Reclaimed water recycling technology used for metal industrial cooling system

A cooling system and cooling water technology, applied in metallurgical wastewater treatment, water pollutants, water/sewage multi-stage treatment, etc., can solve the problems of inability to remove metal ions, complex removal steps, single removal of metal ions, etc., and achieve recycling The effect of reducing, reducing damage, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

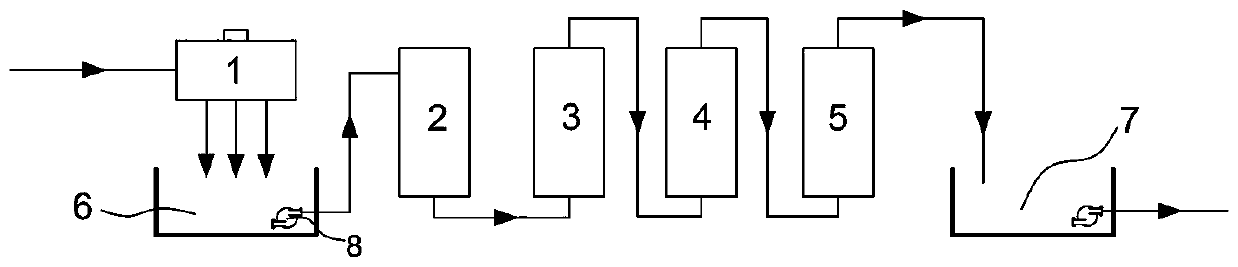

[0027] The present invention is a reclaimed water reuse process for cooling systems in the metal industry, specifically passing the cooling water through a cooling tower 1, a bag filter 2, a manganese sand filter 3, a mixed bed 4, and a chelating resin bed 5 , step by step to remove the iron ions, calcium ions, and magnesium ions in the cooling water, and also filter out the suspended solids and particulate matter in the cooling water, so as to obtain the cooling water that meets the reuse standard.

[0028] Since the cooling water in the production area of the metal industry passes through the production area and takes away the heat of the equipment and metal products, its own temperature is relatively high. The principle of water heat exchange, the heat in the cooling water is taken away through the air to realize the condition of cooling water for reuse. A cooling pool 6 can be set under the cooling tower 1, which can better hold the cooling water after cooling treatment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com