Settling basin for treating high-concentration heavy metal industrial wastewater

A technology for industrial sewage and sedimentation tanks, applied in the field of sedimentation tanks, can solve the problems of easy corrosion and wear of mud scrapers, secondary pollution of water quality, high content of heavy metals, etc., and achieve the effects of inhibiting algae growth, avoiding corrosion, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

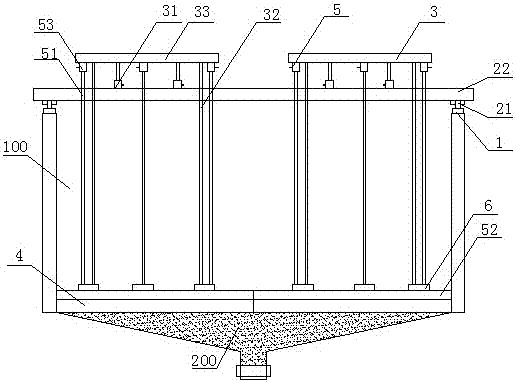

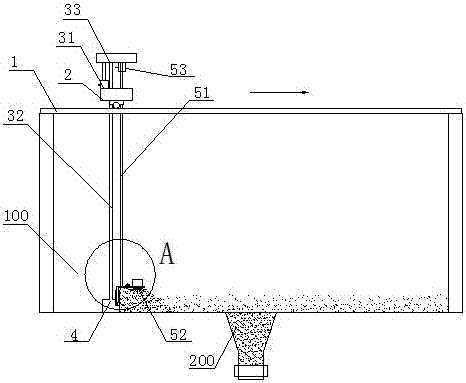

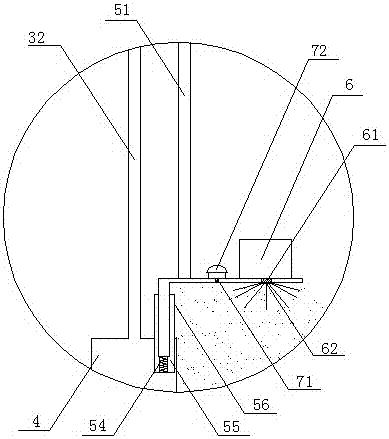

[0024] like figure 1 , figure 2 , image 3 As shown, a settling tank for treating high-concentration heavy metal industrial sewage, a mud scraper is installed on the wall of the settling tank 100, and a sewage outlet 200 is provided at the bottom of the settling tank. The mud scraper includes a track 1, a walking device 2, a lifting mechanism 3, a mud scraper 4, and an anti-lift device 5. The track is arranged on the side wall of the top of the sedimentation tank, and the walking device is arranged on the track. The track 1 includes two that are arranged in parallel.

[0025] The traveling device comprises walking wheels 21, connecting bridges 22 connected to the walking wheels; the lifting mechanism comprises lifting cylinders 31, fixed rods 32, and lifting bridges 33; The other end is connected to the mud scraper, and the anti-lift device includes an anti-lift column 51 and an L-shaped anti-lift plate 52; one end of the anti-lift column is connected to the lifting bridge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com