Method for upsetting high-temperature alloy round ingot

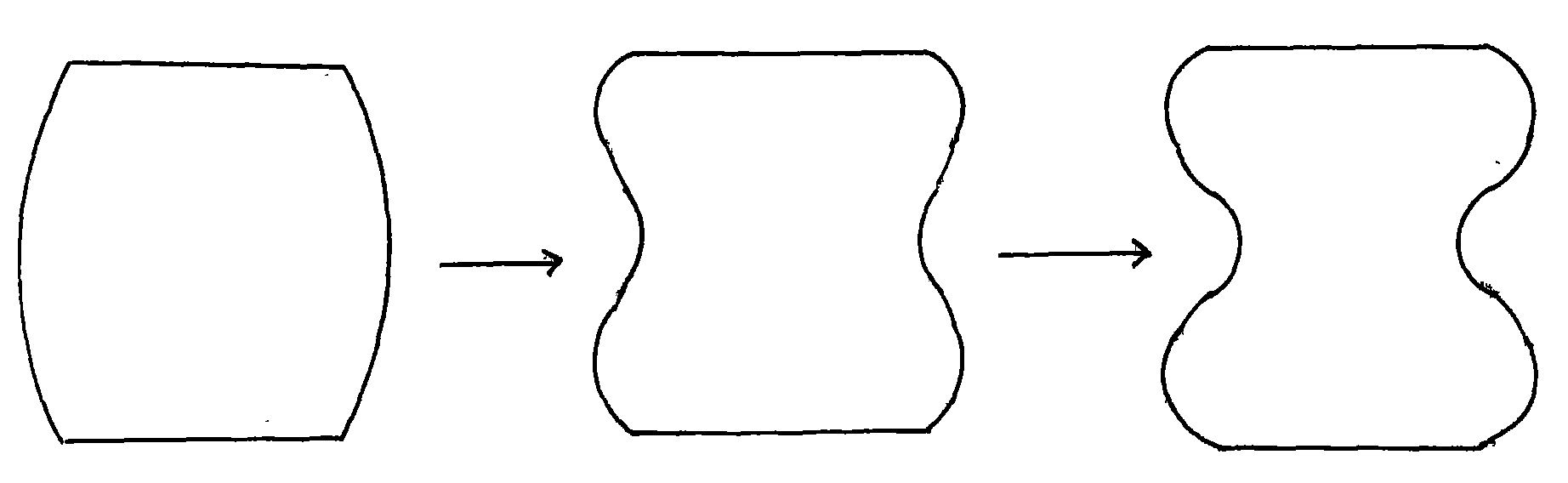

A technology of superalloy and round ingot, which is applied in the field of hot working and forging of superalloy in metallurgical industry, can solve the problems of large energy consumption, large cross-sectional area difference, large temperature drop at both ends of alloy round ingot, etc., so as to improve the finished product. efficiency, improving the quality of forgings, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: Upsetting of GH80A alloy round ingot.

[0027] A) Alloy round ingot pre-processing, first cut the head and tail of the alloy round ingot with a diameter of 340mm and the brand name GH80A, and then use a lathe to flatten the two ends of the alloy round ingot, and make the car flat The end faces of both ends of the alloy round ingot are perpendicular to the axis of the alloy round ingot to ensure that the sagittal direction of the pressure is parallel to the axis of the alloy round ingot during upsetting, so as to avoid bending during upsetting, resulting in a diameter of 340mm and a length of 1265mm Alloy round ingot, measure and calculate the height-diameter ratio to be upset, that is, height-diameter ratio = 1265 / 340 = 3.72:1;

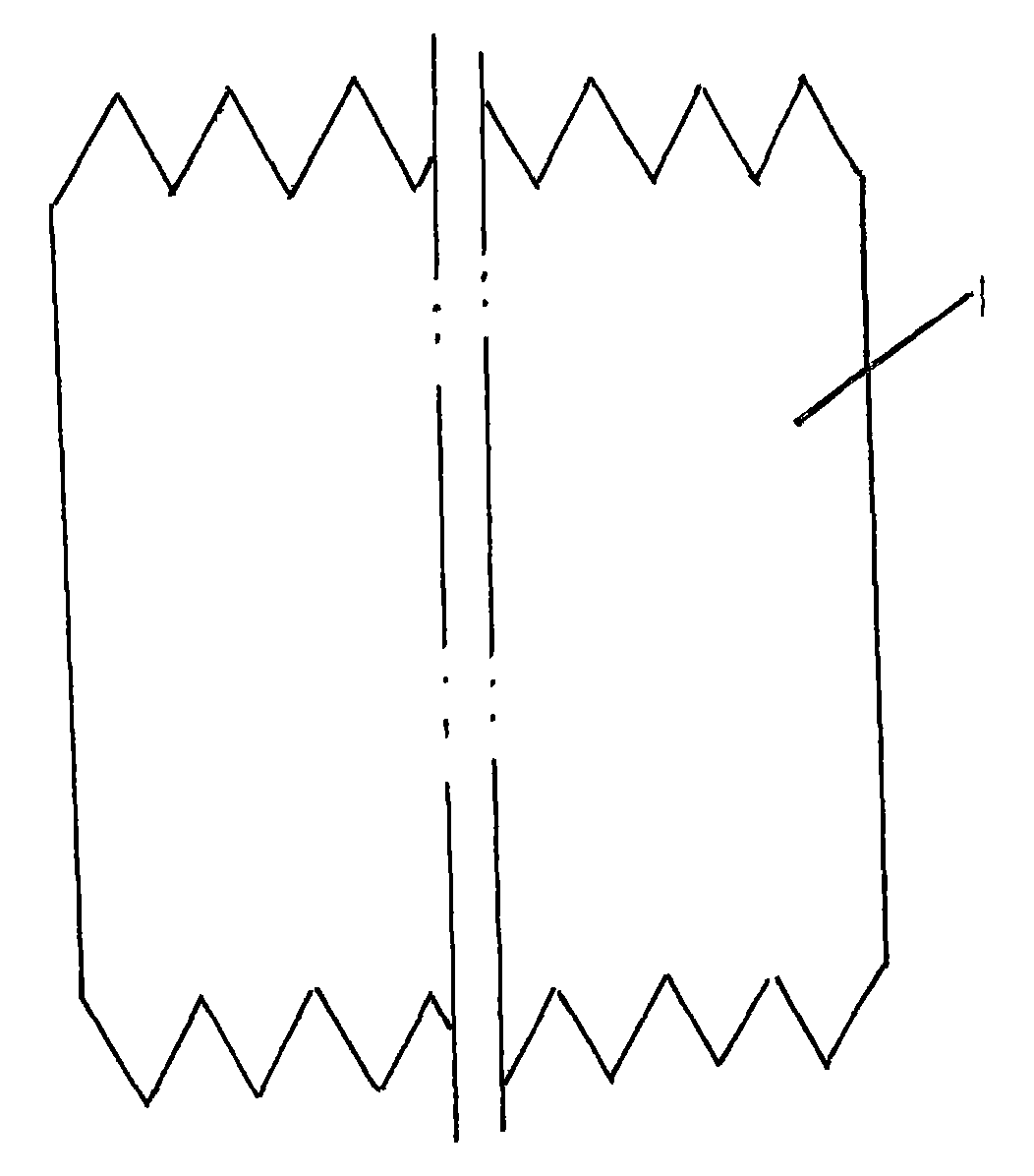

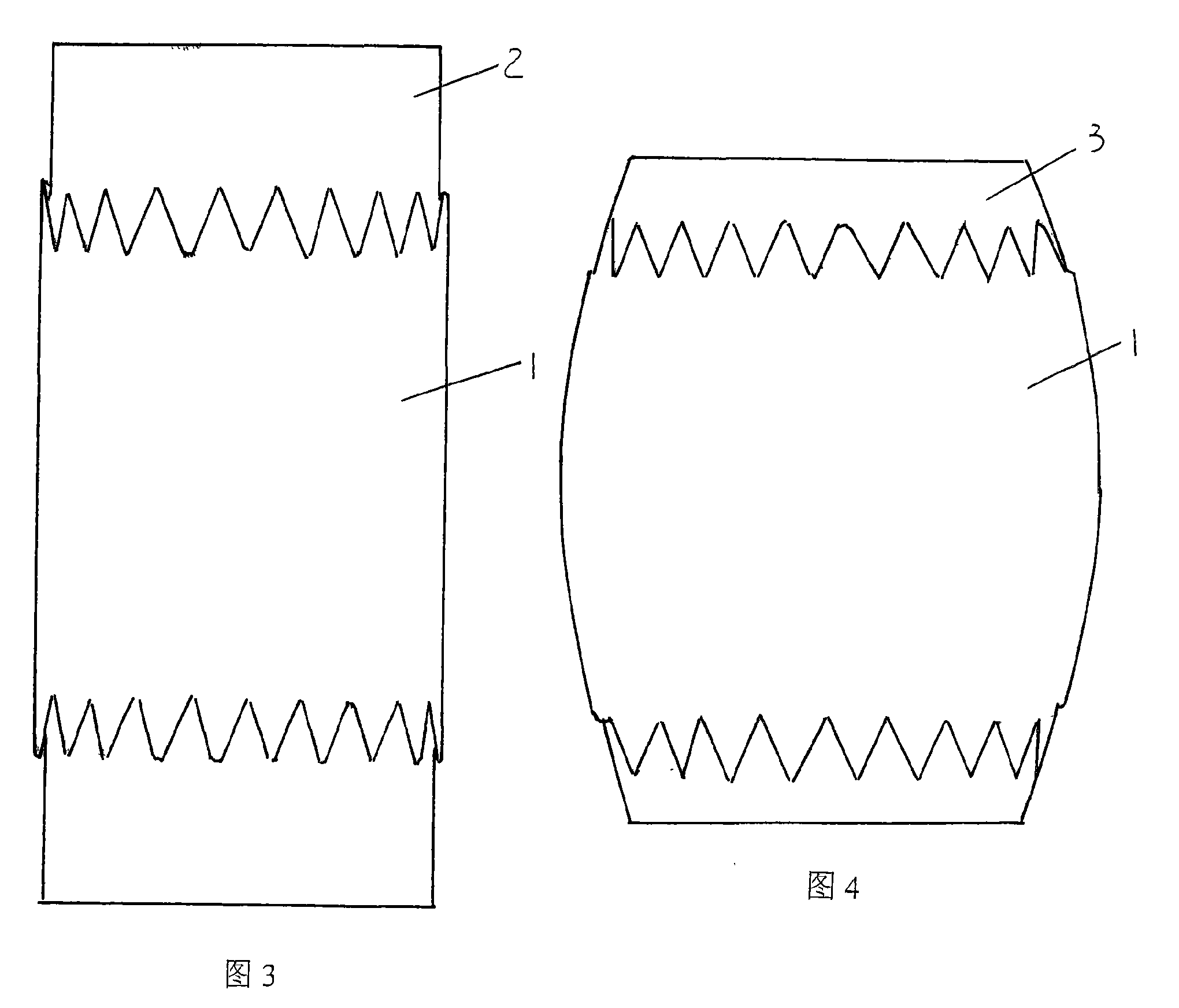

[0028] B) Covering the ceramic thermal insulation blanket 1, at first making or claiming to be prepared by figure 2 In the shown ceramic insulation blanket 1, the width of the ceramic insulation blanket 1 is 1 / 2 of the height of...

Embodiment 2

[0031] Embodiment 2: Upsetting of GH4169 alloy round ingot.

[0032] A) Alloy round ingot pre-processing, first cut the head and tail of the alloy round ingot with a diameter of 360mm and the brand name GH4169, and then use a lathe to flatten the two ends of the alloy round ingot, and make the car flat The end faces of both ends of the alloy round ingot are perpendicular to the axis of the alloy round ingot to ensure that the sagittal direction of the pressure is parallel to the axis of the alloy round ingot during upsetting, and an alloy round ingot with a diameter of 360 mm and a length of 1020 mm is obtained. The height-to-diameter ratio, that is, the height-to-diameter ratio=1020 / 360=2.83:1;

[0033] B) Covering the ceramic thermal insulation blanket 1, at first making or claiming to be prepared by figure 2 In the shown ceramic heat insulating blanket 1, the width of the ceramic heat insulating blanket 1 is 1 / 3 of the height of the alloy round ingot, namely 340 mm, and t...

Embodiment 3

[0036] Embodiment 3: Upsetting of GH4145 alloy round ingot.

[0037] A) Alloy round ingot pre-processing, first cut the head and tail of the alloy round ingot with a diameter of 460mm and the brand name GH4145, and then use a lathe to flatten the two ends of the alloy round ingot, and make the flat surface after turning The end faces of the two ends of the alloy round ingot are perpendicular to the axis of the alloy round ingot, ensuring that the sagittal direction of the pressure is parallel to the axis of the alloy round ingot during upsetting, and an alloy round ingot with a diameter of 460 mm and a length of 1160 mm is obtained. The height-to-diameter ratio, that is, the height-to-diameter ratio=1160 / 460=2.52:1;

[0038] B) Covering the ceramic thermal insulation blanket 1, at first making or claiming to be prepared by figure 2 In the ceramic heat insulating blanket 1 shown, the width of the ceramic heat insulating blanket 1 is 1 / 3 of the height of the alloy round ingot,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com