Heating system for man cabin of shield machine and control method thereof

Technology of a heating system and water heating system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

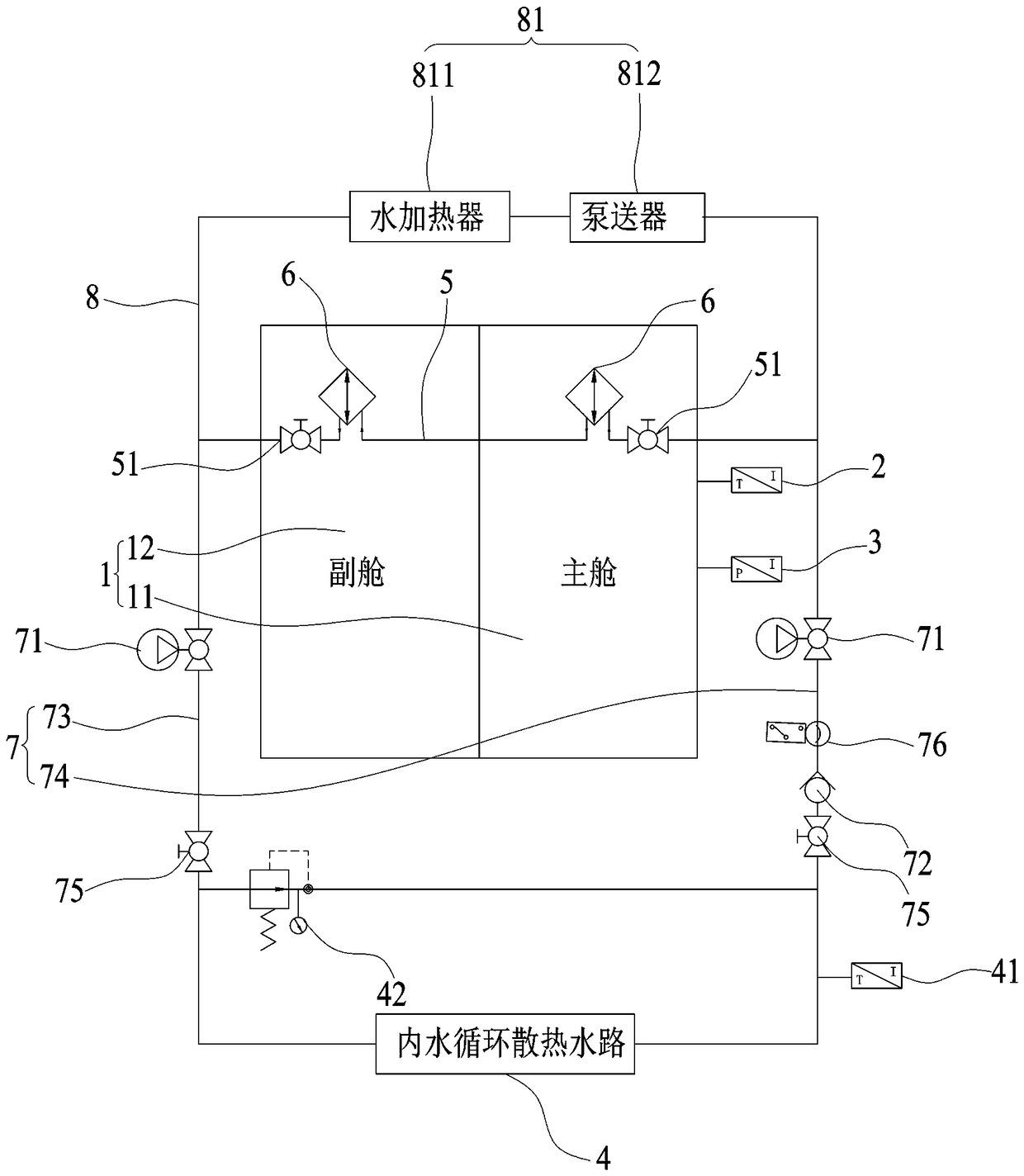

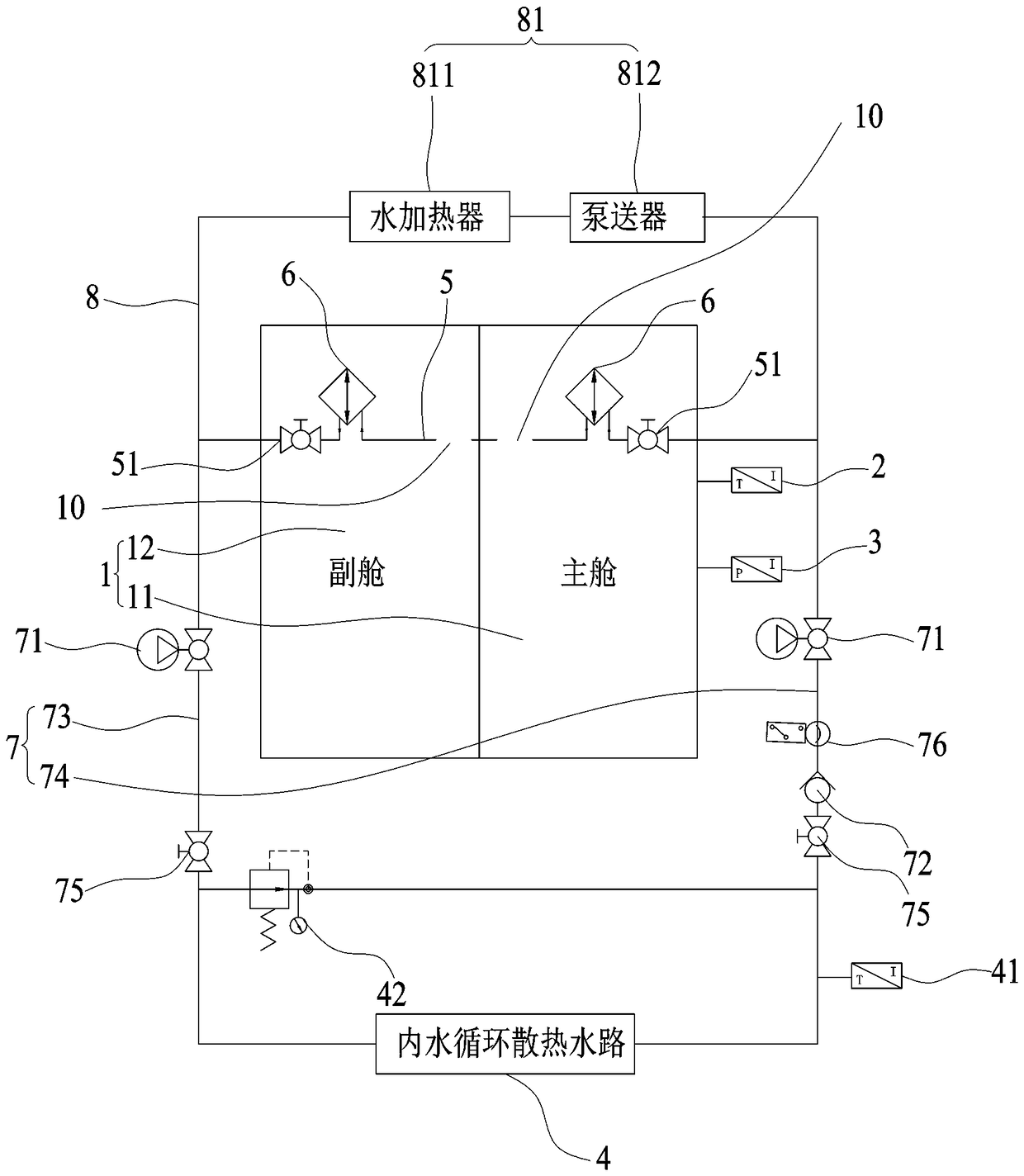

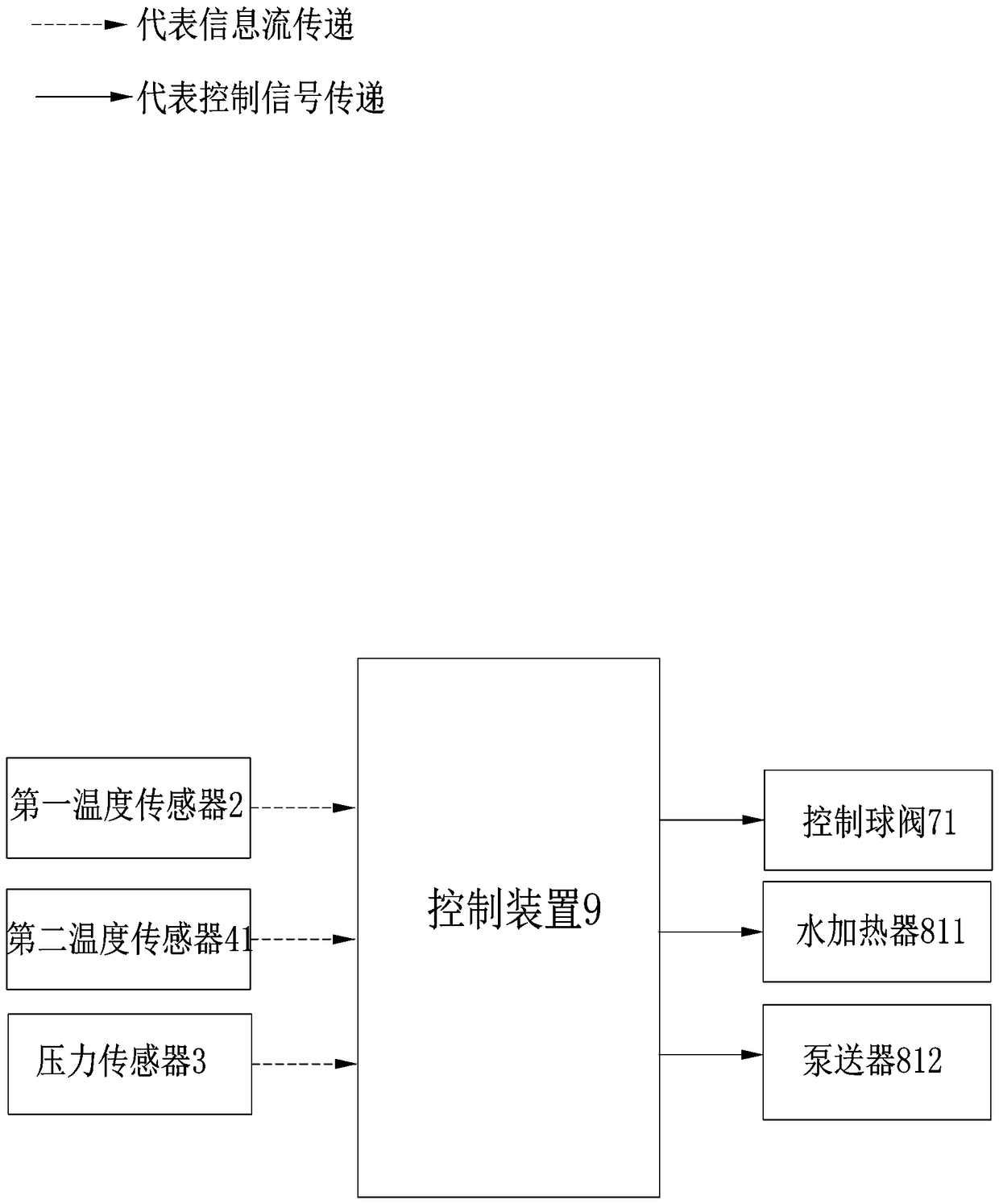

[0044] The invention discloses a heating system for a human cabin of a shield machine, comprising: a human cabin 1 composed of a main cabin 11 and an auxiliary cabin 12; a first temperature sensor 2 for monitoring the temperature in the human cabin 1; a pressure sensor 3, It is used to monitor the pressure value in the man cabin 1; the internal circulation heat dissipation waterway 4 is used for the heat dissipation waterway of the main drive reducer or air compressor or the main drive gear oil system or the super digging knife system in the heat dissipation shield machine. The heat dissipation waterway can only dissipate heat from any one of the aforementioned devices, and can also dissipate heat from all the aforementioned devices, and a second temperature sensor 41 for detecting the waterway is also added in the internal circulation heat di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com