Low-temp nuclear reactor with hypofuel for nuclear power station

A nuclear reactor and spent fuel technology, applied in the field of nuclear reactors, can solve problems such as economics and safety that are not widely accepted, and achieve the effects of improving utilization value, reducing investment and operating costs, and simplifying loading and unloading processes and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

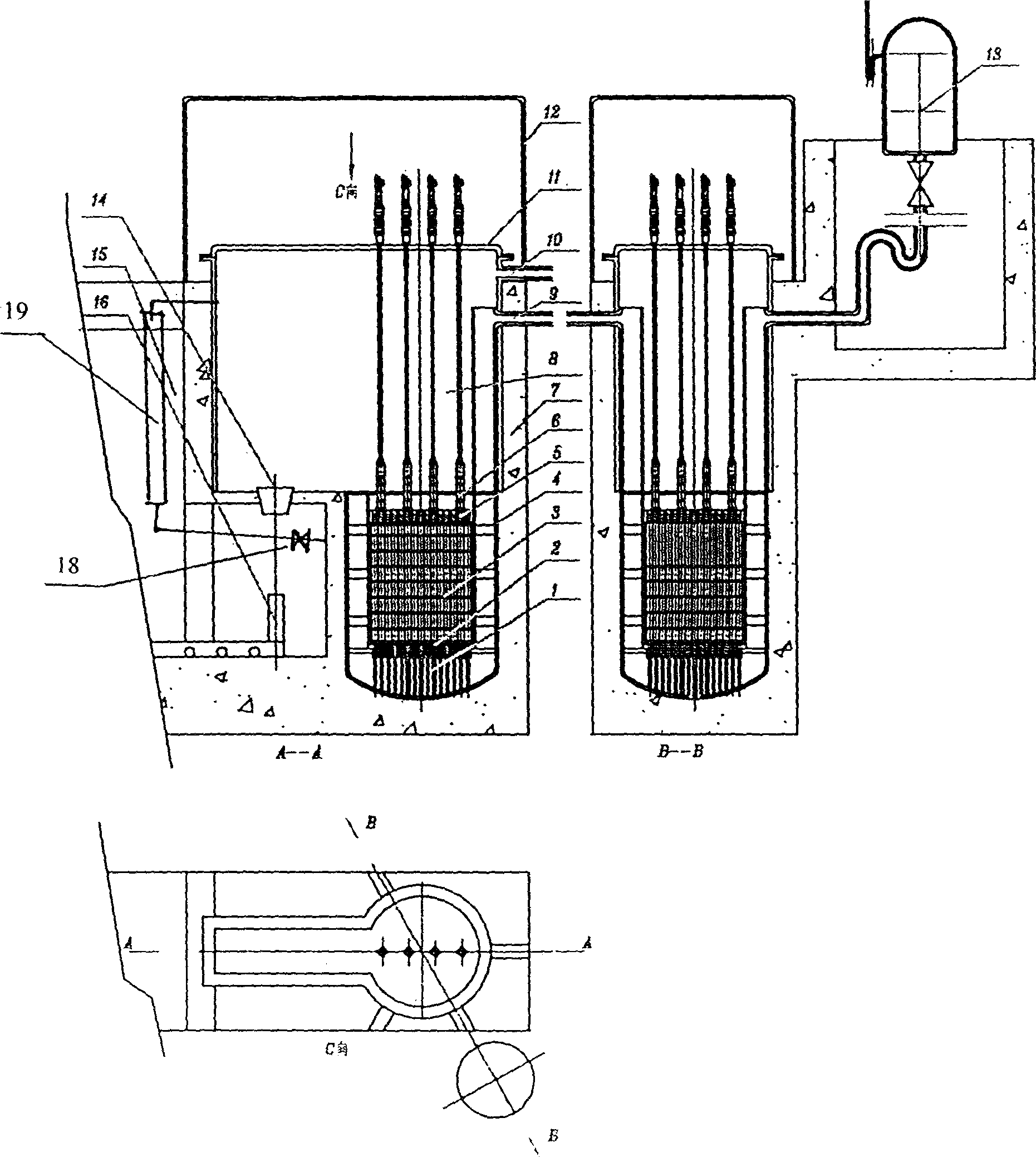

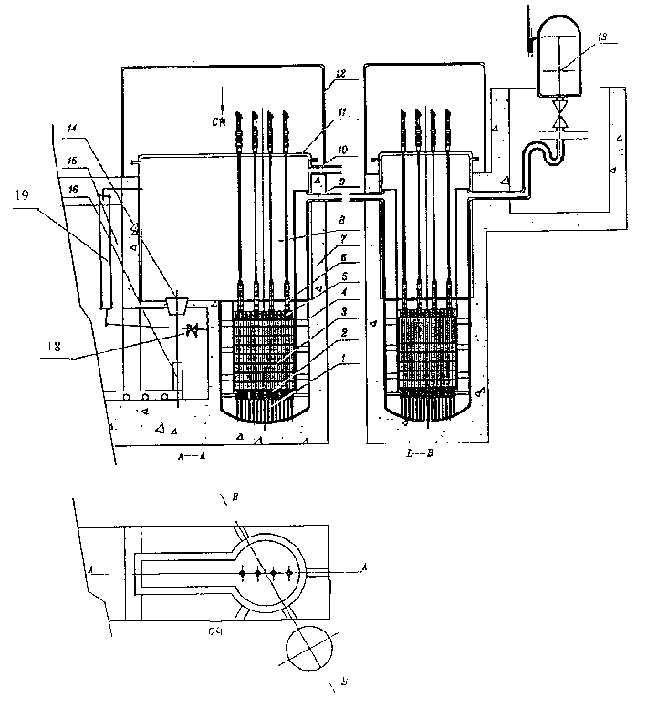

[0031] The present invention takes a heating stack with a thermal power of 200MW as an example, its structure is as follows figure 1 shown. The core pool 8 and the spent fuel storage pool 15 are surrounded by the concrete biological shielding layer 7. The upper part of the core pool 8 is provided with a coolant inlet pipe 9 and a coolant outlet pipe 10. The side of the core pool 8 is provided with an underwater The loading and unloading channel 14 communicates with the spent fuel storage pool 15, which is sealed by a sealing plug during the operation of the reactor to ensure the isolation between the core pool and the spent fuel storage pool. The spent fuel storage pool 15 can place spent fuel transportation containers and spent fuel storage The compartment is equipped with a discharge trolley 16, and the tunnel is opened during discharge to realize the transfer of spent fuel assemblies. The concrete biological shielding layer 7 is covered with stainless steel to ensure that ...

Embodiment 2

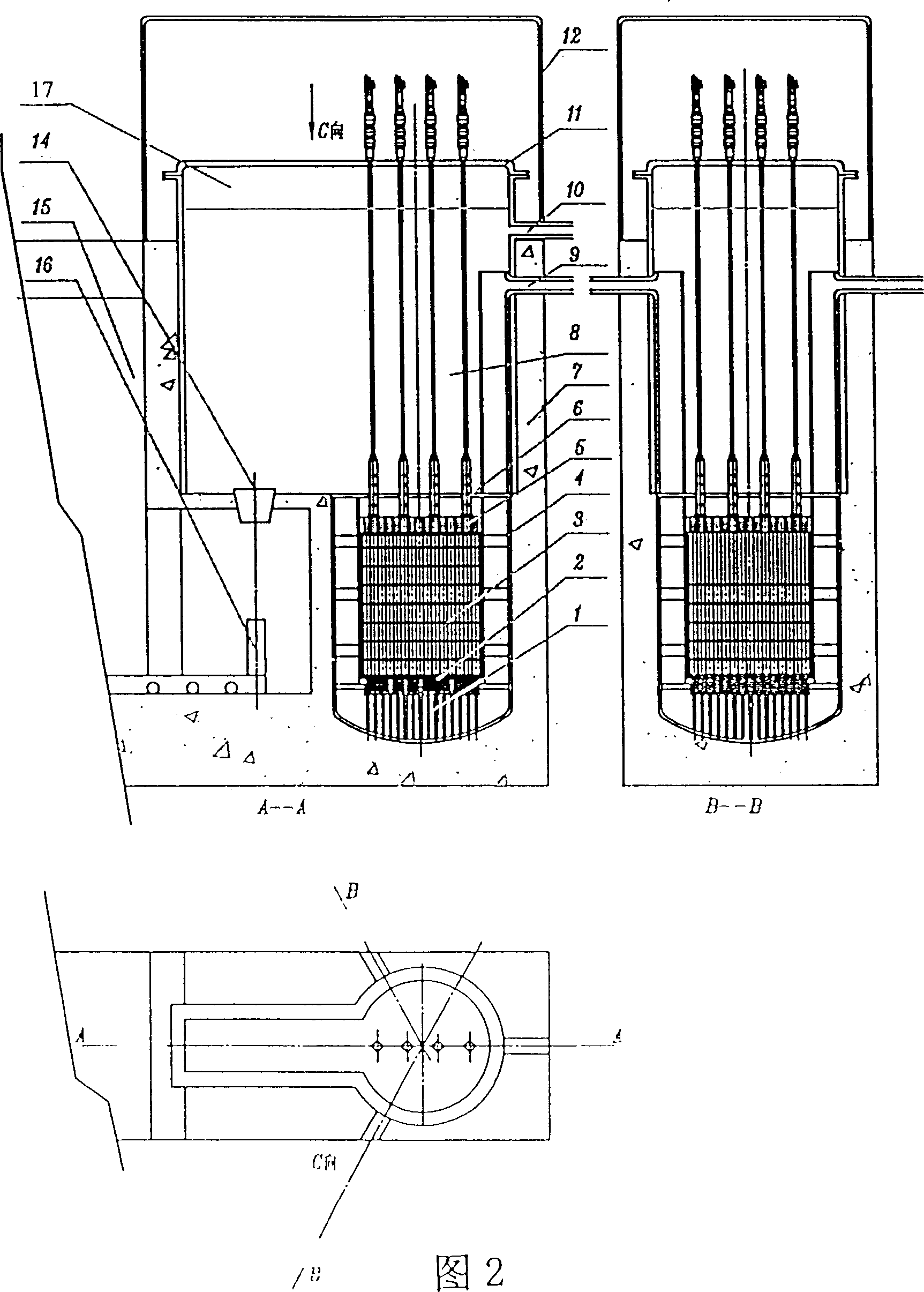

[0033] The difference from Example 1 is that another core structure is to inflate the water pool, and the outlet pressure of the core is formed by using the air pressure, and its structure is shown in FIG. 2 . A gas sealing cover 11 in the shape of a cap is provided on the upper part of the core pool 8 to form a pressurized air cavity 17 filled with air or nitrogen or helium at a certain pressure, and the lower part is the water level fluctuation area of the pool to form a primary gas Seal the barrier. Similarly, an airtight barrier 12 is also provided on the top of the core pool 8 to form a secondary gas barrier, and the area between the gas-tight cover 11 and the airtight barrier 12 on the top of the core pool 8 draws negative pressure to ensure radioactivity Gas does not escape to the environment.

[0034] In order to eliminate the hydrogen and oxygen gas produced by water decomposition and the gaseous iodine and radioactive inert gas produced by fuel fission in the seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com