Three component polyurethane binder system

A technology of adhesives and organic adhesives, applied in polyurea/polyurethane adhesives, non-polymer adhesive additives, adhesive types, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

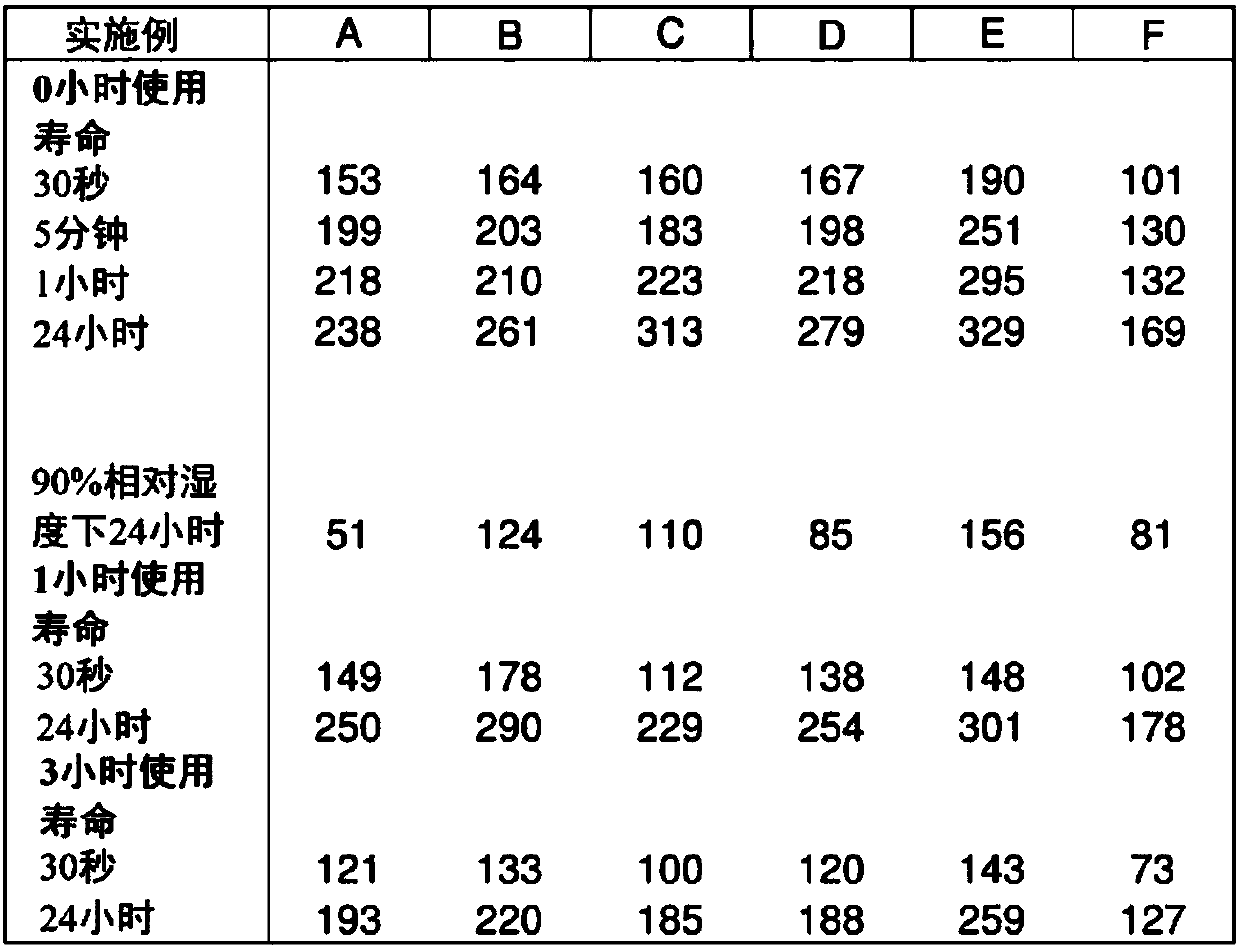

Examples

Embodiment Construction

[0014] One solution to these mold performance problems was clearly found in an adhesive composition that uses a three-component approach to provide a polyurethane cold box (PUCB) adhesive system. In such a system, the Part I component includes the polyol base resin and a suitable set of supplements, the Part II component includes the polyisocyanate with a suitable set of supplements, and the Part III component includes the alkyl silicate Compounds such as tetraethyl orthosilicate (TEOS), alkyl silicate oligomers, and optionally aminosilanes.

[0015] TEOS, also known as tetraethoxysilane, is also identified by CAS registry number 78-10-4. Structurally, it has four ethyl groups attached to the oxygen atoms in the orthosilicate core. 99.999% pure TEOS is commercially available from Sigma-Aldrich and other sources.

[0016] Bipedalaminosilanes are characterized by the following general structure:

[0017] (R 1 O) 3 -Si-R 2 -NH-R 2 -Si-(OR 1 ) 3

[0018] where R 1 is an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com