Process of electron beam cold bed furnace for recycling and remelting TC11 scraps

An electron beam cooling bed furnace, TC11 technology, applied in the field of titanium alloy ingot preparation, can solve problems such as difficulty in the amount and method of adding Al element, volatilization loss of Al element, and chemical composition cannot meet the standard, etc., to solve the problem of Al element The amount of addition is difficult to control, easy to operate, and the effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

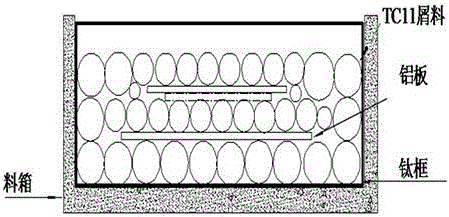

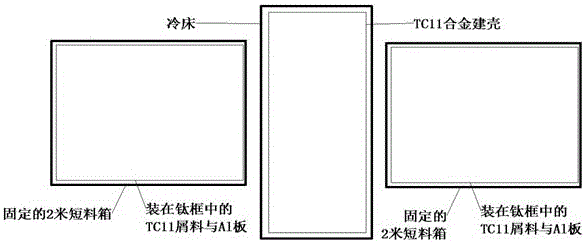

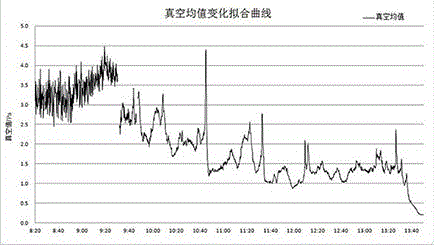

[0038] A process for recovering and remelting TC11 shavings in an electron beam cooling hearth furnace, comprising the following process: material preparation→titanium frame welding→cutting of Al plates→swinging materials→drying→smelting in the furnace. The process steps include: Step 1: Combined with the size of the material box, select a thin titanium plate to weld a titanium frame and weigh it; Step 2: According to the bulk density of the TC11 scrap, estimate the weight of the TC11 scrap that can be contained in the titanium frame, and calculate Add the amount of Al plate and cut it according to the requirements; Step 3: Put the TC11 scraps and Al plates into the titanium frame, and dry the material; Step 4: Send the dried material into the electron beam cooling bed Furnace for smelting, one smelting to get TC11 titanium alloy.

[0039] Further, the welding of the titanium frame in step 1 includes the following steps:

[0040] Step 11: Select a titanium plate with a purity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com