Technical method for recovering ethylene from ethylene containing mixed gas

A mixed gas and process technology, applied in absorption purification/separation, organic chemistry, energy input, etc., can solve the problems of not being further utilized, energy utilization needs to be further optimized, etc., to reduce steam consumption, operation and equipment costs , The effect of reducing the consumption of low temperature cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

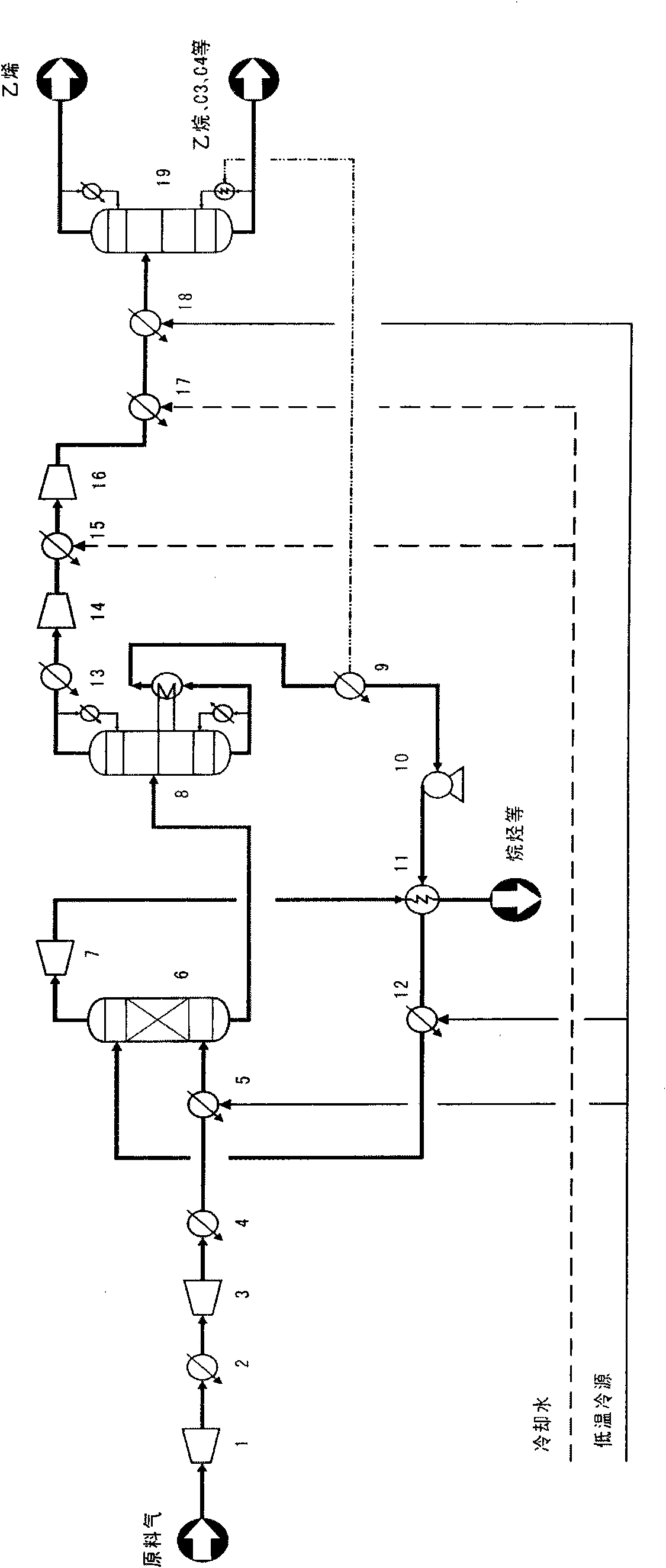

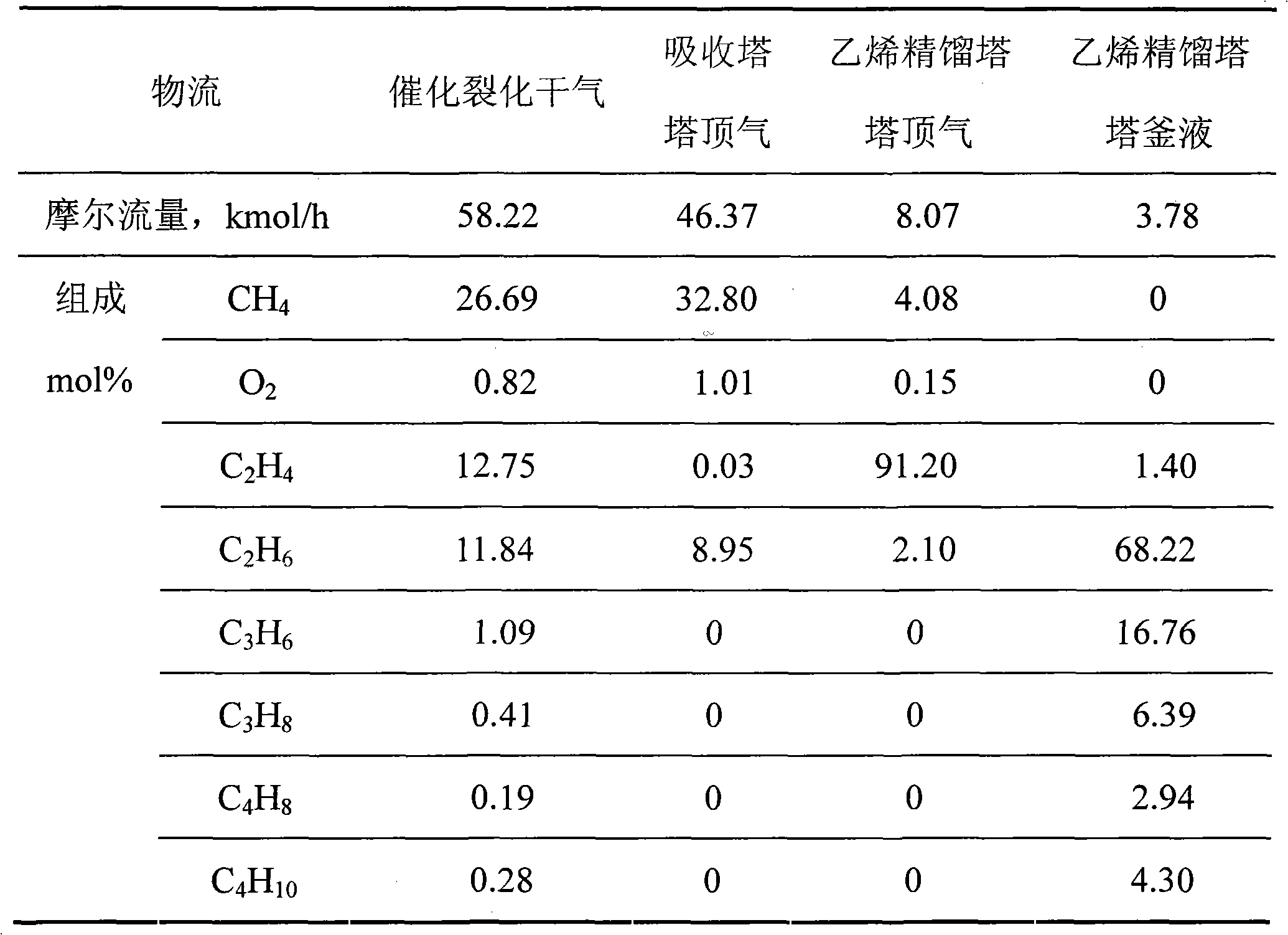

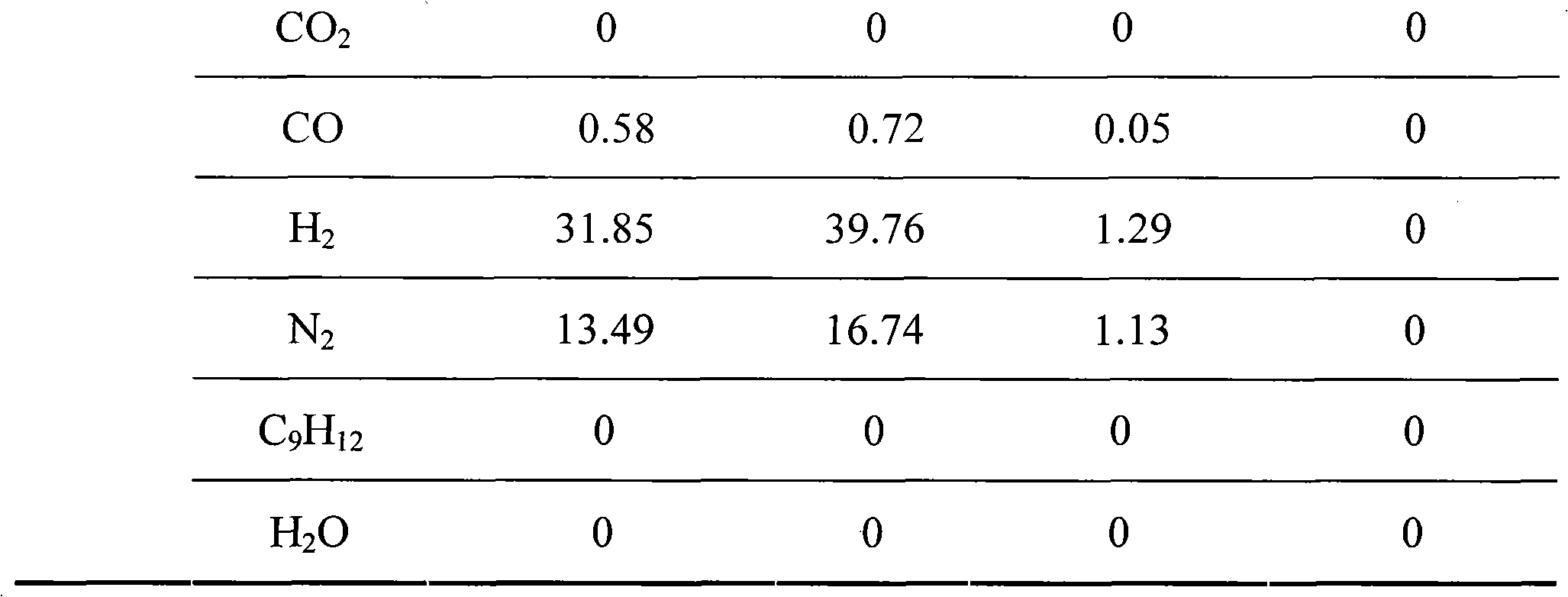

[0017] Example 1: This example uses 1,3,5-trimethylbenzene as an absorbent to recover ethylene gas from refinery dry gas. The feed gas is catalytic cracking dry gas, the temperature is 40°C, the pressure is 0.7MPa, mainly containing methane, N 2 , ethylene (12.75% by mole fraction) and ethane, while containing a small amount of C 3 、C 4 , CO 2 , CO and H 2 . Such as figure 1 Description of the process flow:

[0018] (1) Pretreatment process: The raw material gas with a molar flow rate of 58.22kmol / h is pressurized to 1.5MPa through the gas pretreatment process and the acid gas in it is removed, and then passed through the absorption tower feed heat exchanger 4 and feed cooler 5 is cooled to -20°C and enters the bottom of the absorption tower 6.

[0019] (2) Absorption process: Under the operating pressure of 1.5MPa, the 1,3,5-trimethylbenzene absorbent enters from the top of the absorption tower with a molar flow rate of 27.04kmol / h, contacts the mixed gas in countercur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com