Wheel rake type mulching film strip collecting device and mulching film strip collecting type straw returning machine

A technology of collecting strips and mulching film, which is applied in the field of agricultural machinery, can solve problems such as high operating costs, many operating steps, and secondary pollution, and achieve the effects of easy packaging and collection, convenient use, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

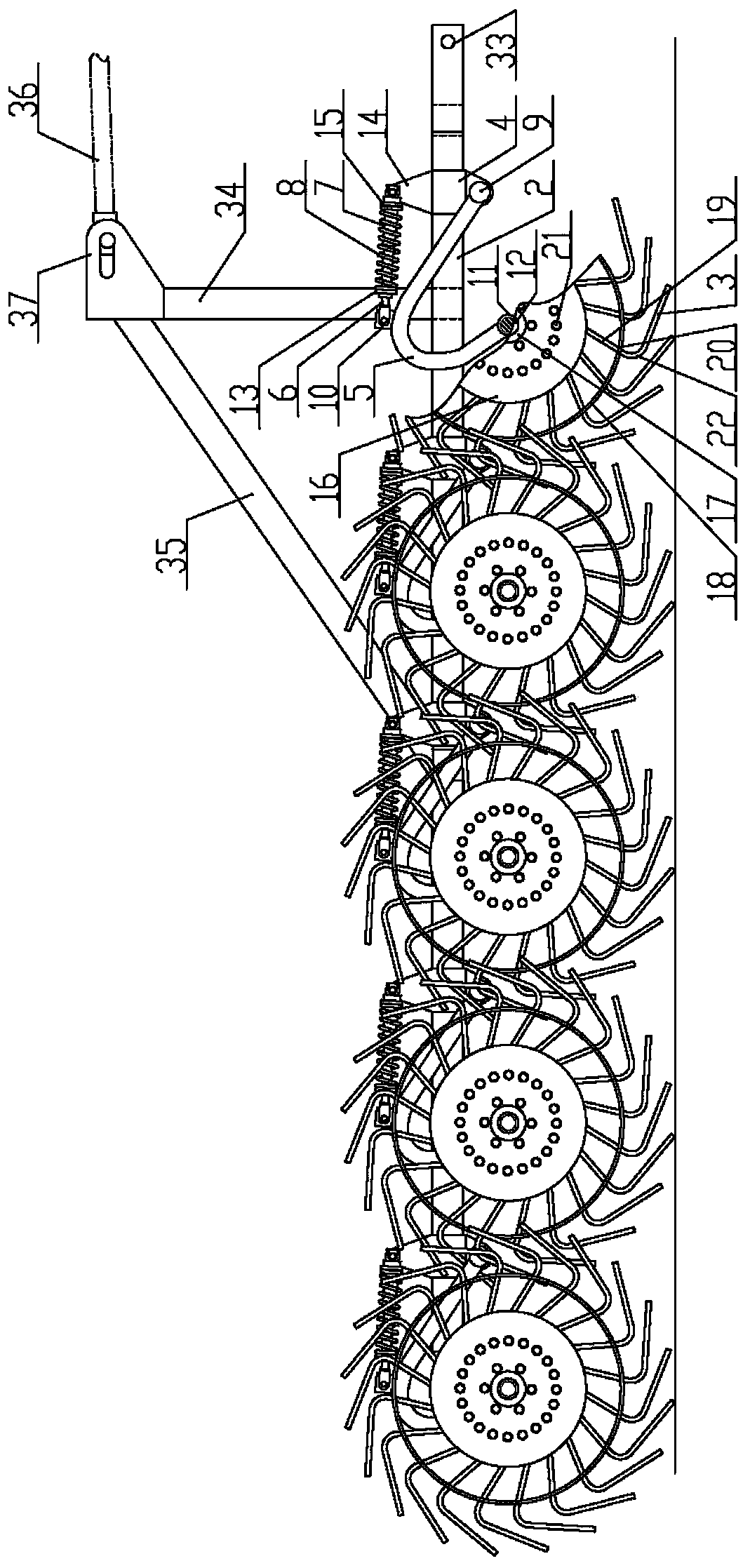

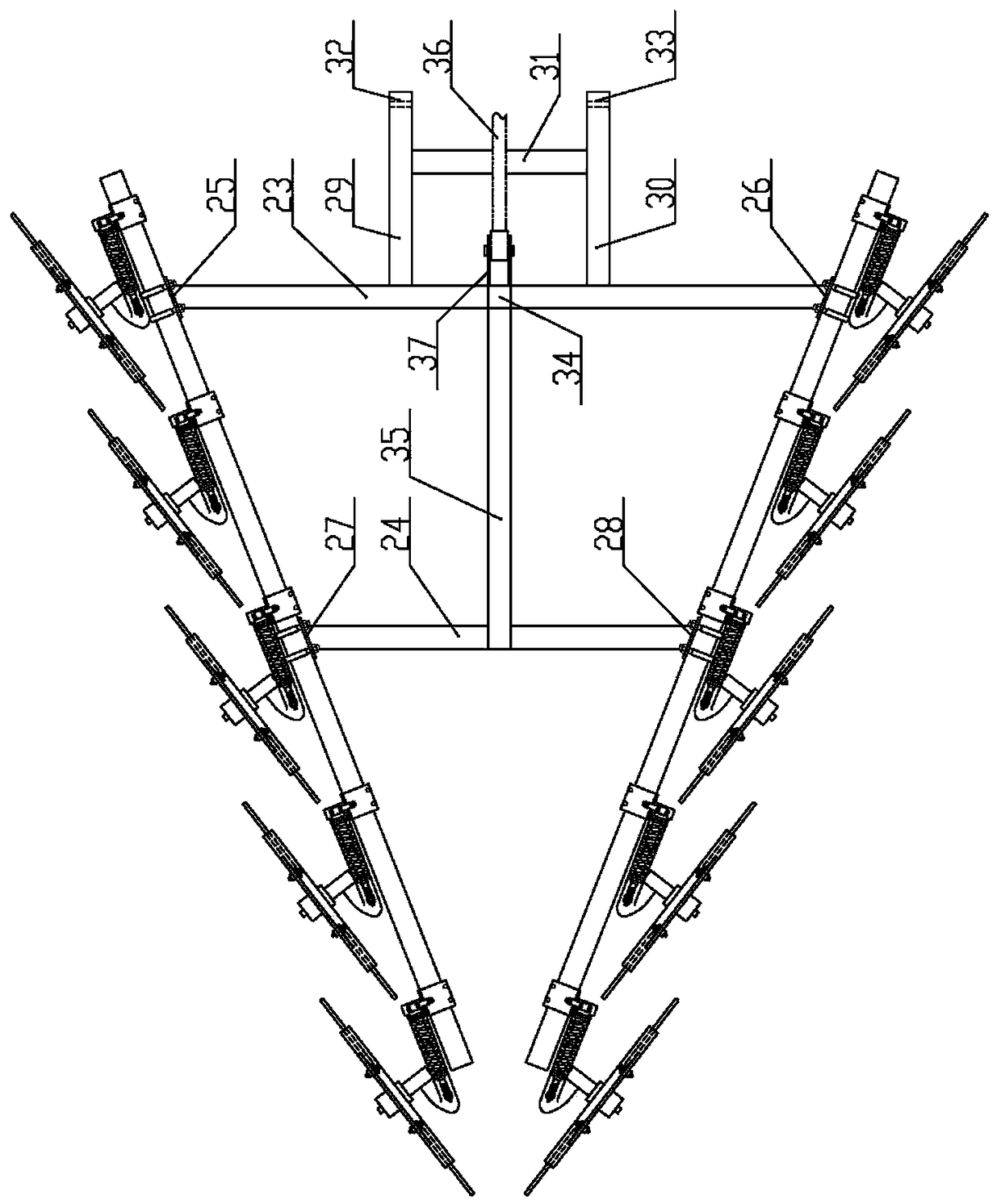

[0021] Embodiment 1: as figure 1 As shown in -2, the wheel-rake type plastic film collection device includes a collection frame and no less than a pair of rake wheel assemblies. The collection frame includes a left rack bar 1 and a right rack bar 2. Wheel and spring cantilever device, the outer circumference of the rake wheel is provided with the film spring teeth 3 that can hold up the mulch, and the left frame bar 1 and the right frame bar 2 are respectively equipped with a rake wheel through a spring cantilever device. The spring cantilever device can make the lower part of the raking wheel close to the ground and follow the undulations of the ground to realize profiling rolling. The left raking wheel is inclined along the left front, right and rear direction, and the right raking wheel is inclined along the right front, left and rear direction. The rake wheels on both sides are symmetrically arranged left and right, and the rake wheels on the left and right sides form a co...

Embodiment 2

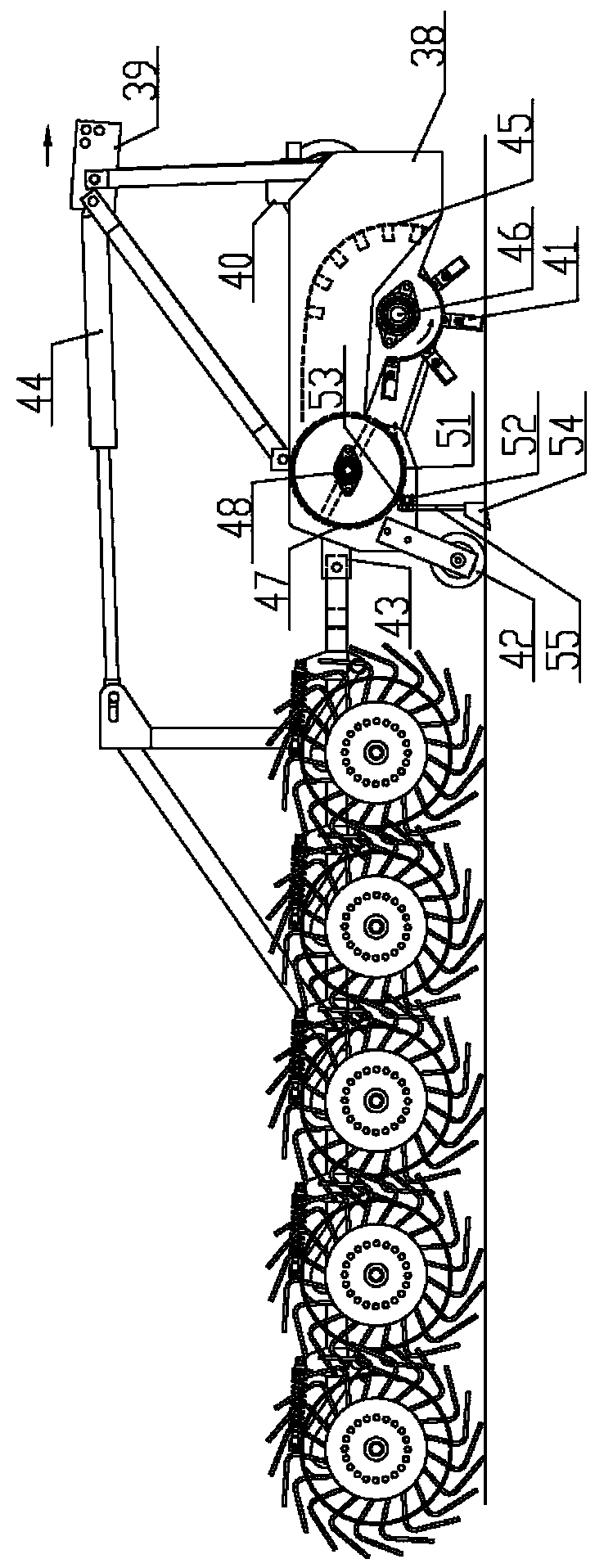

[0025] Embodiment 2: as image 3 As shown in -4, the plastic film collection strip returning machine using the wheel rake type plastic film collection strip device includes a field returning frame 38, a straw crushing device, an auger device and a wheel rake type plastic film collection strip device. The front end of the frame 38 is fixed with a traction frame 39, the front part of the field returning frame 38 is provided with a gearbox 40, the middle part of the field returning frame 38 is provided with a straw crushing device with a fan blade throwing knife device 41, and the straw crushing device rear The field frame 38 is provided with an auger device, and the wind blade throwing knife device 41 can smash the straw and send debris such as broken straw and fallen leaves on the mulch to the auger device, and the auger device can remove the broken straw and The sundries are transported to the furrows on the left and right sides of the film, and the limited depth roller 42 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com