Settling chamber for reclaiming residual naphthalene in synthesizing process of high-efficiency water reducing agent

A high-efficiency water-reducing agent and sedimentation chamber technology, applied in the field of recycling sedimentation chambers, can solve the problems of waste of naphthalene resources, air pollution, incomplete reaction of naphthalene, etc., and achieve the effects of improving the utilization rate of naphthalene, saving production costs, and achieving a remarkable recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

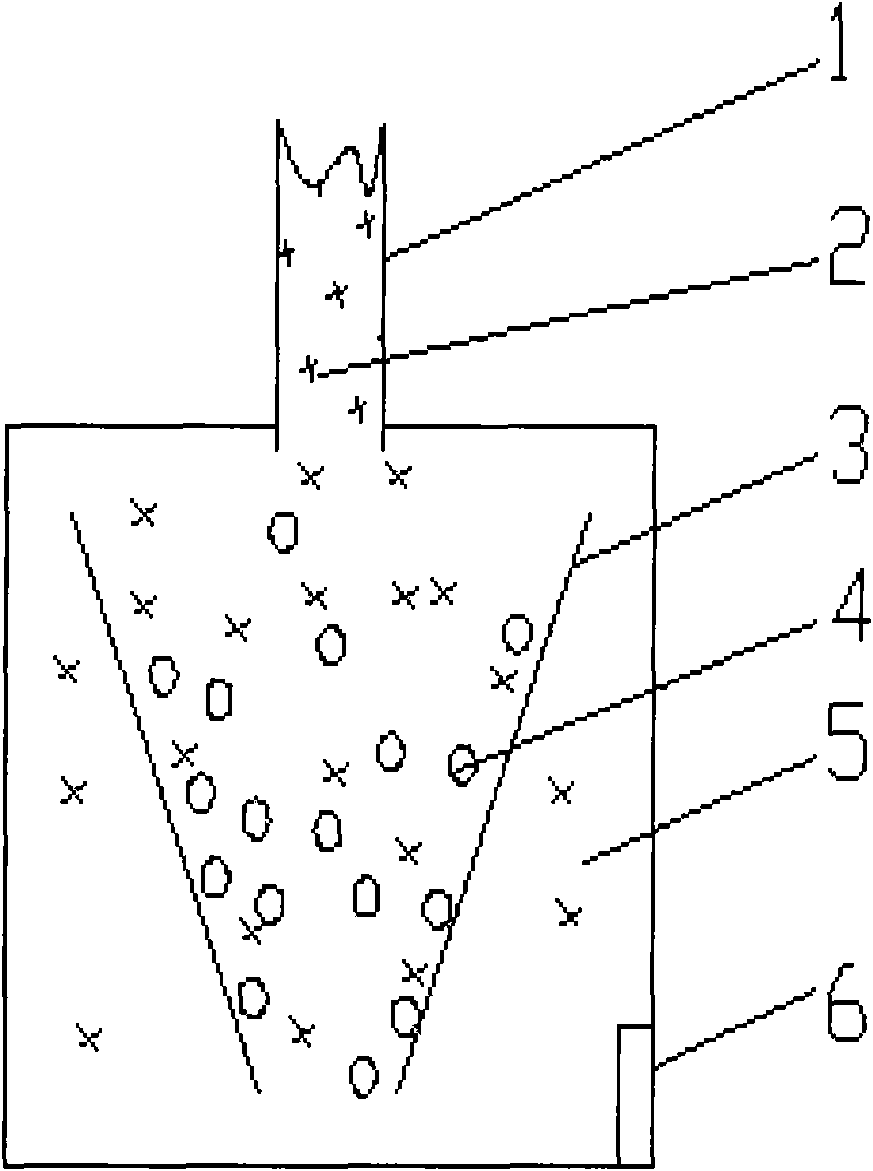

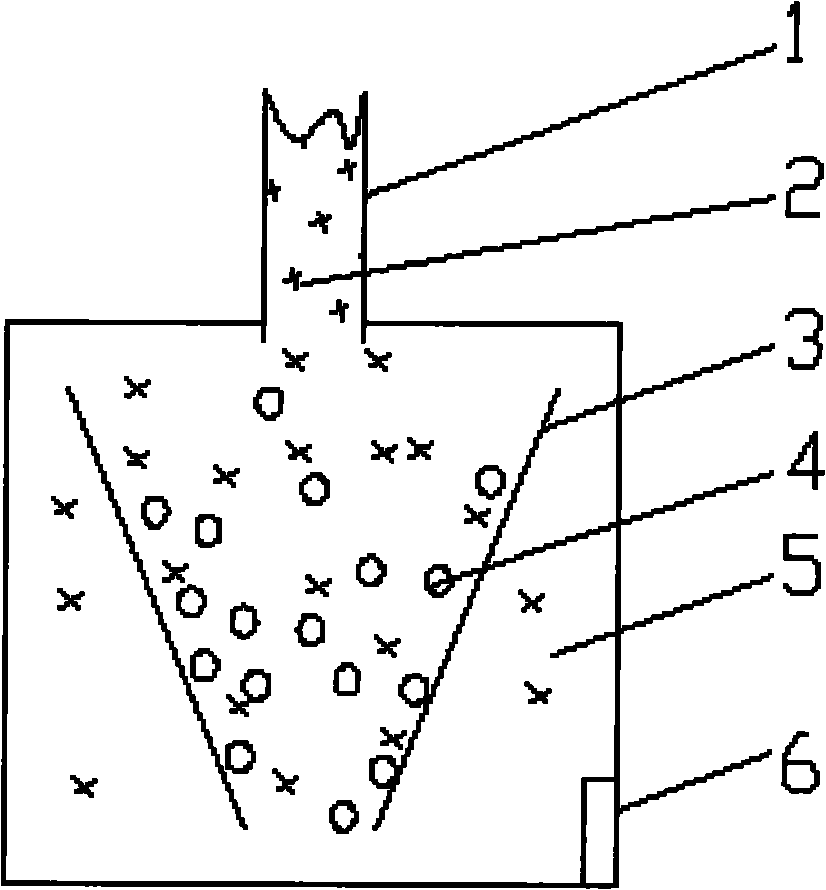

[0010] figure 1 The marks shown are as follows: pipeline 1, naphthalene steam 2, fan-shaped wall 3, solid naphthalene 4, naphthalene recovery settling chamber 5, small closed door 6

[0011] The bottom of the sulfonation reaction kettle is provided with a gas pipeline 1 connected to the naphthalene recovery settling chamber, and the residual naphthalene that has not been completely reacted in the sulfonation reaction enters the sulfonation reaction kettle with a temperature of 80-100 ° C through the pipeline in a gaseous state. The naphthalene recovery settling chamber 5 at 25°C and the pressure at normal pressure has a fan-shaped wall 3, and the naphthalene vapor 2 passes through the buffering effect of the fan-shaped wall 3, and the flow rate gradually decreases, and the temperature gradually decreases. After 3-5 hours, The naphthalene vapor crystallizes into solid naphthalene 4, which settles in the bottom space of the naphthalene recovery settling chamber.

[0012] The si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com