Mineral admixture for concrete and preparation method thereof

A mineral admixture and concrete technology, applied in the field of cement-based materials, can solve the problem of low utilization rate of solid waste, achieve low electric flux, improve mechanical properties and durability, and reduce treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

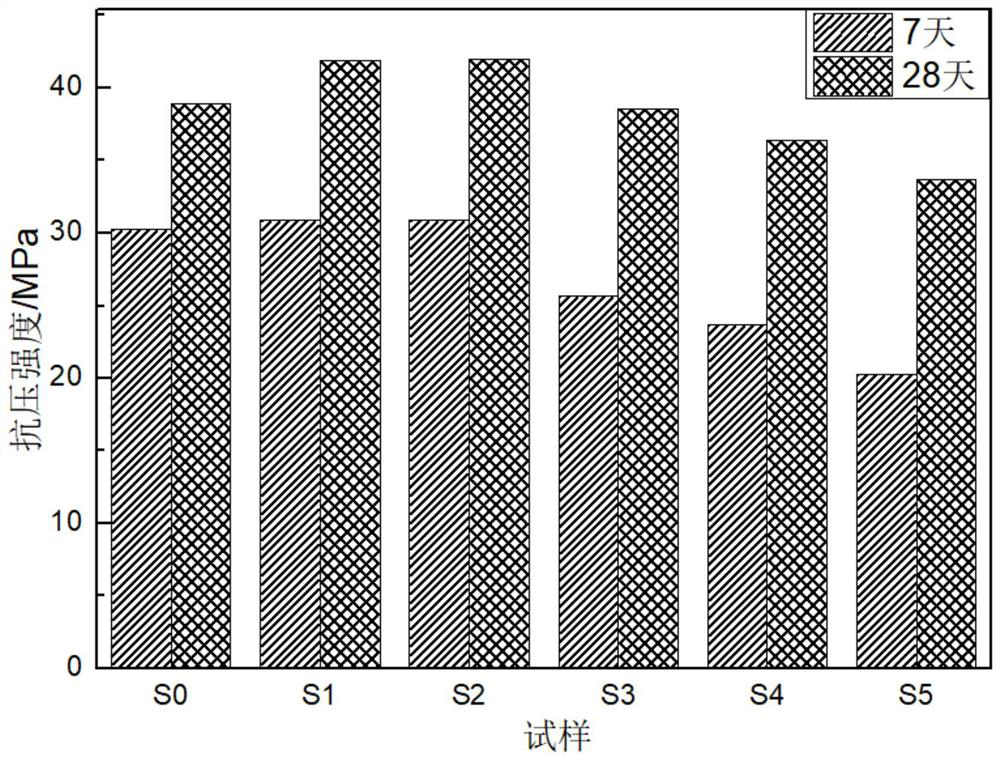

Embodiment 1

[0044] Mineral blending with concrete, including the following components by weight component:

[0045] 220 mixing station waste slurry, 90 stickers, 35 parts of lithium residue, 20 gas segments, 80 of glass slag.

[0046] The preparation method is:

[0047] 100 parts of the stir slurry water, 40 parts of the stirring station, 35 parts of lithium residue, 20 gas segments, and crush the lithium residue and gas segments into a 1.18mm screen, add the material to the grinder And add 0.5 parts of polycarboxylic acid water water repellent to dry to D 50 <8 μM obtained the slurry I;

[0048] 120 parts of the stir slurry water, 50 parts of the stirring station, 80 cases of glass slag, the glass residue is broken to the via diameter of 1.18 mm screen, and the material is added to the grinder and add 0.3 parts of polyethylene glycol. Grinding. To D 50 <25 μm is obtained by the slurry II;

[0049] The resulting slurry I and the slurry II were mixed, and 0.5 parts of polyethylene glycol ester...

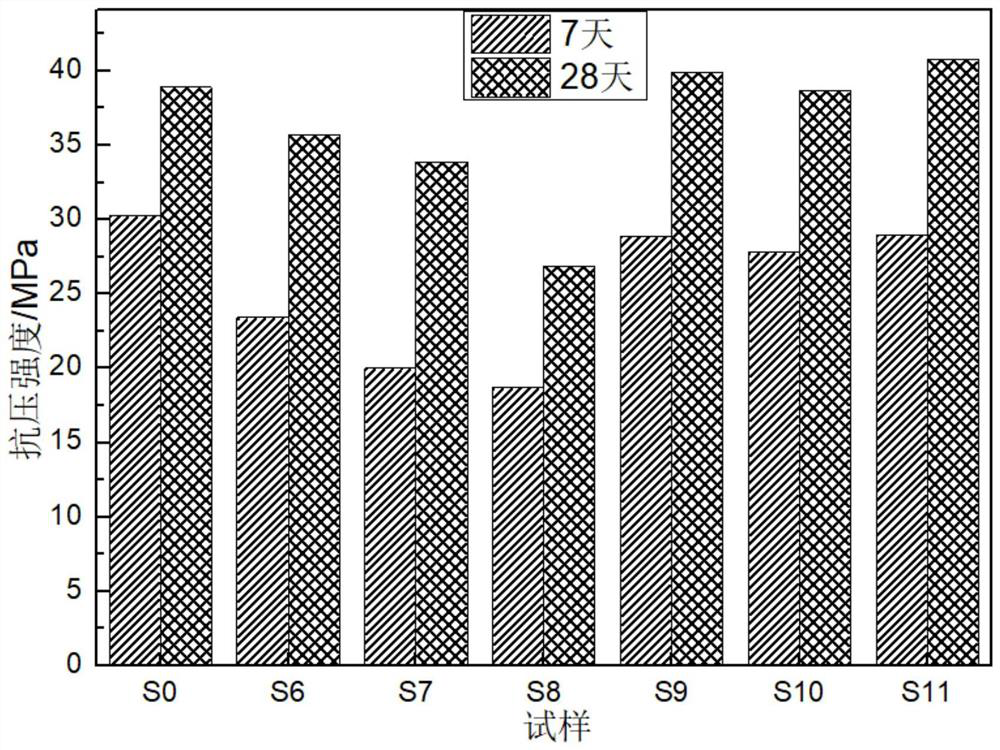

Embodiment 2

[0051]Mineral blending with concrete, including the following components by weight component:

[0052] 200 parts of the stirring station, 100 parts of the stirring station, 20 gas segments, 50 coal gangue.

[0053] The preparation method is:

[0054] 50 parts of the stir slurry water, 50 parts of the stirring station, 20 parts of gas segments, and crushed the gas segments to the perforation of 1.18 mm screen, and the material was added to the grinder and 1 part of the polycarboxylic acid. Decrease agent is ground to D 50 <8 μM obtained the slurry I;

[0055] 150 parts of the stir slurry water, 50 parts of the stirring station, 50 coal gangue, the coal gangue crushed to a 1.18 mm screen, and the material was added to the grinder and added 0.3 parts of the polycarboxylic acid water water reduction agent. Grinding to D 50 <25 μm is obtained by the slurry II;

[0056] The resulting slurry I and the slurry II were mixed, and 0.5 parts of sodium dodecyl sulfonate was added and stirred e...

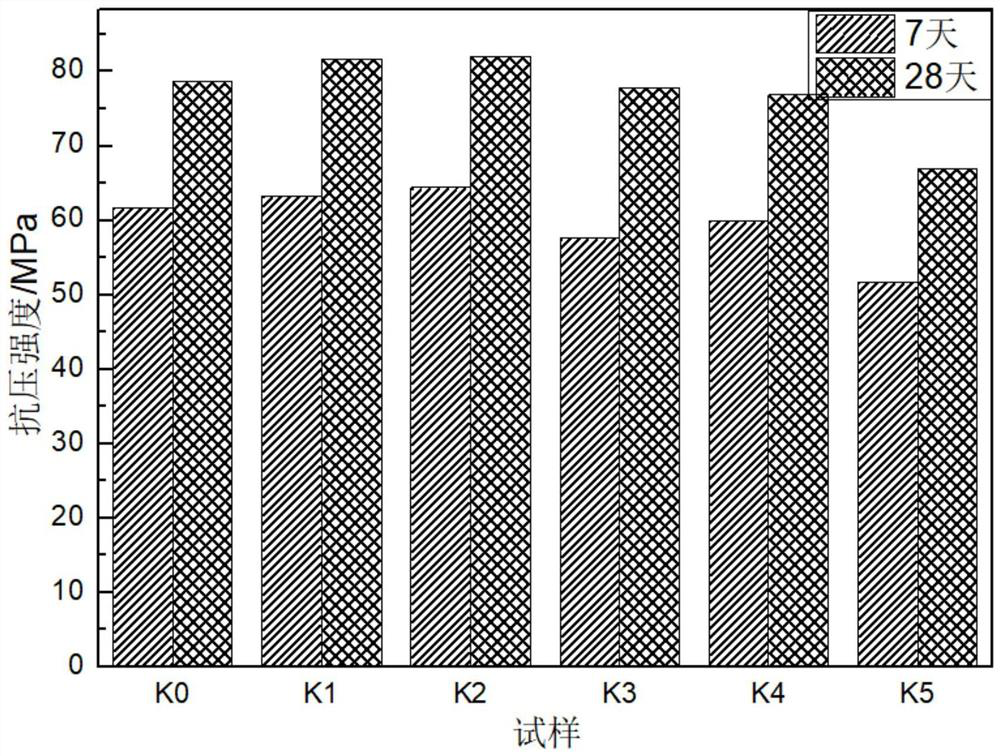

Embodiment 3

[0058] A mineral blending of concrete, taking the mixing station waste slurry aperture is 1.18 mm screen, and the material is added to the grinder and 0.4 parts of polyols are ground to D. 50 <8 μM obtained the slurry I;

[0059] Take the mixing station waste slurry water perforation is 1.18 mm screen, and the material is added to the grinder and 0.2 parts of the polycarboxylic acid water water reducer to ground to D. 50 <25 μm is obtained by the slurry II;

[0060] The resulting slurry I and the slurry II were mixed, and 0.5 parts of water glass was mixed and uniform, i.e., the blend was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com