SiC high-temperature high-energy aluminum ion implantation machine

An aluminum ion implanter technology, applied in the direction of discharge tubes, electrical components, circuits, etc., can solve the problems of small beam current index, high use and maintenance costs, complex ion source structure, etc., achieve consistent implantation angles, and reduce land occupation Area, the effect of ensuring transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

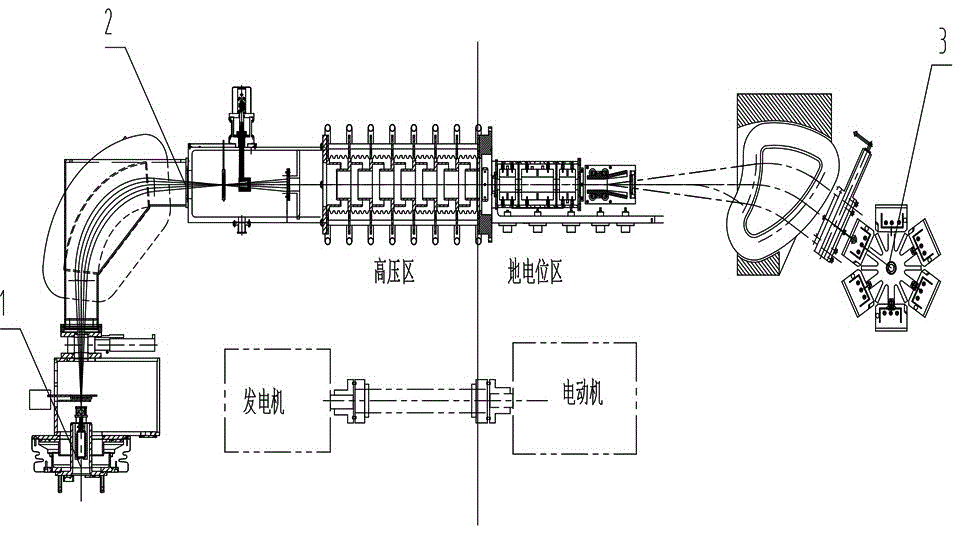

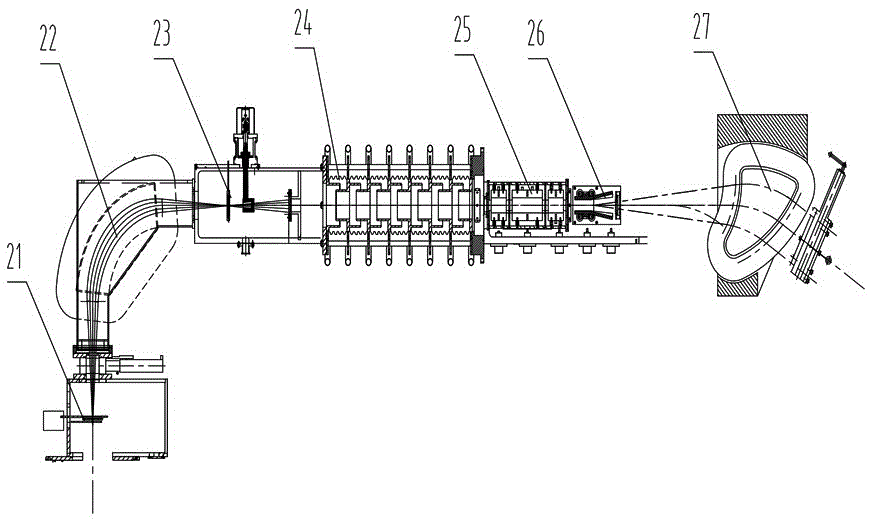

[0030] Such as figure 1 with figure 2 As shown, the SiC high-temperature high-energy aluminum ion implanter of the present invention includes:

[0031] Ion source 1 is used to generate aluminum-containing ions, that is, to generate the required aluminum ions (and other ions, including single charge and double charge);

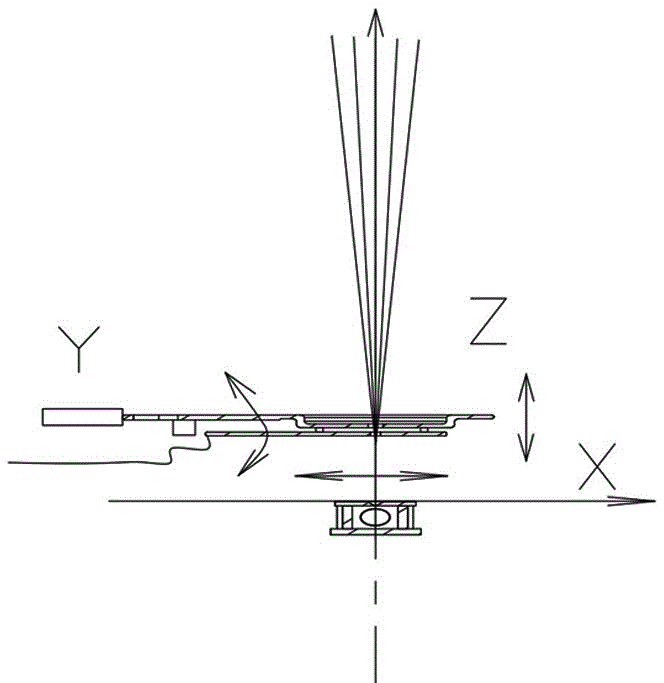

[0032] The ion beam transmission system 2 is used to effectively transmit the aluminum ion beam current; it includes an extraction system 21, a mass analyzer 22, an analysis diaphragm 23, an accelerating tube 24, a vertical scanning electrode plate 25 and a parallel beam lens 26 (such as : 30° parallel beam lens). The extraction system 21 extracts the ions generated by the ion source 1 and forms an ion beam with a certain energy; the ion beam passes through the mass analyzer 22 and the analysis aperture 23 in seque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com