Air-energy two-stage heat pump air-conditioning system

A heat pump air conditioner and air energy technology, which is applied in air conditioning systems, space heating and ventilation, heating methods, etc., can solve problems such as air energy heat pumps not being able to provide normal heating, and achieve the effects of simple installation and maintenance, reduced energy consumption, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

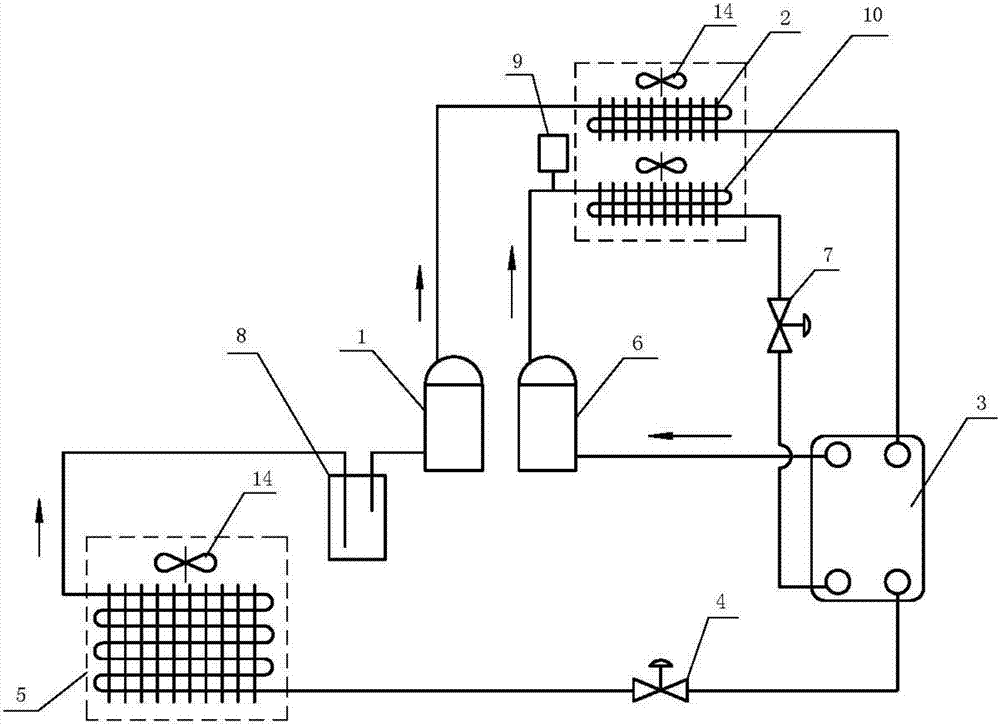

[0029] Such as figure 1 As shown, the air energy two-stage heat pump air conditioning system includes: outdoor low temperature evaporator 5, liquid storage tank 8, low temperature compressor 1, indoor low temperature condenser 2, heat exchanger 3, first expansion valve 4, high temperature compressor 6, Indoor high temperature condenser 10 and second expansion valve 7. The outdoor low-temperature evaporator 5, liquid storage tank 8, low-temperature compressor 1, indoor low-temperature condenser 2, the first circuit of the heat exchanger 3 and the first expansion valve 4 are sequentially connected to form the first circuit, and the high-temperature compressor 6 and the indoor high-temperature The condenser 10, the second expansion valve 7 and the second circuit of the heat exchanger 3 are connected in turn to form a second circuit, and a buffer tank 9 is also installed between the high-temperature compressor 6 and the indoor high-temperature condenser 10; an indoor low-temperatu...

no. 2 example

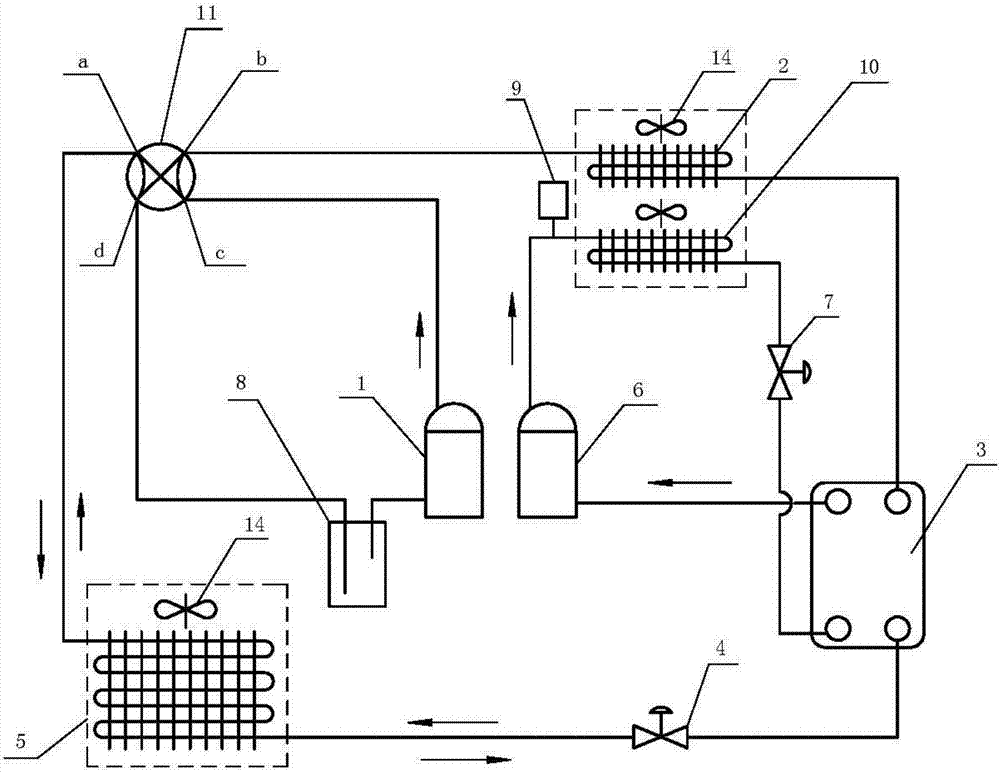

[0035] Such as figure 2 As shown, the second embodiment is basically the same as the first embodiment, the same parts will not be repeated, the difference is: between the outdoor low-temperature evaporator 5, the indoor low-temperature condenser 2, the low-temperature compressor 1 and the liquid storage tank 8 Equipped with a two-position four-way reversing valve 11, the a port of the two-position four-way reversing valve 11 is connected to the outlet of the outdoor low-temperature evaporator 5, and the b port of the two-position four-way reversing valve 11 is connected to the outlet of the indoor low-temperature condenser 2 The inlet is connected, the c port of the two-position four-way reversing valve 11 is connected with the outlet of the cryogenic compressor 1 , and the d-port of the two-position four-way reversing valve 11 is connected with the liquid storage tank 8 . The low-temperature compressor 1, the c port of the two-position four-way reversing valve 11, the b port...

no. 3 example

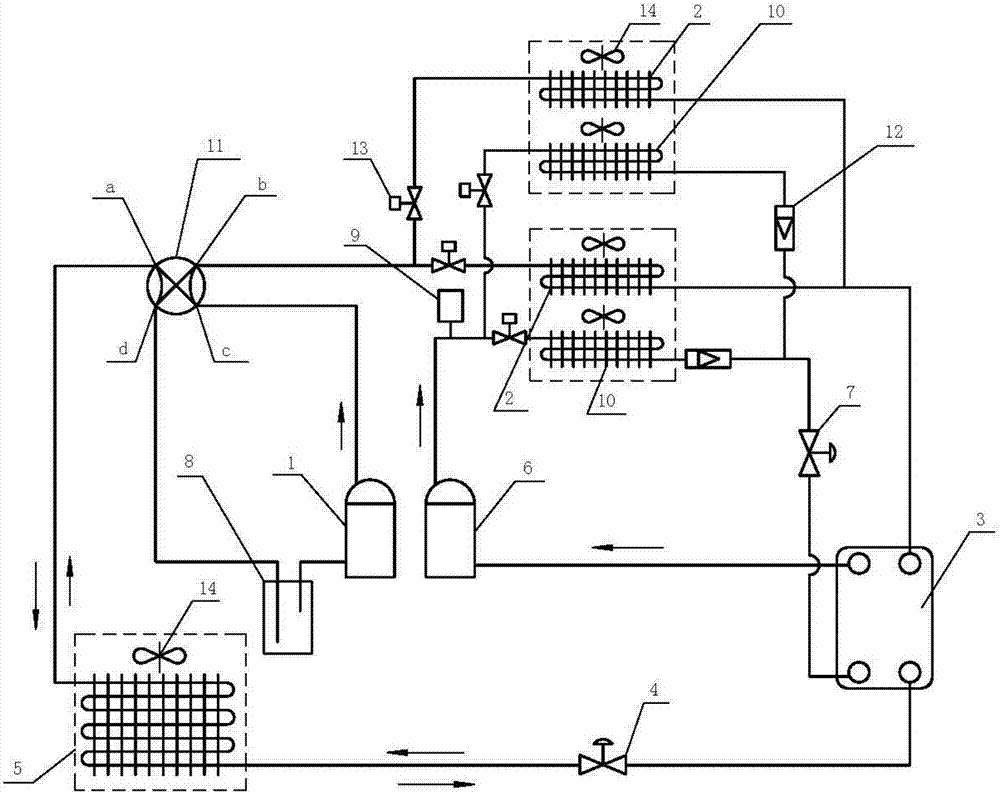

[0040] Such as image 3 As shown, the third embodiment is substantially the same as the second embodiment. The difference is that there are two sets of indoor condensers. That is, there are two indoor high-temperature condensers 10 and two indoor low-temperature condensers 2 respectively, the two indoor high-temperature condensers 10 are connected in parallel, and the two indoor low-temperature condensers 2 are connected in parallel. This embodiment can realize heating to two rooms at the same time. An electromagnetic valve 13 is installed between the two indoor low-temperature condensers 2 and the port b of the two-position four-way reversing valve 11, and an electromagnetic valve 13 is respectively installed between the two indoor high-temperature condensers 10 and the high-temperature compressor 6. Valve 13, a one-way valve 12 is installed between the two indoor high-temperature condensers 10 and the second expansion valve 7 respectively.

[0041] The heating and cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com