Comprehensive recycling method for leaching residues in electrolytic manganese metal production

A technology for electrolytic manganese metal and leaching slag, which is applied in the direction of manganese compounds, non-metallic elements, chemical instruments and methods, etc., and can solve the problems of wasting useful resources of slag and not being able to effectively recover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

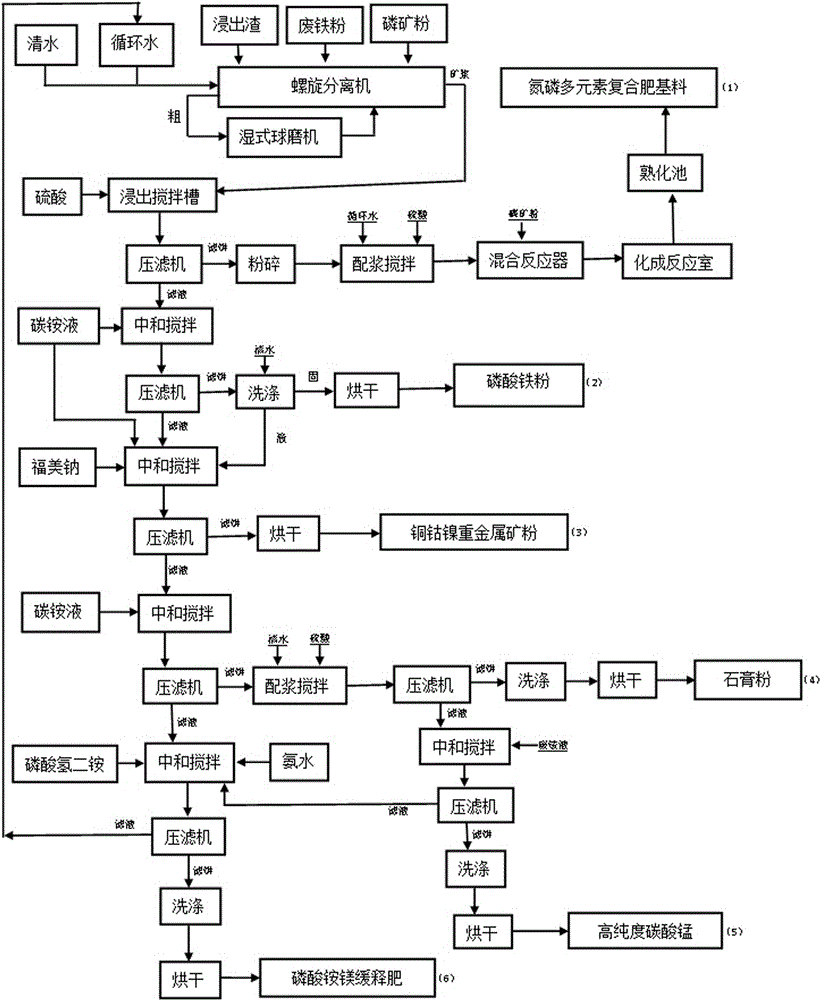

Method used

Image

Examples

Embodiment 1

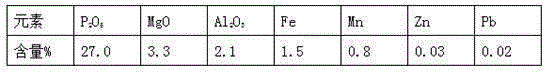

[0099] 1. Select 1000Kg of electrolytic manganese metal leaching slag from Daxin Manganese Industry Co., Ltd. of CITIC Dameng Daxin Branch, and its main element content is shown in Table 1

[0100] Table 1 Contents of main elements in leaching slag

[0101]

[0102] 2. Scrap iron powder was purchased from an iron powder factory in Guangdong, and the Fe content was 88%;

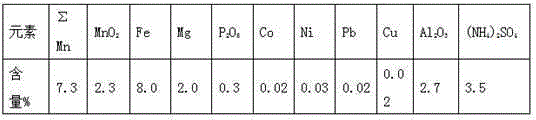

[0103] 3. Phosphate rock powder was purchased from a phosphate mine in Yunnan, and its main element content is shown in Table 2:

[0104] Table 2 Contents of main elements in phosphate rock powder

[0105]

[0106] 4. Industrial-grade concentrated sulfuric acid, purchased from a sulfuric acid factory in Nanning, with a concentration of 98%;

[0107] 5. Industrial grade ammonia water, purchased from a chemical factory in Nanning, with a concentration of 25%;

[0108] 6. Agricultural grade ammonium bicarbonate, purchased from a nitrogen fertilizer factory in Nanning, with a content of 99.2%;

[0109]...

Embodiment 2

[0139] 1. Select 1500Kg of electrolytic metal manganese leaching slag from Daxin Manganese Industry Co., Ltd. of CITIC Dameng Daxin Branch, and its main element content is shown in Table 1

[0140] Table 1 Contents of main elements in leaching slag

[0141]

[0142] 2. Scrap iron powder was purchased from an iron powder factory in Guangdong, and the Fe content was 88%;

[0143] 3. Phosphate rock powder was purchased from a phosphate mine in Yunnan, and its main element content is shown in Table 2:

[0144] Table 2 Contents of main elements in phosphate rock powder

[0145]

[0146] 4. Industrial-grade concentrated sulfuric acid, purchased from a sulfuric acid factory in Nanning, with a concentration of 98%;

[0147] 5. Industrial grade ammonia water, purchased from a chemical factory in Nanning, with a concentration of 25%;

[0148] 6. Agricultural grade ammonium bicarbonate, purchased from a nitrogen fertilizer factory in Nanning, with a content of 99.2%;

[0149]...

Embodiment 3

[0179] 1. Select 1000Kg of electrolytic manganese leaching slag from Sanmanganlong Manganese Industry Co., Ltd., Daxin County, Guangxi, and its main element content is shown in Table 1

[0180] Table 1 Contents of main elements in leaching slag

[0181]

[0182] 2. Scrap iron powder was purchased from an iron powder factory in Guangdong, and the Fe content was 88%;

[0183] 3. Phosphate rock powder was purchased from a phosphate mine in Yunnan, and its main element content is shown in Table 2:

[0184] Table 2 Contents of main elements in phosphate rock powder

[0185]

[0186] 4. Industrial-grade concentrated sulfuric acid, purchased from a sulfuric acid factory in Nanning, with a concentration of 98%;

[0187] 5. Industrial grade ammonia water, purchased from a chemical factory in Nanning, with a concentration of 25%;

[0188] 6. Agricultural grade ammonium bicarbonate, purchased from a nitrogen fertilizer factory in Nanning, with a content of 99.2%;

[0189] 7. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com