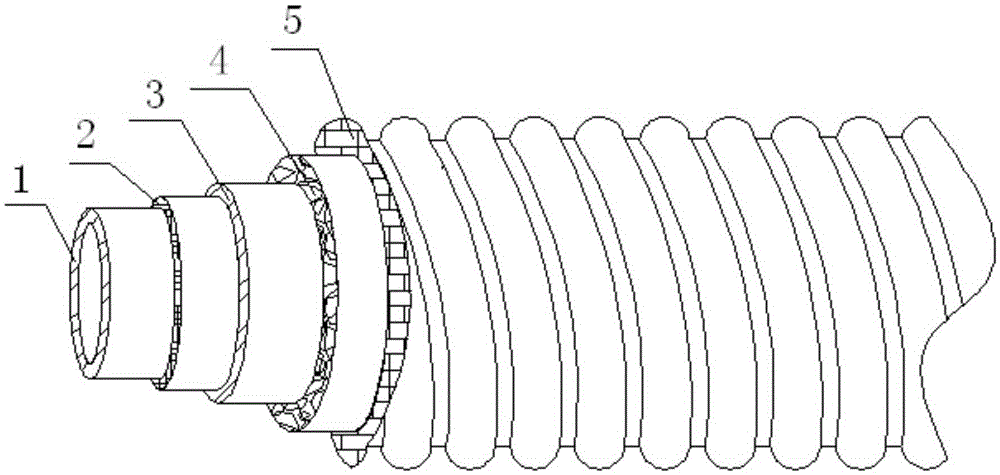

Production technique for external corrugated reinforced plastic heat-preservation heating/cooling pipe

A production process, corrugated technology, applied in the direction of thermal insulation, protection of pipelines through thermal insulation, pipes/pipe joints/fittings, etc., can solve the problems of inability to make full use of fiber reinforcement, single continuous fiber reinforcement, limiting the application of composite pipes, etc. , to achieve excellent temperature resistance, smooth inner wall, and reduce maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

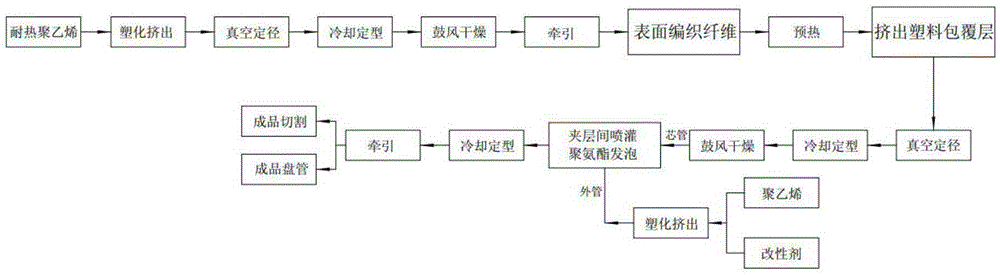

[0045] Such as figure 2 As shown, the heating / cooling pipe described in this embodiment is prepared according to the following steps:

[0046] Put the heat-resistant polyethylene (Total XRT70) into the extruder for uniform plasticization, and the extrusion temperature is 190-220 ° C. According to the conventional preparation process, the heat-resistant polyethylene is prepared by vacuum sizing, cooling and setting, blast drying, and traction. Vinyl inner tube, traction speed is 0.5-0.9 m / min; the nominal outer diameter of the inner tube is 16mm-400mm, and the wall thickness is 2.3mm-36.6mm.

[0047] Choose glass fiber, weave according to the rhombus two-dimensional structure, the weaving angle is 30°, weaving 5 layers, the number of spindles is 48, the yarn rotation speed: 0.23 m / min, the inner tube traction speed: 0.5 m / min. The outer layer of the heat-resistant polyethylene inner tube is braided glass fiber.

[0048] Evenly preheat the outer layer of the heat-resistant po...

Embodiment 2

[0053] Such as image 3 As shown, the heating / cooling pipe described in this embodiment is prepared according to the following steps:

[0054] Put the heat-resistant polyethylene (Total XRT70) into the extruder for uniform plasticization, and the extrusion temperature is 190-220 ° C. According to the conventional preparation process, the heat-resistant polyethylene is prepared by vacuum sizing, cooling and setting, blast drying, and traction. Vinyl inner tube, traction speed is 0.5-0.9 m / min; the nominal outer diameter of the inner tube is 16mm-400mm, and the wall thickness is 2.3mm-36.6mm.

[0055] Choose polyester fiber, weave according to the three-dimensional structure of the four-step method, the weaving angle is 45°, weaving 5 layers, the length of flower joints is 3.5-200mm, the number of spindles is 144, and the inner tube traction speed: 0.4-0.6 m / min. The outer layer of the heat-resistant polyethylene inner pipe is braided with polyester fibers.

[0056] Evenly pre...

Embodiment 3

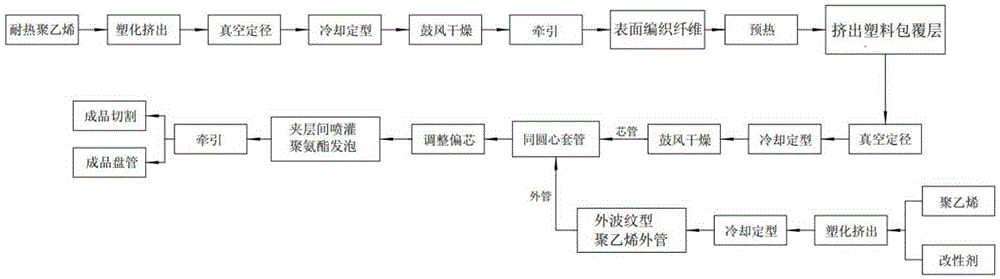

[0061] Such as image 3 As shown, the heating / cooling pipe described in this embodiment is prepared according to the following steps:

[0062] Put the heat-resistant polyethylene (Total XRT70) into the extruder for uniform plasticization, and the extrusion temperature is 190-220 ° C. According to the conventional preparation process, the heat-resistant polyethylene is prepared by vacuum sizing, cooling and setting, blast drying, and traction. Vinyl inner tube, traction speed is 0.5-0.9 m / min; the nominal outer diameter of the inner tube is 16mm-400mm, and the wall thickness is 2.3mm-36.6mm.

[0063] Select nylon fiber, weave according to the three-dimensional structure of the two-step method, the weaving angle is 15°, weaving 3 layers, the length of flower joints is 3.5-20mm, the number of spindles is 48-60, and the weaving process of inner tube traction speed: 0.4-0.6 m / min , weaving nylon fibers on the outer layer of the heat-resistant polyethylene inner tube.

[0064] Eve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Radial thickness | aaaaa | aaaaa |

| Radial thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com