Method for synthesizing in-situ formed ceramic particle reinforced iron-aluminum-based composites by laser combustion

An in-situ self-generated, ceramic particle technology, applied in the field of materials, can solve the problems of reinforcement pollution, poor wettability, high temperature rise rate, etc., and achieve the effects of improving comprehensive performance, shortening the preparation process, and advanced preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Mix tungsten ore powder, iron powder, aluminum powder and carbon powder with a particle size below 200 mesh, and the mixing ratio is iron powder: tungsten ore powder: aluminum powder: carbon powder=80: 0.3: 18: 1.2 by weight, and then place Mix in a ball mill for 4 hours at a ball milling speed of 200 rpm to obtain a mixed powder.

[0028] The mixed powder is pressed into a compact under the pressure condition of 400MPa, and the thickness of the compact is 25mm.

[0029] Using CO 2 The laser processing machine emits a high-energy laser beam to ignite the surface of the green compact, triggering the self-propagating sintering of the green compact. The reaction speed is 3mm / s, and the in-situ self-generated ceramic particle-reinforced iron-aluminum matrix composite material is generated. The laser output power is 550W, and the laser ignition time is 25s. .

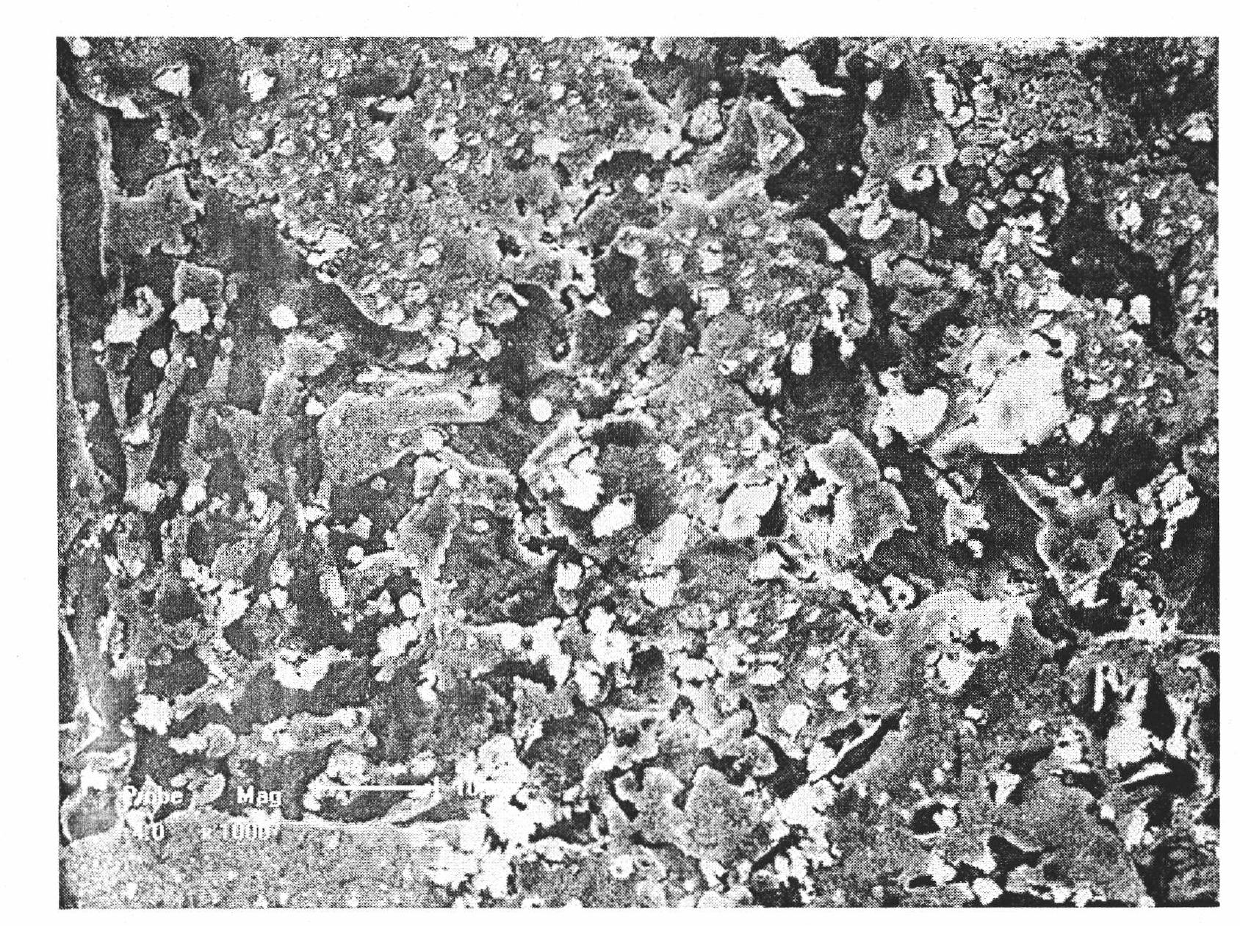

[0030] SEM image of microstructure of Fe-Al matrix composites reinforced by self-generated ceramic particles fig...

Embodiment 2

[0034] Mix tungsten ore powder, iron powder, aluminum powder and carbon powder with a particle size below 200 mesh, and the mixing ratio is iron powder: tungsten ore powder: aluminum powder: carbon powder = 80: 0.6: 18.5: 0.9, and then place Mix in a ball mill for 6 hours at a ball milling speed of 150 rpm to obtain a mixed powder.

[0035] The mixed powder is pressed into a compact under the pressure condition of 500MPa, and the thickness of the compact is 20mm.

[0036] Using CO 2 The laser processing machine emits a high-energy laser beam to ignite the surface of the green compact, triggering self-propagating sintering of the green compact, with a reaction speed of 4mm / s to generate in-situ self-generated ceramic particle-reinforced iron-aluminum matrix composites. The laser output power is 600W, and the laser ignition time is 20s .

[0037] The average hardness of the obtained composite material is 160HB, compared with the metallurgical sintered FeAl alloy, the relative we...

Embodiment 3

[0040] Mix tungsten ore powder, iron powder, aluminum powder and carbon powder with a particle size below 200 mesh, and the mixing ratio is iron powder: tungsten ore powder: aluminum powder: carbon powder=80: 1.0: 19: 1.2 by weight, and then place Mix in a ball mill for 8 hours at a ball milling speed of 100 rpm to obtain a mixed powder.

[0041] The mixed powder is pressed into a compact under the pressure condition of 600MPa, and the thickness of the compact is 15mm.

[0042] Using CO 2 The laser processing machine emits a high-energy laser beam to ignite the surface of the green compact, triggering self-propagating sintering of the green compact, with a reaction speed of 3mm / s, and generates in-situ self-generated ceramic particle-reinforced iron-aluminum matrix composite materials. The laser output power is 650W, and the laser ignition time is 10s .

[0043] The average hardness of the obtained composite material is 110HB, compared with the metallurgical sintered FeAl al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com