Improvement method for ink ribbon cartridge for ink-jet typewriter

An inkjet printer, ink cartridge technology, applied in printing and other directions, can solve problems such as affecting user efficiency, ink exhaustion, and unbearable ink cartridge economic expenditure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation details of the ink cartridge remanufacturing method of the present invention will be described in detail below with reference to the accompanying drawings.

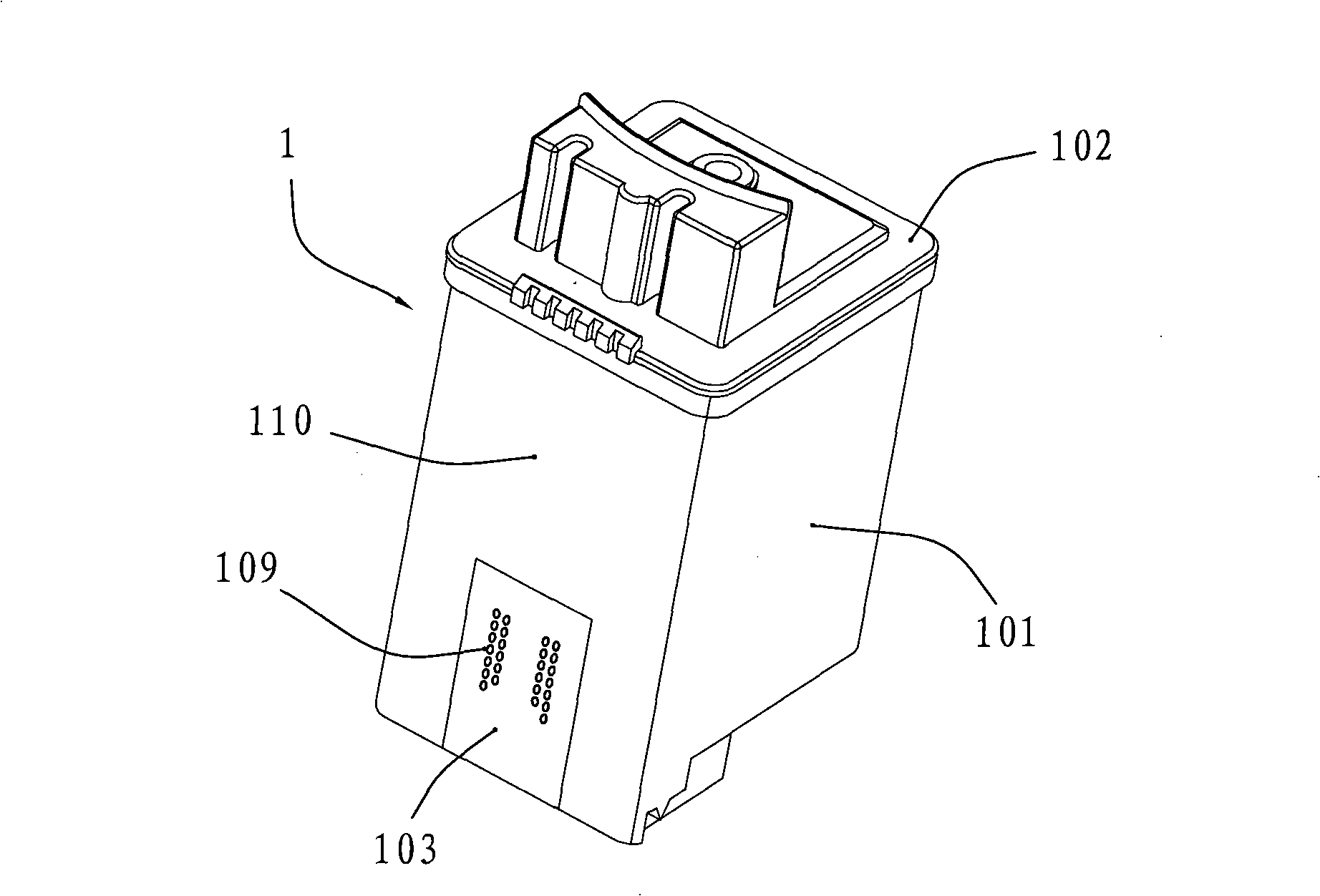

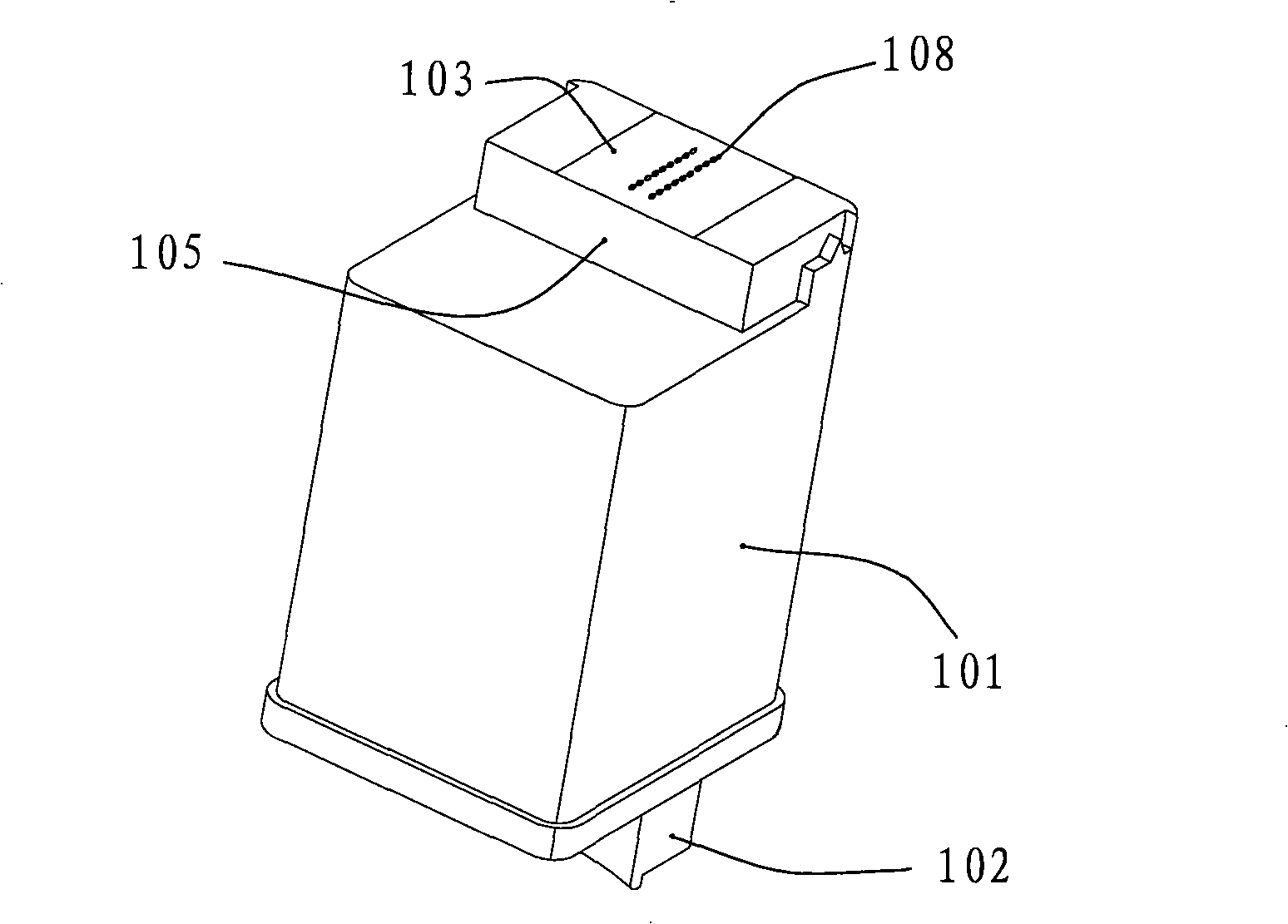

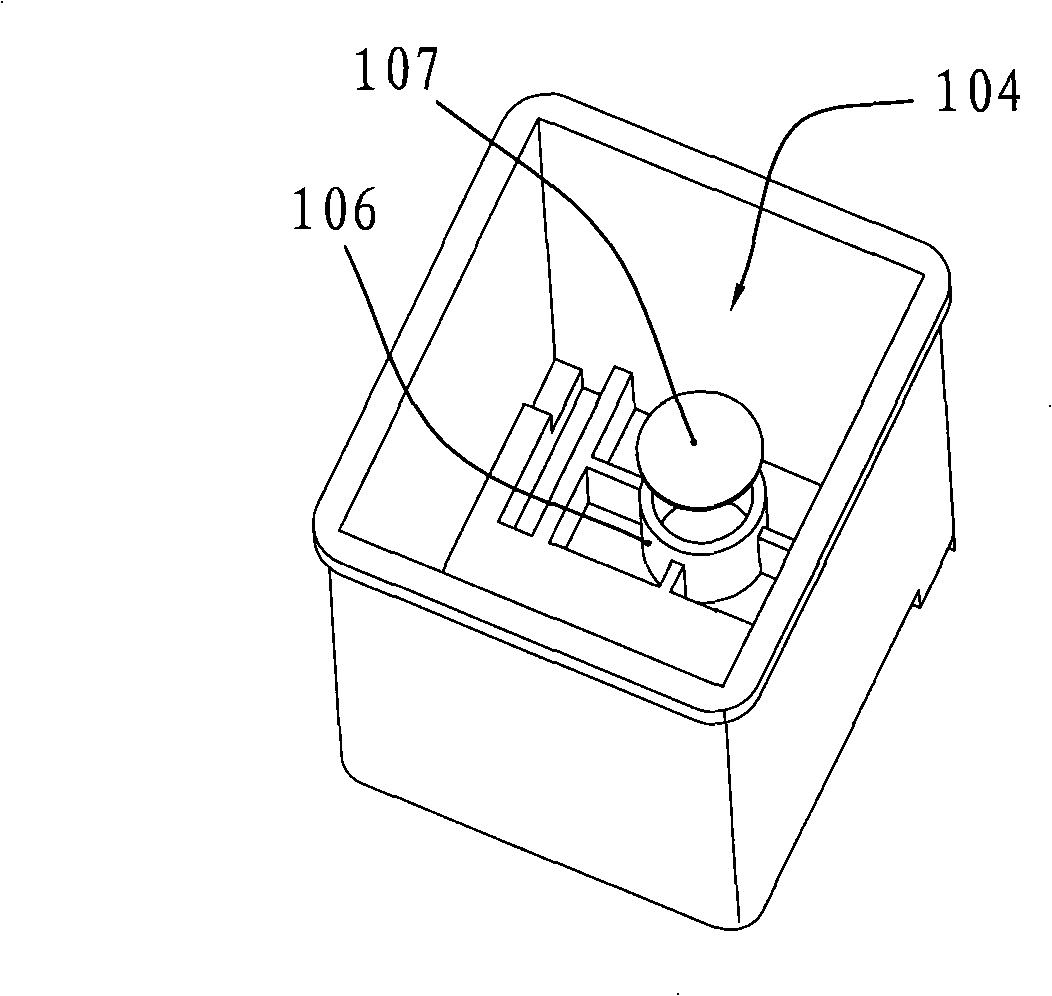

[0032] see Figure 4a , 4b, 5a, 5b, 6 are the structure of the ink-jet printer cartridge involved in the remanufacturing method of the present invention. The exterior shape of the ink cartridge 2 is basically a rectangular parallelepiped, which is formed by a plurality of side walls continuously connected and surrounded by each other. It includes a box body 201 , a box cover 202 , and a flexible printed circuit sheet 203 . The box body 201 can be prepared by injection molding of raw materials such as polyethylene and polyvinyl chloride, and inside it is a hollow ink storage cavity 204 for storing liquid such as ink. The bottom sidewall of the ink storage chamber 204 expands outwards to form a stepped platform 205 . The side of the platform 205 facing the ink storage chamber 204 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com