Metal industry installation and method for tracking a vessel, in particular a metallurgical vessel

A technology for industrial facilities and metals, applied in the direction of lighting and heating equipment, improvement of process efficiency, furnace control devices, etc., can solve problems such as high-cost failure effects, and achieve the effects of simplified condition monitoring, low maintenance work, and fast facility costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] While the invention has been more particularly illustrated and described by means of preferred exemplary embodiments, the invention is not limited to the disclosed examples. A person skilled in the art will be able to deduce variations from these examples without departing from the scope of protection of the invention, as defined by the following patent claims.

[0033] The present invention relates to a wireless data connection of the tracking position of a tracking system used within a plant to track metallurgical vessels.

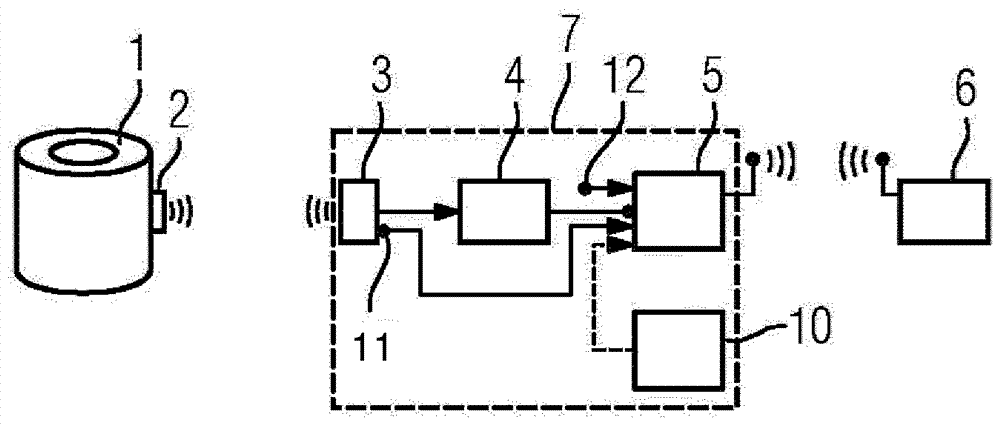

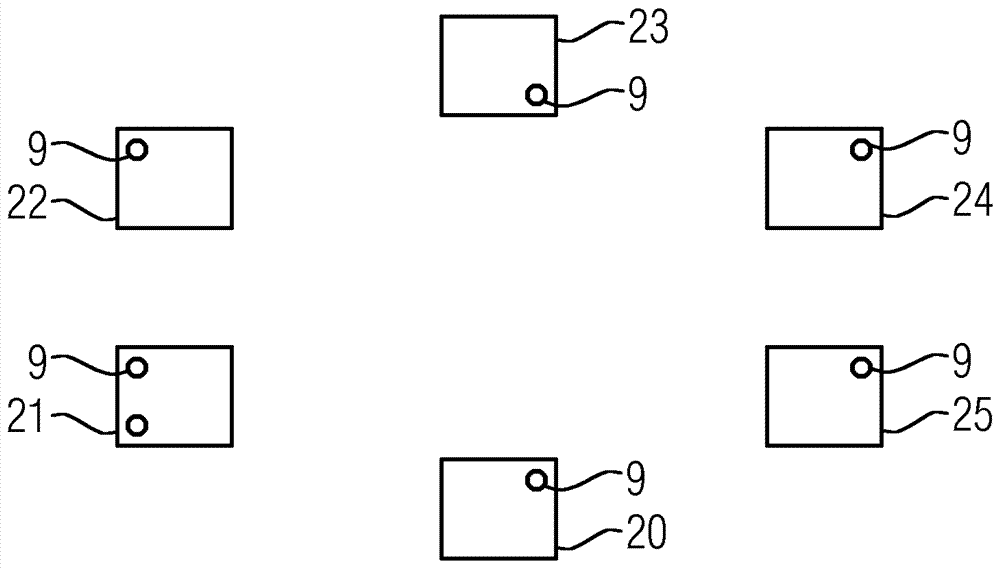

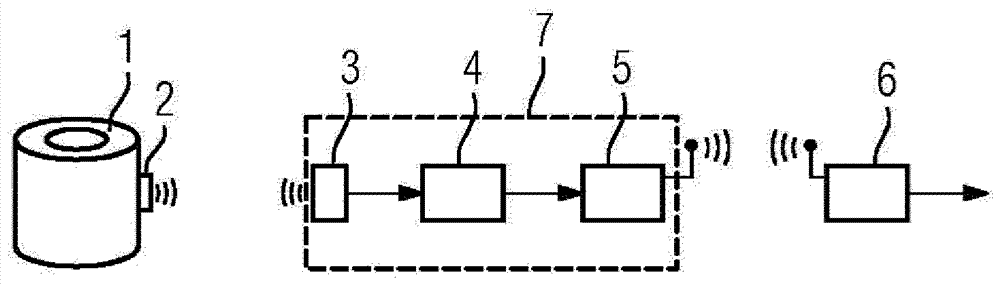

[0034] figure 1 The installation according to the invention is schematically shown. In order to track metallurgical containers, the container 1 is usually equipped with a transponder 2 . The transponder 2 can be firmly or releasably connected to the container 1 . The so-called tracking position 9 ( Figure 5 ) at various locations within the plant (however, locations off-site are also conceivable). In this case, track position 9 ( Figure 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com