Centrifugal concentrator

A concentrator and centrifugal technology, applied in centrifuges, centrifuges with rotating drums, solid separation, etc., can solve the problems of screw and outer cone wear, design complexity, defects, etc., and achieve simplified design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

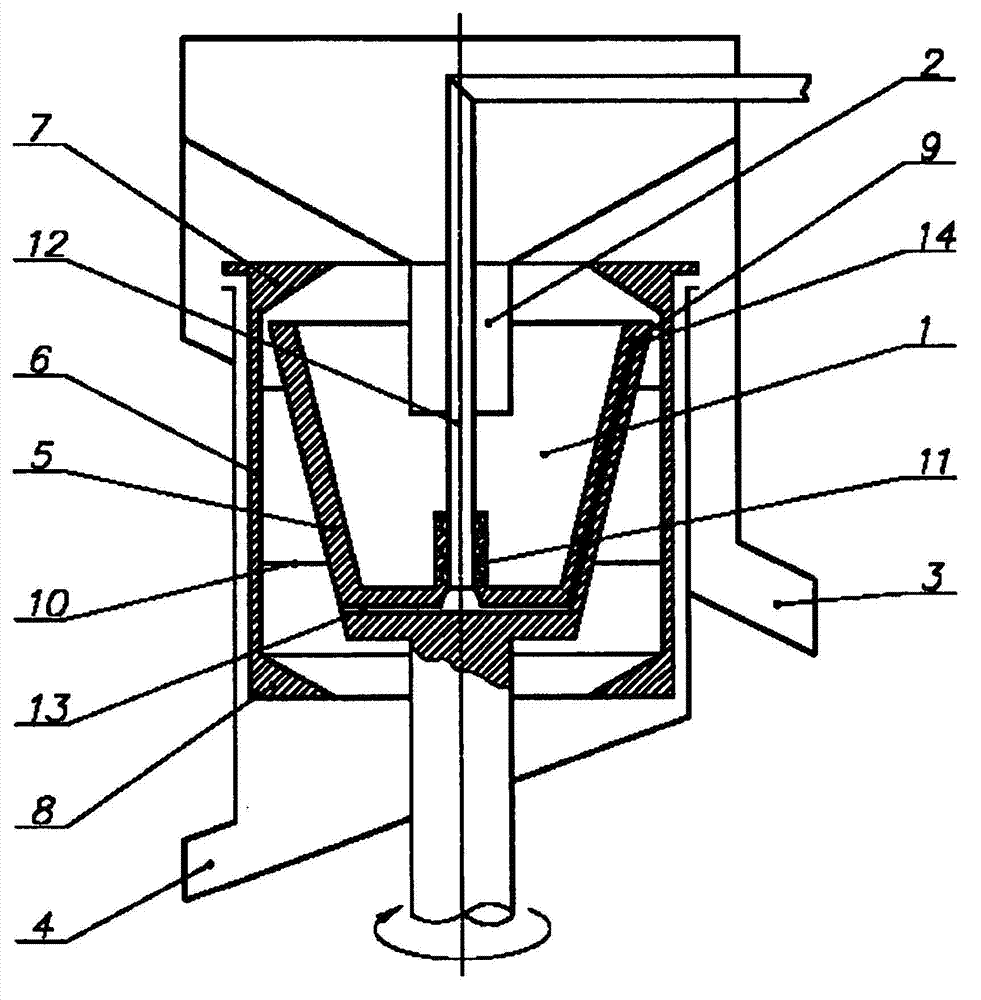

[0018] The concentrator operates as follows:

[0019] Raw material in the form of a slurry is pumped through the supply sleeve 2 into the rotor to the bottom of the cone 5 . Centrifugal force forces the slurry to be ejected against the walls of the cone and as it moves towards the boundary 7 the slurry is separated into layers. The heavy mineral deposits on the inner surface of the cone 5, slides towards the slot 9, and enters the casing 6 from which the slurry is flushed out of the casing at the boundary 8 by the flow exiting the tube 12 into the heavy debris collector 4 . Light debris flows over boundary 7 into receiver 3 . The inner diameter of border 8 may be equal to or smaller than the inner diameter of border 7 . The diameter length depends on the position of the rotor axis, the magnitude of the centrifugal force, and the mineral composition of the raw material. The outflow of heavy fragments of fixed inner diameter with boundary 8 is varied by the water flow fed th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com