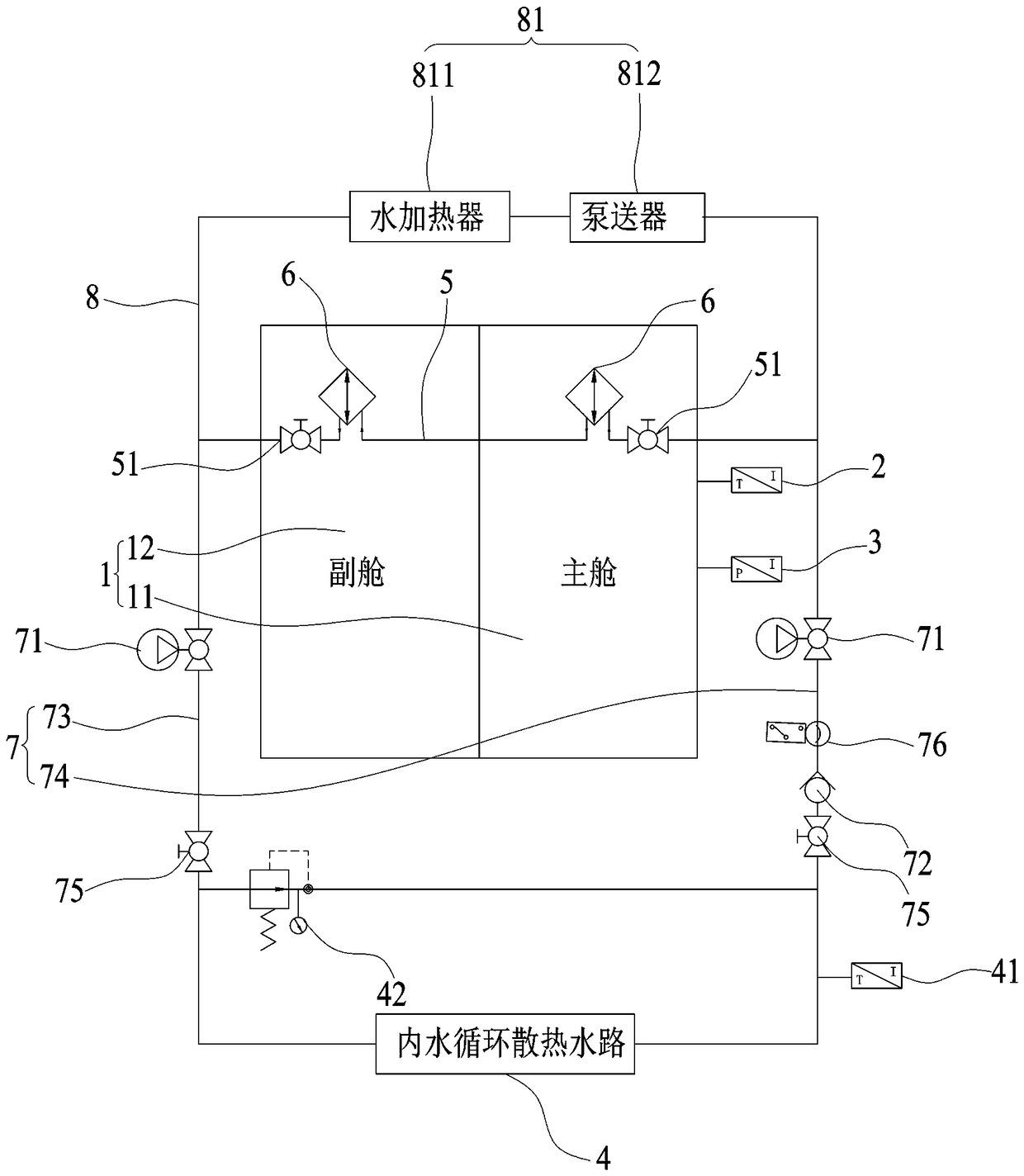

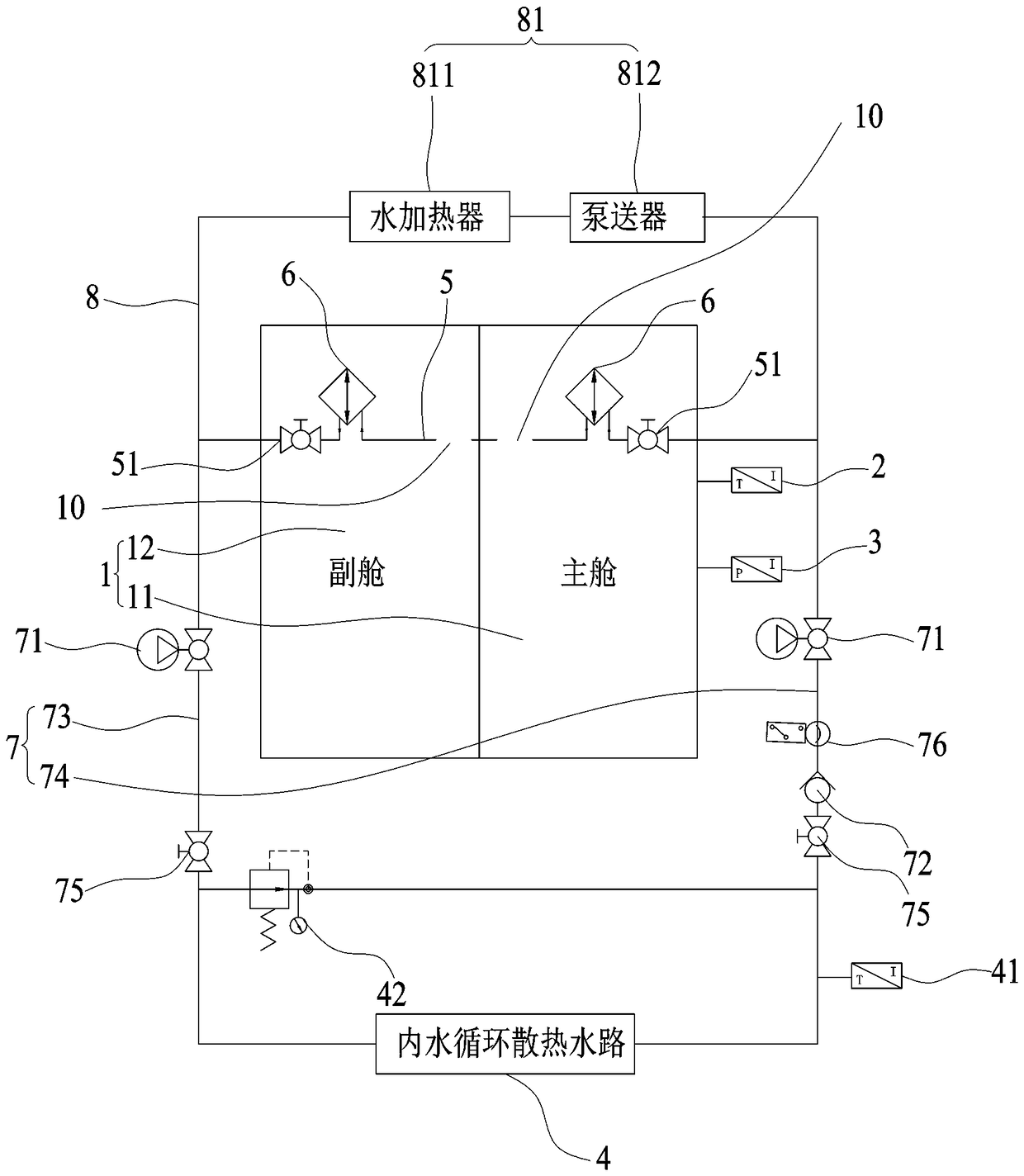

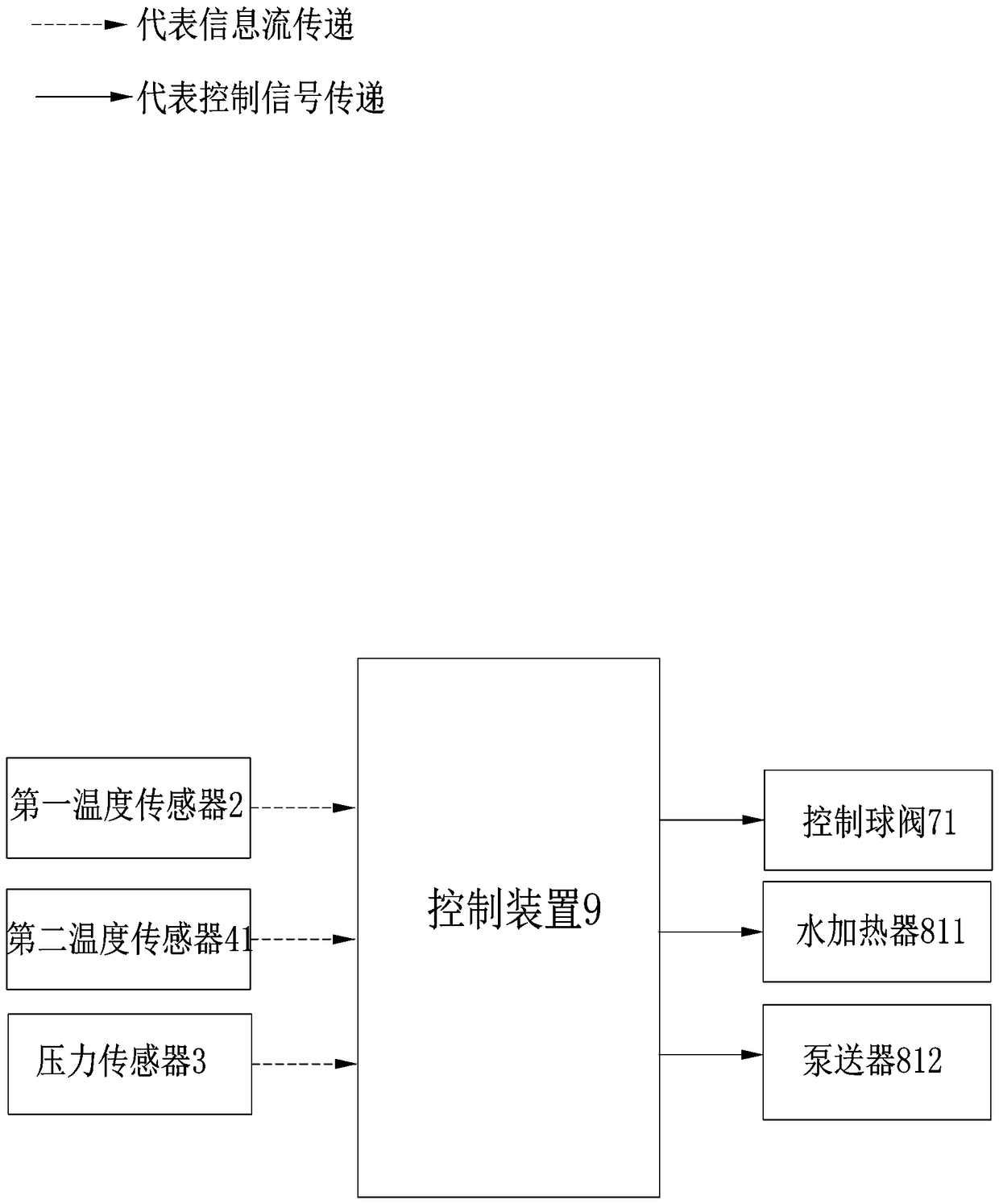

Heating system for man cabin of shield machine and control method thereof

PendingCN108612537AAchieve heatingAvoid safety hazardsSpace heating and ventilation detailsWater heatersEngineeringWater pipe

A heating system for a man cabin of a shield machine comprises the man cabin, a first temperature sensor, a pressure sensor and an internal circulating heat dissipation water path, wherein the first temperature sensor and the pressure sensor are arranged in the man cabin. At least one water-passing pipeline is arranged in the man cabin, a heat dissipation device and a first manual ball valve are connected to each water-passing pipeline, the two ends of the water-passing pipelines are externally connected with a first heating water path and a second heating water path correspondingly, and the first heating water path communicates with the internal circulating heat dissipation water path mutually. Control ball valves and a one-way valve are additionally arranged on the first heating water path, and the second heating water path is externally connected with a water heating system. The heating system further comprises a control device. The control device receives temperature signals transmitted by the first temperature sensor and a second temperature, compares the temperature signals and then sends out control instructions to the control ball valves and the water heating system for achieving opening / closing of the control ball valves and starting / stopping of the water heating system, and thus communicating of the water passing pipelines and the first heating water path or the second heating water path is achieved finally.

Owner:XIAMEN XIAGONG CHINA RAILWAY HEAVY MACHINERY CO LTD

Moisturizing and production increasing technique of bagged straw mushroom via pleurotus eryngii residue clinker

InactiveCN107114116AReduce manufacturing costLow costCalcareous fertilisersBio-organic fraction processingPleurotus eryngiiVolvariella volvacea

The invention belongs to a moisturizing and production increasing technique of bagged straw mushroom via pleurotus eryngii residue clinker, and relates to the field of edible mushroom panting. Waste mushroom residues generated by pleurotus eryngii yearly causes pollution, the waste mushroom residues can be recycled, manioc waste accessories are added to prepare a lot of compost, which is low in cost and easy to obtain. The straw mushrooms like high temperature and high humidity. The traditional straw mushroom production mode has difficulty in solving the moisturization problem, and the hypha is air dried, which is unbeneficial for the growth of the straw mushrooms. The invention provides a straw mushroom production mode, which stably maintains the moisture, keeps high humidity, shortens the period, improves the yield and reduces the cost. The process flows comprise: bagging pretreated compost, sterilizing, inoculating, germinating the straw mushrooms, after the hypha fills the bag, sterilizing and debagging, and placing naked hypha on a culture frame, covering a layer of waste cotton on the naked hypha, performing mushroom harvest management, harvesting and processing the mushrooms. The moisturizing and production increasing technique has the beneficial effects of stably maintaining the moisture, keeping high humidity, shortening the period, improving the yield and reducing the cost.

Owner:GUANGXI POLYTECHNIC

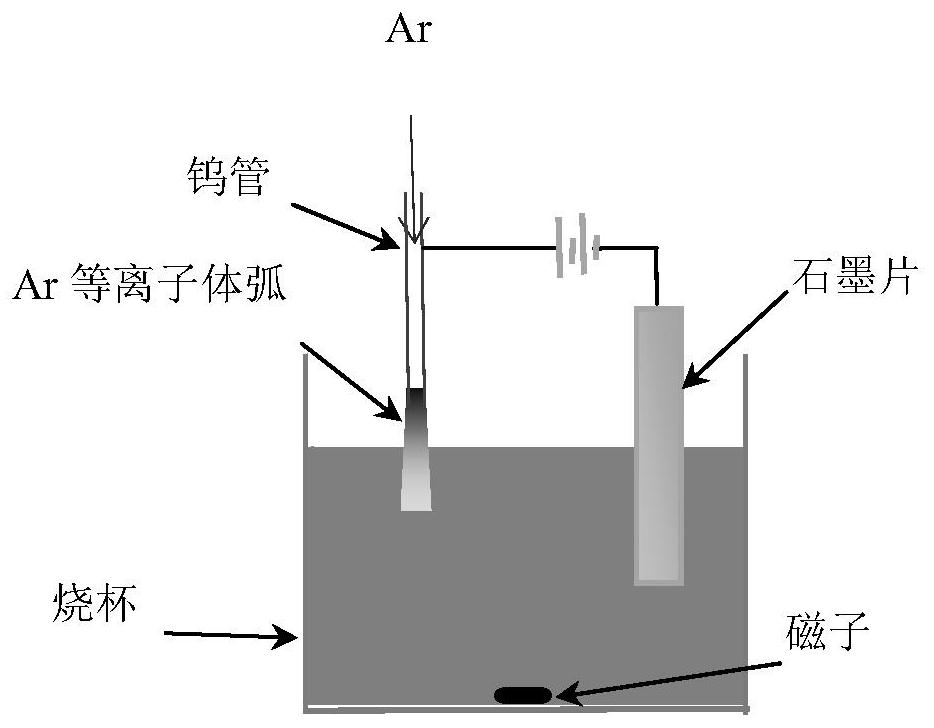

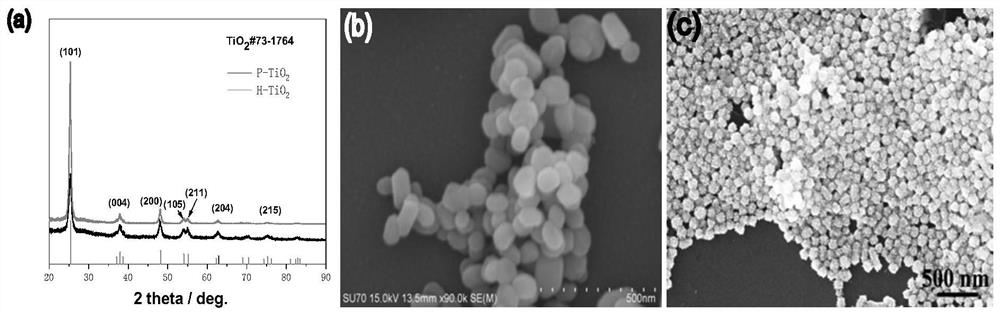

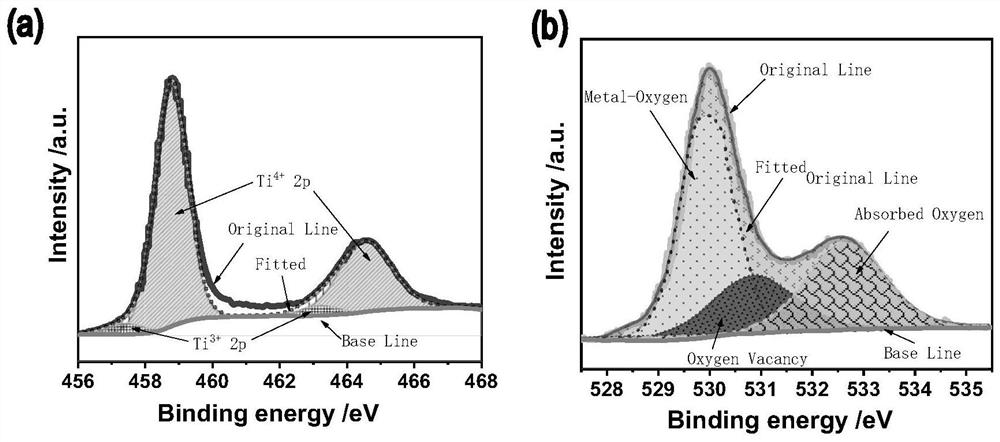

Oxygen-vacancy-rich titanium dioxide material, preparation and application of oxygen-vacancy-rich titanium dioxide material in lithium oxygen battery

ActiveCN113351194APromote barriersReduce overpotentialPhysical/chemical process catalystsCell electrodesMetallic electrodeOxygen vacancy

The invention provides an oxygen-vacancy-rich titanium dioxide material, preparation and an application thereof in a lithium-oxygen battery, the preparation comprises the following steps: S1, a tubular electrode is placed above a titanium salt solution, and the distance between the lower end of the tubular metal electrode and the liquid level is 0.1-10 mm; a sheet electrode is placed in the titanium salt solution; S2, inert gas is continuously blown out in the liquid level direction through the tubular electrode; and S3, the tubular electrode and the sheet electrode are connected with a high-voltage direct-current power supply, and plasma is generated between the lower end of the tubular electrode and the liquid level by controlling voltage; and voltage stable discharge is kept for a period of time, and a precipitation product is collected at the bottom of the liquid, namely the oxygen-vacancy-enriched titanium dioxide material. The material can reduce the overpotential of the lithium-air battery in the charge-discharge process and improve the cycling stability of the lithium-air battery.

Owner:XIAMEN UNIV

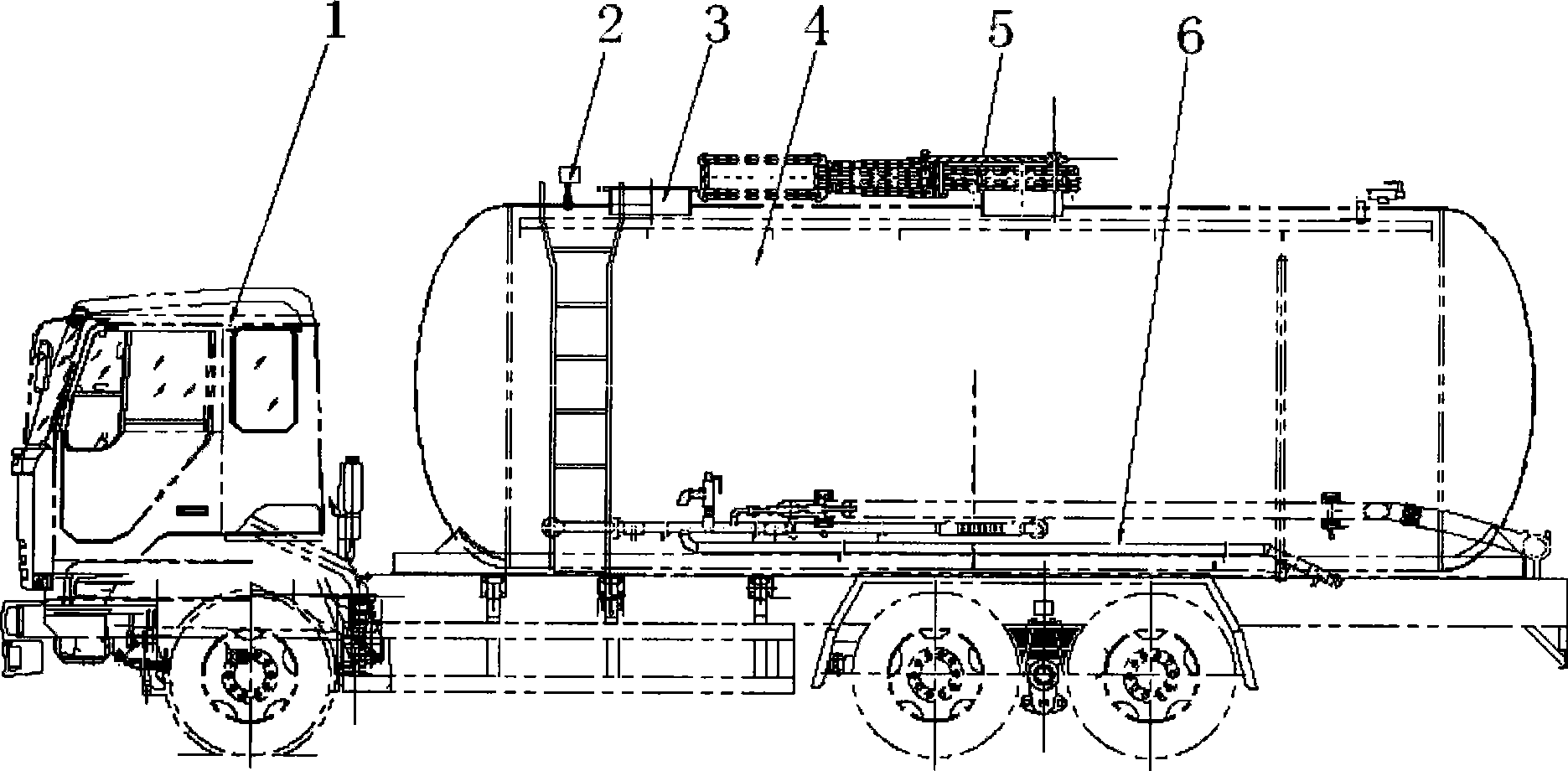

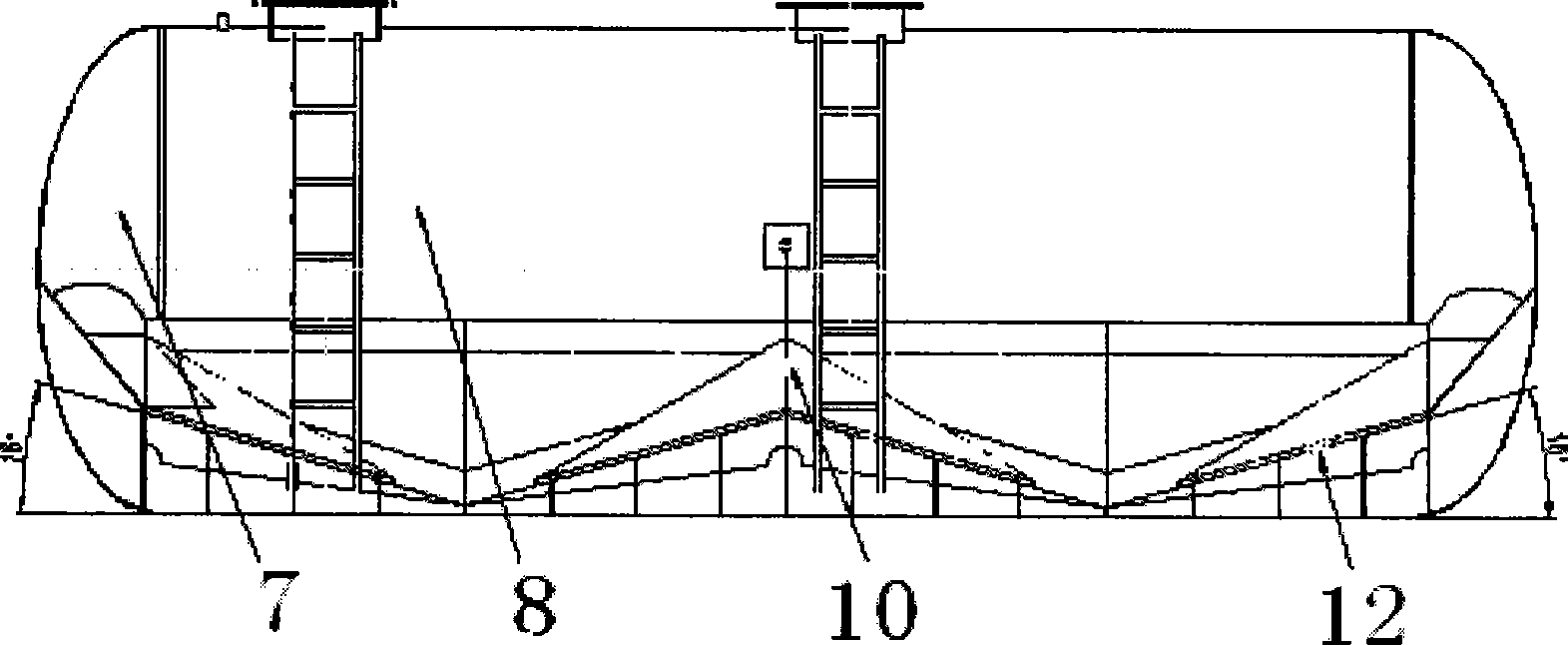

Powdered iron flour dust transport vehicle

InactiveCN101428579AGood for secondary useIncrease profitItem transportation vehiclesState of artIron powder

The invention discloses an iron powder dust transport vehicle which comprises a chassis, a tank body assembly and a pipe line assembly, wherein a fluid bed is arranged in the tank body assembly; the angle of the fluid bed is 10 to 20 degrees; and a material level controller, a manhole cover and an access cover are arranged at the upper part of the tank body assembly. The invention can effectively solve the technical problems of great iron powder waste in the dust during transportation, low loading and unloading efficiency, low safety factor and the like in the prior transport vehicle; and the invention ensures that the secondary utilization can be effectively performed on the dust, so that the waste is reduced, and the conveying efficiency is improved. By adopting the iron powder dust transport vehicle of the invention, the transportation of material with a larger proportion, such as iron powder dust and the like, can be achieved, the traditional method of transportation is changed, the pollution is reduced, the utilization ratio of the iron powder is improved, and the powder transportation produces economic benefits.

Owner:WUHU CIMC RUIJIANG AUTOMOBILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com