A type zeolite and preparation method thereof

A zeolite and paper-made technology, applied in the field of A-type zeolite and its preparation, can solve the problems of reduced performance stability of zeolite, high production cost of A-type zeolite, difficulty in controlling the quality of zeolite, etc., achieves fast crystallization speed and increases market competitiveness , the effect of superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] The preparation of incineration ash also has an impact on the quality of subsequent A-type zeolite products. Continuous low-temperature incineration with an incineration temperature below 500 ° C will not cause SiO contained in the incineration ash 2 Crystallization occurs, and the solubility in alkaline solvents such as NaOH is improved, and the SiO contained in the incineration ash is effectively utilized to the maximum extent 2 ; In addition, the incineration ash should be stirred during incineration, so that the raw materials for incineration in the incinerator can be burned at a uniform temperature, so as to increase the SiO in the incineration ash. 2 non-crystalline nature. When stirring the incinerator, it can also reduce the content of unburned carbon element (C), providing good conditions for the synthesis of white zeolite;

[0015] Raw materials for incineration can be rice husk, bagasse, diatomaceous earth, coal or paper.

[0016] Proceed as follows:

[00...

Embodiment 1

[0035] (1) Dissolution: Put the modified rice husk in an incinerator and incinerate at a temperature of 500°C for 25 minutes to obtain incineration ash. After heating the 3N NaOH solution, the temperature was 98°C, and heated for 2.5 hours, the SiO in the obtained solution 2 The dissolution rate is more than 90%;

[0036] (2) Crystallization: aluminum hydroxide and sodium hydroxide in a weight ratio of 7:5, react at 90-100°C for 2 hours, and prepare sodium metaaluminate according to the added amount of modified rice husk ash The volume ratio of 1:5 is added to the solution of step (1) for crystallization, the crystallization time is 2 hours, and the crystallization temperature is 98°C; during the reaction process, continue to add 3N sodium metaaluminate to make the alkalinity in the reaction system The solution concentration is kept at 0.8 ~ 3N;

[0037] (3) Drying: Filter the crystallized solution and dehydrate it to obtain a type A zeolite paste with a water content of 40%...

Embodiment 2

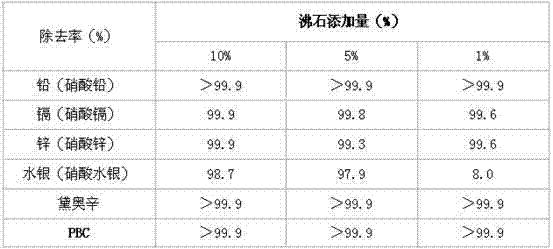

[0038] Embodiment 2 Type A zeolite is to the adsorption test of heavy metal in water

[0039] Add the heavy metal in 500CC of water at a specified concentration and mix and stir evenly, then add the specified amount of A-type zeolite prepared in Example 1, and after stirring for 30 minutes, analyze the residual amount of heavy metal in the aqueous solution and calculate the adsorption rate (removal rate). Pb, Cd, Zn, and Hg ions were added in the form of nitric acid compounds at 10 ppm each, while dioxin and PCB were added in the form of sols at 10 ppm and 300 ppm because they were insoluble in water. A-type zeolite (Ca-type: CEC=260 / 100g) is added in an amount of 1%, 5%, and 10% of the aqueous solution. As shown in Table 1, type A zeolite has a strong adsorption and removal effect on heavy metals.

[0040] Table 1 Adsorption test of A-type zeolite to heavy metals in water

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com