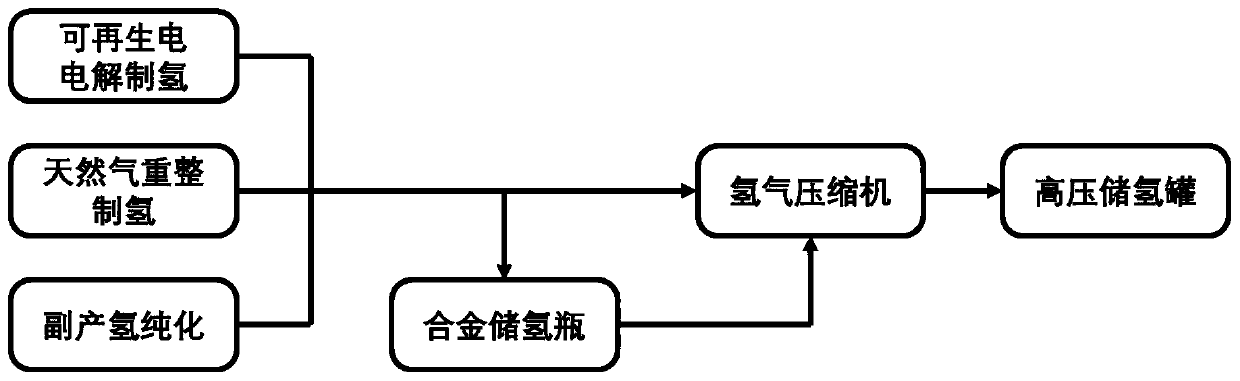

Small-scale low-energy-consumption stepped hydrogen storage system and method

A low-energy, small-scale technology, applied in container filling methods, container discharge methods, hydrogen technology, etc., can solve problems such as increasing operating power consumption, reducing system hydrogen storage efficiency, increasing investment costs and operating costs, and reducing The effect of hydrogen compression energy consumption, stable hydrogen storage, and safe and reliable strategy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

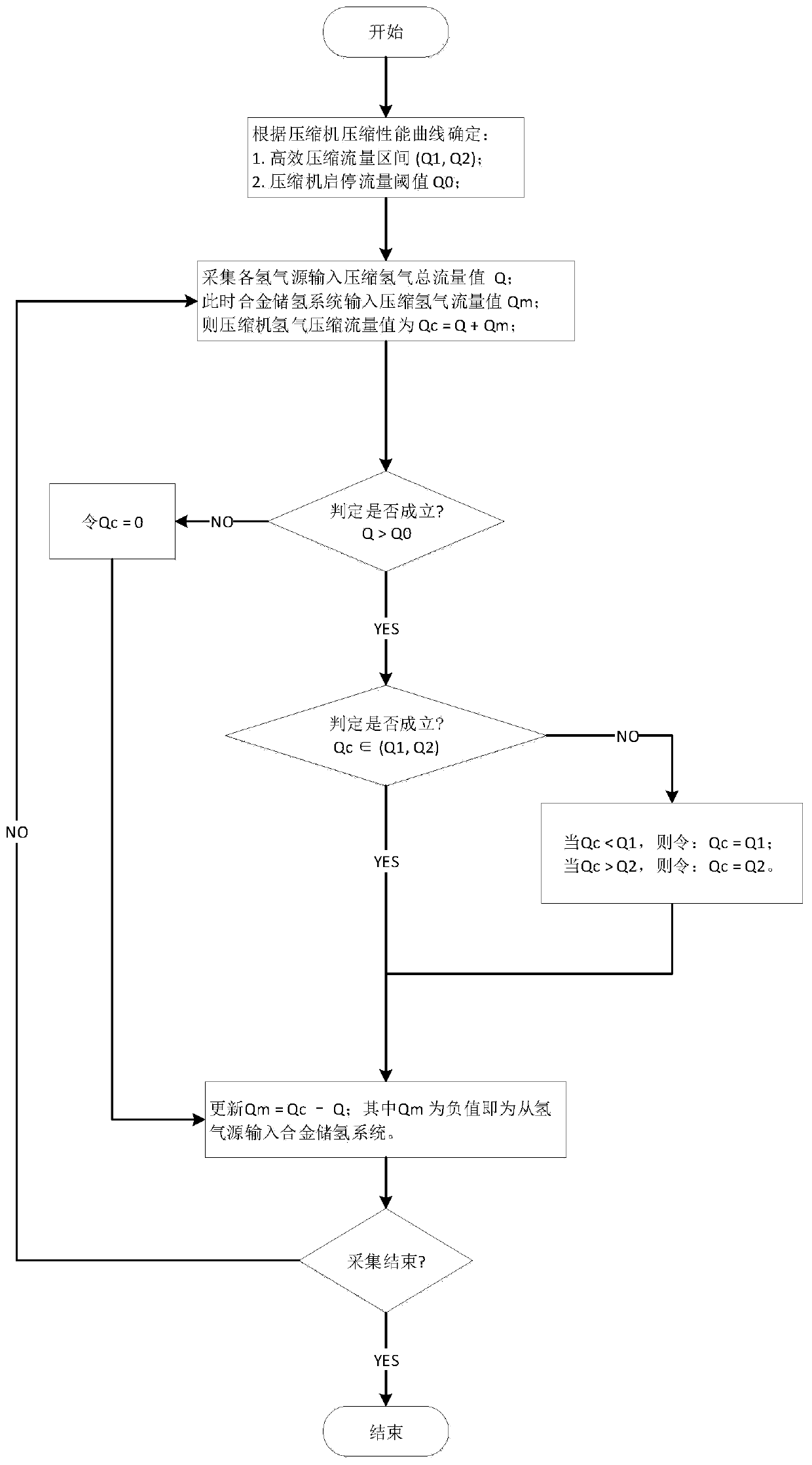

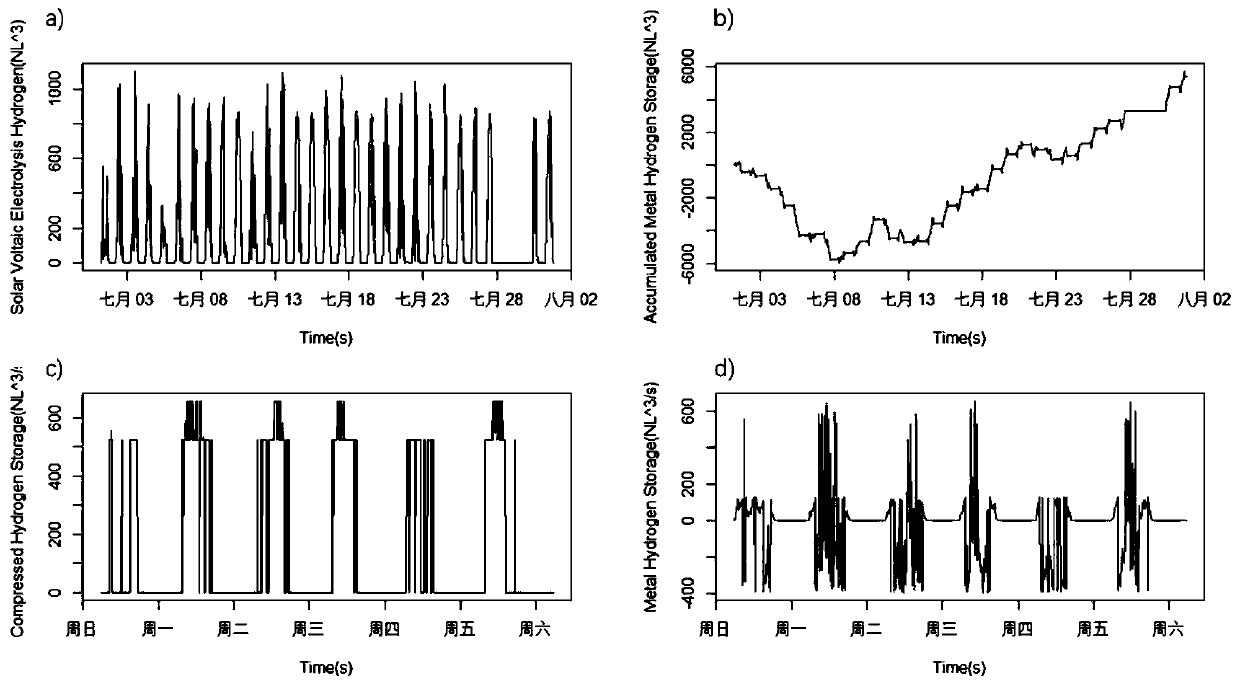

[0045] Using actual photovoltaic power generation data, if photovoltaic power generation-electrolytic hydrogen production is used as a fluctuating hydrogen source, the small-scale low-energy hydrogen storage process can be numerically simulated: ①Determine the high-efficiency compression flow rate for the compressor to work efficiently according to the power flow curve of the compressor The interval is (524.8, 656) L3 / s, and the threshold flow rate for starting the compressor is set to 131.2L3 / s; ② When the hydrogen flow rate fluctuates from the source (such as image 3 When the value shown in a) is lower or higher than the high-efficiency compression flow range, charge or discharge hydrogen from the alloy hydrogen storage system with low energy consumption and reversible hydrogen charging and discharging respectively, so that the compressor can keep working in the high-efficiency compression flow range; ③ When the source fluctuates If the hydrogen flow rate is lower than the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com