Patents

Literature

34 results about "Bagasse ash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

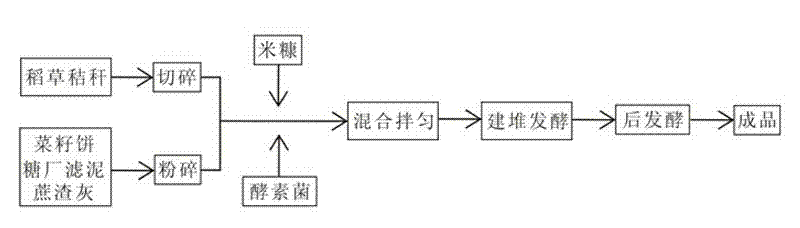

Organic fertilizer or bio-mixed organic fertilizer special for rice and preparing method thereof

ActiveCN102503611ARestore fertilityReduce manufacturing costBio-organic fraction processingOrganic fertiliser preparationChaffRapeseed

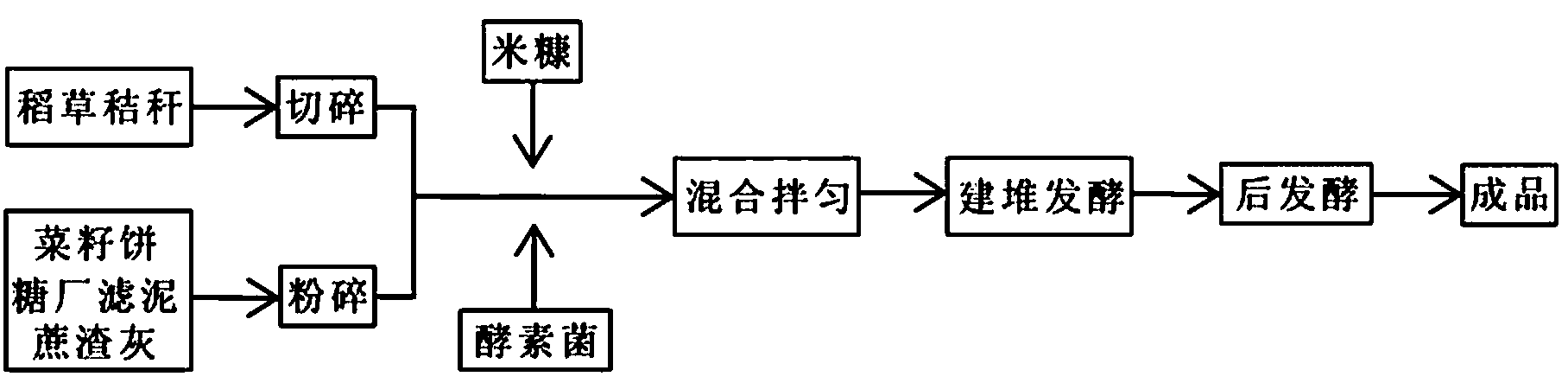

The invention discloses an organic fertilizer or a bio-mixed organic fertilizer special for rice and a preparing method thereof. The organic fertilizer or the bio-mixed organic fertilizer special for rice is prepared by composting and fermenting raw materials (dry basis) according to the following weight percentage: 10%-20% of straw stalks, 25%-30% of rice chaff (bran), 25%-35% of rapeseed cakes (dregs), 5%-20% of sugar refinery filtered mud, 5%-10% of bagasse ash and 0.1% of ferment bacterial fertilizer. The organic fertilizer or the bio-mixed organic fertilizer is good in fertilizer effect and environment-friendly, can lead nutritional components absorbed by rice, rape and sugarcanes from the soil to return to the land so as to restore soil fertility, leads circular economy to be developed, use quantity of fertilizers and pesticides are reduced, green and organic agricultural products are produced, production cost and environment cost are reduced, food safety is improved, environment is protected, and modern agriculture and green agriculture development are promoted.

Owner:广西宾阳县华彦新材料科技有限公司

Cheap nutritional biological deodorization packing and preparation method thereof

InactiveCN104692763AHigh strengthLarge specific surface ratioSolid waste managementDispersed particle separationWood ashNutrition

The invention provides cheap nutritional biological deodorization packing and a preparation method thereof. The deodorization packing is prepared from the following materials: coal ash, zeolite powder, lime, gypsum, cement, sodium hydroxide, sodium silicate, wood ash, bagasse ash and waste molasses. The packing is high in strength, high in breathability and stable in performance, has rich nutrition and can provide enough nutrient substances for microbes, so that the problems that organic carriers are low in strength and the like can be solved, and the problem that growth of deodorizing bacteria is influenced because inorganic packing is short of nutrition can be solved. The packing is long in service life, and the forming speed of a biological deodorization film is high. In addition, the nutritional biological deodorization packing prepared by the invention is low in cost and changes wastes into valuable materials, the pollution is reduced, and the environmental benefits, economical benefits and social benefits can be simultaneously realized.

Owner:SUN YAT SEN UNIV

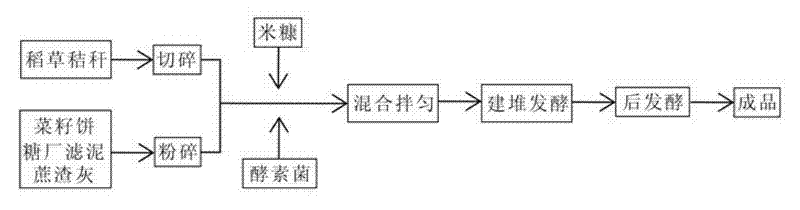

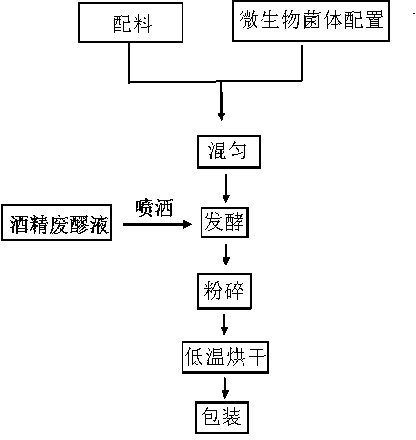

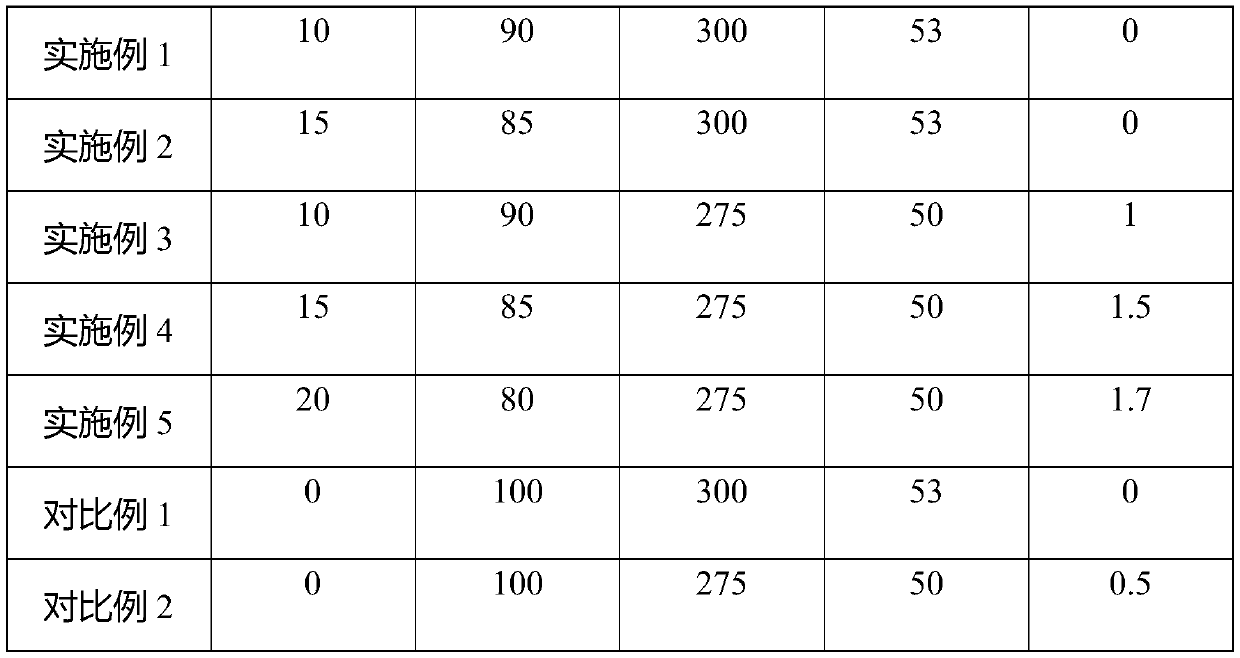

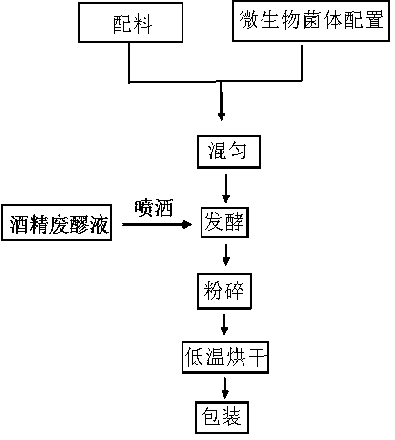

Method for producing straw decomposition agent by utilizing filter mud, cassava residues and waste alcohol mash

InactiveCN103787708AAchieve recyclingReduce manufacturing costBio-organic fraction processingOrganic fertiliser preparationBacillus licheniformisDecomposition

The invention provides a method for producing a straw decomposition agent by utilizing filter mud, cassava residues and waste alcohol mash. The method is characterized by mixing filter mud, cassava residues and bagasse ash in a weight ratio of (3-4):(3-4):(1-2), then adding a microorganism thallus prepared from bacillus subtilis Cohn, bacillus licheniformis, bacillus polymyxa, aspergillus niger and aspergillus oryzae and mixing the materials uniformly, fermenting the mixture for 5-10 days, and then grinding and drying the fermented product at low temperature, thus obtaining the straw decomposition agent. Used for producing the straw decomposition agent, the method has the advantages of low production cost, high viable organism amount and obvious decomposing effect and can be used for decomposing objects such as banana cores, corn straws, wheat straws, rice straws, cereal straws, rape straws, weeds, leaves, household garbage with high content of fibrous matters and the like.

Owner:宾阳县明翔新材料科技有限公司

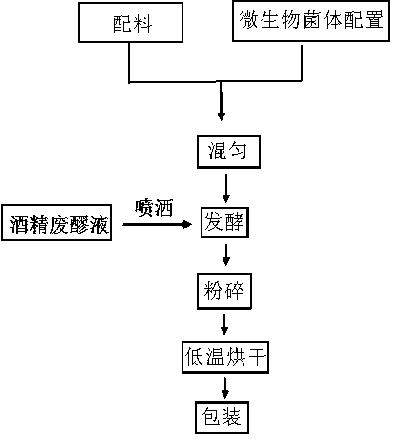

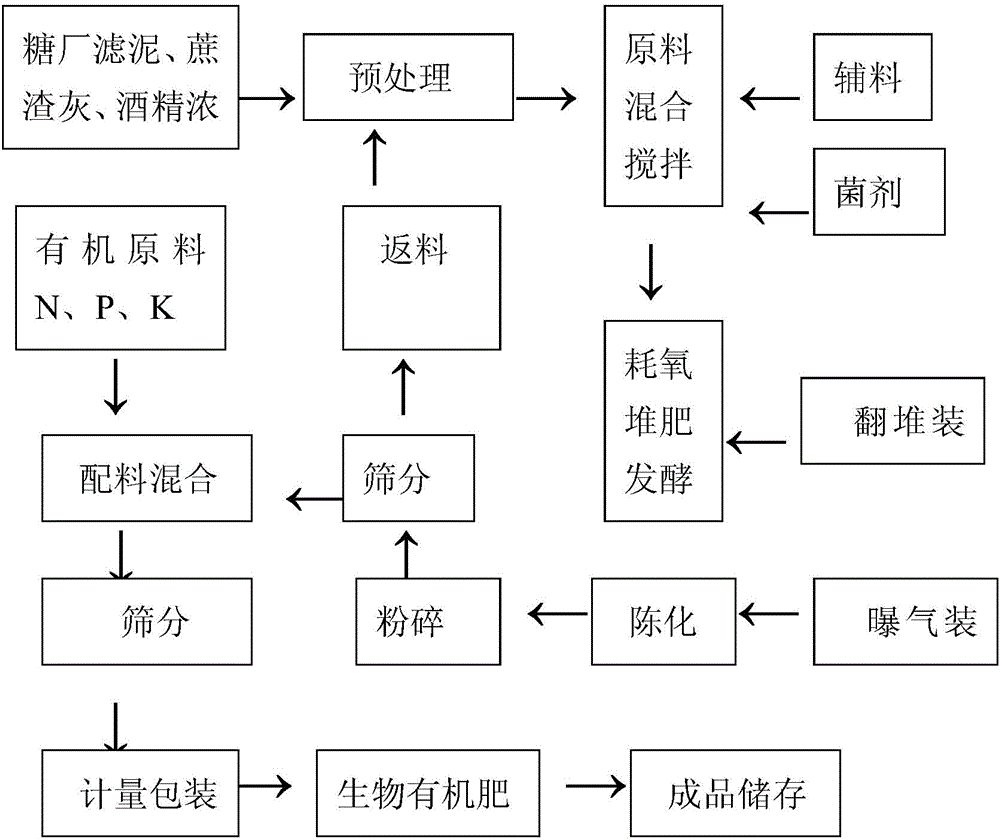

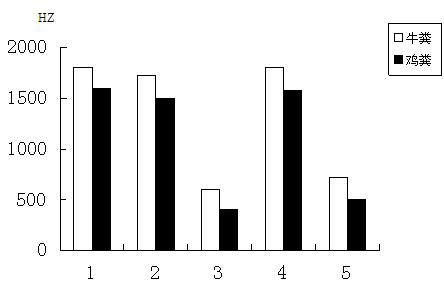

Bio-organic fertilizer and production method thereof

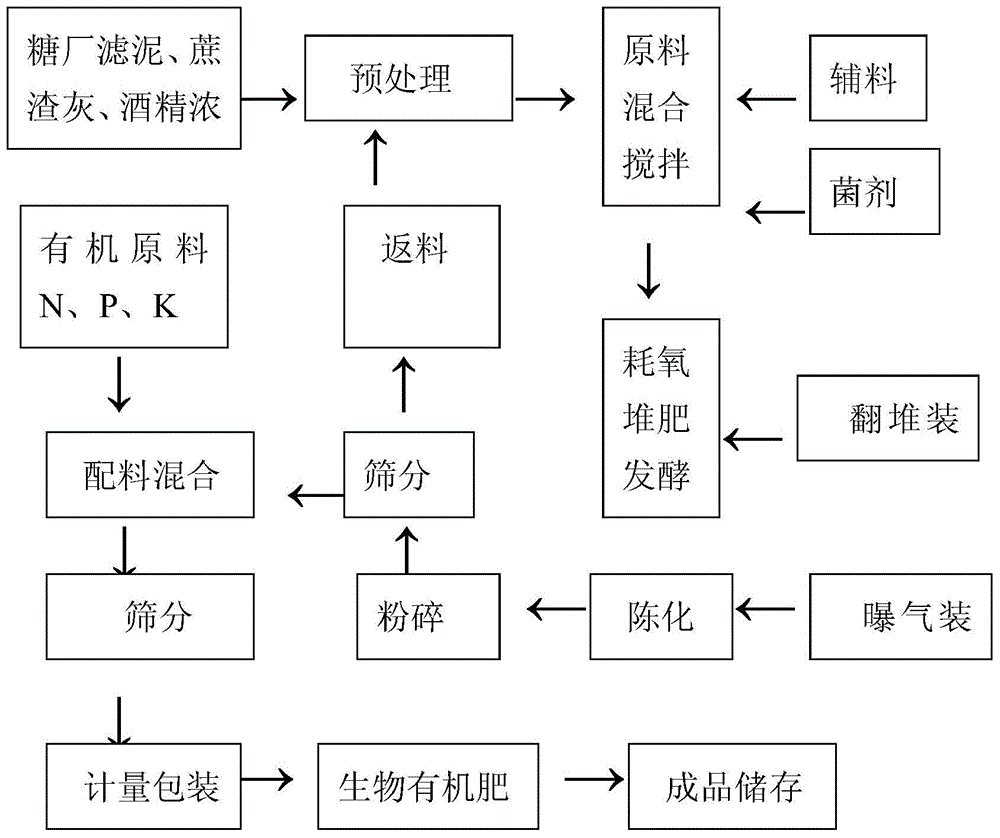

ActiveCN104045385AAccelerate the lossEasy to sieveBio-organic fraction processingOrganic fertiliser preparationFiltrationMoisture

The invention discloses bio-organic fertilizer. Through fermentation, the bio-organic fertilizer is prepared from 6-26wt% of filter mud produced by a sugar refinery, 55-75wt% of bagasse ash and 10-30wt% of ethanol concentrate. The production method comprises the following steps of 1, carrying out mixing stacking on filter mud produced by a sugar refinery, bagasse ash and ethanol concentrate, 2, removing moisture by filtration, 3, stacking the raw material mixture in a strip-shaped stack way, adding bifidobacterium, lactic acid bacteria, bacillus, saccharomycetes, actinomycetes and acetic bacteria into the stacked mixture, and carrying out fermentation, 4, keeping the primary fermented stack temperature above 60 DEG C and keeping material moisture content in a range of 40-45%, 5, increasing the height of the primary fermented stack, and carrying out secondary fermentation for aging until material moisture content is in a range of 30-35%, 6, adding the aged material into organic raw materials of N, P and K and carrying out mixing and 7, packaging the mixture to obtain the product. The bio-organic fertilizer has good fertilizer efficiency and is conducive to absorption by crops. The production method utilizes simple production equipment, has simple production processes and can be operated easily. The production method reduces a cost and has high income.

Owner:广西凭祥桂商现代农业投资有限公司

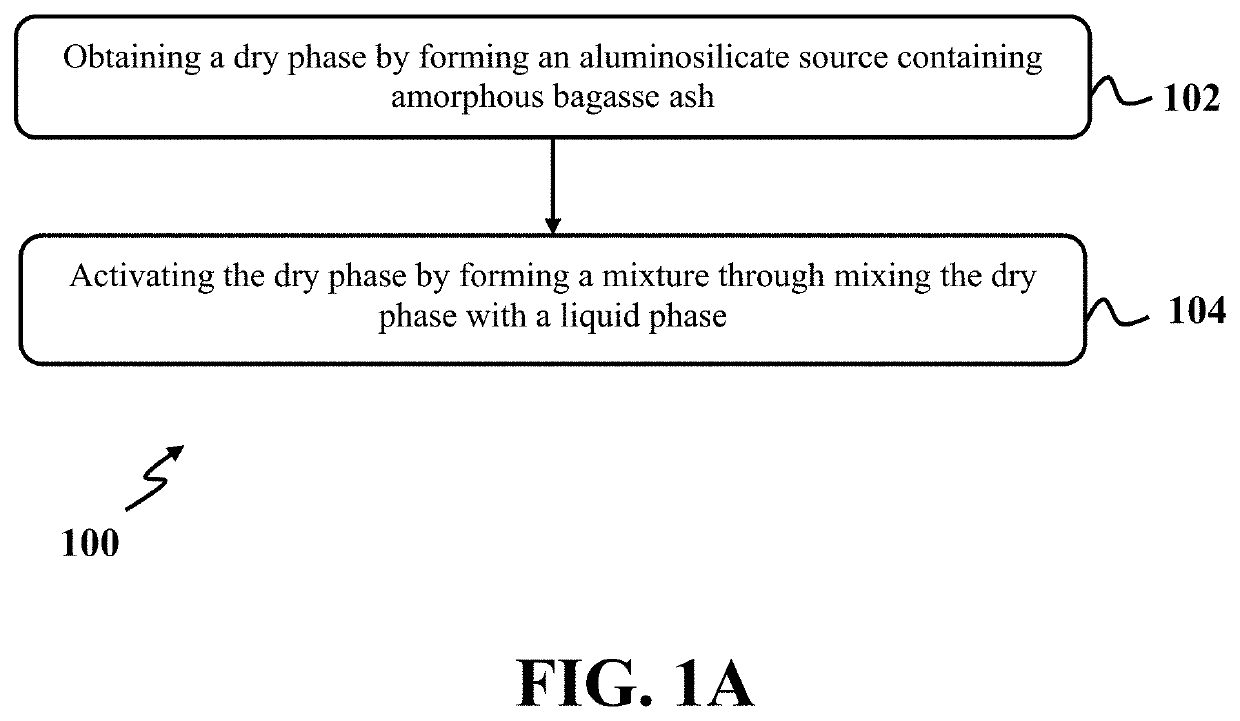

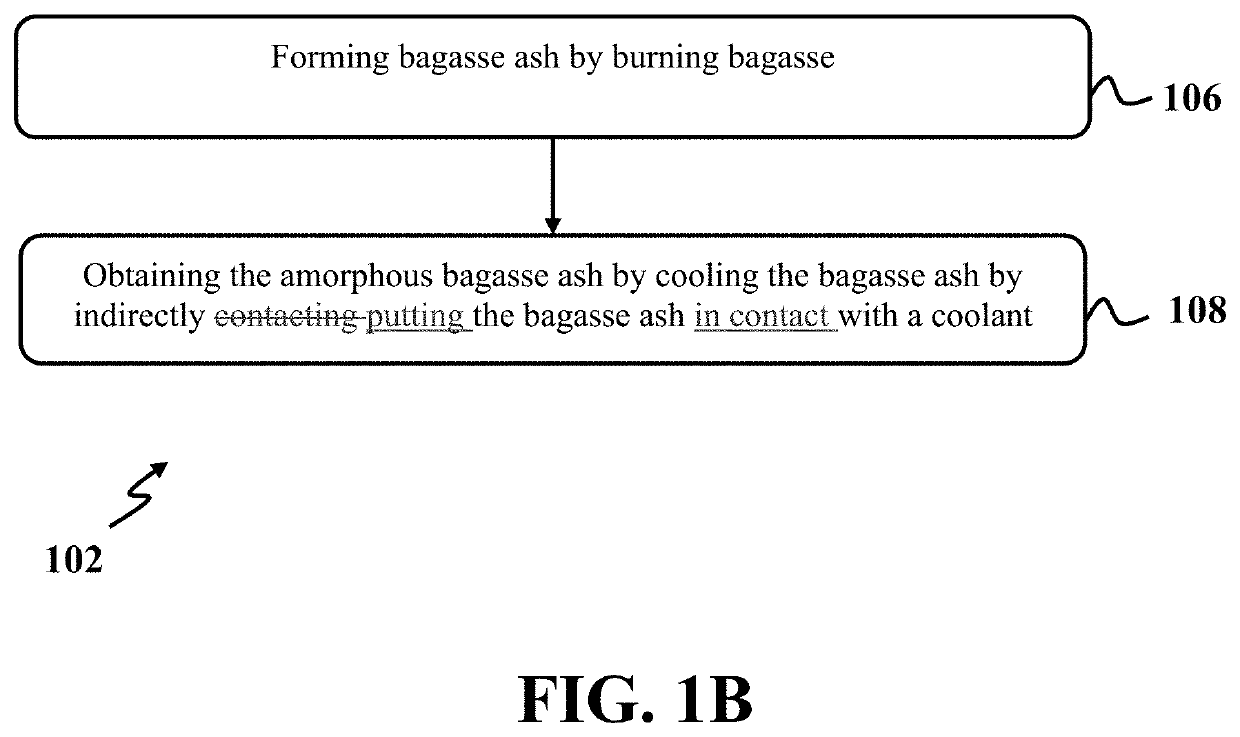

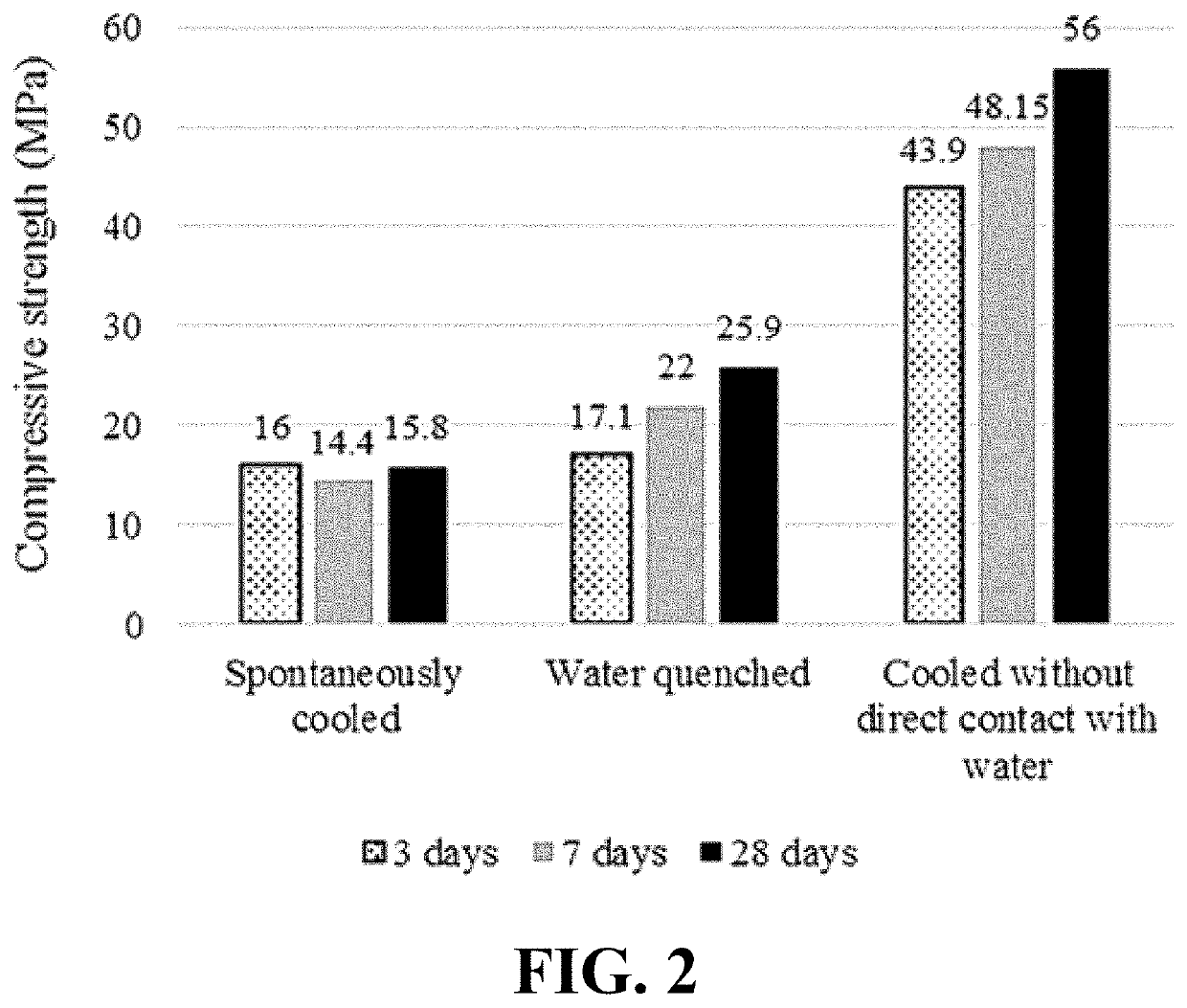

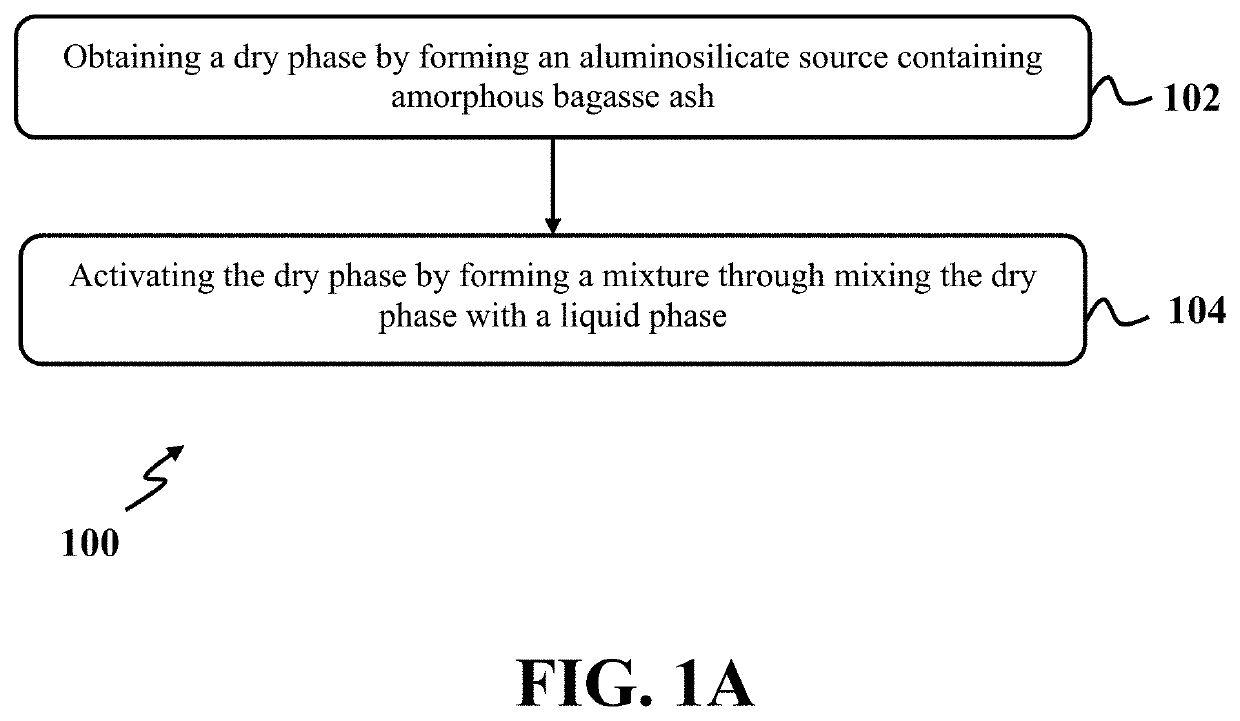

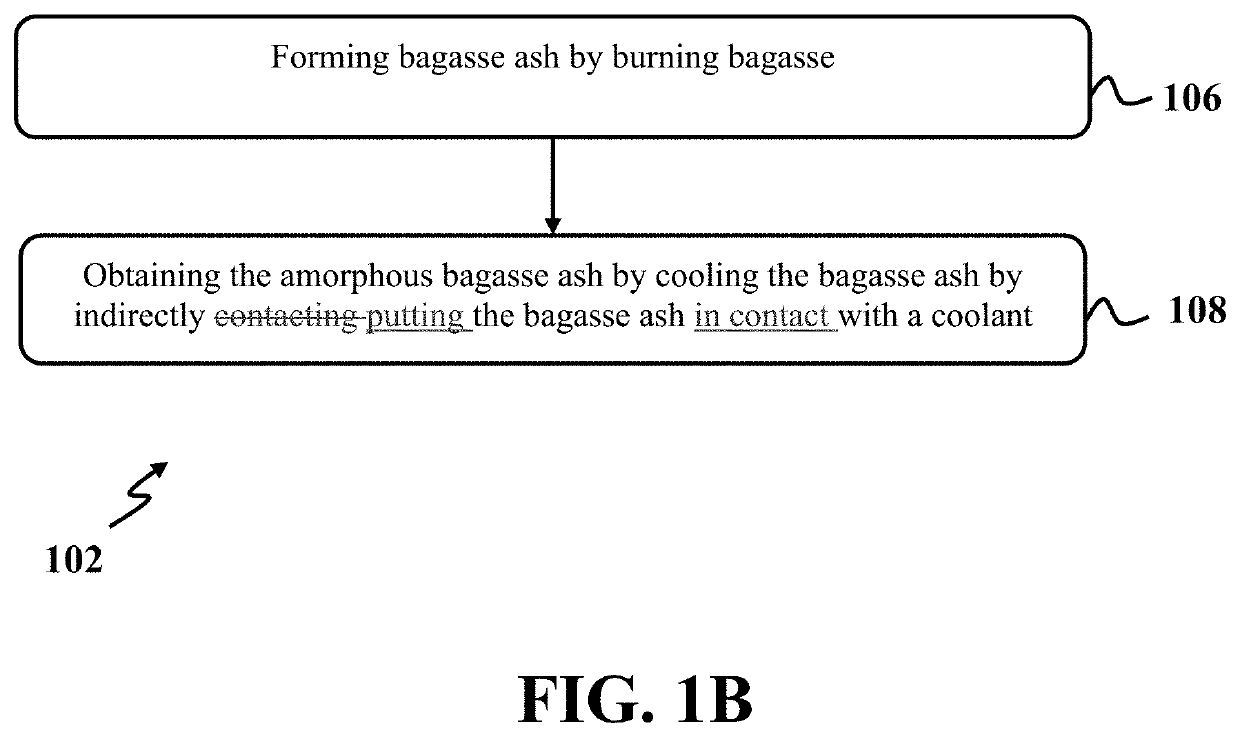

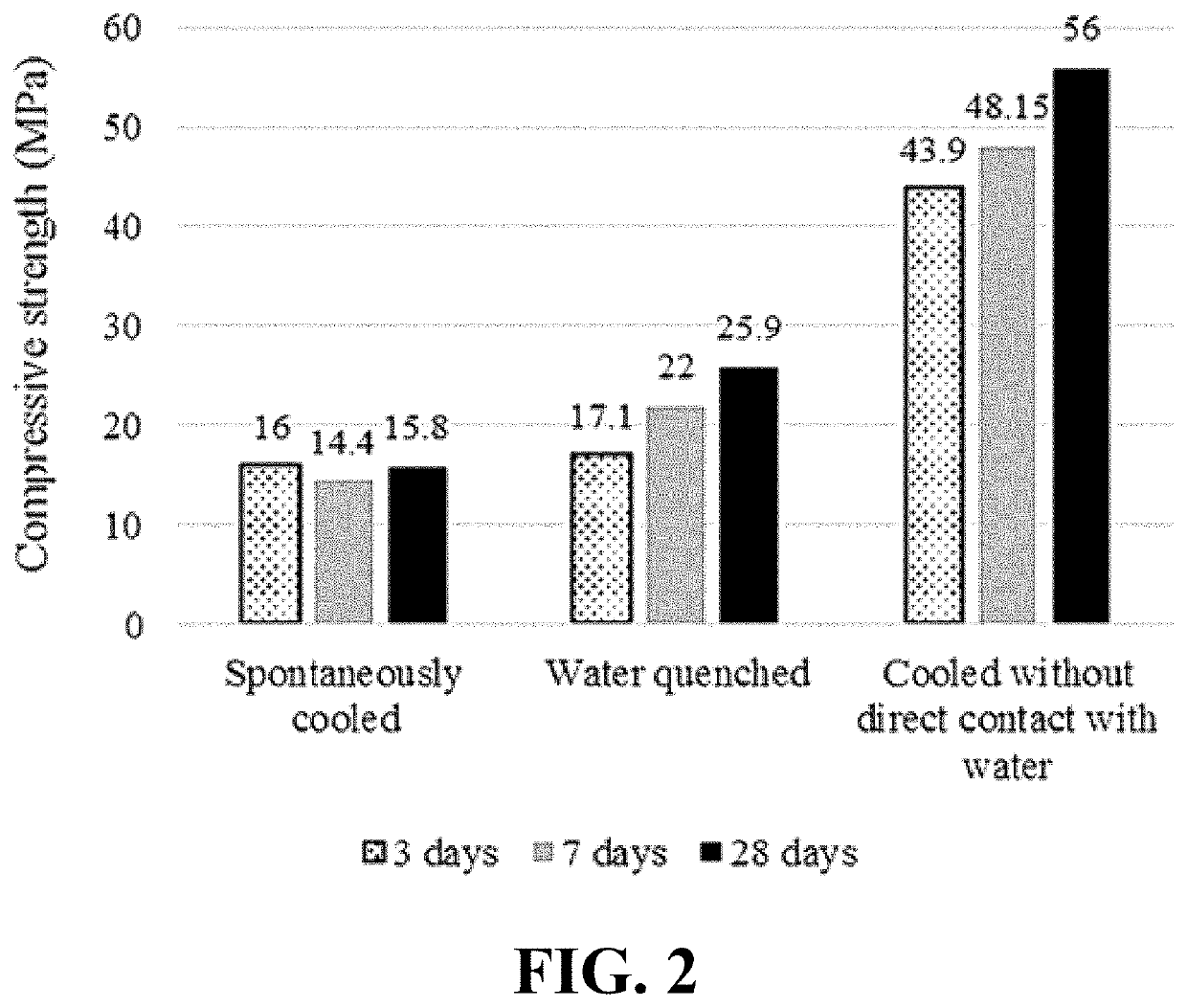

Cement compositions based on amorphous bagasse ash

A cement composition including a dry phase and a liquid phase. The dry phase includes an aluminosilicate source, including amorphous bagasse ash with a concentration between 40 wt. % and 100 wt. % of the weight of the dry phase. The liquid phase includes at least one of water and an alkaline activator solution. The alkaline activator solution includes at least one of an alkali metal stearate, an alkali metal silicate, and an alkali metal hydroxide.

Owner:MORADI KHOU AMIR BAHADOR +1

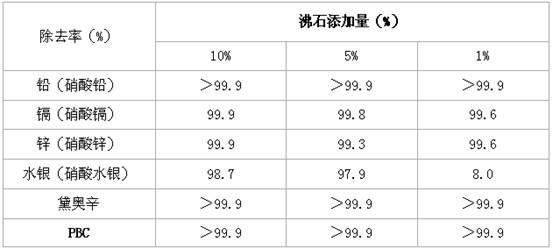

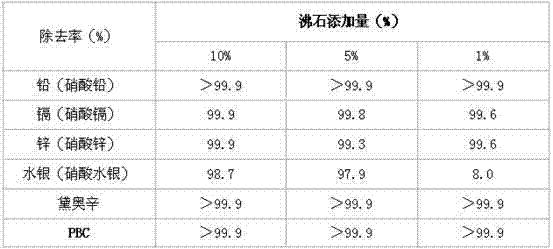

A type zeolite and preparation method thereof

InactiveCN101811703AStable and superior performanceShorten the timeSolid waste disposalAluminosilicate zeolite type-ACombustionHusk

The invention provides an A type zeolite and a preparation method thereof. The invention solves the problems of high manufacture cost and complex process step of the A type zeolite in the prior art and the technical problems of reduced performance stability of the generated zeolite and difficult control of zeolite quality when the combustion ash, such as paddy husk ash, bagasse ash, diatomite, and the like are adopted as raw materials. The A type zeolite is prepared from burning ash, the main component of which is SiO2, as a raw material in an alkaline solution through hydrothermal reaction. The method comprises the following steps of: hydrothermally dissolving the burning ash in the alkaline solution; adding sodium metaaluminate for crystallization; washing in water, filtering and drying to obtain the A type zeolite. The method has shorter reaction time, high crystallizing speed, more favorable and stable performance of the generated A type zeolite and obvious economic benefit, obviously reduces the production cost, simplifies the preparation step, and improves the yield and the market competition of products.

Owner:杨辉

Method for producing straw decomposition agent by utilizing filter mud, cassava residues and waste alcohol mash

InactiveCN103787707AAchieve recyclingReduce manufacturing costBio-organic fraction processingClimate change adaptationDecompositionAspergillus niger

The invention provides a method for producing a straw decomposition agent by utilizing filter mud, cassava residues and waste alcohol mash. The method is characterized by mixing filter mud, cassava residues and bagasse ash in a weight ratio of (3-4):(3-4):(1-2), then adding a microorganism thallus prepared from aspergillus niger and aspergillus oryzae in a ratio of (1-4):(1-4) and mixing the materials uniformly, fermenting the mixture for 15-30 days, and then grinding and drying the fermented product at low temperature, thus obtaining the straw decomposition agent. Used for producing the straw decomposition agent, the method has the advantages of low production cost, high viable organism amount and obvious decomposing effect and can be used for decomposing objects such as banana cores, corn straws, wheat straws, rice straws, cereal straws, rape straws, weeds, leaves, household garbage with high content of fibrous matters and the like.

Owner:宾阳县明翔新材料科技有限公司

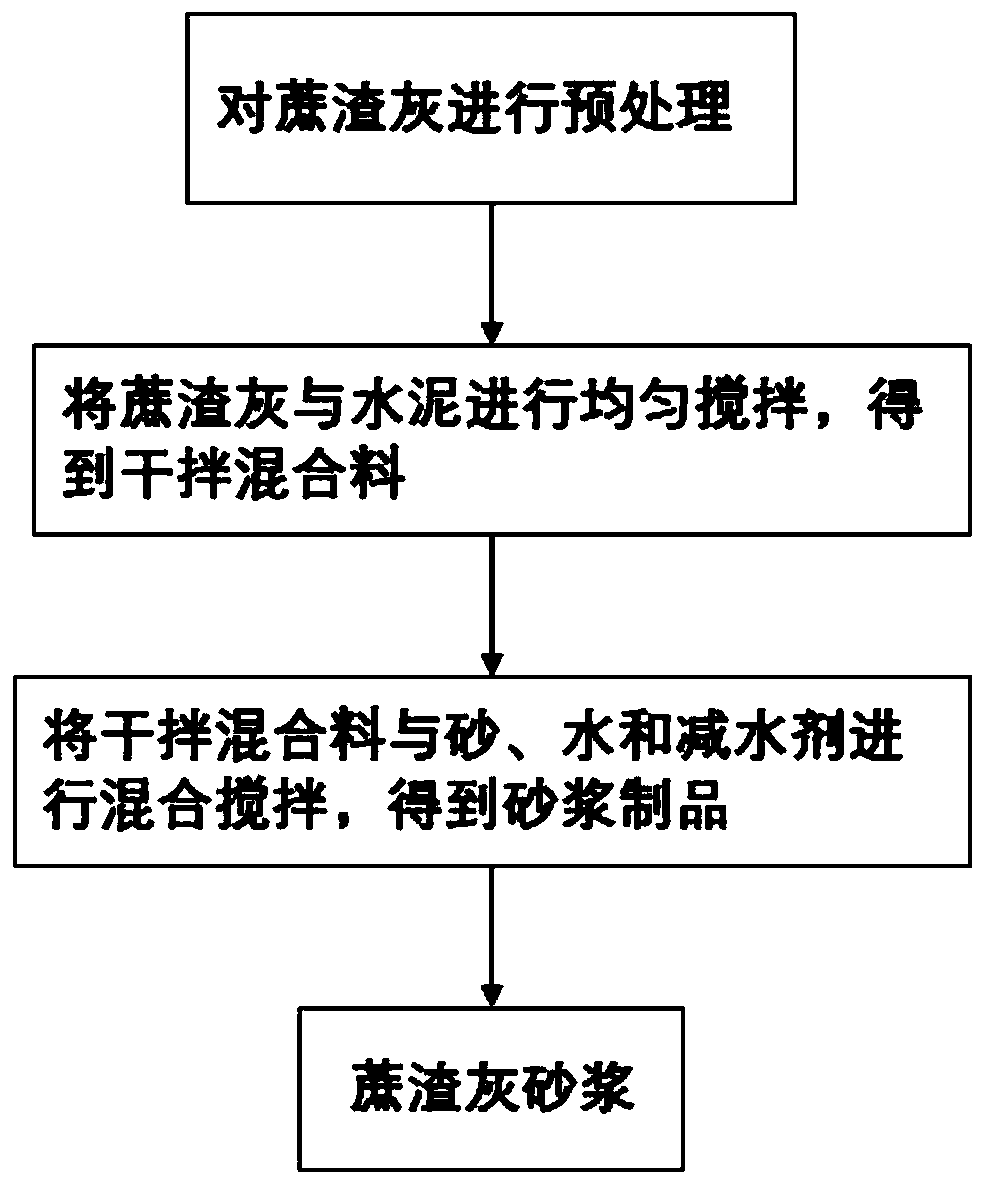

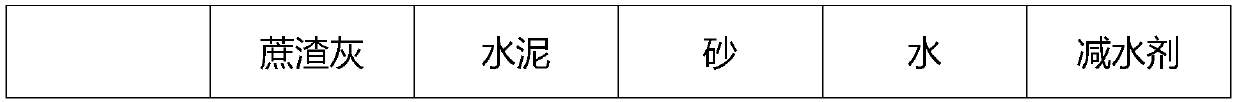

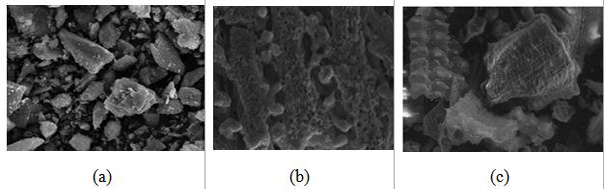

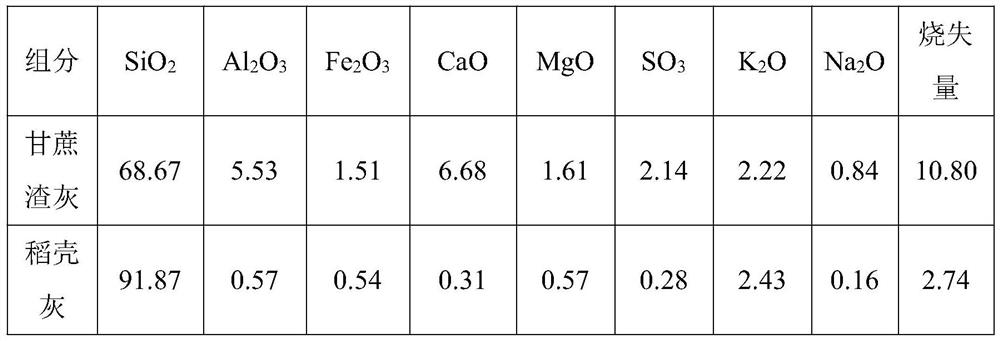

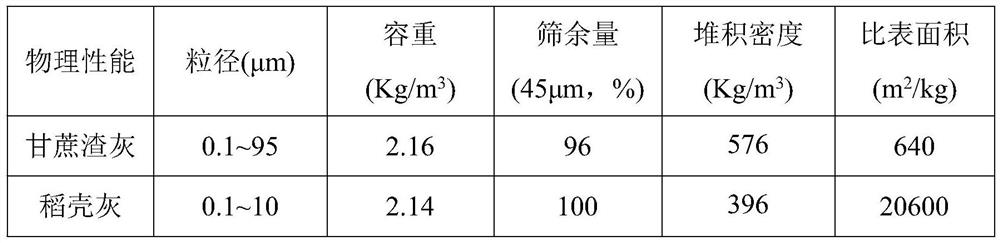

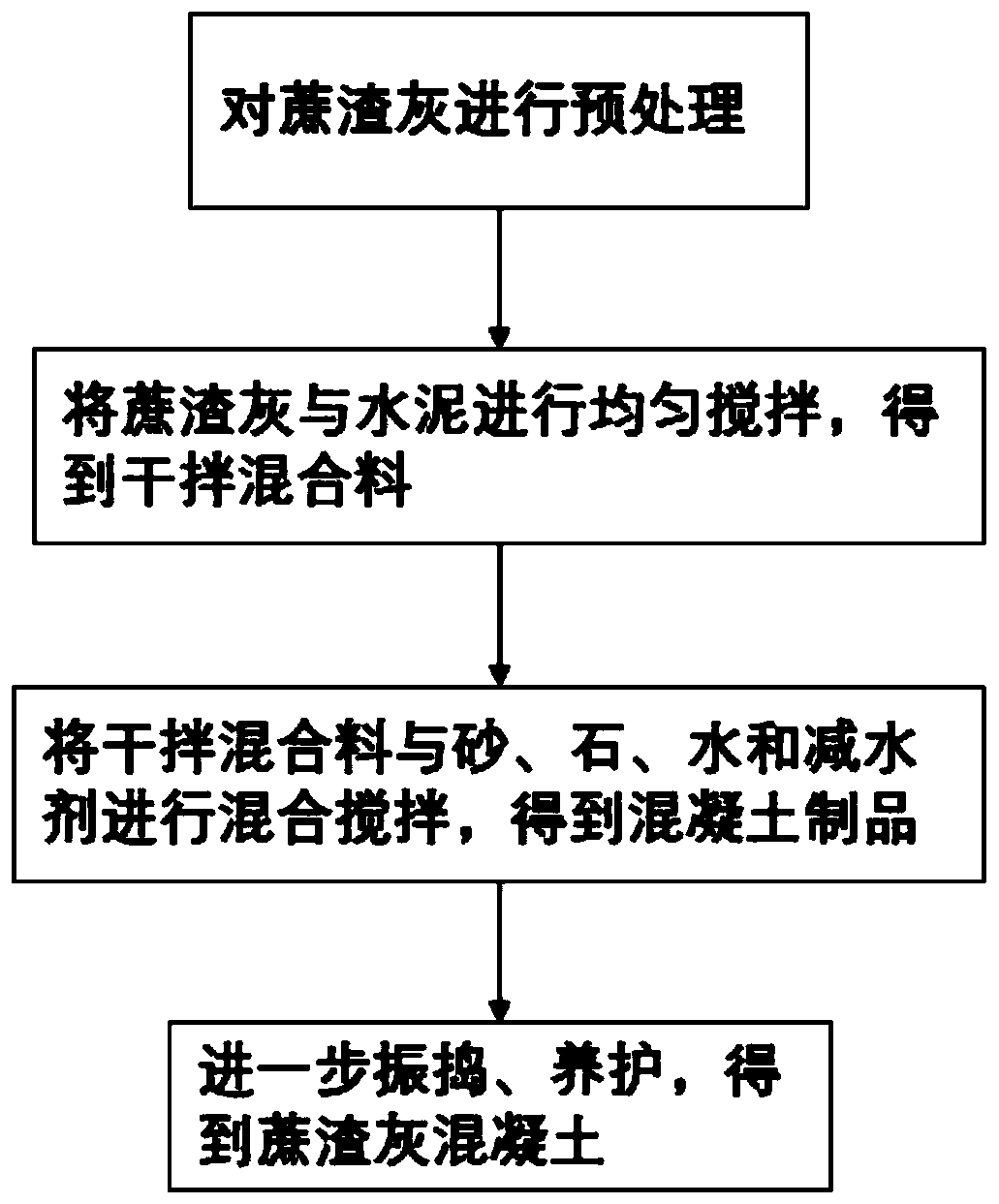

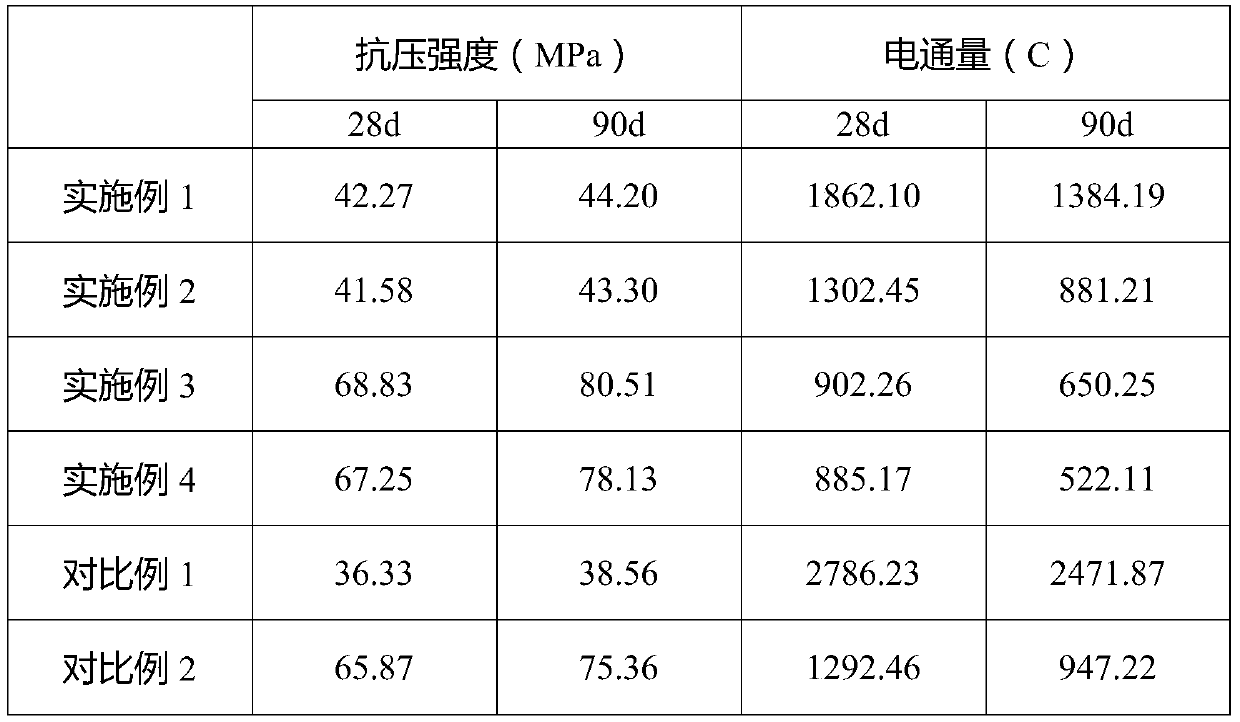

Preparation method for bagasse ash mortar

InactiveCN110282917AIncreased pozzolanic activityImprove compactnessSolid waste managementResource consumptionUltimate tensile strength

The invention discloses a preparation method for bagasse ash mortar. The preparation method comprises the following steps that bagasse ash discharged from a burning furnace of a sugar refinery is pretreated, so that the activity of the bagasse ash is improved; and the pretreated bagasse ash serves as a raw material for preparing the mortar, the pretreated bagasse ash, sand, water, cement and a water reducer are mixed, stirred, poured and vibrated so as to prepare a bagasse ash mortar product, and standard curing is further adopted. The bagasse ash mortar prepared through the preparation method has higher structural strength and durability. Compared with traditional mortar, the bagasse ash mortar prepared through the preparation method has the advantages that on the premise that the performance is improved, the bagasse ash can be fully reused, the resource consumption is reduced, and economical and environmentally-friendly production is facilitated.

Owner:GUANGXI UNIV +1

Method for removing sulfate radical in molasses alcohol wastewater by using bagasse ash

ActiveCN102873079AReduce generationImprove anaerobic methane production rateWater/sewage treatment by centrifugal separationSolid waste disposalSulfate radicalsSuspended solids

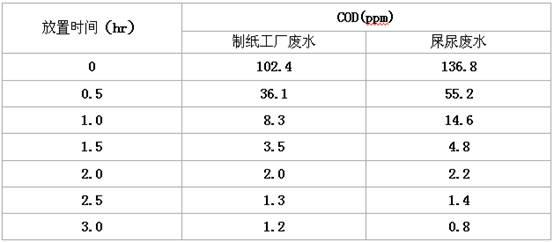

The invention discloses a method for removing sulfate radical in molasses alcohol wastewater by using bagasse ash. The method includes steps: (1), bagasse ash pretreatment, namely, taking 50g of bagasse ash and placing into a crucible, placing in a high-temperature ashing furnace of 800 DEG C for ashing and overnighting; and screening particles with the grain size of 0.177-0.250mm, and placing in a drying vessel after cooling for standby; (2), taking 500ml of molasses alcohol wastewater for centrifugation and separation of suspended solid; and (3), taking 100ml of wastewater obtained in the step (2) and adding water to dilute to 1000ml; using a conical flask of 300ml to take 100ml of diluent and respectively adding 10g of the bagasse ash after pretreatment in the step (2), placing in a constant-temperature rotary shaker for adsorption, adjusting temperature to be 30 DEG C and pH to be 3.5-4.5, and using a centrifugal machine of 6000rpm for centrifugation for 10min after adsorption for 60min. The bagasse ash is used to adsorb and precipitate the sulfate radical in the molasses alcohol wastewater to improve anaerobic methane production rate, so that generation of smelly gases such as hydrogen sulfide is reduced, and anaerobic reaction treatment and gas production efficiency is improved.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Method for producing straw decomposition agent by using filter mud, cassava residue and waste alcohol sediment liquid

InactiveCN103755397APlay a synergistic roleNutritiousBio-organic fraction processingOrganic fertiliser preparationAlcoholDecomposition

The invention relates to a method for producing a straw decomposition agent by using filter mud, cassava residue and waste alcohol sediment liquid. The method is characterized by comprising the steps of batching the filter mud, the cassava residue and bagasse ash according to the weight ratio of (3-4): (3-4): (1-2), then, adding microbial thalli of aspergillus oryzae, uniformly mixing together, fermenting for 25-40 days, and then, crushing and baking at low temperature, thereby obtaining the straw decomposition agent. The straw decomposition agent produced by the method is low in production cost, high in viable strain number and obvious in decomposition effect, and can be used for decomposing objects, such as banana cores, corn stalks, wheat straws, rice straws, grain stalks, rape stalks, weeds, leaves, domestic garbage with high content of fibrous substances, and the like.

Owner:宾阳县明翔新材料科技有限公司

A type zeolite and preparation method thereof

InactiveCN101811703BImprove performanceHigh yieldSolid waste disposalAluminosilicate zeolite type-ASodium aluminateProcess engineering

The invention provides an A type zeolite and a preparation method thereof. The invention solves the problems of high manufacture cost and complex process step of the A type zeolite in the prior art and the technical problems of reduced performance stability of the generated zeolite and difficult control of zeolite quality when the combustion ash, such as paddy husk ash, bagasse ash, diatomite, and the like are adopted as raw materials. The A type zeolite is prepared from burning ash, the main component of which is SiO2, as a raw material in an alkaline solution through hydrothermal reaction. The method comprises the following steps of: hydrothermally dissolving the burning ash in the alkaline solution; adding sodium metaaluminate for crystallization; washing in water, filtering and dryingto obtain the A type zeolite. The method has shorter reaction time, high crystallizing speed, more favorable and stable performance of the generated A type zeolite and obvious economic benefit, obviously reduces the production cost, simplifies the preparation step, and improves the yield and the market competition of products.

Owner:杨辉

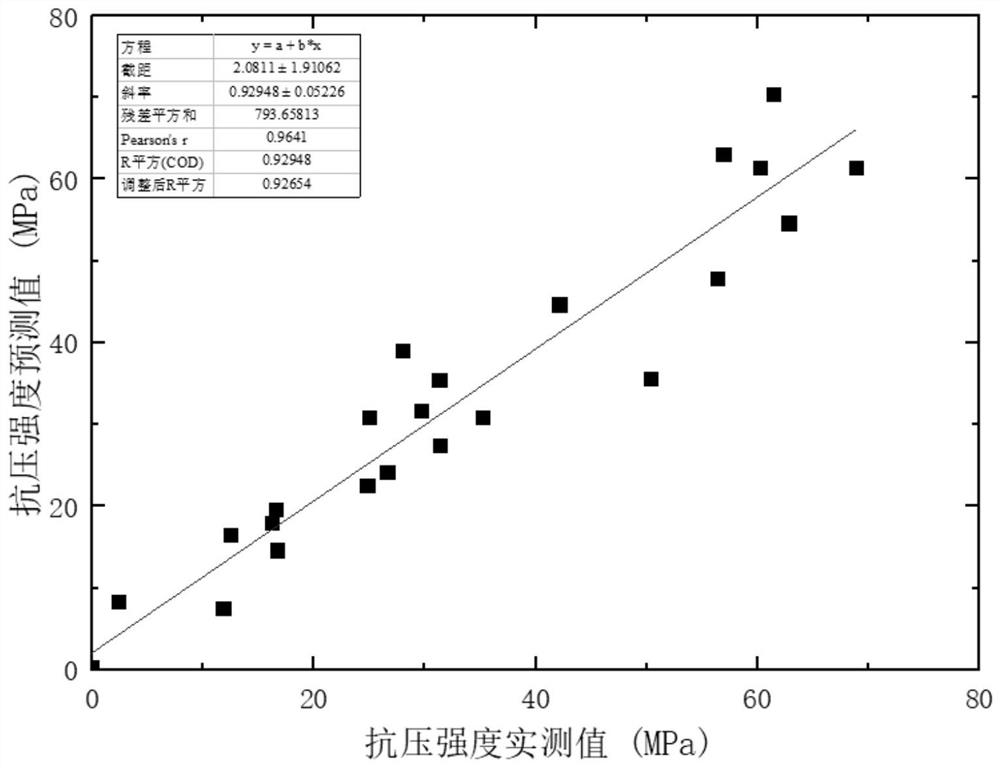

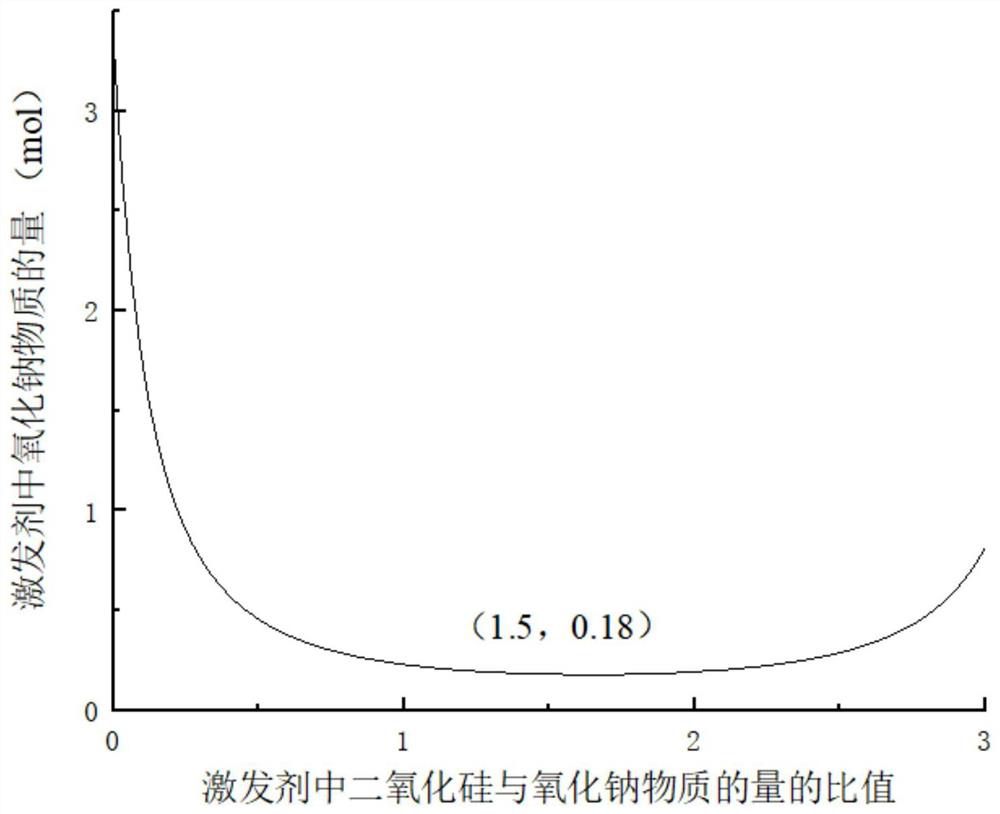

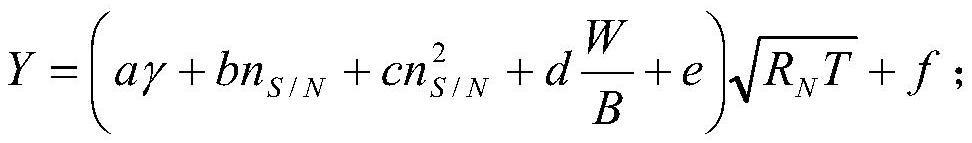

Alkali-activated bagasse ash/slag low-carbon mortar mix proportion design method based on strength regulation and control

ActiveCN113742816AImprove universalityIncrease profitGeometric CADSolid waste managementSlagSilicon dioxide

The invention relates to an alkali-activated bagasse ash / slag low-carbon mortar mix proportion design method based on strength regulation and control. The method comprises the following steps of: (1) preparing alkali-activated bagasse ash / slag low-carbon mortar composed of different raw materials; (2) testing the strength of the low-carbon mortar composed of different raw materials; (3) establishing a low-carbon mortar strength prediction model based on raw material parameters; and (4) calculating the raw material parameters based on strength design requirements, and determining the mix proportion of the low-carbon mortar. By adopting the method, the utilization rate of the bagasse ash can be greatly increased, solid wastes are recycled, calcining treatment and cement compound doping are not needed, and the emission of carbon dioxide is remarkably reduced. Meanwhile, a strength prediction model of the mortar strength, the proportion of bagasse ash to a precursor, the amount of sodium oxide, the ratio of the amount of silicon dioxide to the amount of sodium oxide in the alkali activator, the water-binder ratio and the age is established, the precursor is prepared by homogenizing the bagasse ash and slag, and the model provides reference and prediction for practical engineering application.

Owner:GUANGXI UNIV

Method for preparing low-shrinkage concrete from bagasse ash

PendingCN113443877ARealize resource utilizationReduce autogenous shrinkageSolid waste managementOrganic chemistryDecreased carbon dioxide

The invention belongs to the technical field of concrete preparation, and particularly relates to a method for preparing low-shrinkage concrete from bagasse ash. The method comprises the following steps: calcining and grinding recycled bagasse ash, and carrying out chemical part analysis and performance characterization on the calcined and ground bagasse ash. The bagasse ash is used for replacing cement according to a certain proportion and is mixed with cement, water, natural fine aggregate and natural coarse aggregate according to a certain proportion, and the low-shrinkage concrete with the performance meeting requirements is prepared. When bagasse is calcined at a certain temperature, bagasse ash contains a large amount of amorphous oxide, is internally porous and can be used as an auxiliary cementing material to replace cement, green high-performance concrete is prepared, and self-constriction of the concrete is reduced. Therefore, the method provided by the invention not only can reduce the self-constriction of the concrete, but also can reduce the emission of carbon dioxide, save land and protect the environment.

Owner:FUZHOU UNIV

Bagasse ash concrete and preparation method thereof

InactiveCN110330281AIncreased pozzolanic activityImprove compactnessPulp and paper industryPre treatment

The invention discloses bagasse ash concrete and a preparation method thereof. The preparation method comprises the following steps: pretreating bagasse ash discharged from a furnace of a sugar refinery so that the activity of the bagasse ash is improved; taking the pretreated bagasse ash as a raw material for preparing concrete, mixing and stirring with sand, stone, water, cement and a water reducing agent, pouring and vibrating to prepare a bagasse ash concrete product, and further curing by one of standard curing and thermal curing. The prepared bagasse ash concrete has high structural strength and durability. Compared with traditional concrete, the bagasse ash concrete has the advantages that on the premise that the performance is improved, the bagasse ash can be fully reused, the resource consumption is reduced, and economic and environment-friendly production is facilitated.

Owner:GUANGXI UNIV +1

Organic fertilizer special for cultivating citruses

InactiveCN108164297AWide variety of sourcesLow costExcrement fertilisersBioloigcal waste fertilisersOrganic fertilizerCompost

The invention discloses an organic fertilizer special for cultivating citruses. The organic fertilizer is prepared through the following steps of uniformly mixing and stirring chicken manure, peanut bran, bagasse ash, fishpond lime sludge and tea residue leavening and conducting compost fermentation for 5-6 months. In the compost fermentation process, turning is conducted 3-4 times, and during thesecond time of turning, a fermentation preparation is added. The tea residue leavening is adopted as one of the raw materials, in the fermentation process, sufficient nutrients can be provided for later fermentation of zymophyte, and continued fermentation of the zymophyte is promoted; further, the substance obtained when tea residues are fermented by white granulated sugar can form an organic Nfertilizer in later fermentation, and thus the fertilizer effect of the organic fertilizer can be improved maximally. The raw materials are wide in source, the cost is low, the preparing process is concise, the operation is simple, and the fertilizer can be fully absorbed by the citruses and is environmentally friendly.

Owner:贵港市新梅农业科技有限公司

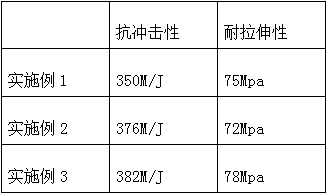

Preparation method of anti-tensile nano SiO2-high density polyethylene-lignocellulose fiber composite plastic

The invention provides a preparation method of anti-tensile nano SiO2-high density polyethylene-lignocellulose fiber composite plastic, aiming at solving the problems that polyethylene has poor impactresistance, is easy to age and easily becomes brittle at low temperature. The preparation method comprises the following steps: firstly, preparing bagasse ash and rice husk ash by utilizing a high-temperature furnace; then uniformly mixing the bagasse ash, the rice husk ash, nano silicon dioxide, high density polyethylene and maleic anhydride grafted polyethylene, and adding into an extruding machine; carrying out injection molding to obtain a nano SiO2-high density polyethylene-lignocellulose fiber compound; finally, uniformly mixing the nano SiO2-high density polyethylene-lignocellulose fiber compound, a natural plasticizer and a thermal stabilizer, and then heating, smelting and cooling to obtain the anti-tensile nano SiO2-high density polyethylene-lignocellulose fiber composite plastic. The plastic provided by the invention has good impact resistance and anti-tensile performance and can be widely applied to preparation of neck rings of shampoo and bath gel packaging bottles.

Owner:SHANTOU TENGYE PLASTIC IND

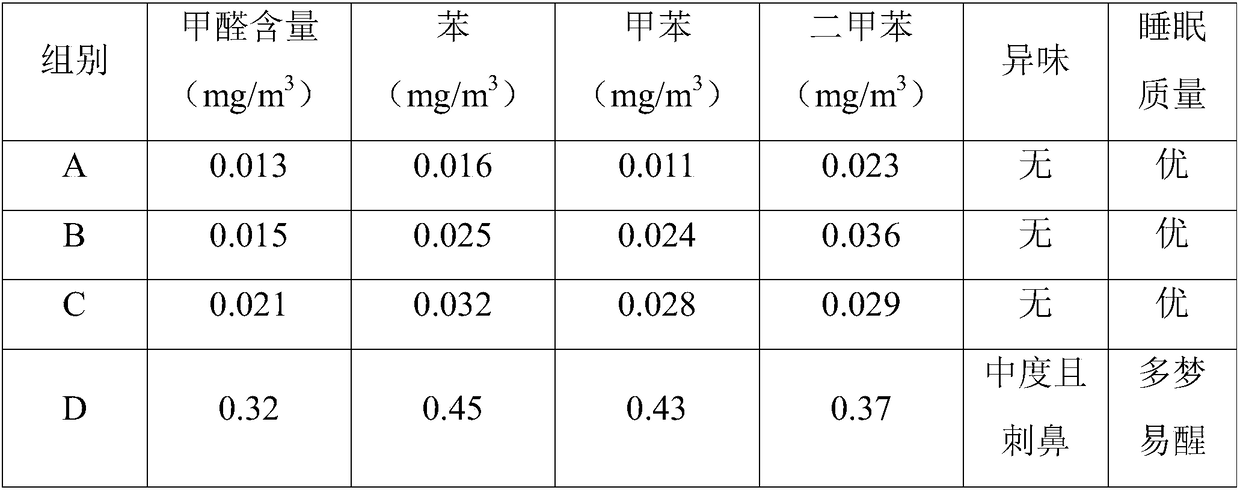

Environment-friendly wall with formaldehyde removal and deodorizing functions and preparation method of environment-friendly wall

InactiveCN108978929AImprove the living environmentWith load-bearing functionCovering/liningsWallsEnvironmental resistanceAdhesive

The invention belongs to the field of environment-friendly decoration and discloses an environment-friendly wall with formaldehyde removal and deodorizing functions and a preparation method of the environment-friendly wall. The environment-friendly wall comprises a wall matrix and putty powder, the wall matrix comprises a supporting layer for providing structural strength and an indoor waste gas adsorption layer on the outer periphery of the supporting layer, and the putty powder is sprayed to an end face, opposite to the wall matrix, of the indoor waste gas adsorption layer. The supporting layer is prepared from, by weight, 40-60 parts of toona sinensis branches, 30-50 parts of pinus massoniana branches, 20-30 parts of tung tree branches, 10-20 parts of cypress branches, 5-10 parts of a first adhesive and 3-5 parts of a softening agent. The indoor waste gas adsorption layer is prepared from, by weight, 15-30 parts of cornstalk ash, 10-20 parts of sorghum stalk ash, 15-25 parts of bagasse ash, 5-15 parts of natural peach tree resin, 7-20 parts of natural pine tree resin and 3-5 parts of a second adhesive. The environment-friendly wall has advantages of convenience in mounting and capability of adsorption of indoor waste gas pollutants.

Owner:杭州绿馨环保科技有限公司

Method for preparing silicon dioxide aerogel by using bagasse ash

InactiveCN108358211ASolving Green Disposal ProblemsSolve the problem of production sourceSilicon compoundsTrimethylsilyl chlorideBis(trimethylsilyl)amine

The invention provides a method for preparing silicon dioxide aerogel by using bagasse ash. The method is characterized by comprising the following steps: (1) mixing the bagasse ash with a sodium hydroxide solution, carrying out heating boiling, carrying out continuous stirring, and carrying out filtering so as to obtain sodium silicate filter liquor; (2) mixing the sodium silicate filter liquor with acidic ion exchange resin, and carrying out continuous stirring so as to obtain a silicic acid solution; (3) adding trimethylchlorosilane into the silicic acid solution, and carrying out stirringfor 10 to 40 minutes, so as to obtain a primary modified solution; (4) adding hexamethyldisilazane into the primary modified solution, and carrying out stirring for 10 to 40 minutes, so as to obtain asecondary modified solution; (5) adjusting the pH of the secondary modified solution to 4 with an ammonium hydroxide solution, so as to obtain silicon dioxide aquagel; (6) subjecting the silicon dioxide aquagel to standing heat-preserving treatment, so as to obtain gel; (7) drying the gel under ordinary pressure, thereby obtaining the silicon dioxide aerogel.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

A cheap nutrient biological deodorizing filler and its preparation method

InactiveCN104692763BHigh strengthLarge specific surface ratioSolid waste managementDispersed particle separationNutritionWood ash

The invention provides cheap nutritional biological deodorization packing and a preparation method thereof. The deodorization packing is prepared from the following materials: coal ash, zeolite powder, lime, gypsum, cement, sodium hydroxide, sodium silicate, wood ash, bagasse ash and waste molasses. The packing is high in strength, high in breathability and stable in performance, has rich nutrition and can provide enough nutrient substances for microbes, so that the problems that organic carriers are low in strength and the like can be solved, and the problem that growth of deodorizing bacteria is influenced because inorganic packing is short of nutrition can be solved. The packing is long in service life, and the forming speed of a biological deodorization film is high. In addition, the nutritional biological deodorization packing prepared by the invention is low in cost and changes wastes into valuable materials, the pollution is reduced, and the environmental benefits, economical benefits and social benefits can be simultaneously realized.

Owner:SUN YAT SEN UNIV

Method for producing straw decomposition agent by utilizing filter mud, cassava residues and waste alcohol mash

InactiveCN103787706APlay a synergistic roleNutritiousBio-organic fraction processingClimate change adaptationMicroorganismAlcohol

The invention provides a method for producing a straw decomposition agent by utilizing filter mud, cassava residues and waste alcohol mash. The method is characterized by mixing filter mud, cassava residues and bagasse ash in a weight ratio of (3-4):(3-4):(1-2), then adding a microorganism thallus prepared from aspergillus niger and mixing the materials uniformly, fermenting the mixture for 25-40 days, and then grinding and drying the fermented product at low temperature, thus obtaining the straw decomposition agent. Used for producing the straw decomposition agent, the method has the advantages of low production cost, high viable organism amount and obvious decomposing effect and can be used for decomposing objects such as banana cores, corn straws, wheat straws, rice straws, cereal straws, rape straws, weeds, leaves, household garbage with high content of fibrous matters and the like.

Owner:宾阳县明翔新材料科技有限公司

A Soilless Organic Waste Substrate Suitable for Raising Rubber Tree Seedlings

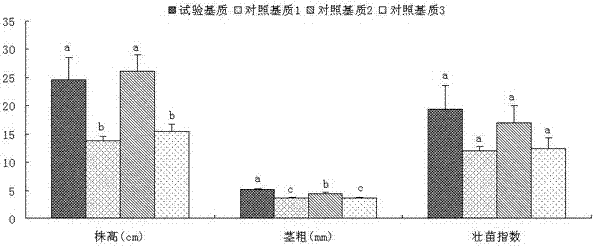

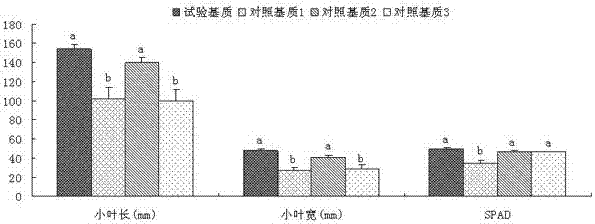

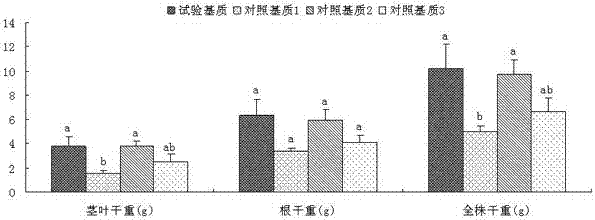

InactiveCN104957014BAbundant resourcesLow priceBio-organic fraction processingGrowth substratesBiologySeedling

The invention belongs to the technical field of rubber tree seedling culture and particularly discloses a soil-free organic waste substrate suitable for rubber tree seedling culture. The substrate is composed of cassava peels, bagasse ash and peanut shells; the cassava peels and the peanut shells are subjected to stack retting composting treatment. According to the substrate suitable for rubber tree seedling culture, organic materials such as common agricultural and forestry residues easy to obtain in rubber planting areas are utilized, in addition, components and matching of the substrate are optimized, the obtained substrate achieves good physicochemical properties, the quality of rubber seedlings can be effectively improved, the production period is shortened, and the production cost is reduced.

Owner:ZHANJIANG EXPERIMENTAL STATION CHINESE ACAD OF TROPICAL AGRI SCI

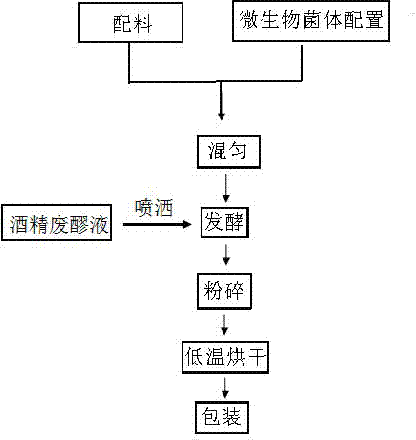

Composite material for outdoor table tennis table

The invention relates to a composite material for an outdoor table tennis table. The composite material comprises the following raw materials in parts by weight: 90-110 parts of cement, 55-65 parts of river sand, 0.5-0.8 part of redispersible latex powder, 0.3-0.6 part of polypropylene fiber, 4-8 parts of fly ash, 3-6 parts of bagasse ash, 0.3-0.8 part of lignocellulose, 0.2-0.4 part of a reducing agent, 1-3 parts of metakaolin loaded zirconium dioxide, 36-48 parts of water, 5-10 parts of epoxy resin, 1-2 parts of a curing agent and 0.4-1 part of an auxiliary agent. The problems that an existing wooden table tennis table top is not suitable for outdoor use, not resistant to corrosion and prone to aging are solved.

Owner:QUANZHOU SHUNTONG CRAFTS

A special fertilizer for multi-season chives and its production method and application method

InactiveCN104961560BMeet the needs of the growth processImprove qualityBio-organic fraction processingOrganic fertiliser preparationDiseaseLivestock manure

The invention discloses fertilizer special for multi-season chive and a production method and a using method of the fertilizer. The fertilizer is composed of, by weight, 620 parts of inorganic fertilizer and 380 parts of organic premix, the inorganic fertilizer comprises, by weight, 190 parts of urea, 60 parts of monoammonium phosphate, 260 parts of potassium sulfate, 80 parts of silicon-calcium fertilizer, 20 parts of magnesium sulfate, 5 parts of zinc sulfate and 5 parts of borax, and the organic premix comprises tobacco powder, poultry and livestock manure, alcohol wastewater and bagasse ash according to a weight ratio of 4:2:2:2. The production method includes: preparation of the organic premix: (1) weighing, (2) mixing and stirring, (3) stacking, fermenting and decomposing and (4) adding of additives; and preparation of the special fertilizer. The using method includes the steps of: (1) soil preparation and base fertilizer application, (2) field planting and seedling application (3) first-time additional application and soil loosening, weeding and water spraying and (4) second-time additional application and soil loosening, weeding and water spraying. The fertilizer comprises an adjusting agent, a disease preventing agent, organic matter and inorganic nutrient, can meet growing needs of chive and is high in yield and environment friendly, and the product method and the using method are easy to popularize.

Owner:LIUJIANG COUNTY SANDU TOWN JIUYUAN AGRI PLANTING FARMER PROFESSIONAL COOP

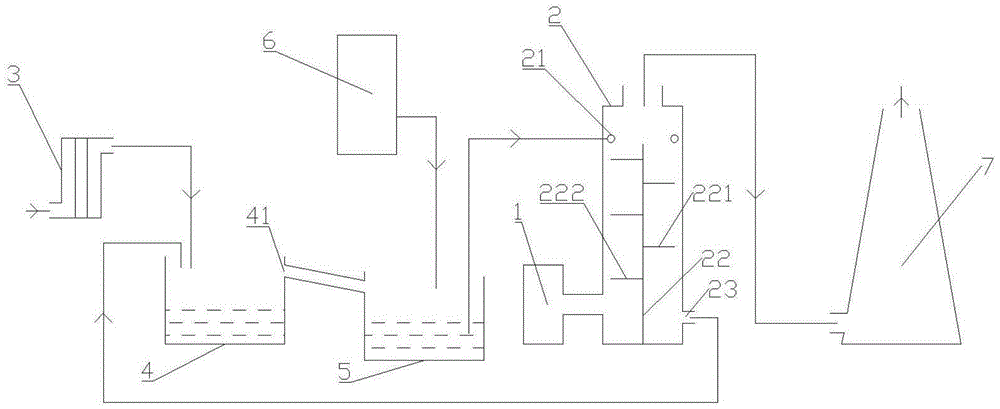

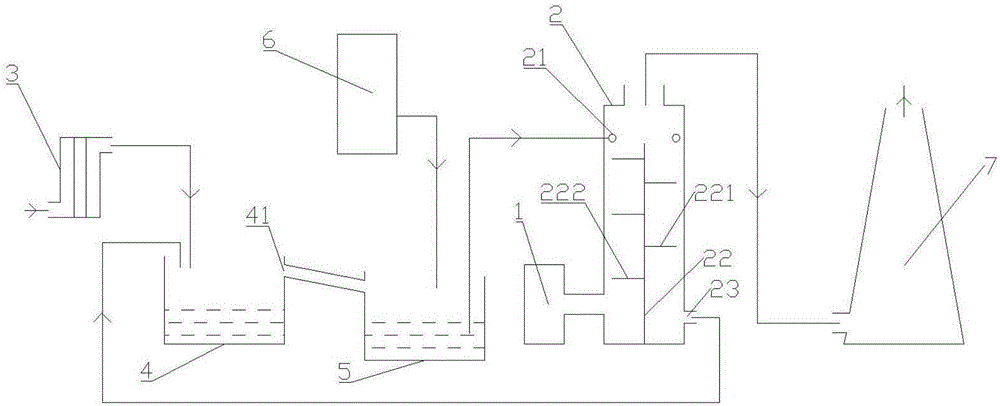

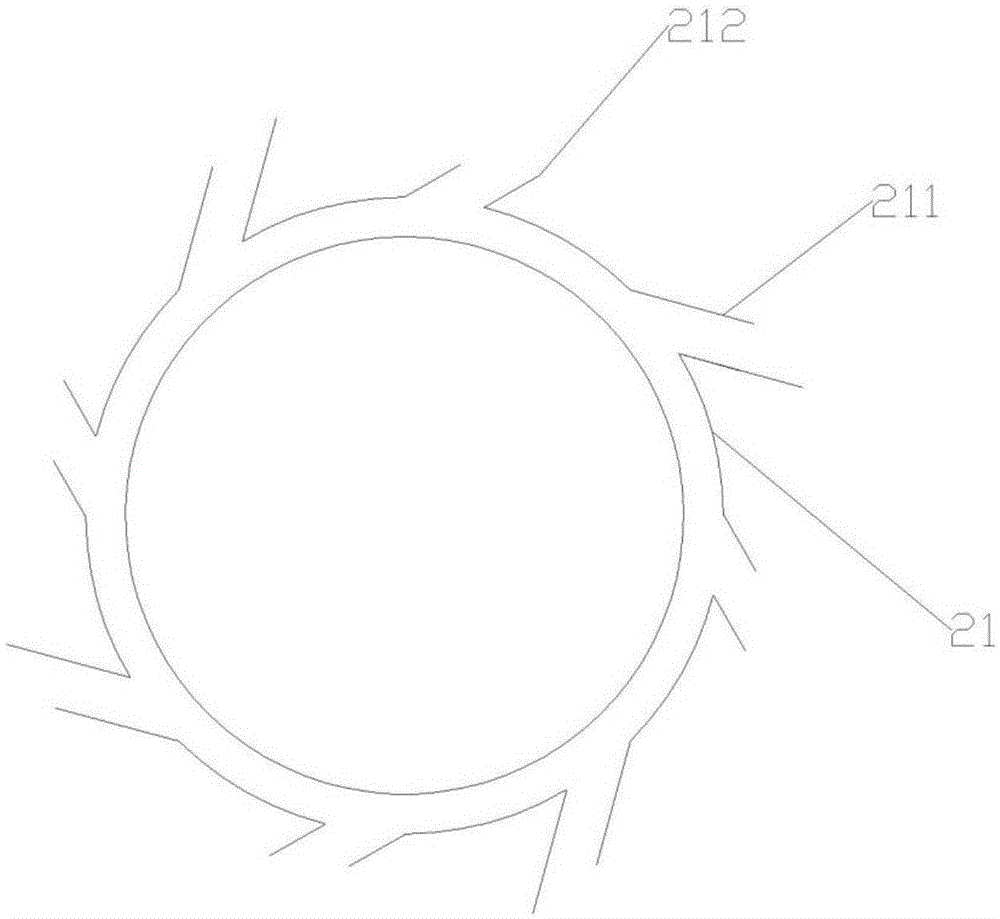

Waste brine reuse system

The present invention discloses a waste brine reuse system using waste brine in a sugar refinery to wash bagasse ash in flue gas discharged from a bagasse boiler. The system comprises: a housing and a liquid inlet tube, wherein the housing is a vertically arranged cylindrical structure; a gas inlet is formed in the lower side wall of the housing; the gas inlet is arranged along the circumferential and tangential direction, and is used for receiving the flue gas; a gas outlet is formed in the top of the housing; and the liquid inlet tube is arranged on the upper part of the housing, and is used for guiding the waste brine into the housing, and enabling the waste brine to downwards flow along the inner wall of the housing. The waste brine reuse system provided by the invention can effectively remove the bagasse ash in the flue gas from the bagasse boiler, and the water consumption of the sugar refinery is greatly reduced because of the repeated use of waste brine.

Owner:广西糖业集团防城精制糖有限公司

Method for removing sulfate radical in molasses alcohol wastewater by using bagasse ash

ActiveCN102873079BReduce generationImprove anaerobic methane production rateWater/sewage treatment by centrifugal separationSolid waste disposalSulfate radicalsSulfate radical

The invention discloses a method for removing sulfate radicals in molasses alcohol waste liquid with bagasse ash. (1) Pretreatment of bagasse ash: put 500g of bagasse ash into a crucible, put it into a high-temperature ashing furnace at 800°C for overnight ashing; sieve out a particle diameter of 0.177‐0.250mm, and put it into a drying dish after cooling (2) take 500mL of molasses alcohol waste liquid and carry out centrifugation to separate suspended solids; (3) take 100mL of waste liquid obtained in step (2) and add water to dilute to 1000mL; Add 10g of bagasse ash pretreated in step (1), and perform adsorption in a constant temperature rotary oscillator. Centrifuge for 10 minutes. The invention utilizes bagasse ash to adsorb and precipitate sulfate ions in molasses alcohol waste liquid to increase its anaerobic methane production rate, thereby reducing the generation of hydrogen sulfide and other odorous gases, and improving anaerobic reaction treatment and gas production efficiency.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Fertilizer special for multi-season chive and production method and using method of fertilizer

InactiveCN104961560ASolve the adjustmentSolve the problem of pest controlBio-organic fraction processingOrganic fertiliser preparationSulfate zincLivestock manure

The invention discloses fertilizer special for multi-season chive and a production method and a using method of the fertilizer. The fertilizer is composed of, by weight, 620 parts of inorganic fertilizer and 380 parts of organic premix, the inorganic fertilizer comprises, by weight, 190 parts of urea, 60 parts of monoammonium phosphate, 260 parts of potassium sulfate, 80 parts of silicon-calcium fertilizer, 20 parts of magnesium sulfate, 5 parts of zinc sulfate and 5 parts of borax, and the organic premix comprises tobacco powder, poultry and livestock manure, alcohol wastewater and bagasse ash according to a weight ratio of 4:2:2:2. The production method includes: preparation of the organic premix: (1) weighing, (2) mixing and stirring, (3) stacking, fermenting and decomposing and (4) adding of additives; and preparation of the special fertilizer. The using method includes the steps of: (1) soil preparation and base fertilizer application, (2) field planting and seedling application (3) first-time additional application and soil loosening, weeding and water spraying and (4) second-time additional application and soil loosening, weeding and water spraying. The fertilizer comprises an adjusting agent, a disease preventing agent, organic matter and inorganic nutrient, can meet growing needs of chive and is high in yield and environment friendly, and the product method and the using method are easy to popularize.

Owner:LIUJIANG COUNTY SANDU TOWN JIUYUAN AGRI PLANTING FARMER PROFESSIONAL COOP

Cement compositions based on amorphous bagasse ash

A cement composition including a dry phase and a liquid phase. The dry phase includes an aluminosilicate source, including amorphous bagasse ash with a concentration between 40 wt. % and 100 wt. % of the weight of the dry phase. The liquid phase includes at least one of water and an alkaline activator solution. The alkaline activator solution includes at least one of an alkali metal stearate, an alkali metal silicate, and an alkali metal hydroxide.

Owner:MORADI KHOU AMIR BAHADOR +1

Organic fertilizer or bio-mixed organic fertilizer special for rice and preparing method thereof

ActiveCN102503611BRestore fertilityReduce manufacturing costBio-organic fraction processingOrganic fertiliser preparationChaffRapeseed

The invention discloses an organic fertilizer or a bio-mixed organic fertilizer special for rice and a preparing method thereof. The organic fertilizer or the bio-mixed organic fertilizer special for rice is prepared by composting and fermenting raw materials (dry basis) according to the following weight percentage: 10%-20% of straw stalks, 25%-30% of rice chaff (bran), 25%-35% of rapeseed cakes (dregs), 5%-20% of sugar refinery filtered mud, 5%-10% of bagasse ash and 0.1% of ferment bacterial fertilizer. The organic fertilizer or the bio-mixed organic fertilizer is good in fertilizer effect and environment-friendly, can lead nutritional components absorbed by rice, rape and sugarcanes from the soil to return to the land so as to restore soil fertility, leads circular economy to be developed, use quantity of fertilizers and pesticides are reduced, green and organic agricultural products are produced, production cost and environment cost are reduced, food safety is improved, environment is protected, and modern agriculture and green agriculture development are promoted.

Owner:广西宾阳县华彦新材料科技有限公司

A kind of biological organic fertilizer and its production method

ActiveCN104045385BAccelerate the lossEasy to sieveBio-organic fraction processingOrganic fertiliser preparationFiltrationSugar refinery

The invention discloses bio-organic fertilizer. Through fermentation, the bio-organic fertilizer is prepared from 6-26wt% of filter mud produced by a sugar refinery, 55-75wt% of bagasse ash and 10-30wt% of ethanol concentrate. The production method comprises the following steps of 1, carrying out mixing stacking on filter mud produced by a sugar refinery, bagasse ash and ethanol concentrate, 2, removing moisture by filtration, 3, stacking the raw material mixture in a strip-shaped stack way, adding bifidobacterium, lactic acid bacteria, bacillus, saccharomycetes, actinomycetes and acetic bacteria into the stacked mixture, and carrying out fermentation, 4, keeping the primary fermented stack temperature above 60 DEG C and keeping material moisture content in a range of 40-45%, 5, increasing the height of the primary fermented stack, and carrying out secondary fermentation for aging until material moisture content is in a range of 30-35%, 6, adding the aged material into organic raw materials of N, P and K and carrying out mixing and 7, packaging the mixture to obtain the product. The bio-organic fertilizer has good fertilizer efficiency and is conducive to absorption by crops. The production method utilizes simple production equipment, has simple production processes and can be operated easily. The production method reduces a cost and has high income.

Owner:广西凭祥桂商现代农业投资有限公司

Waste brine reuse system

The present invention discloses a waste brine reuse system using waste brine in a sugar refinery to wash bagasse ash in flue gas discharged from a bagasse boiler. The system comprises: a housing and a liquid inlet tube, wherein the housing is a vertically arranged cylindrical structure; a gas inlet is formed in the lower side wall of the housing; the gas inlet is arranged along the circumferential and tangential direction, and is used for receiving the flue gas; a gas outlet is formed in the top of the housing; and the liquid inlet tube is arranged on the upper part of the housing, and is used for guiding the waste brine into the housing, and enabling the waste brine to downwards flow along the inner wall of the housing. The waste brine reuse system provided by the invention can effectively remove the bagasse ash in the flue gas from the bagasse boiler, and the water consumption of the sugar refinery is greatly reduced because of the repeated use of waste brine.

Owner:广西糖业集团防城精制糖有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com