Low-shrinkage-percentage resin mineral composite cement-based material and preparation method thereof

A technology of composite cement and low shrinkage, which is applied in the field of cement-based material modification, can solve the problems of reducing the physical and mechanical properties of hardened cement paste, increasing the porosity of cement-based materials, and the use of concrete that is prone to cracking, so as to improve the environment. And economic benefits, improve shrinkage cracking, reduce the effect of shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Raw material ratio: Portland cement accounts for 95wt.% of the total amount of cementitious materials, silica fume accounts for 2.5wt.% of the total amount of cementitious materials, and 0.4wt.% of super absorbent resin (SAP) is added externally. Carboxylic acid water reducing agent, the dosage is 0.6wt.% of the total amount of cement paste formed by mixing superabsorbent resin and water.

[0030] Preparation method: first add water to the stirring device, then add water reducing agent, and stir evenly; then add silica fume, then add cement, and finally add water-absorbing super absorbent resin, stir and place it on the mixer for 4 minutes .

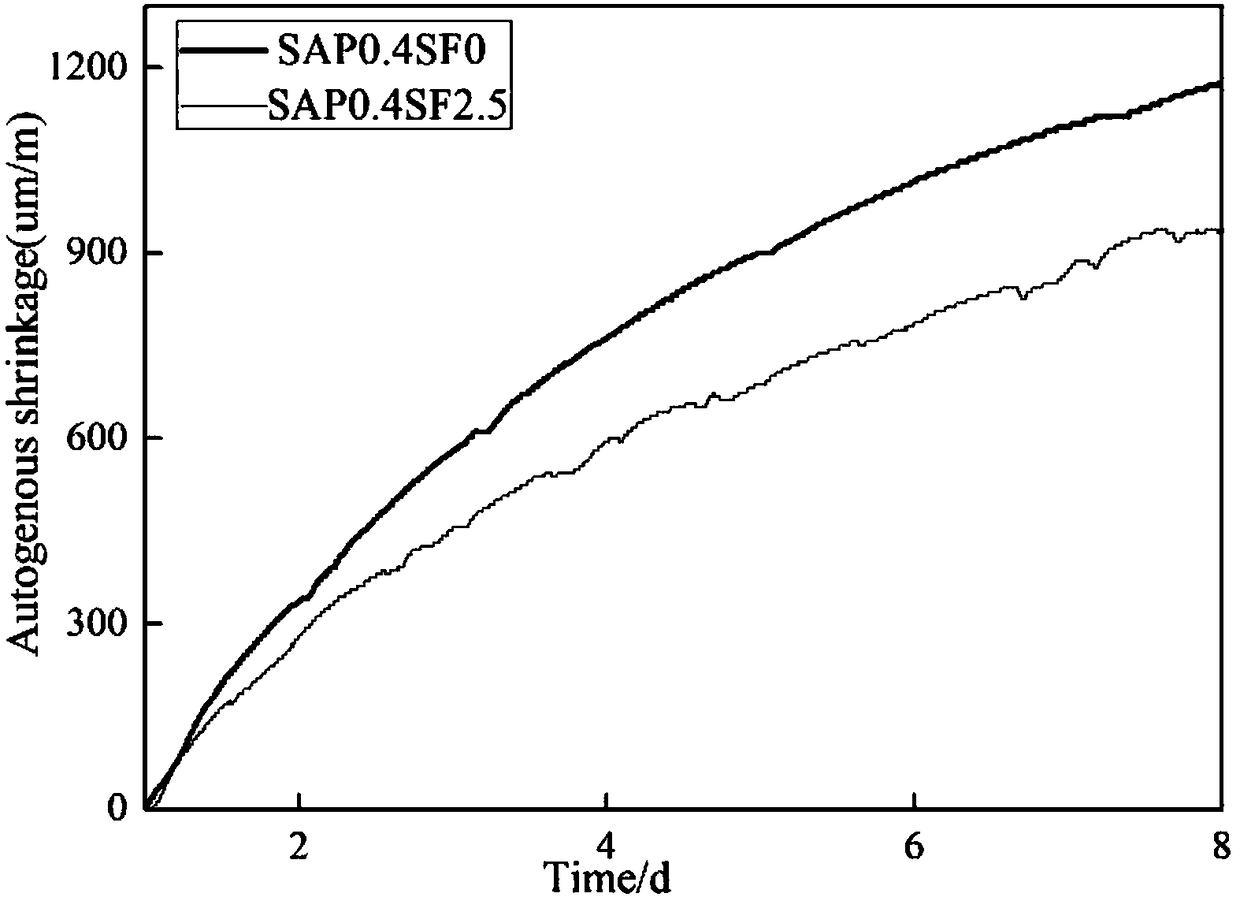

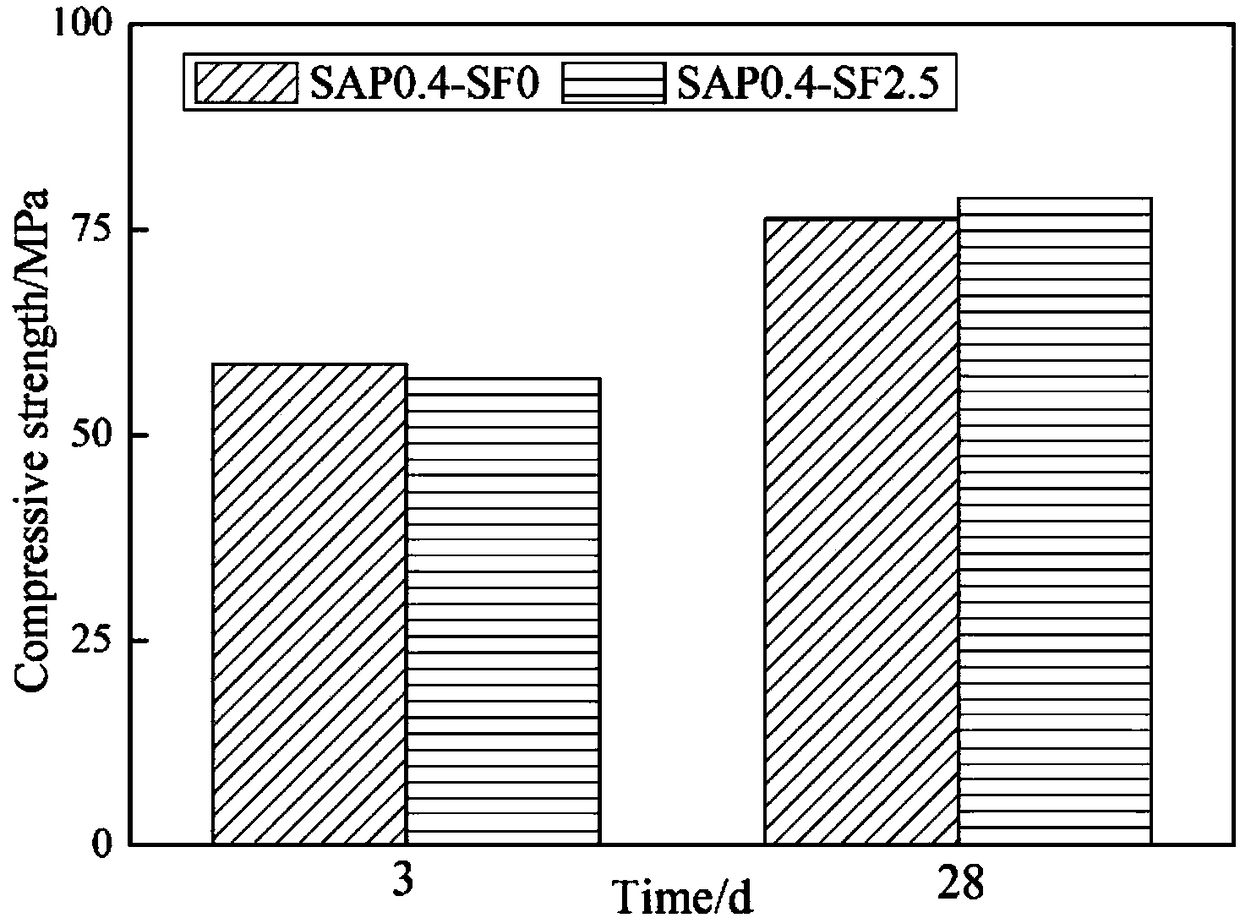

[0031] Test situation: test the self-shrinkage of hardened cement paste within 7 days of age, and test the compressive strength of cement paste within 28 days of age. The test results are as figure 1 and figure 2 As shown, when the silica fume content is 2.5wt.%, the autogenous shrinkage of the hardened cement paste within 7 d...

Embodiment 2

[0033] Raw material ratio: Portland cement accounts for 97.5wt.% of the total cementitious material, silica fume accounts for 2.5wt.% of the total cementitious material, and 0.4wt.% superabsorbent resin (SAP) is added externally. The polycarboxylate water reducer is used in an amount of 0.6wt.% of the total amount of the cement paste mixed with superabsorbent resin and water.

[0034] Preparation method: first add water to the stirring device, then add water reducing agent, and stir evenly; then add silica fume, then add cement, and finally add water-absorbing super absorbent resin, stir and place it on the mixer for 4 minutes .

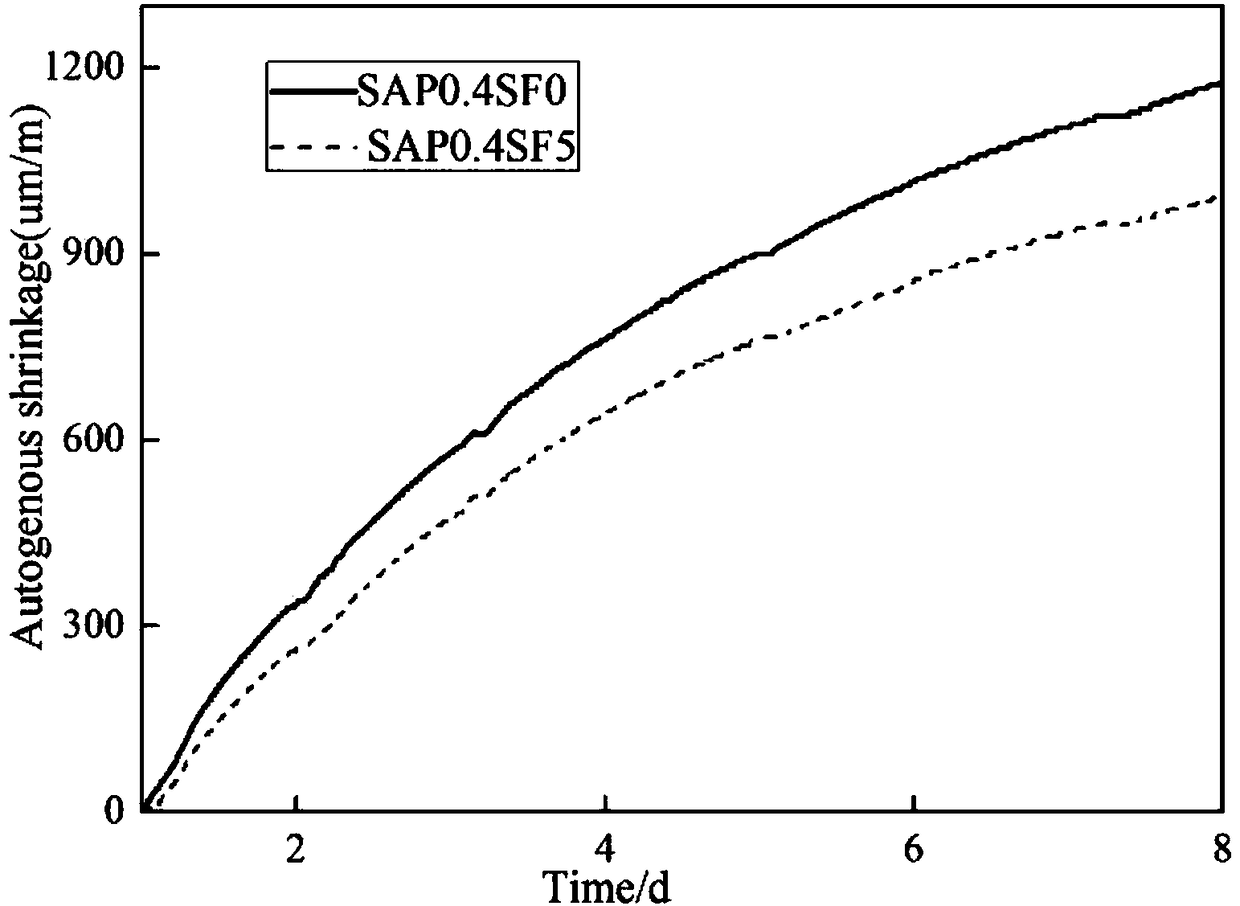

[0035] Test situation: test the self-shrinkage of hardened cement paste within 7 days of age, and test the compressive strength of cement paste within 28 days of age. The test results are as figure 1 and figure 2 It is shown that when the silica fume content is 5wt.%, the autogenous shrinkage of hardened cement paste within 7 days of age is signi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com