Two-stage backpressure machine reheating steam extraction heating supply system and method

A technology for steam extraction and heat supply and back pressure machine, which is applied in separation methods, chemical instruments and methods, preheating, etc., can solve the problems of increasing steam introduction and extraction devices, difficulty in design, and high pressure on environmental protection, so as to reduce energy The effect of consumption, saving layout space and avoiding waste of heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

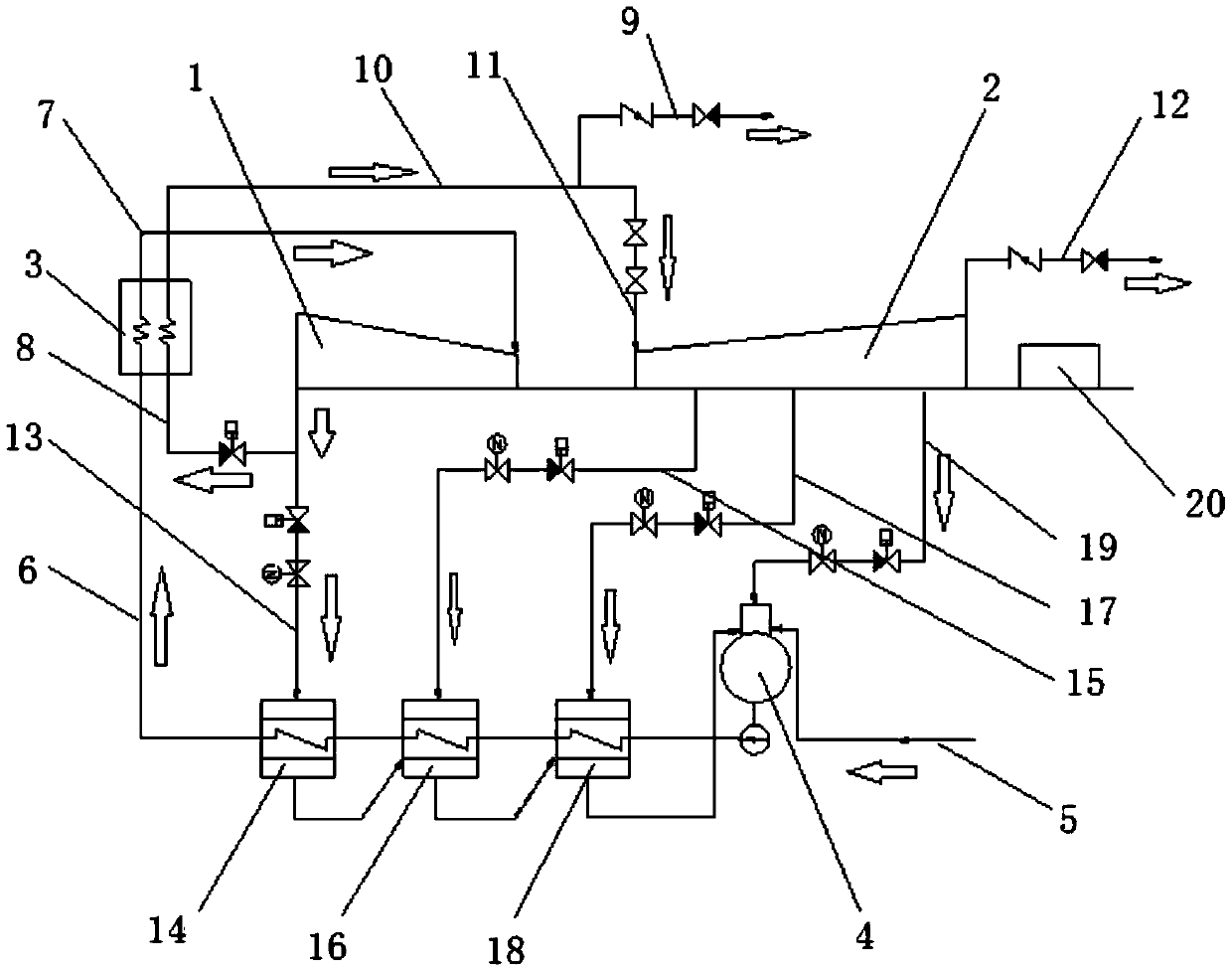

[0031] Such as figure 1 As shown, in this embodiment, a two-stage back pressure machine reheating steam extraction heating system includes a deaerator inlet pipe 5, a deaerator 4, a boiler inlet pipe 6, and a boiler outlet pipe that are sequentially connected in accordance with the water flow direction. Water pipe 7, high-pressure back pressure machine 1 and high-pressure steam supply pipe 9, the boiler water inlet pipe 6 is provided with a boiler 3, the high-pressure steam supply pipe 9 is connected with a low-pressure steam inlet pipe 11, and the low-pressure inlet The steam pipe 11 is connected with a low pressure back pressure machine 2 , and the low pressure back pressure machine 2 is connected with a low pressure steam supply pipe 12 .

[0032] Water enters the deaerator 4 from the deaerator inlet pipe 5 for deoxygenation, and then enters the boiler 3 through the boiler inlet pipe 6, and the boiler 3 heats the water in the boiler inlet pipe 6 to form high-temperature and...

Embodiment 2

[0036] The steam outlet of the high-pressure back pressure machine 1 is communicated with a high-pressure exhaust pipe 8 connected to the boiler reheater of the boiler 3, and a reheating steam outlet pipe is communicated between the high-pressure exhaust pipe 8 and the high-pressure steam supply pipe 9 10. When the steam entering the high-pressure back-pressure machine 1 is discharged from the high-pressure back-pressure machine 1, and the steam temperature does not meet the demand for high-pressure steam, adjust the parameters of the boiler 3 so that the high-pressure gas enters the boiler 3 through the high-pressure exhaust pipe 8, The boiler reheater of the boiler 3 heats the steam to increase the parameters of the gas again until the demand for high-pressure steam is met.

[0037] When it is only necessary to meet the high-pressure steam demand, the high-pressure steam demand is 4MPa, and the back pressure of the back pressure machine is maintained by the heat user system....

Embodiment 3

[0040] On the basis of the above embodiments, in this embodiment, the high-pressure exhaust pipe 8 is connected with a first-stage heat extraction pipe 13, and the boiler inlet pipe 6 is provided with a first-stage heat extraction pipe 13 Connected primary high pressure heater 14.

[0041] Part of the high-pressure gas can be diverted from the high-pressure exhaust pipe 8 through the first-stage heat extraction pipe 13, and it can enter the first-stage high-pressure heater 14, and the first-stage high-pressure heater 14 is used to make the high-pressure gas and the boiler The water in the water inlet pipe 6 performs heat exchange, thereby increasing the temperature of the water passing through the primary high-pressure heater 14 , thereby improving the efficiency of the boiler 3 in raising the temperature and pressure of the feed water in the boiler 3 .

[0042] A control switch is arranged on the first-stage heat recovery pipe 13 . In this embodiment, the control switch adop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com