Seamless wrapper belt and manufacture method thereof

A roll-assist, seamless technology, applied in chemical instruments and methods, conveyors, transportation and packaging, etc., can solve the problems of poor shape stability, joint fracture, unstable joint strength, etc., to meet the surface, meet the personalized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

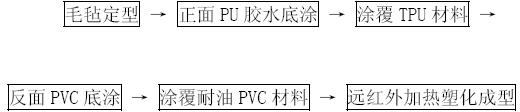

Method used

Image

Examples

Embodiment Construction

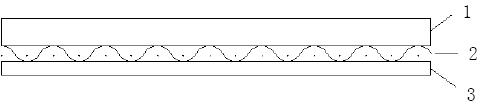

[0037] see figure 1 As shown in the schematic cross-sectional structure of the present invention, a seamless coiler belt is used to wrap cold-rolled metal sheets, such as steel plates or aluminum plates, wherein the coiler belt is made of endless polyester fabric felt 2 It is a skeleton material, and the front side of the skeleton material is a TPU material layer 1, and the reverse side is an oil-resistant PVC material layer 3.

[0038] The base fabric of the polyester fabric felt is ultra-low shrinkage polyester multifilament in the warp direction and polyester yarn in the weft direction, and the structure is a plain weave structure with one up and one down. , the needle-punched yarn is polyester yarn.

[0039] The Shore hardness of the thermoplastic polyurethane elastomer material is 88-90A.

[0040] The formula of the oil-resistant polyvinyl chloride layer includes the following components in parts by weight:

[0041] 100 parts by weight of polyvinyl chloride paste resin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com