A method for producing hydrocarbon mixtures by one-step methanol conversion in a fixed-bed adiabatic reactor

A technology for adiabatic reactors and hydrocarbon mixtures, which is applied in the preparation of liquid hydrocarbon mixtures, the production of hydrocarbons from oxygen-containing organic compounds, and biological raw materials. The effect of lower consumption, lower gas cycle ratio, and lower compression energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

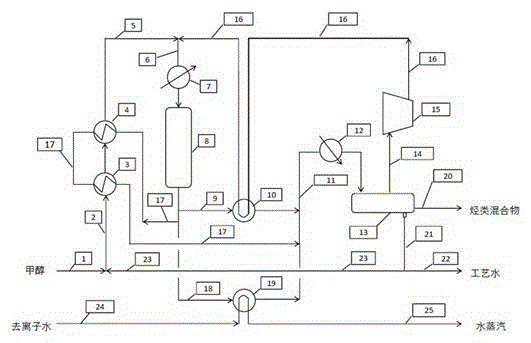

Image

Examples

Embodiment 1

[0030] Example 1

[0031] The fixed bed adiabatic reactor 8 has an inner diameter of 4000 mm, 62.3 tons of ZSM-5 molecular sieve catalyst inside, the total height of the catalyst bed is 8000 mm, the aspect ratio of the total catalyst bed is 2.0, and the raw material is refined methanol.

[0032] The whole system is purged with nitrogen, and the oxygen content is confirmed to be less than 0.5%, and the system pressure is controlled at 1.8MPa.

[0033] Turn on the circulation compressor to establish the nitrogen circulation of the system, and the nitrogen flow rate is 100000Nm 3 / h, relative to the volume space velocity of the catalyst in the reactor is 1000h -1 . The reactor temperature was raised to 260° C. by turning on the heater 7 . Methanol vapor is introduced at the inlet of pipeline 1, and methanol reacts under the action of the ZSM-5 molecular sieve catalyst filled in the reactor, and is converted into hydrocarbon products and a small amount of CO, CO 2 , H 2And ot...

Embodiment 2-5

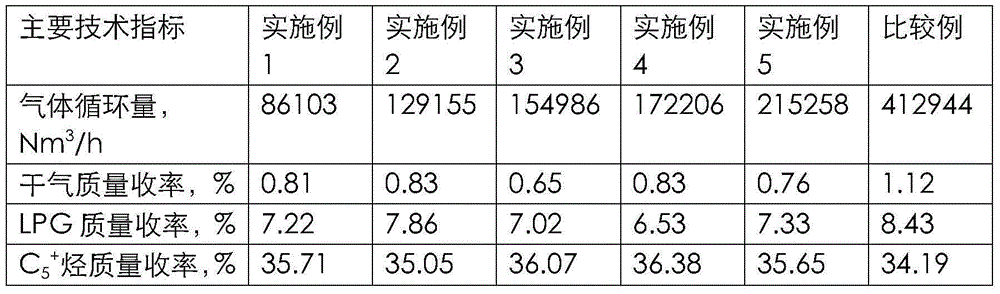

[0039] With the condition of embodiment 1, adopt identical reactor, identical catalyst, catalyst loading amount is identical. Change the operating pressure of the reaction system, process water circulation ratio, gas circulation ratio, catalyst bed inlet temperature and outlet temperature and other parameters. The operating parameters after embodiment 2-5 reaches steady state are shown in Table 1.

[0040] The main technical indicators of Embodiment 2-5 are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com