Moisturizing and production increasing technique of bagged straw mushroom via pleurotus eryngii residue clinker

A technique of planting Pleurotus eryngii mushroom chaff and clinker bags, which is applied in the direction of organic fertilizers, inorganic fertilizers, calcium fertilizers, etc., can solve the problems of straw mushroom mycelium drying and production reduction, and achieve shortened production cycles, reduced costs, and The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

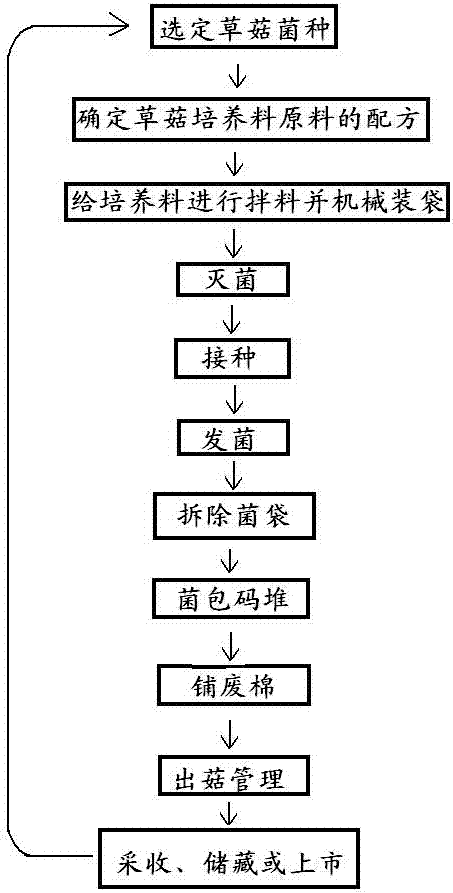

[0064] Such as figure 1 As shown, the production process of the technical solution of Embodiment 1 is as follows:

[0065] Step 1: Select the straw mushroom strain, and select the black and excellent variety of straw mushroom;

[0066] Step 2: Determine the formula of the straw mushroom compost raw material, weigh it according to 60% of Pleurotus eryngii mushroom chaff clinker, 20% of cassava residue, 15% of bran, and 5% of lime, and make it by adding water and stirring according to the water content of 70%;

[0067] Step 3: Fermentation of compost compost, compost volume is 15 cubic meters, pH value is 11, and the compost is turned three times during the period;

[0068] Step 4: Packing, choose 30cm×45cm polypropylene plastic bags to pack the compost, in order to improve efficiency, generally use mechanical automatic bagging;

[0069] Step 5: Sterilize the bagged compost, control the sterilization temperature to 126°C, and the sterilization time to 2 hours;

[0070] Step 6...

Embodiment 2

[0078] The production flow of embodiment two technical schemes is as follows:

[0079] Step 1: Select the straw mushroom strain, and select the black and excellent variety of straw mushroom;

[0080] Step 2: Determine the formula of the straw mushroom compost raw material, weigh it according to 60% of Pleurotus eryngii mushroom chaff clinker, 20% of cassava residue, 15% of bran, and 5% of lime, and make it by adding water and stirring according to the water content of 70%;

[0081] Step 3: Compost fermentation, the volume of the compost is 13.3 cubic meters, the pH value is 10, and the compost is turned three times during the period;

[0082] Step 4: Mix the compost and pack it into bags. Use 20cm×45cm polypropylene plastic to pack the compost. In order to improve efficiency, mechanical automatic bagging is generally used, and manual bagging is not recommended;

[0083] Step 5: Sterilize the culture material in the bag, control the sterilization temperature to be 126°C, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com