Bagasse ash concrete and preparation method thereof

A technology for concrete products and bagasse ash, which is applied in the field of building materials, can solve the problems of unstable combustion of furnace temperature, large particle size and high porosity, and achieve the effects of realizing environmental protection production, enhancing compactness and reducing porosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

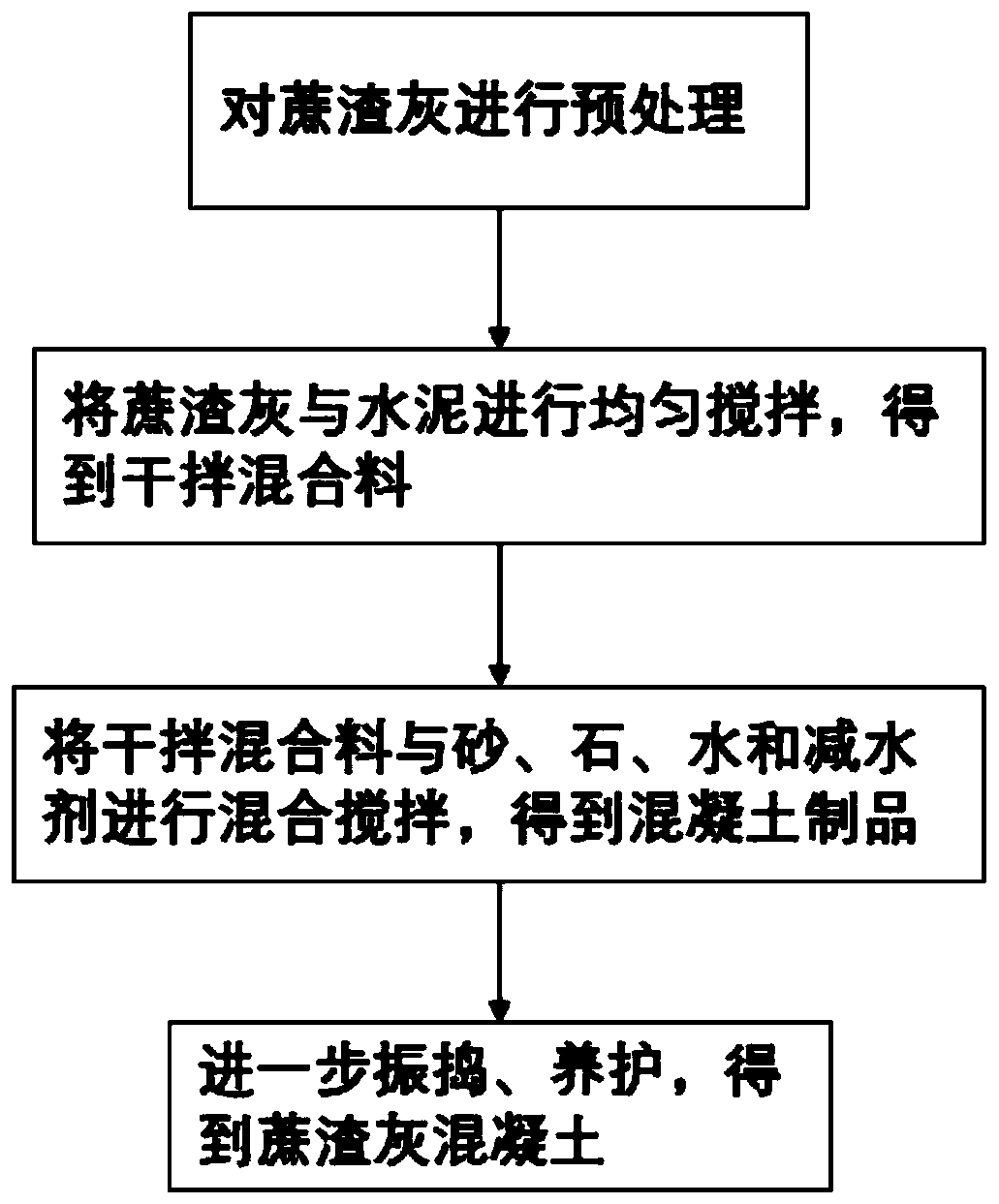

Method used

Image

Examples

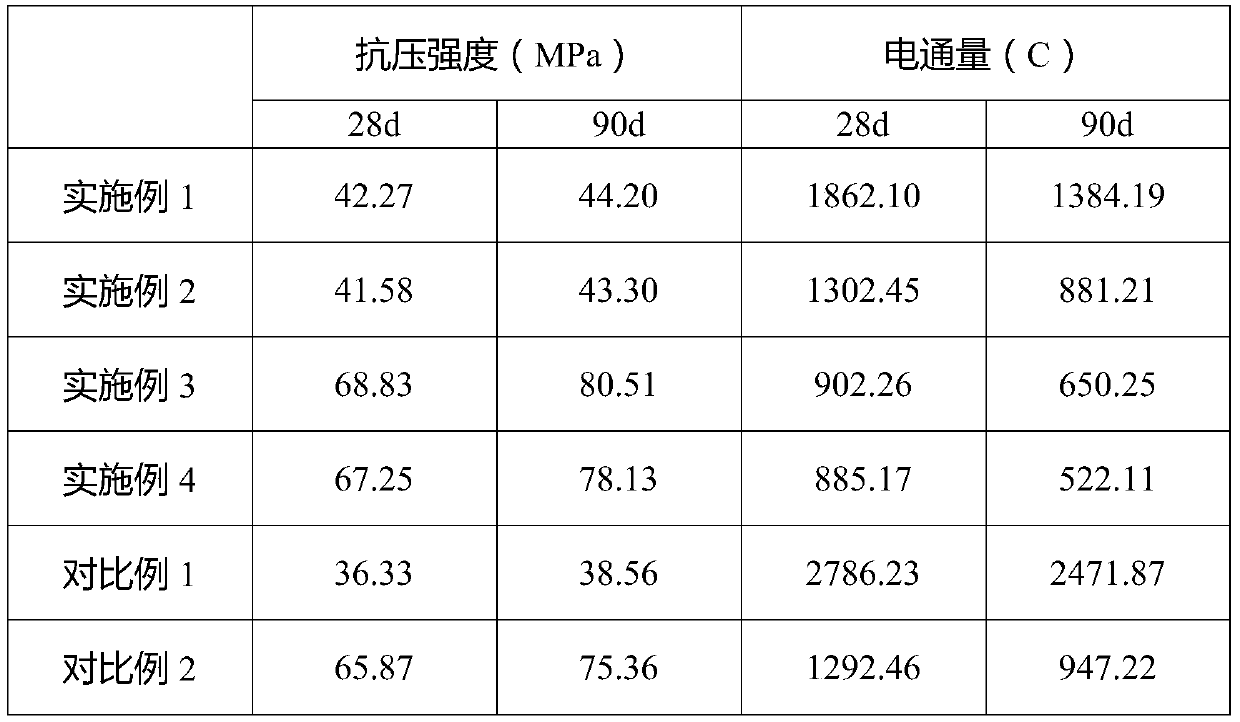

Embodiment 1

[0023] This embodiment is an example of the preparation method of the bagasse ash concrete of the present invention. The components and their corresponding parts by mass are shown in Table 1. The bagasse ash in this embodiment is used to replace part of the cement in an amount of 10%. Prepare bagasse ash concrete according to above-mentioned proportioning, comprise the steps:

[0024] Step 1: Calcining the bagasse ash at a high temperature of 650° C. for 1 hour, and cooling naturally. Add 0.05% triisopropanolamine (TIPA) to the cooled bagasse ash raw material, grind it in a ball mill until the sieve residue of 45 μm is less than 10%, and the specific surface area of the bagasse ash prepared at this time is 943m 2 / kg.

[0025] Step 2: Put the bagasse ash and cement pretreated in corresponding parts by mass into a mixer and stir for 3 minutes to obtain a dry mix mixture, and further mix and stir with gravel, sand, water, and water reducing agent for 3 minutes to obtain a ba...

Embodiment 2

[0029] This embodiment is another example of the preparation method of bagasse ash concrete according to the present invention. The components and their corresponding parts by mass are shown in Table 1. The specific preparation method is basically similar to Example 1, except that this Example of bagasse ash to replace part of the cement with a dosage of 15%.

Embodiment 3

[0031] This example is another example of the preparation method of bagasse ash concrete according to the present invention. The difference is that the components and their corresponding parts by mass are shown in Table 1, and the bagasse ash is calcined at a high temperature of 400 ° C. 1h, natural cooling. Add 0.05% triisopropanolamine (TIPA) to the cooled bagasse ash raw material, grind it in a ball mill until the sieve residue of 45 μm is less than 5%, and the specific surface area of the bagasse ash prepared at this time is 1250m 2 / kg, while the curing method adopts thermal curing curing treatment, and the bagasse ash in this example replaces part of the cement with a dosage of 10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com