Coal bed gas deoxidation, nitrogen removal, concentration method based on product gas methane replacement and device thereof

A coalbed methane and gas methane technology, applied in the field of coalbed methane deoxygenation and nitrogen removal, can solve the problems of methane enrichment effect and oxygen concentration reduction, so as to reduce methane and oxygen concentration, increase methane concentration and ensure safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

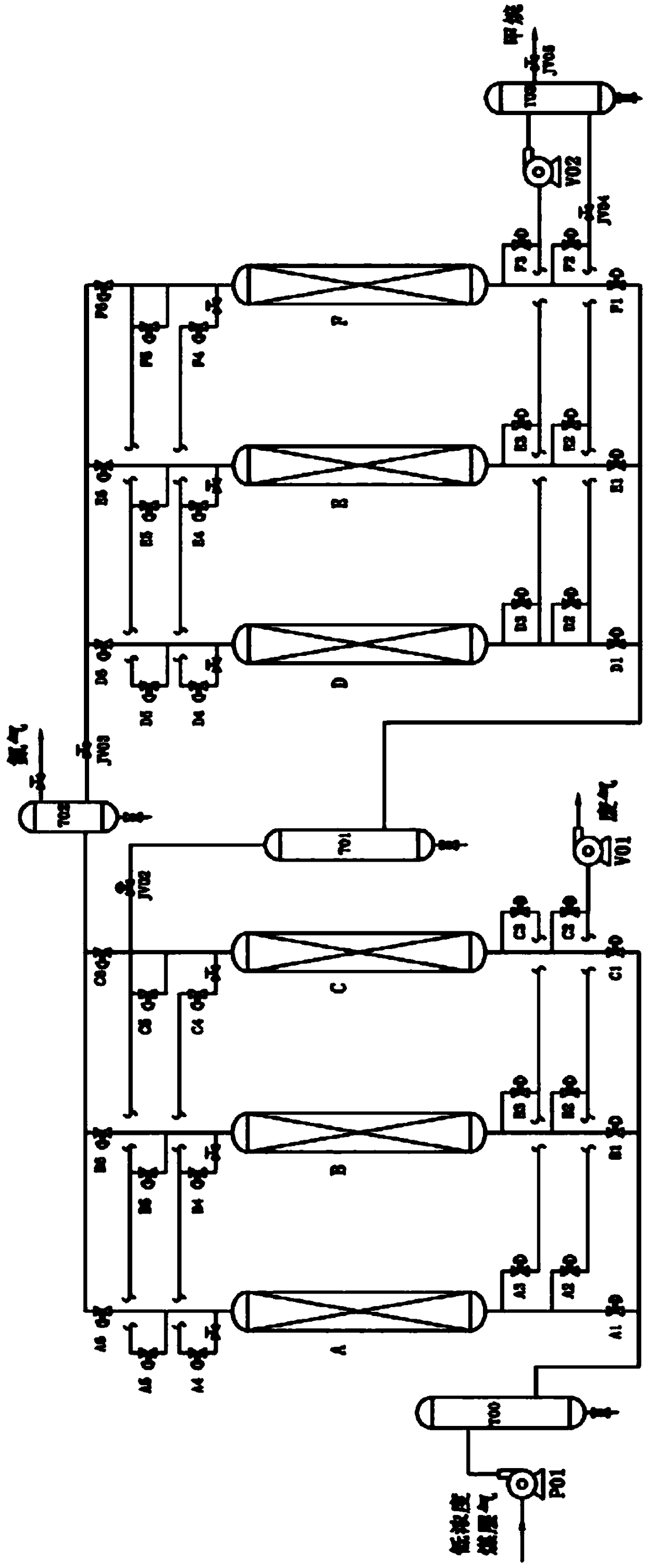

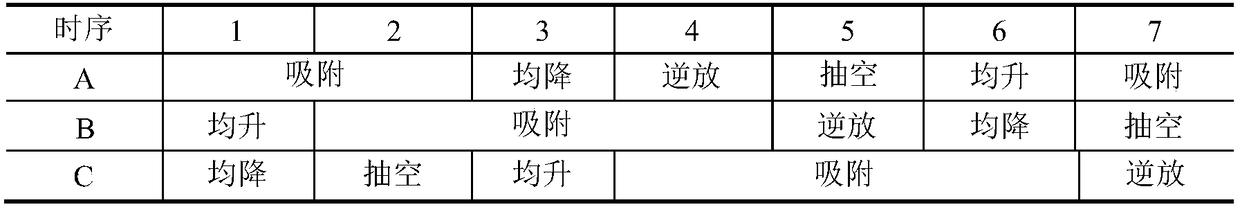

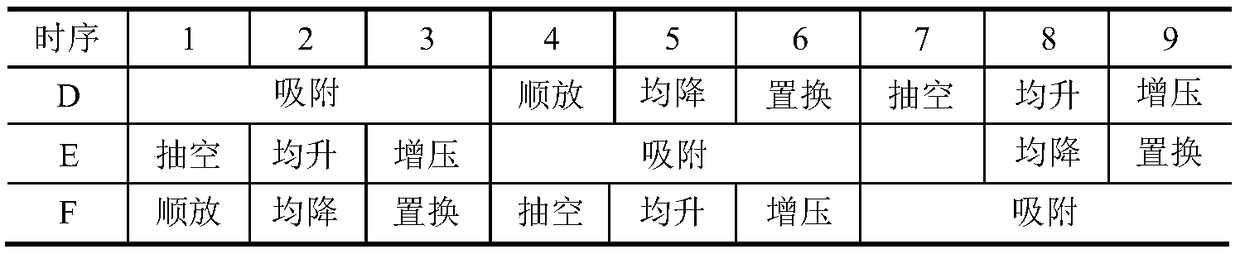

[0036] Specific embodiments of the present invention will be described in detail below in conjunction with specific drawings. It should be noted that the technical features or combinations of technical features described in the following embodiments should not be regarded as isolated, and they can be combined with each other to achieve better technical effects. In the drawings of the following embodiments, the same reference numerals appearing in each drawing represent the same features or components, which can be used in different embodiments.

[0037] A coalbed methane deoxygenation and denitrogenation enrichment method based on product gas methane replacement, including the following two-stage process:

[0038] The first stage: remove the oxygen in the coalbed methane;

[0039] The second stage: remove the nitrogen in the coalbed methane;

[0040] The concentration of oxygen in the product gas enriched by the above concentration and separation method is below 0.3%; the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com