Method and device for treating organic wastewater

A technology of organic wastewater treatment and organic wastewater, applied in the direction of heating water/sewage treatment, etc., can solve the problems of high cost and complicated process, and achieve the effects of saving energy, reducing environmental pollution, and facilitating secondary utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

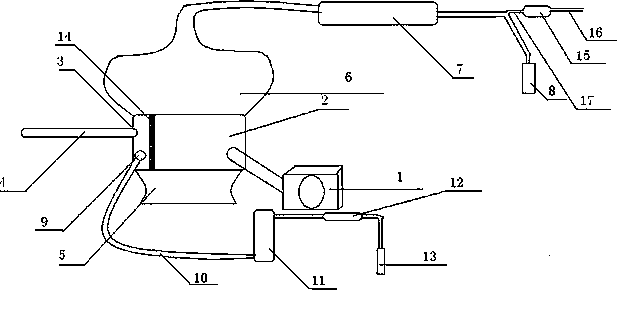

[0020] Start the air extraction device 1, because the air extraction device is connected to the waste liquid tank 2, so the air pressure in the waste liquid tank 2 drops, and the organic waste liquid is pressed into the waste liquid tank 2 from the water inlet 3 by the atmospheric pressure through the water inlet pipe 4 . Start the heating device 5, the temperature of the waste liquid tank 2 rises, when the temperature rises and reaches the boiling point of substances such as ethylene glycol, the light components are vaporized and overflow from the bell collector 6, due to the addition of the bell collector One end is passed in the condenser 7, so the temperature drops, and the temperature of the heating device 5 is raised step by step with 10° C. until being raised to 105° C. Now the water liquid liquefies into water vapor, and overflows from the bell-shaped collector 6, passes through the condenser 7, liquefies into water containing a small amount of impurities, and collects...

Embodiment 2

[0022] Start the air extraction device 1, because the air extraction device is connected to the waste liquid tank 2, so the air pressure in the waste liquid tank 2 drops, and the organic waste liquid is pressed into the waste liquid tank 2 from the water inlet 3 by the atmospheric pressure through the water inlet pipe 4 . Since the filter device 14 is included in the device, the sundries therein can be filtered on the filter screen, and at the same time, because the filter device is detachable, when the filter screen needs to be cleaned, or when the filter screen is not needed, it can be It can be easily removed without affecting the normal use of other parts. Start the heating device 5, the temperature of the waste liquid tank 2 rises, when the temperature rises and reaches the boiling point of substances such as ethylene glycol, the light components are vaporized and overflow from the bell collector 6, due to the addition of the bell collector One end is passed in the conde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com