Natural rubber microbial deodorization processing technology

A technology for microbial deodorization and natural rubber, applied in the field of natural rubber microbial deodorization processing technology, can solve problems such as affecting workers' work mood and health, inability to achieve fast and high quality, and infeasibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

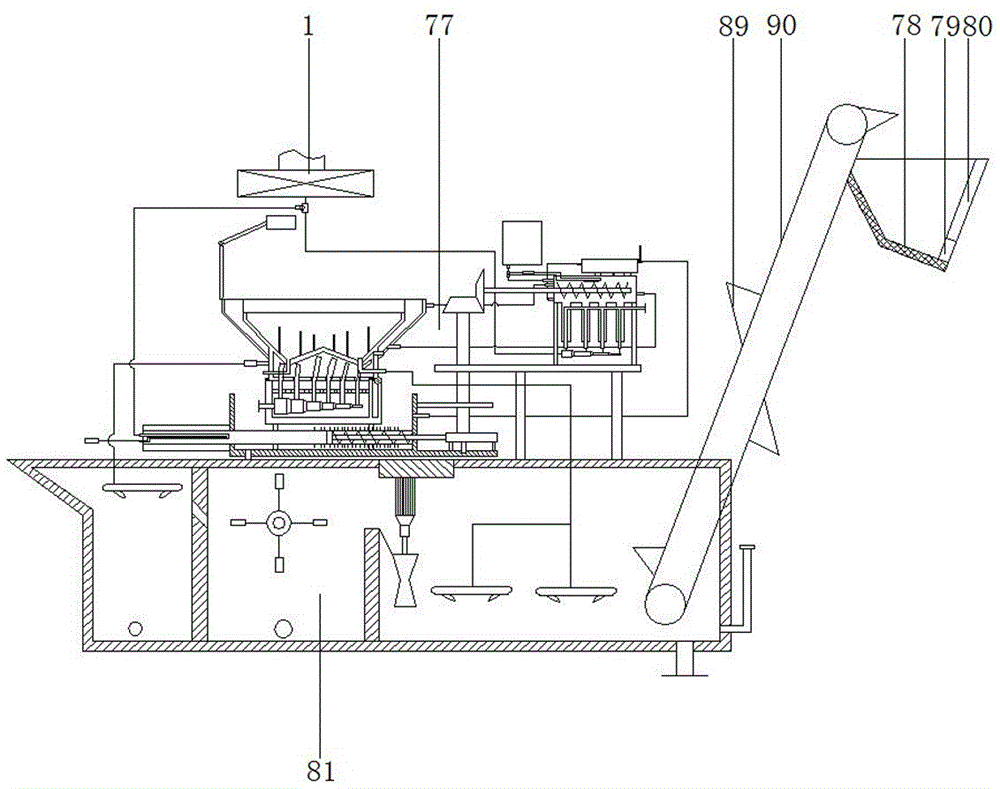

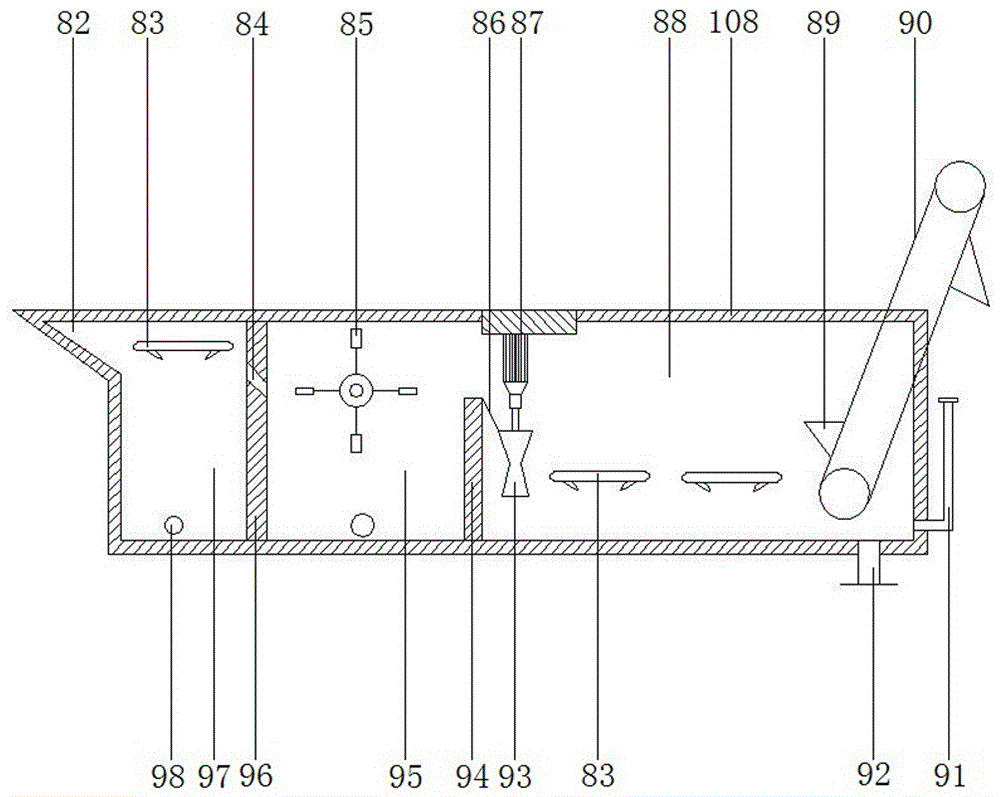

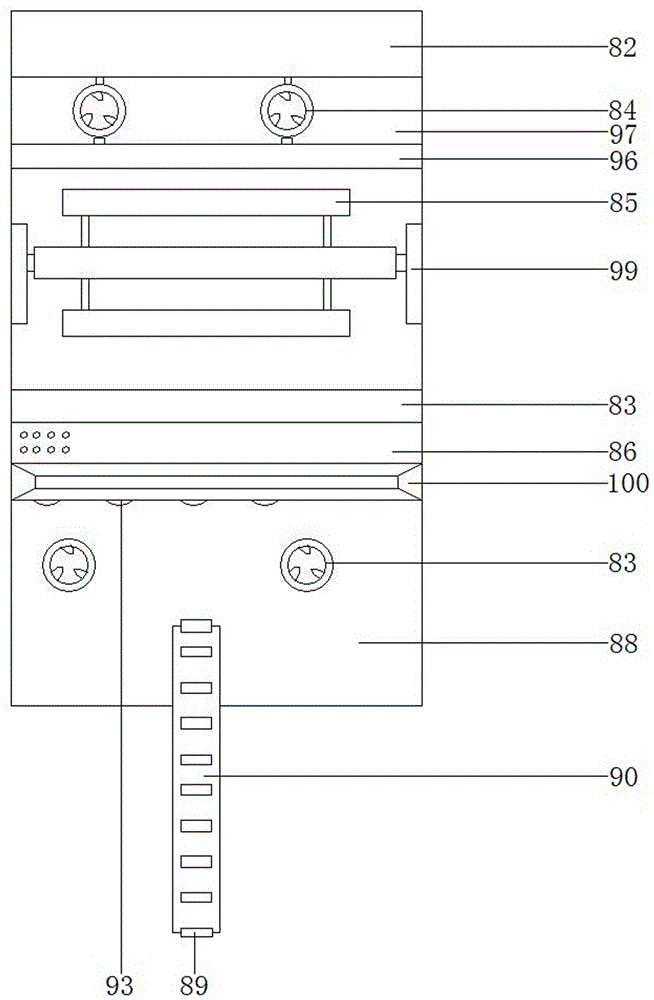

[0047] A natural rubber microbial deodorization processing technology, including, crushing, extrusion crushing, crimping, deodorizing symbiotic microbial liquid cleaning, granulation, drying, and packaging, is characterized in that the deodorizing symbiotic microbial liquid cleaning is The symbiotic flora cleaning solution cultivated in the corresponding structure of the deodorizing cleaning pool is injected into the corresponding structure of the deodorizing cleaning pool, and the creped natural rubber is cleaned and deodorized in the structure, and the secondary processed product is finally obtained through the above steps Odorless natural rubber.

[0048] As a further improvement of the present invention, the symbiotic flora cleaning solution mainly contains self-sufficient symbiotic flora, and the self-sufficient symbiotic flora consists of photosynthetic bacteria, acetic acid bacteria, lactic acid bacteria, yeasts, and actinomycetes, wherein the photosynthetic bacteria Th...

Embodiment 2

[0073] A natural rubber microbial deodorization processing technology, including, crushing, extrusion crushing, crimping, deodorizing symbiotic microbial liquid cleaning, granulation, drying, and packaging, is characterized in that the deodorizing symbiotic microbial liquid cleaning is The symbiotic flora cleaning solution cultivated in the corresponding structure of the deodorizing cleaning pool is injected into the corresponding structure of the deodorizing cleaning pool, and the creped natural rubber is cleaned and deodorized in the structure, and the secondary processed product is finally obtained through the above steps Odorless natural rubber.

[0074]As a further improvement of the present invention, the symbiotic flora cleaning solution mainly contains self-sufficient symbiotic flora, and the self-sufficient symbiotic flora consists of photosynthetic bacteria, acetic acid bacteria, lactic acid bacteria, yeasts, and actinomycetes, wherein the photosynthetic bacteria The...

Embodiment 3

[0088] A natural rubber microbial deodorization processing technology, including, crushing, extrusion crushing, crimping, deodorizing symbiotic microbial liquid cleaning, granulation, drying, and packaging, is characterized in that the deodorizing symbiotic microbial liquid cleaning is The symbiotic flora cleaning solution cultivated in the corresponding structure of the deodorizing cleaning pool is injected into the corresponding structure of the deodorizing cleaning pool, and the creped natural rubber is cleaned and deodorized in the structure, and the secondary processed product is finally obtained through the above steps Odorless natural rubber.

[0089] As a further improvement of the present invention, the symbiotic flora cleaning solution mainly contains self-sufficient symbiotic flora, and the self-sufficient symbiotic flora consists of photosynthetic bacteria, acetic acid bacteria, lactic acid bacteria, yeasts, and actinomycetes, wherein the photosynthetic bacteria Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com