Electrocatalysis synthesis reactor

A synthesis reactor and electrocatalysis technology, applied in chemical instruments and methods, chemical methods for reacting liquid and gaseous media, chemical/physical processes, etc., can solve high operation and maintenance costs, huge equipment cost, easy catalyst Inactivation and other problems, to achieve the effect of easy reaction speed, lower production cost, and overcome high energy consumption of compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

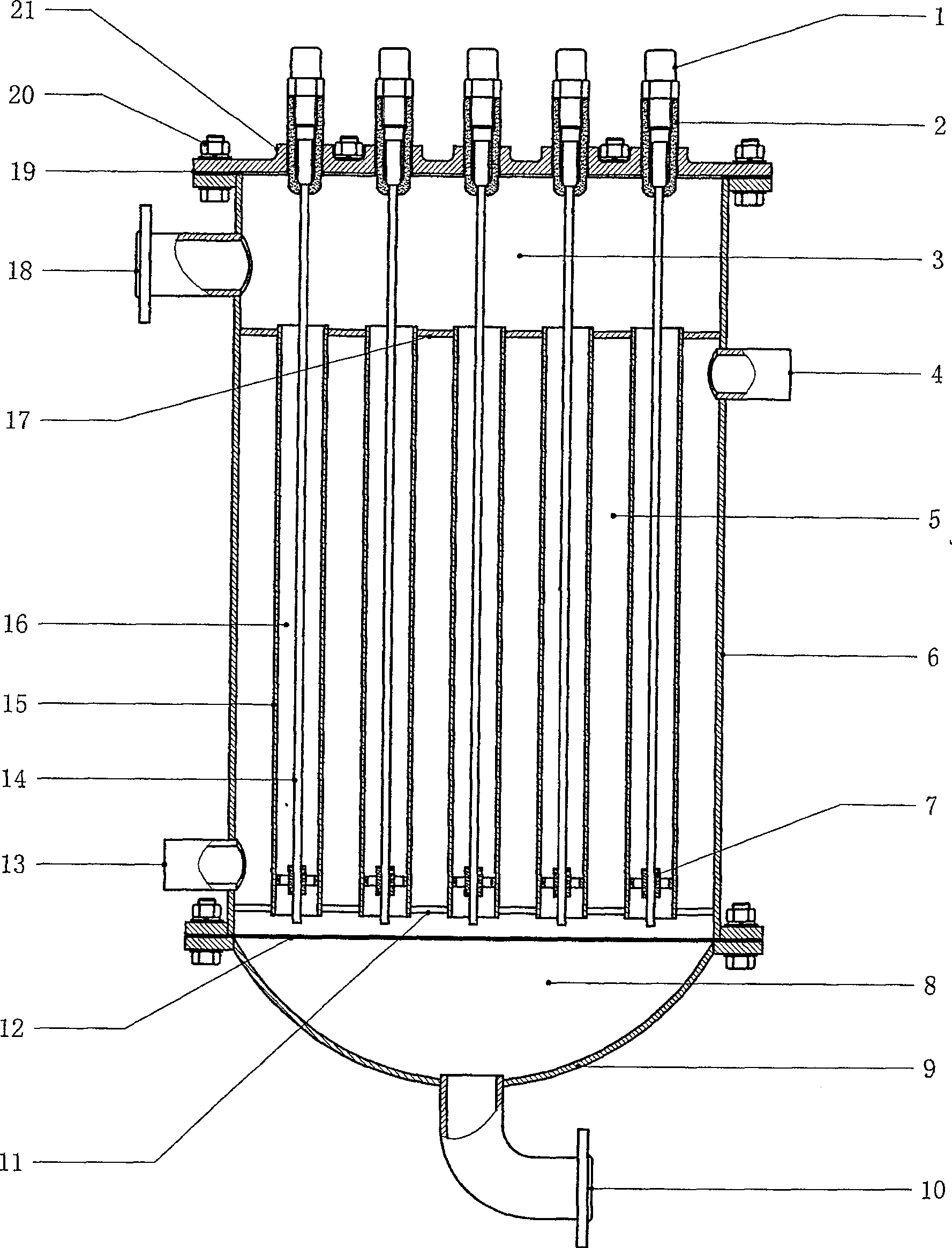

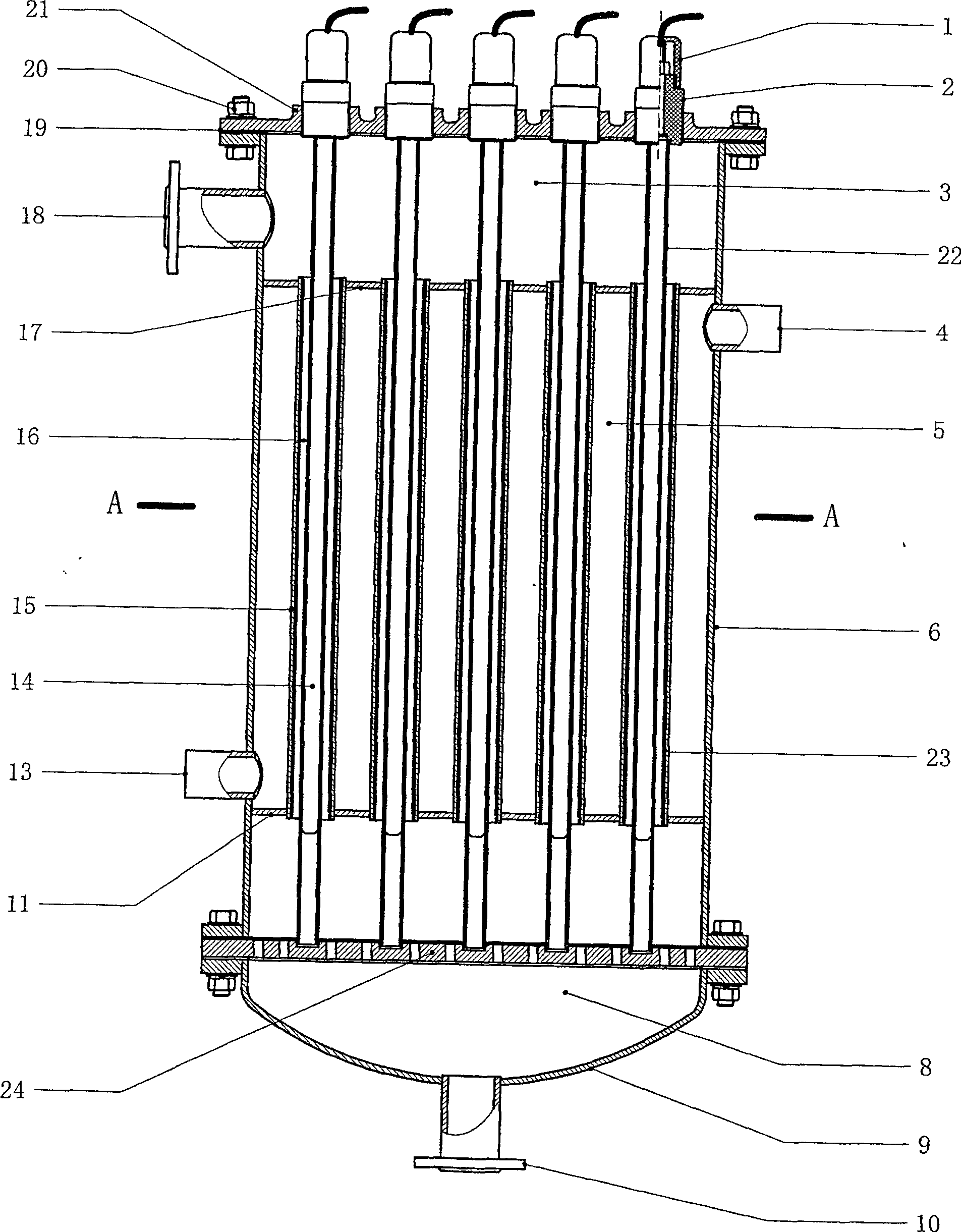

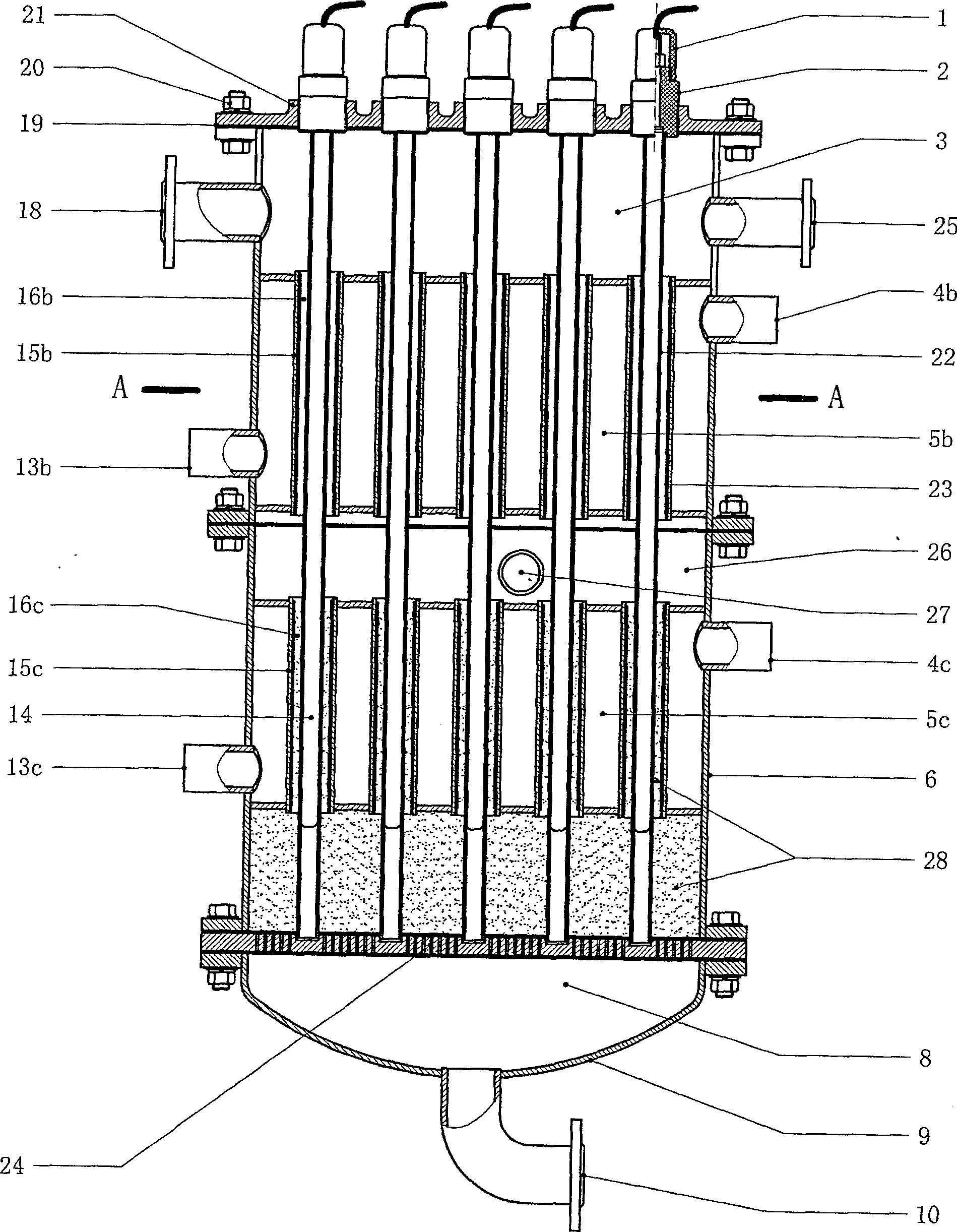

[0019] figure 1 In the embodiment shown, the electrocatalytic synthesis reactor is mainly composed of feed gas inlet 18, gas distribution chamber 3, tubular electrocatalytic chamber 16, center electrode 14, insulating plug 2, outer electrode tube bundle 15, collecting chamber 8, product The outlet 10, the coolant chamber 5, the coolant inlet 13, the coolant outlet 4, and the shell 6 are composed of: the raw gas inlet 18 is connected from the side of the gas dividing chamber 3; the gas dividing chamber 3 passes through the tubular electrocatalytic chamber 16 is connected to the collecting chamber 8; the product outlet 10 is connected from the bottom of the collecting chamber 8; each electrocatalytic chamber 16 of tubular type is composed of the inner space of the outer electrode tube bundle 15, and each electrocatalytic chamber 16 has a central electrode 14 The periphery of the outer electrode tube bundle 15 is the coolant chamber 5; the circulating medium water enters the coolant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com