A kind of preparation method of micron polymer hollow microsphere

A technology of hollow microspheres and polymers, which is applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of inability to apply biological materials and medical materials, and achieve the effects of avoiding extreme instability, simple raw materials, and less harmful residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of the present invention is as follows:

[0023] Step 1: Mix 10 parts of polyether and 15-20 parts of polyisocyanate evenly, heat up to 50-70°C, and react for 20-30 minutes to obtain a mixture of polyurethane and isocyanate;

[0024] Step 2, cooling the mixture obtained in Step 1, stirring evenly with water of 9 to 10 times the mass of the mixture to obtain an emulsion;

[0025] Step 3, using liquid nitrogen to cool the emulsion obtained in Step 2 to obtain an ice cube solid;

[0026] Step 4, vacuum-dry the ice cube-shaped solid obtained in Step 3 at a drying pressure of 5-10 Pa, and obtain hollow microspheres after drying.

[0027] In step 1, the polyether is a polyethylene glycol ether with an average relative molecular weight of 350-450 g / mol, one end is a hydroxyl group, and the other end is an inactive alkyl group.

[0028] In step 1, the polyisocyanate is an isocyanate containing more than two isocyanate groups, which is isophorone diisocy...

Embodiment 1

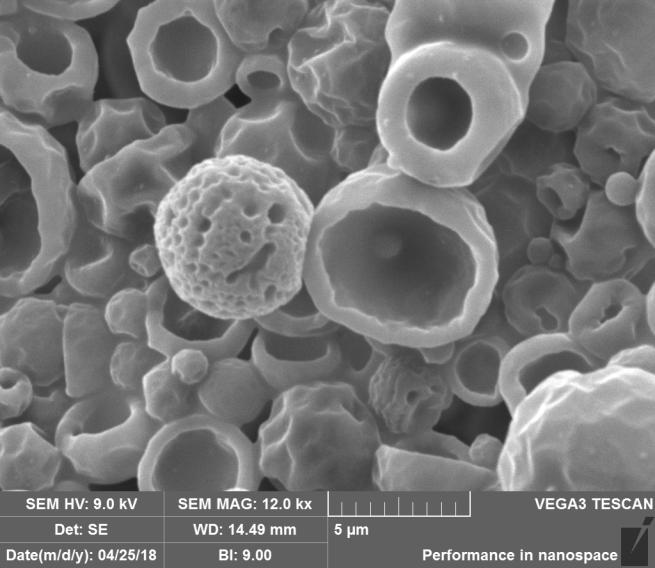

[0032] Weigh 15 parts of hexamethylene diisocyanate HDI and 10 parts of polyethylene glycol ether, wherein the average relative molecular mass of polyethylene glycol ether is 350g / mol, one end of the polyether is a hydroxyl group, and one end is a methyl group. Mix well and react at 60°C for 30 minutes. The resulting mixture was cooled to room temperature, 225 g of water was added, and stirred to form an emulsion. The emulsion was rapidly cooled to a solid with liquid nitrogen. The obtained solid was placed in a vacuum desiccator, and the pressure was set at 5 Pa. After 24 hours of drying, the obtained solid was polymer hollow microspheres. The diameter of the microsphere is 1~5μm, and the thickness of the shell is 300~500nm, such as figure 1 shown.

Embodiment 2

[0034] Weigh 20g of isophorone diisocyanate IPDI and 10g of polyethylene glycol ether, wherein the average relative molecular weight of polyethylene glycol ether is 450g / mol, one end of the polyether is a hydroxyl group, and the other end is an ethyl group, mix the two evenly React at 60°C for 30 minutes. The resulting mixture was cooled to room temperature, 300 g of water was added, and stirred to form an emulsion. The emulsion was rapidly cooled to a solid with liquid nitrogen. The obtained solid was placed in a vacuum desiccator, and the pressure was set at 5 Pa. After 30 hours of drying, the obtained solid was polymer hollow microspheres. The diameter of the microsphere is 1~10μm, and the shell thickness is 200~600nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com