Compound tailing slag microcrystal glass and preparation method thereof

A technology of glass-ceramic and tailings slag, which is applied in the field of composite tailings-slag glass-ceramic and its preparation, can solve the problems of difficulty in large-scale popularization and application, low product added value, low utilization rate of tailings slag, etc. Good abrasion resistance and thermal stability, the effect of eliminating harm to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

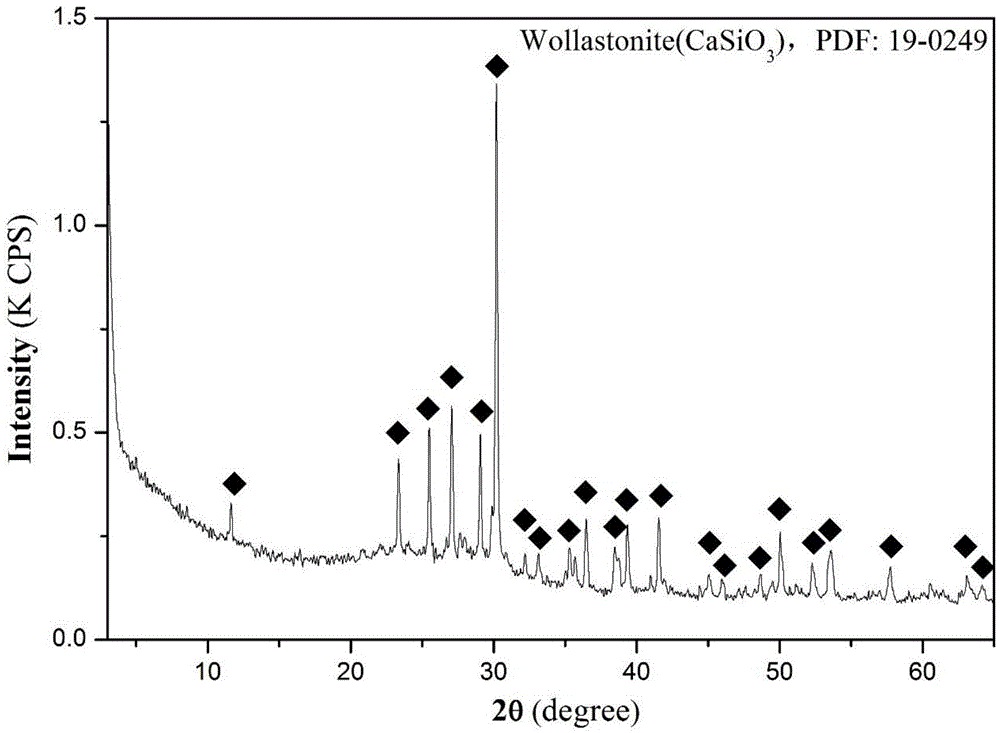

Image

Examples

Embodiment 1

[0024] A composite tailings slag glass-ceramic prepared by the following method:

[0025] (1) Weigh raw materials according to the distribution ratio of each component: 30 parts of electrolytic manganese slag, 20 parts of lead-zinc flotation tailings, 30 parts of quartz sand, 20 parts of feldspar; after mixing evenly, obtain glass raw material;

[0026] (2) Melt the glass raw material into glass liquid at high temperature, the melting temperature is 1350°C, and the melting time is 2 hours; then it is poured into water and quenched into glass particles, and then the glass particles are dried, crushed, ground, and passed through 60 After being sieved with square holes, it is laid flat into a refractory mold to form, with a thickness of 10-40mm;

[0027] (3) Put the shaped glass particles into the kiln, raise the temperature to 900°C at a heating rate of 5-8°C / min, keep it warm for 1 hour for sintering and nucleation treatment, and then raise the temperature at a heating rate of ...

Embodiment 2

[0029] A composite tailings slag glass-ceramic prepared by the following method:

[0030] (1) Weigh raw materials according to the distribution ratio of each component: 60 parts of electrolytic manganese slag, 7 parts of lead-zinc flotation tailings, 20 parts of quartz sand, 13 parts of feldspar; after mixing evenly, obtain glass raw material;

[0031] (2) Melt the glass raw material into glass liquid at high temperature, the melting temperature is 1400°C, and the melting time is 1h; then pour it into water and quench it into glass particles, then dry the glass particles, crush them, grind them finely, and pass them through 200 After being sieved with square holes, it is laid flat into a refractory mold to form, with a thickness of 10-40mm;

[0032] (3) Put the formed glass into the kiln, raise the temperature to 760°C at a heating rate of 5-8°C / min, keep it warm for 2 hours for sintering and nucleation treatment, and then raise the temperature to 760°C at a heating rate of 3-...

Embodiment 3

[0034] A composite tailings slag glass-ceramic prepared by the following method:

[0035] (1) Weigh raw materials according to the distribution ratio of each component: 90 parts of electrolytic manganese slag, 5 parts of lead-zinc flotation tailings, 5 parts of quartz sand, 0 part of feldspar; after mixing evenly, obtain glass raw material;

[0036] (2) Melt the glass raw materials into molten glass at a high temperature, the melting temperature is 1350°C, and the melting time is 2 hours; then it is poured into water and quenched into glass particles, and then the glass particles are dried, crushed, ground, and passed through 100 After being sieved with square holes, it is laid flat into a refractory mold to form, with a thickness of 10-40mm;

[0037] (3) Put the formed glass into the kiln, raise the temperature to 850°C at a heating rate of 5-8°C / min, keep it warm for 1 hour for sintering and nucleation treatment, and then raise the temperature to 850°C at a heating rate of 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com