Method for producing straw decomposition agent by utilizing filter mud, cassava residues and waste alcohol mash

A technology of straw decomposing agent and alcohol waste mash, which is applied in the field of microbial preparations and preparation of microbial preparations, can solve the problems of low bacterial activity, low enzyme production, high production costs, etc., reduce the use of chemical fertilizers, and have a wide range of applications , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

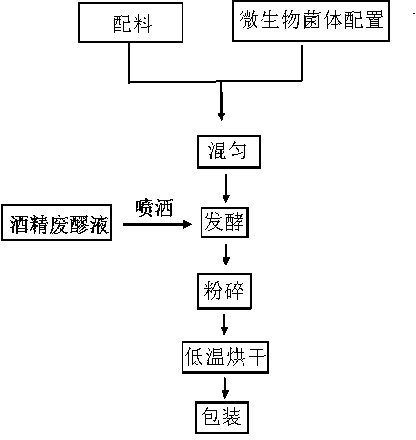

Image

Examples

Embodiment 1

[0021] It is formulated with Aspergillus niger and Aspergillus oryzae according to the ratio of 1:2 bacterial population, and the microbial cells are prepared for use. The filter mud, cassava bagasse, and bagasse ash are prepared according to the weight ratio of 3:3:1, and then added to the prepared The microbial thallus is mixed evenly together, and the amount of the microbial thallus added is 2% of the weight sum of the raw materials such as filter mud, cassava bagasse, and bagasse ash. Fermentation was started under the conditions of normal temperature and pH value of 7.0. When the temperature of the fermentation substrate rose to 50°C, the substrate was turned over and sprayed with alcohol waste mash to lower it to normal temperature and then continue to ferment. Repeat 3 times for a total of After 15 days of fermentation, it is crushed into particles with a particle size of 1 mm, and then the crushed straw decomposing agent is dried at 75° C. under normal pressure until th...

Embodiment 2

[0023] It is formulated with Aspergillus niger and Aspergillus oryzae according to the ratio of 2:3 bacterial population, and the microbial cells are prepared for use. The filter mud, cassava bagasse, and bagasse ash are prepared according to the weight ratio of 4:4:2, and then added to the prepared The microbial thallus is mixed together, and the amount of the microbial thallus added is 4% of the weight sum of the raw materials such as filter mud, cassava bagasse, and bagasse ash. Fermentation started under the condition of normal temperature and pH value of 7.0. When the temperature of the fermentation substrate rose to 55°C, the substrate was turned over and sprayed with alcohol waste mash to lower it to normal temperature to continue fermentation. Repeat 4 times for a total of After 20 days of fermentation, it is crushed into particles with a particle size of 2 mm, and then the crushed straw decomposing agent is dried at 80° C. under normal pressure until the water weight p...

Embodiment 3

[0025] It is formulated with Aspergillus niger and Aspergillus oryzae according to the ratio of 3:4 bacterial population, and the microbial cells are prepared for use. The filter mud, cassava bagasse, and bagasse ash are prepared according to the weight ratio of 3:4:2, and then added to the prepared The microbial thallus is mixed evenly together, and the amount of the microbial thallus added is 6% of the weight sum of the raw materials such as filter mud, cassava bagasse, and bagasse ash. Start fermentation under normal temperature and pH value of 7.0. When the temperature of the fermentation substrate rises to 60°C, turn over the substrate and spray alcohol waste mash to lower it to normal temperature and continue fermentation. Repeat 3 to 5 times , after 25 days of co-fermentation, crushed into particles with a particle size of 3mm, and then dried the crushed straw decomposing agent at 85°C under normal pressure until the water weight percentage was lower than 5%. The straw ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com