Blast furnace oxygen delivery system and working method

A delivery system, oxygen technology, applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of blast furnace oxygen waste, achieve energy saving and consumption reduction, avoid release, and save energy consumption of oxygen compression Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

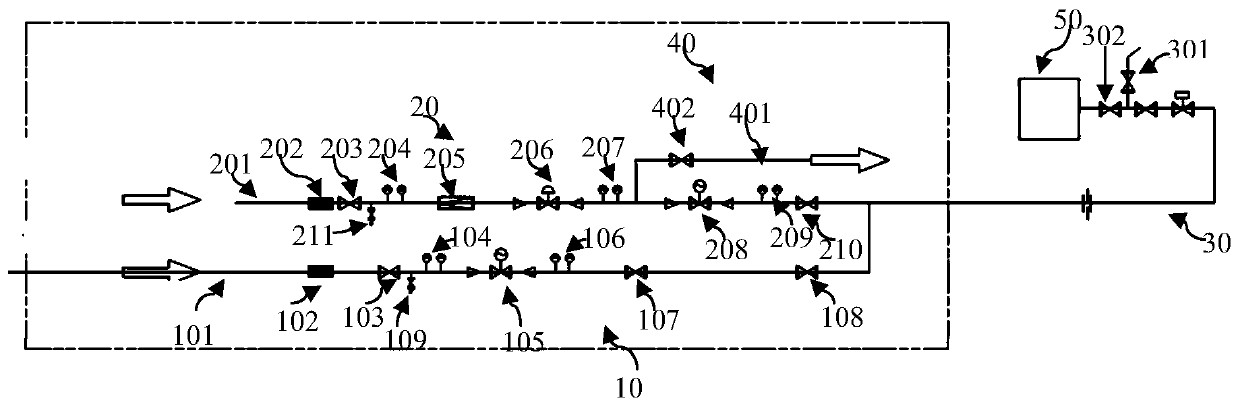

[0027] Embodiment 1: as figure 1 As shown, the blast furnace oxygen delivery system of the present invention includes a first oxygen delivery system 10, a second oxygen delivery system 20 and a delivery main pipe 30;

[0028] In this embodiment, the first oxygen storage system connected to the air inlet of the first delivery pipe 101 is a low-pressure oxygen delivery system, the first oxygen storage system is a 0.8MPa low-pressure oxygen compressor, and the first oxygen delivery system 10 includes a first delivery Pipe 101, the air inlet of the first conveying pipe 101 communicates with the outlet of the first oxygen storage system, the gas outlet of the first conveying pipe 101 communicates with the air inlet pipe of the conveying main pipe 30, and the first conveying pipe 101 is sequentially provided with first The flame arrester 102, the first cut-off valve 103, the first pressure gauge 104, the first decompression regulating valve 105, the second pressure gauge 106, the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com