Powdered iron flour dust transport vehicle

A technology for transporting vehicles and dust, which is applied in the direction of article transporting vehicles, transporting objects, transportation and packaging, etc., which can solve the problems of low loading and unloading efficiency, low safety factor, waste of iron powder, etc., to reduce waste, improve the utilization rate of iron powder, The effect of improving transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

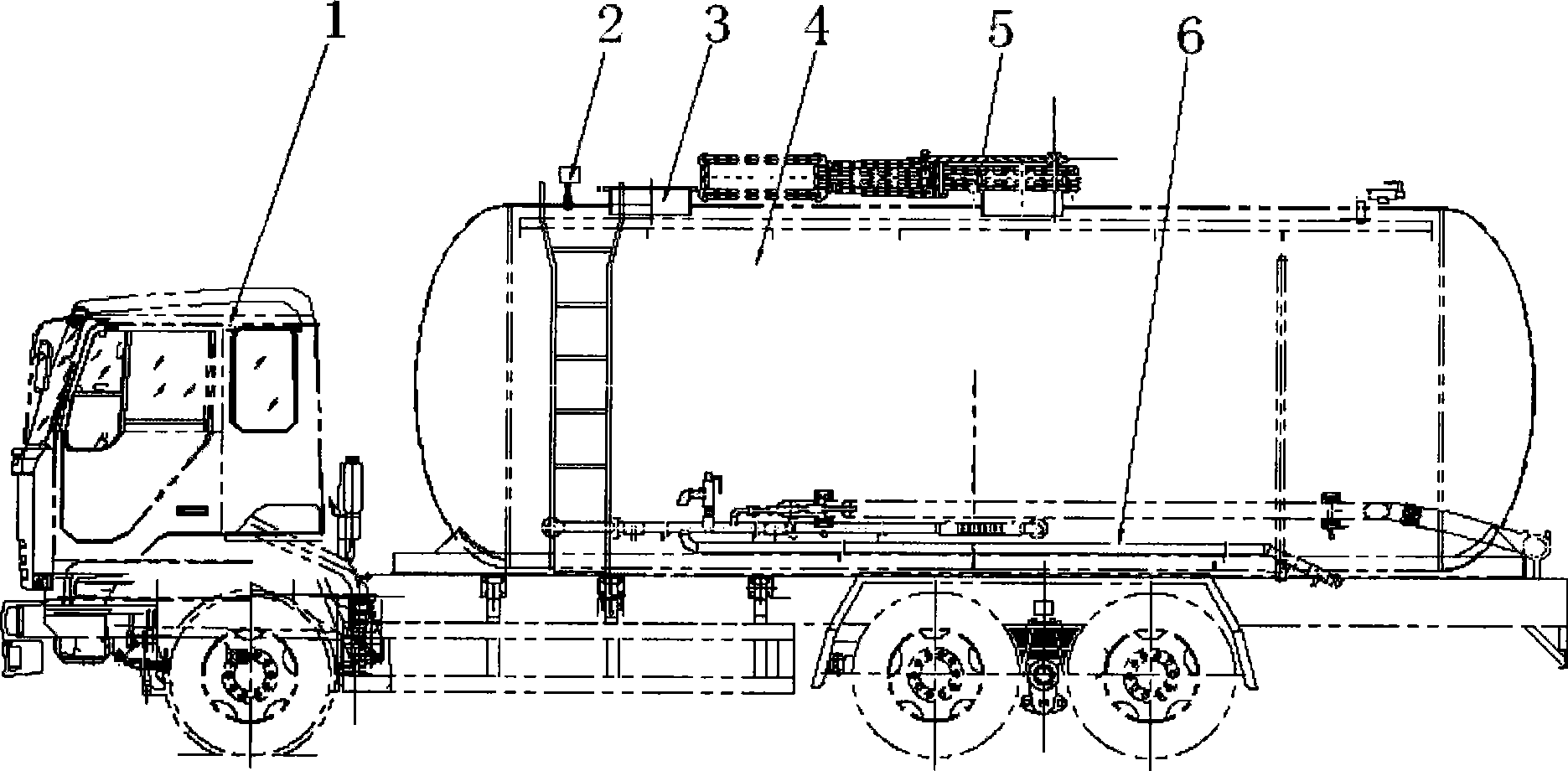

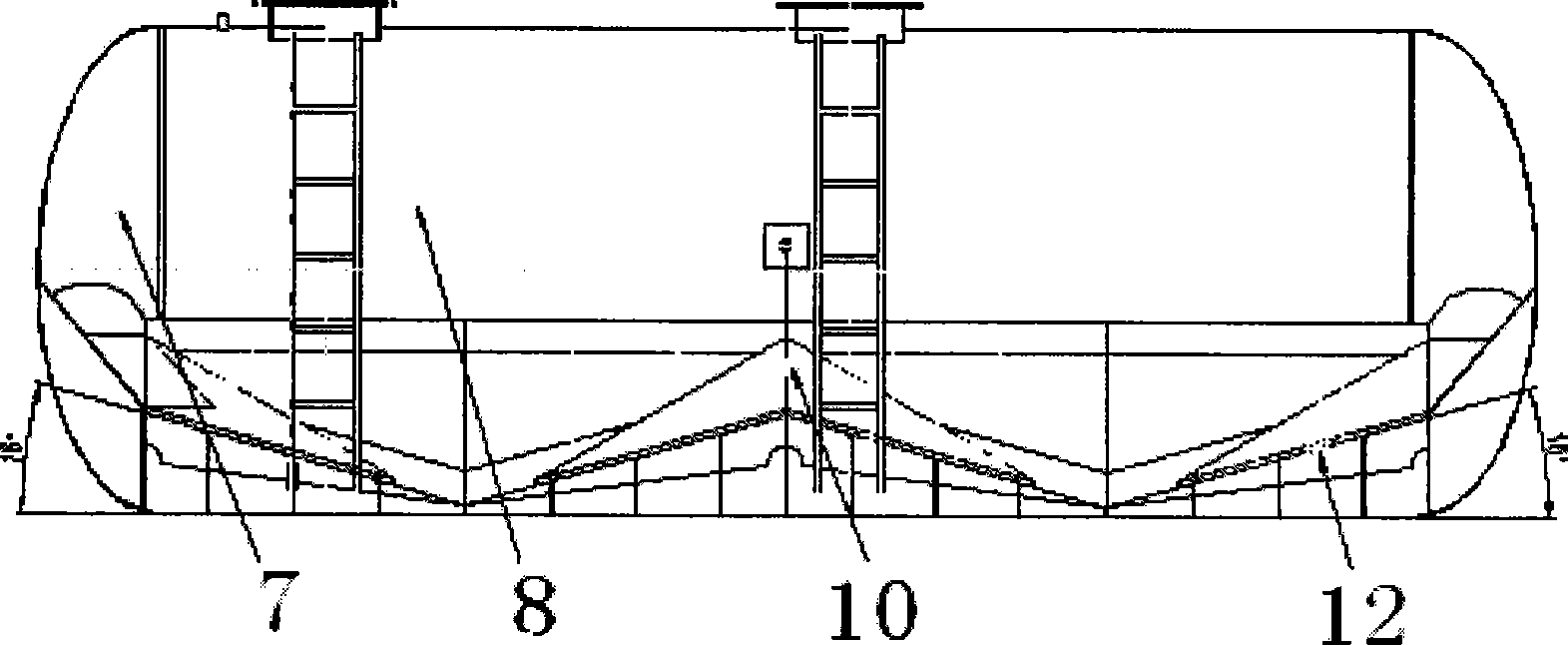

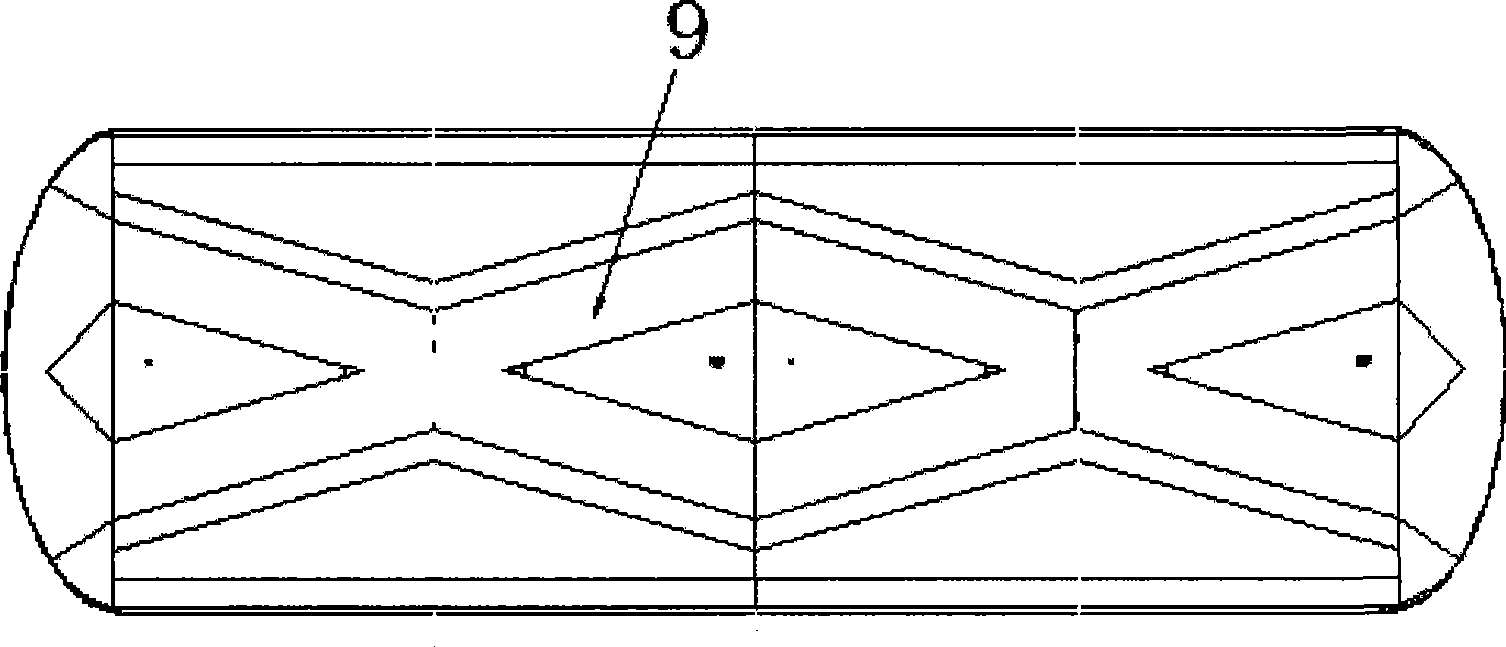

[0025] Such as Figure 1-7 As shown, the technical solution provided by the present invention is an iron powder dust transport vehicle, including a chassis 1, a tank assembly 4 and a pipeline assembly 6, the tank assembly 4 is provided with a vulcanized bed, and the The angle of the vulcanized bed is set at 10-20 degrees, and the upper part of the tank body assembly 4 is provided with a level controller 2 , a manhole cover 5 and an inspection cover 3 .

[0026] The angle of the fluidized bed adopts 10 degrees or 20 degrees respectively, and compared with the prior art, the speed of the iron powder dust fluidization output is improved somewhat; when the angle of the fluidized bed is set to 14 degrees or 18 degrees , the speed of the fluidized output of the iron powder dust is significantly increased; after repeated tests, when the angle of the fluidized bed is set to 16 degrees, the fluidized output of the iron powder dust is the best value.

[0027] The tank body also include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com