Integrated intelligent heating microlite plate

A technology of microcrystalline stone and integrated board, which is applied in the field of materials, can solve the problems of high heating cost, complicated operation, unsafe and unstable operation, etc., and achieve the effect of simple structure, convenient use and good environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

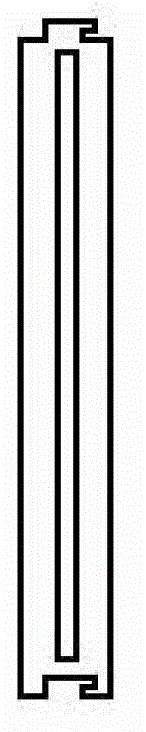

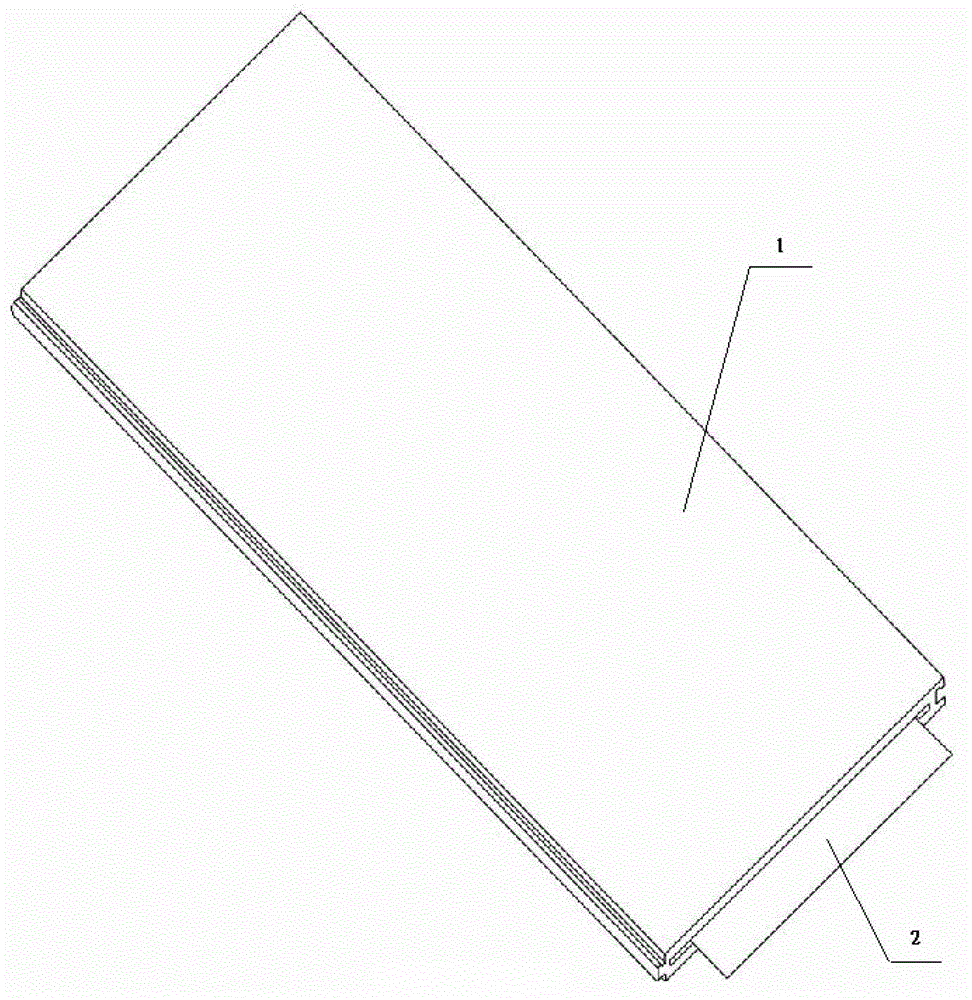

[0031] Example 1, such as Figure 1 to Figure 3 Shown, the technical scheme of the concrete implementation of the present invention is:

[0032] A microcrystalline intelligent thermal energy integrated board is characterized in that it includes a floor body a1 and a thermal wafer a2. The floor body a1 is composed of 60 parts (parts by mass) of microcrystalline stone, 20 parts (parts by mass) of PVC resin, 8 parts (parts by mass) of a composite stabilizer, and 8 parts (parts by mass) of Made of CPE and 4 parts (mass parts) of alumina; mix the materials according to the mass parts, and then when the temperature of the extrusion equipment is raised to 210°C, pour the mixture into the Extrude in the shaping die to pull out the floor body a1. A rectangular installation hole is opened at the cross section of the narrow side of the floor body a1, and the thermal wafer a2 is installed at the installation hole of the floor body a1. Preferably in this embodiment, the floor body a1 ha...

Embodiment 2

[0033] Example 2, such as Figure 4 to Figure 6 Shown, the technical scheme of the concrete implementation of the present invention is:

[0034] A microcrystalline intelligent thermal energy integrated board is characterized in that it includes a floor body b3 and a thermal wafer b4. The floor body b3 is composed of 55 parts (parts by mass) of microcrystalline stone, 18 parts (parts by mass) of PVC resin, 8 parts (parts by mass) of a composite stabilizer, and 6 parts (parts by mass) of Made of CPE and 3 parts (mass parts) of alumina; the materials are mixed according to the mass parts, and then when the temperature of the extrusion equipment is raised to 215 ° C, the mixture is poured into the pre-installed on the shaping table Extrude in the shaping die to pull out the floor body b3. A rectangular groove is formed on the bottom surface of the floor body b3, and the thermal wafer b4 is installed at the rectangular groove of the floor body b3. Preferably in this embodiment, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com