Oxygen-vacancy-rich titanium dioxide material, preparation and application of oxygen-vacancy-rich titanium dioxide material in lithium oxygen battery

A technology of titanium dioxide and vacancies, which is applied in the direction of battery electrodes, circuits, electrical components, etc., to achieve the effect of improving cycle stability, improving stability, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

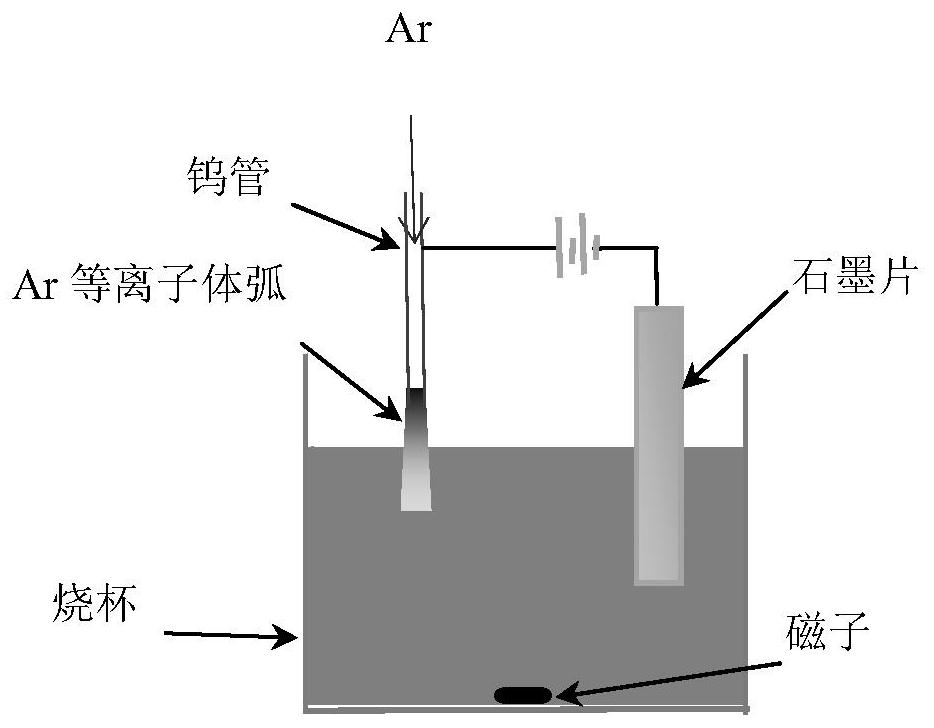

[0032] An embodiment of the present invention provides a method for preparing an oxygen-vacancy titanium dioxide material, comprising the following steps:

[0033] S1, placing a tubular electrode above the titanium salt solution, the distance from the lower end of the tubular metal electrode to the liquid surface is 0.1-10 mm, preferably 2-5 mm, and the optimal power of the plasma arc can be guaranteed within this distance. Place the sheet electrode in the titanium salt solution.

[0034] S2, the inert gas is continuously blown towards the liquid surface through the tubular electrode; the gas flow is controlled by the glass rotameter in order to obtain the plasma with the highest efficiency and the best arc performance. In this embodiment, the flow rate of the inert gas is preferably 45-55 sccm; the inert protective gas is preferably Ar.

[0035] S3, connect the tubular electrode and the sheet electrode to a high-voltage DC power supply, and control the voltage to generate pl...

Embodiment 1

[0048] Preparation of Oxygen-Vacancy-Rich Titanium Dioxide Material:

[0049] (1) Dissolve titanium chloride into water, and configure 50mL of 5mM solution;

[0050] (2) Take a 10cm tungsten tube with an inner diameter of 2mm and an outer diameter of 5mm as the A electrode, and the distance from its lower end to the liquid surface is about 2mm;

[0051] (3) Place a graphite sheet with a length of 10 cm, a width of 1 cm, and a thickness of 0.5 cm in the solution as the B electrode, according to the attached figure 1 Build a simple electrochemical reaction device and keep the minimum distance between the tungsten tube electrode and the graphite sheet electrode at 10cm;

[0052] (4) The inert gas Ar is continuously fed into the liquid surface direction through the tubular A electrode, and the glass rotameter controls the gas flow rate to 50 sccm;

[0053] (5) Connect the tungsten tube electrode and the graphite electrode to a high-voltage DC power supply, and control the voltag...

Embodiment 2

[0057] Preparation of Oxygen-Vacancy-Rich Titanium Dioxide Material:

[0058] (1) Dissolve titanium nitrate in water and configure 50mL of 5mM solution;

[0059] (2) Take a 10cm tungsten tube with an inner diameter of 2mm and an outer diameter of 5mm as the A electrode, and the distance from its lower end to the liquid surface is about 2mm;

[0060] (3) Place a tungsten sheet with a length of 10 cm, a width of 1 cm, and a thickness of 0.5 cm in the solution as the B electrode. figure 1 Build a simple electrochemical reaction device and keep the minimum distance between the tungsten tube electrode and the graphite sheet electrode at 5cm;

[0061] (4) The inert gas Ar is continuously fed into the liquid surface direction through the tubular A electrode, and the glass rotameter controls the gas flow rate to 50 sccm;

[0062] (5) Connect the tungsten tube electrode and the graphite electrode to a high-voltage DC power supply, and control the voltage to 1000V through a regulated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com