Production method and production equipment for sodium bicarbonate

A sodium bicarbonate and production method technology, applied in the field of sodium bicarbonate preparation, can solve the problems of ineffective utilization of CO, environmental pollution, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

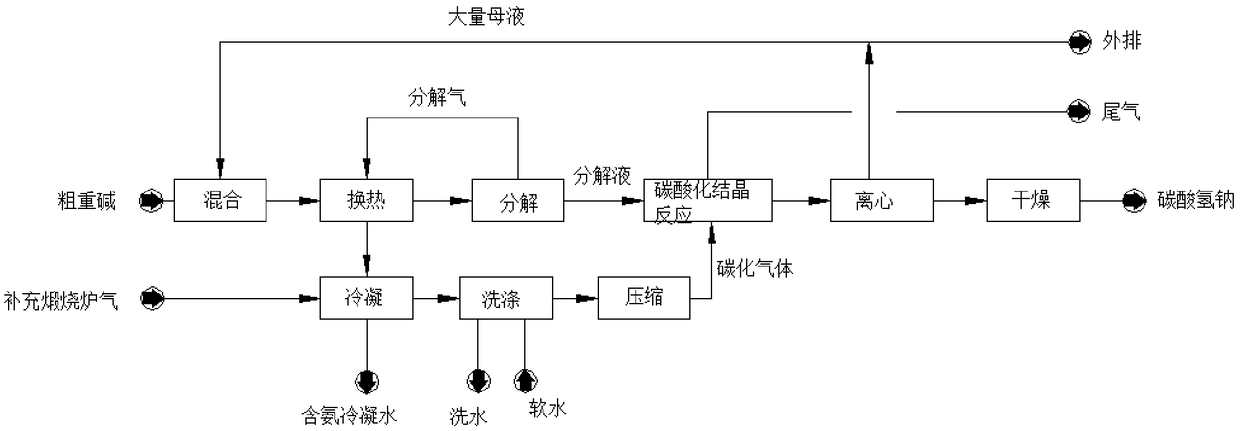

[0034] During the preparation of soda ash, the following process steps are generally followed: ① Preparation of ammonia brine; ② Carbonation reaction and crystallization of ammonia brine to obtain a solid-liquid mixture; ③ Filtration of the solid-liquid mixture to obtain a crude heavy alkali solid; ④ Calcination and decomposition of crude heavy alkali Get soda ash. Among them, the main component of crude heavy alkali is NaHCO 3 , will also contain a certain amount of NH4 HCO 3 and NaCl, after which the crude heavy alkali is calcined to obtain soda ash Na 2 CO 3 . A large amount of decomposition gas will be produced during the calcination and decomposition of crude heavy alkali. The main components of the decomposition gas are the mixed gas of carbon dioxide, water vapor and ammonia. Due to the 2 can be used as Na 2 CO 3 The reaction gas of the carbonation crystallization reaction, so through the purification treatment of the decomposition gas to remove the water vapor an...

Embodiment 1

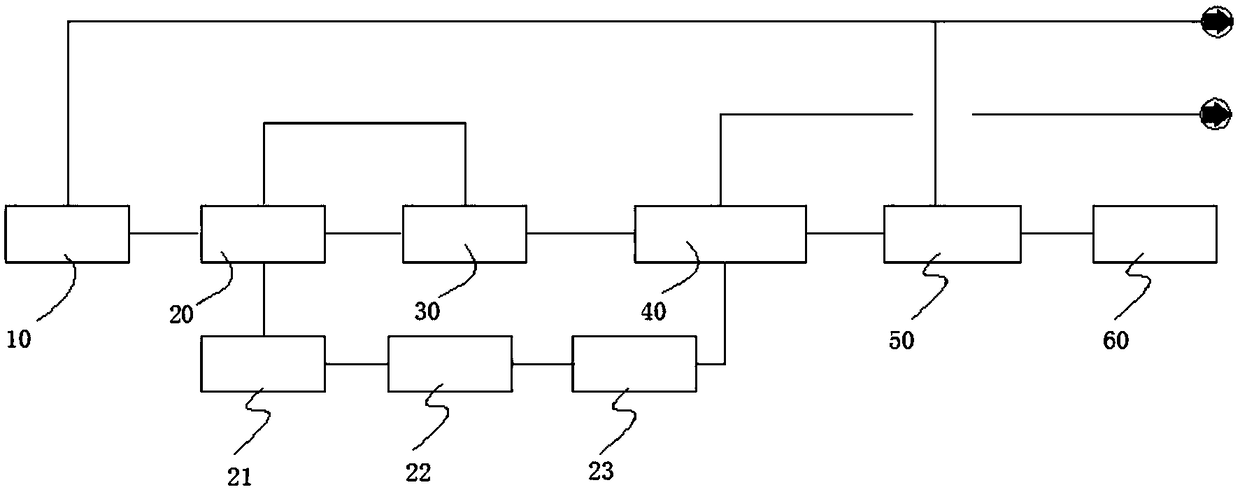

[0066] Such as figure 1 Shown, present embodiment is a kind of production equipment of sodium bicarbonate, comprises mixer 10, heat exchanger 20, decomposition tower 30, reaction crystallizer 40 and centrifuge 50 connected successively, and liquid begins to flow sequentially from mixer 10 Through heat exchanger 20, decomposition tower 30, reaction crystallizer 40 and centrifuge 50. The liquid outlet of the centrifuge 50 is connected to the mixer 10 . Wherein, the reaction crystallizer 40 is an OSL crystallizer.

[0067] In addition, the gas outlet of decomposition tower 30 is connected with the gas inlet of heat exchanger 20, and the gas outlet of heat exchanger 20 is connected with the gas inlet of condenser 21, and the gas outlet of condenser 21 is connected with the gas inlet of scrubber 22, washing The gas outlet of device 22 is connected with the inlet of compressor 23, and the outlet of compressor 23 is connected with the gas inlet of reaction crystallizer 40, and decomp...

Embodiment 2

[0070] Present embodiment is a kind of production method of sodium bicarbonate, utilizes the production equipment that embodiment 1 provides to produce, figure 2 The technological process of this production method is shown, in this method, the crude heavy alkali that produces in the soda ash production process is used as raw material, and its main component is: 70.88% NaHCO 3 , 7.02% Na 2 CO 3 , 4.14% NH 4 HCO 3 , 0.2% NaCl and 17.76% H 2 O, the specific production method comprises the following steps:

[0071] A) in mixer, thick heavy alkali is dissolved in the saturated solution of sodium bicarbonate, obtains solid-liquid mixture after mixing, dissolves thick heavy alkali with the saturated solution of sodium bicarbonate to be convenient to the separation out of sodium bicarbonate crystal in follow-up process; Wherein , the solid-liquid ratio of the solid-liquid mixture is 1:10;

[0072] b) The solid-liquid mixture flows through the heat exchanger and enters the decom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com