Patents

Literature

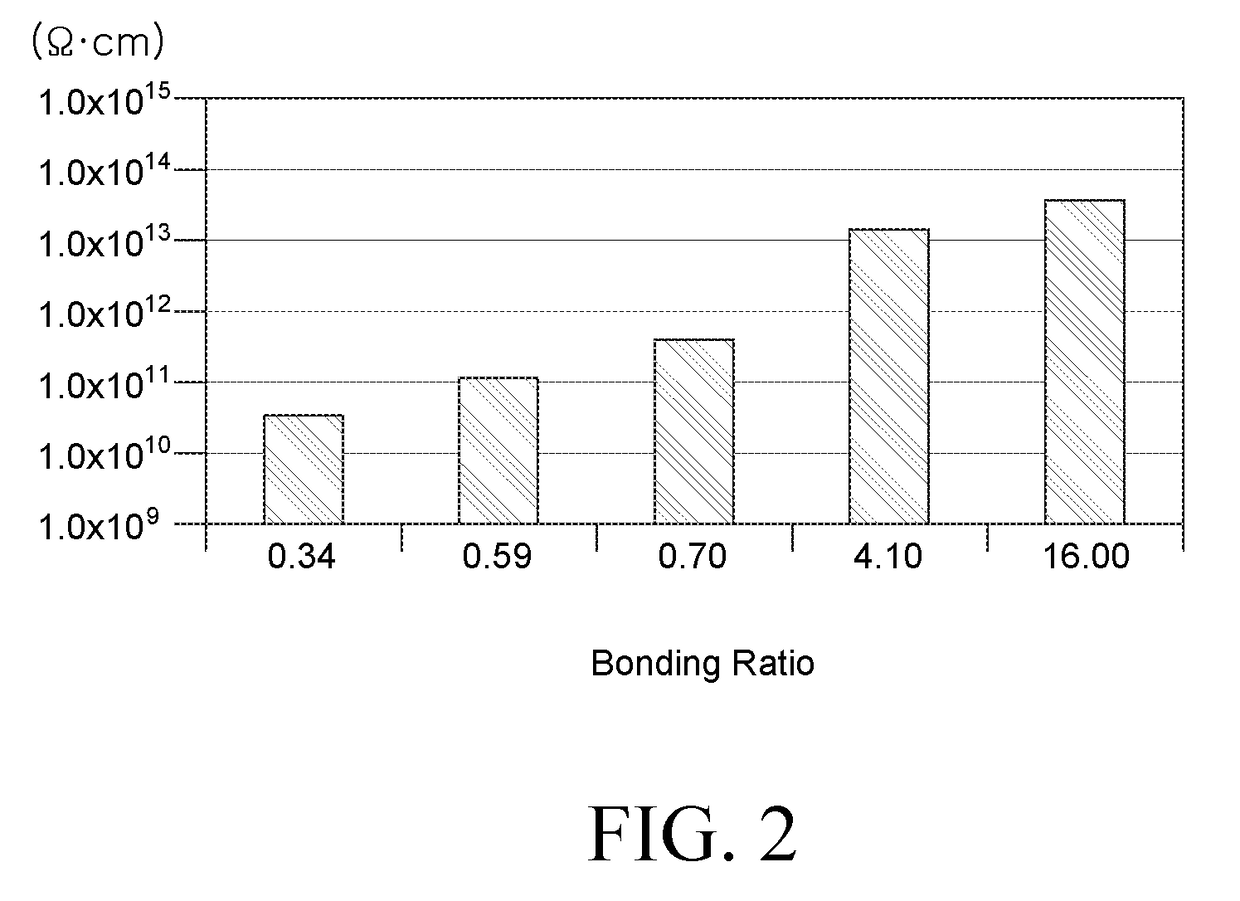

64results about How to "Reduce volume resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Conducting fiber containing nano car bon tube and its prepn. method

ActiveCN1563526AGood electrical conductivityReduce volume resistanceElectroconductive/antistatic filament manufactureMonocomponent polyesters artificial filamentElectrically conductivePolyester

A conducting fiber containing carbon nm tubes includes the following three components polyester, carbon nm tube and coupler with the weight ration of polyester 80-94.9, carbon nm tube 0.05-10, the coupler 0.05-10. The three components are prepared to conducting fibers via mix, extrusion and fiber spinning having the composite shapes of interlayer, sheath-core and island, characterizing in utilizing the fine conductivity of the carbon nm tubes and extremely length-diameter ratio to prepare conducting fibers, Special coupler is selected to strongthen the interaction of carbon nm tube and the polyerter to open the coacervates of the tube in the blend process by cutting.

Owner:TSINGHUA UNIV

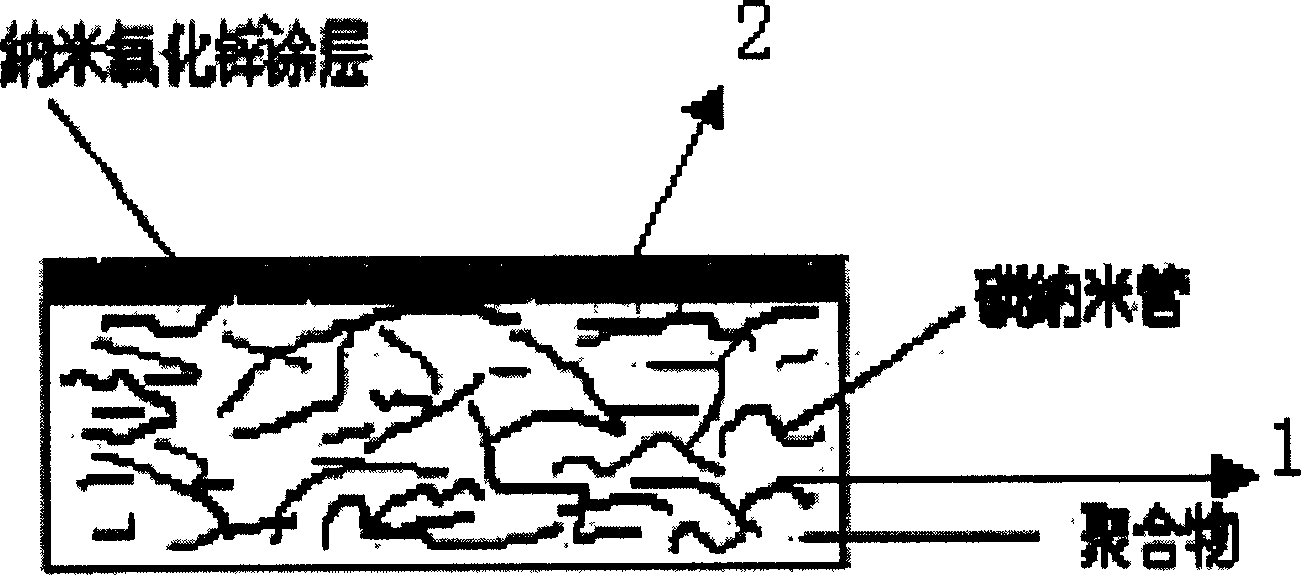

Carbon nano-pipe composite coating layer type wave absorption material and its preparation method

ActiveCN1651524AImprove conductivityAdjust the frequency rangeConjugated diene hydrocarbon coatingsRadiation-absorbing paintsThermal energyZno nanoparticles

A coated layer type composite wave absorbing material containing carbon nanotubes is composed of the basic substrate consisting of the polymer chosen from rubber, resin and plastics and carbon nanotubes, and the coated layer consisting of paint and nano-zinc oxide. Its advantages are high effect to absorb radar waves and adjustable frequency range of wave-absorbing peak.

Owner:TSINGHUA UNIV

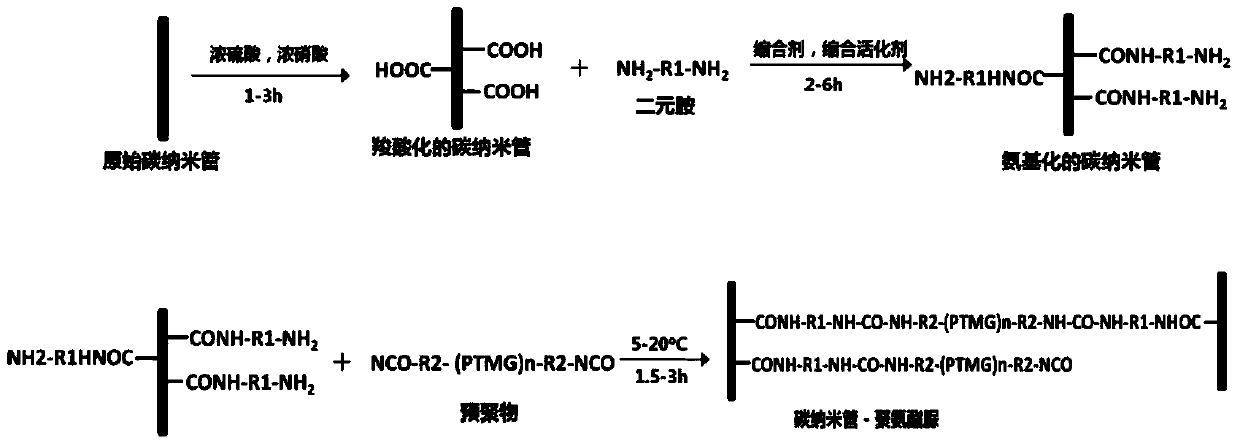

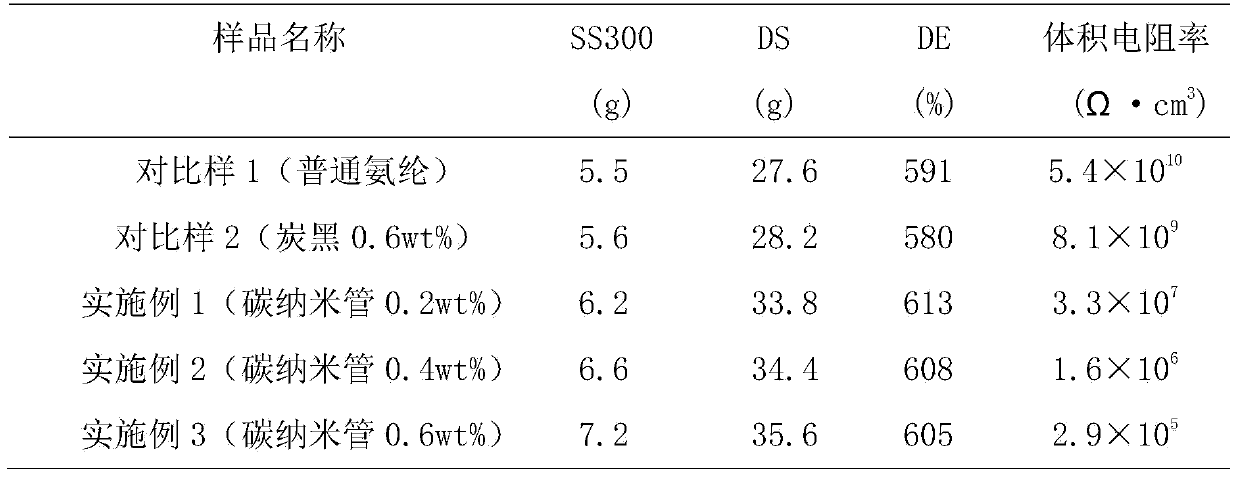

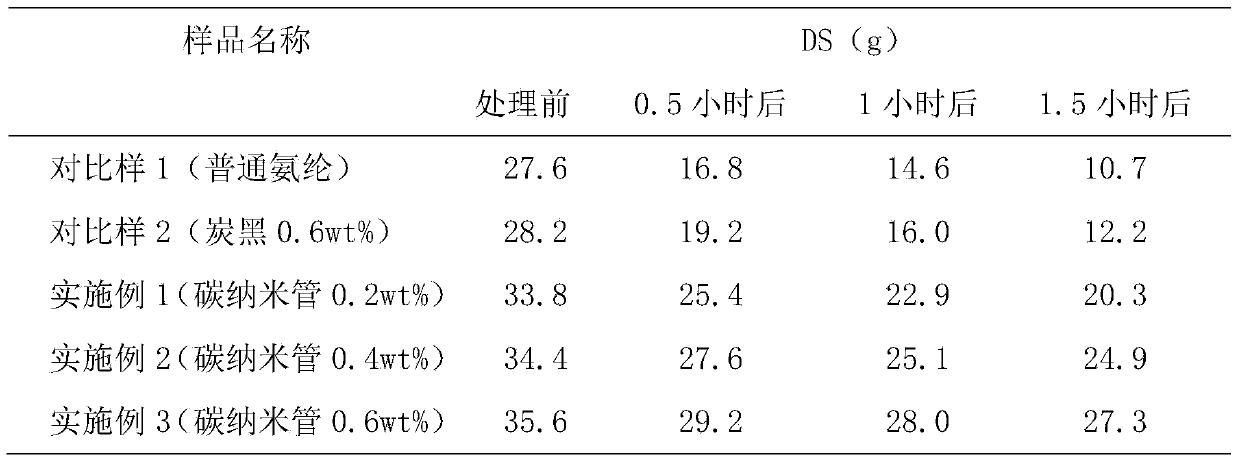

Black polyurethane-urea elastic fiber added with carbon nanotube and preparation method thereof

ActiveCN103726127AAvoid chain scissionImprove conductivityElectroconductive/antistatic filament manufactureMonocomponent synthetic polymer artificial filamentFiberCarbon nanotube

The invention discloses black polyurethane-urea elastic fiber added with a carbon nanotube and a preparation method thereof. In the elastic fiber, the carbon nanotube is used as black packing of spandex; after the carboxylation and amination treatment on the surface, the carbon nanotube can be uniformly dispersed in spandex and forms an effective chemical bonding effect with polymer molecules; the addition amount of the carbon nanotube is 0.01-1% of the mass of the polyurethane-urea elastic fiber. In the invention, the carbon nanotube is used as a coloring agent of black spandex for the first time, and the problem of difficult dispersion of the carbon nanotube in spandex and the shortcoming of weak bonding effect of a two-phase interface are avoided. The black spandex prepared by the method has good black effect and color fastness, high mechanical strength, high elongation, low volume resistivity and excellent antistatic effect; moreover, the black spandex has excellent heat resistance and high temperature resistance and can endure long-time high-temperature boiling while the retention rate of mechanical strength is high.

Owner:ZHEJIANG HUAFENG SPANDEX

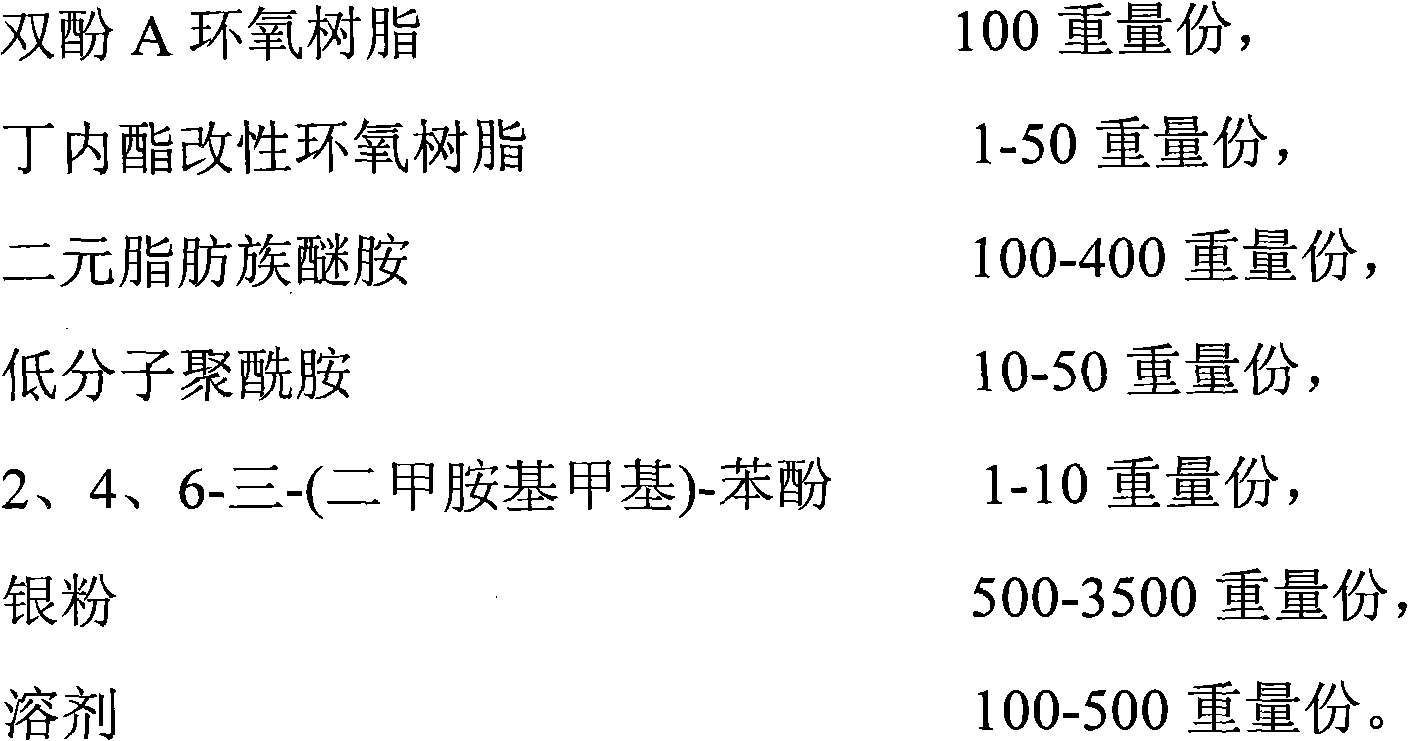

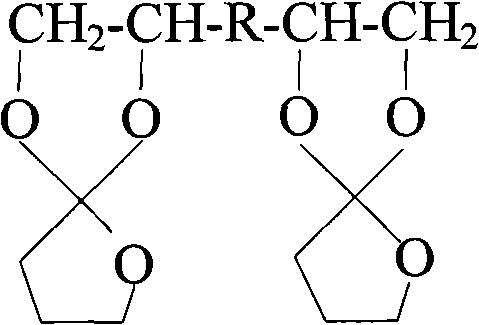

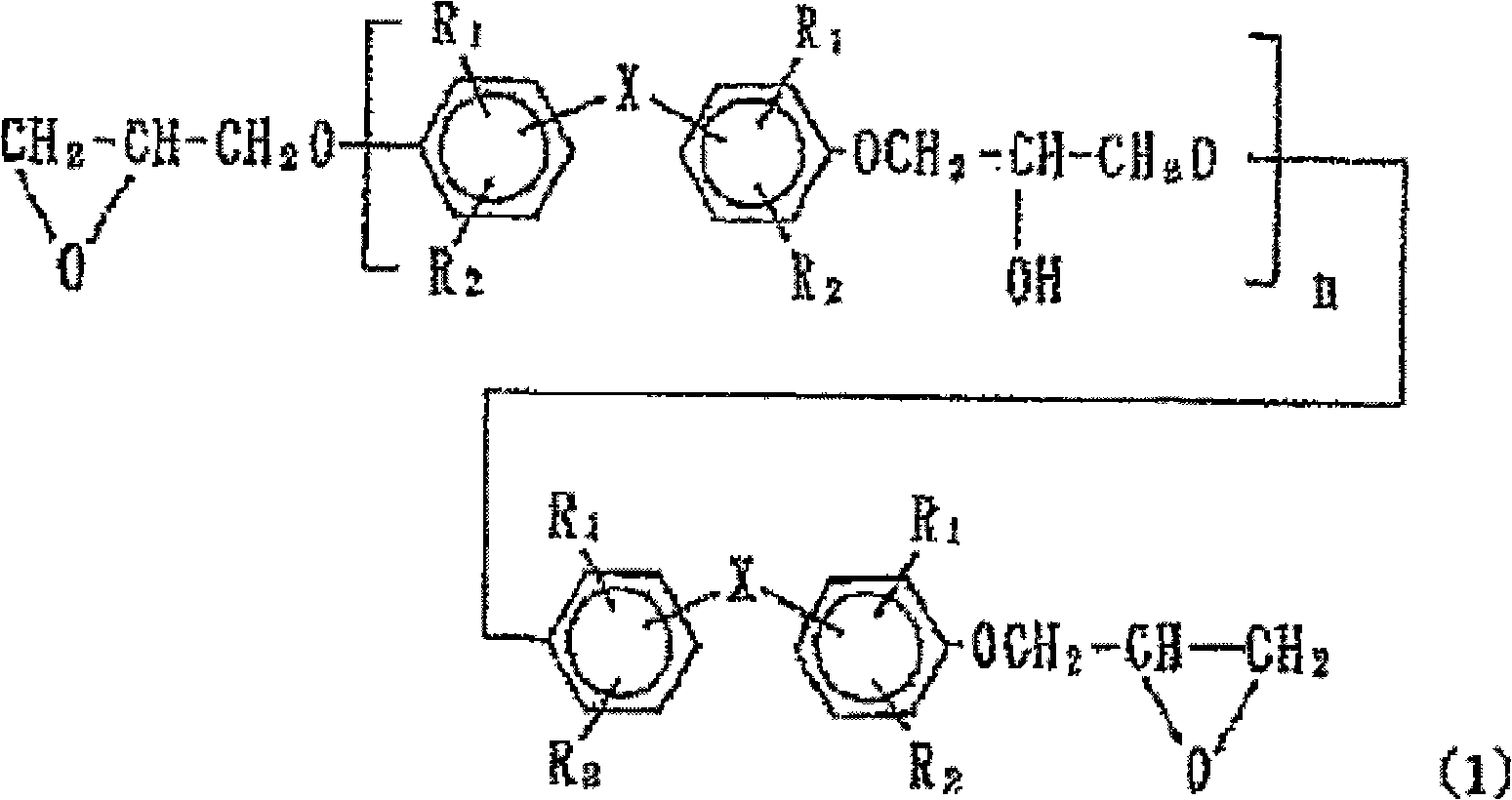

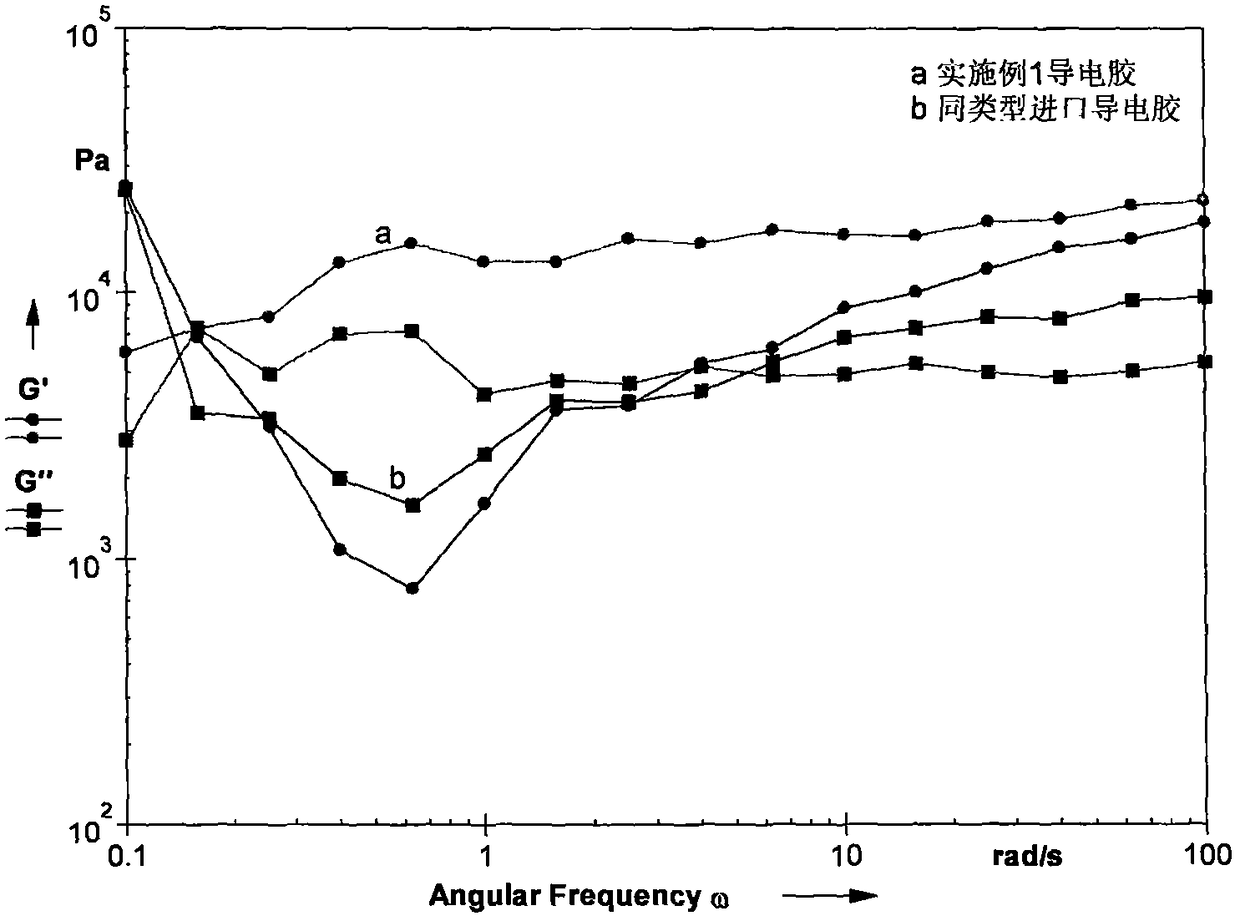

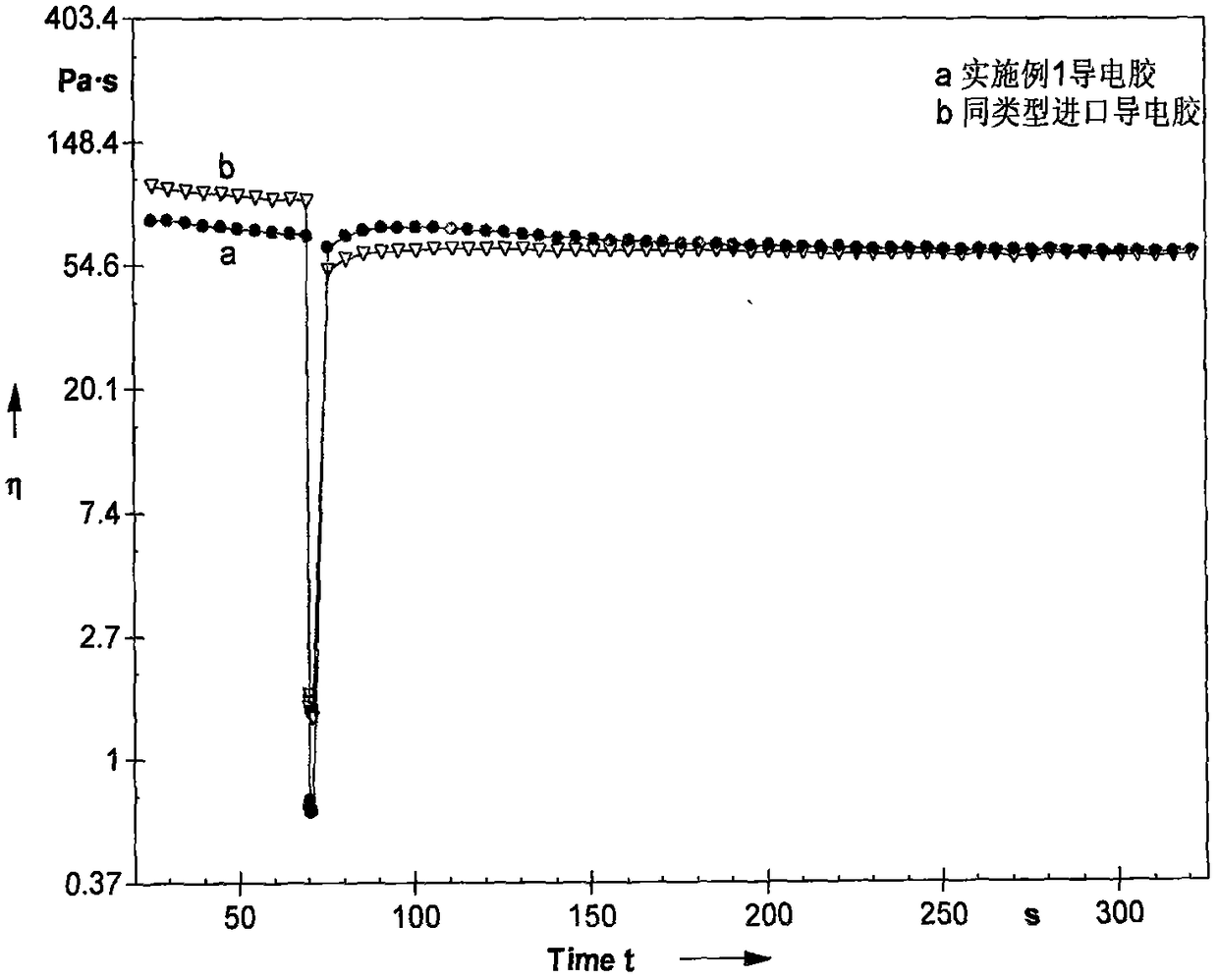

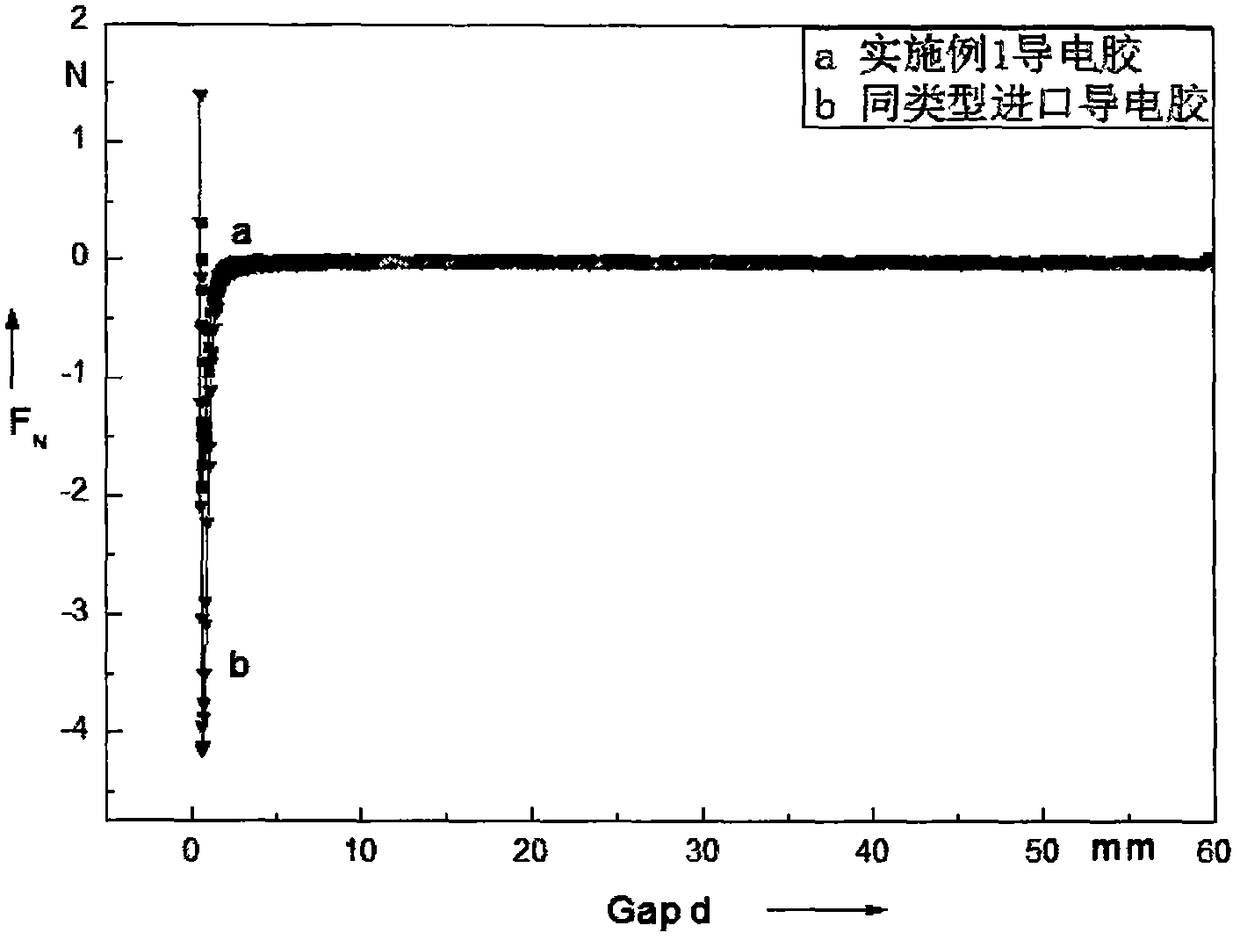

Silver conductive adhesive and preparation method thereof

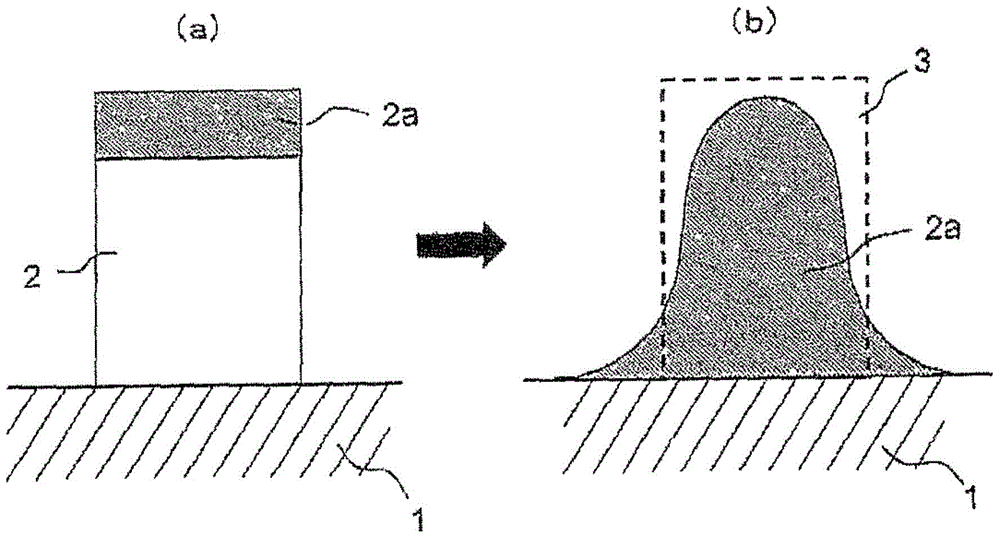

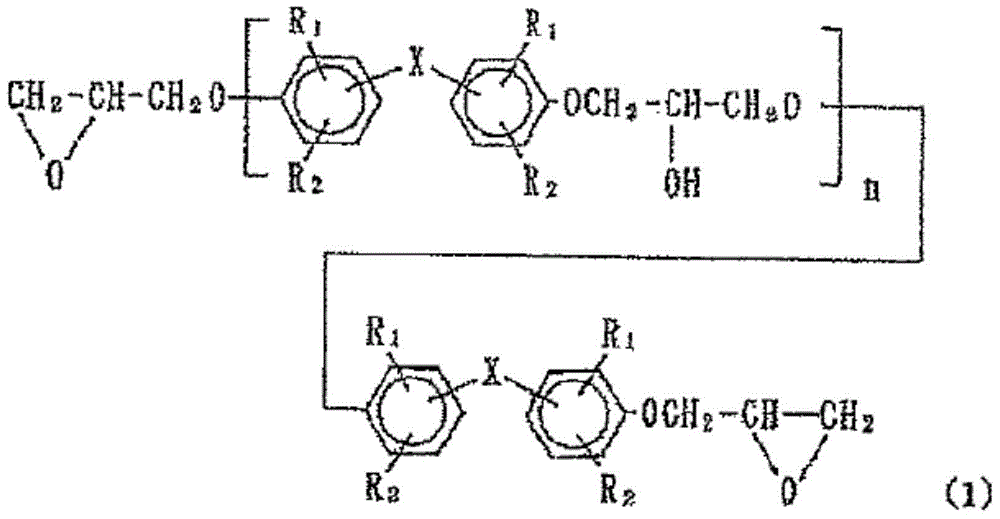

InactiveCN102040934AReduce expansionReduce volume resistanceNon-macromolecular adhesive additivesEpoxy resin adhesivesSolventEther

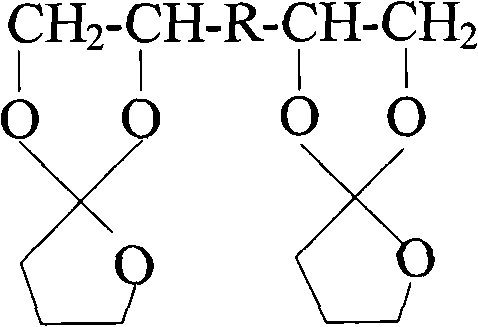

The invention provides a silver conductive adhesive, comprising a basic resin, a curing agent, a curing accelerator, a conductive material and a solvent, wherein the basic resin is an epoxy resin including a bisphenol A epoxy resin and a gamma-butyrolactone modified epoxy resin, the curing agent is binary aliphatic ether amine and versamid, the curing accelerator is 2,4,6-tri-(dimethylaminomethyl)-phenol, and the conductive material is silver powder. The invention further provides a preparation method of the silver conductive adhesive. In the invention, the gamma-butyrolactone modified epoxy resin is introduced into the epoxy system silver conductive adhesive, and when the modified epoxy resin is cured, a polycyclic structure is subjected to ring-opening polymerization to result in volumetric expansion, by jointly applying the modified epoxy resin and the epoxy resin to the silver conductive adhesive, the prepared silver conductive adhesive has low shrinkage rate and low expansion rate as well as low volume resistance. The silver conductive adhesive prepared in the invention can be widely applied to various environments.

Owner:BYD CO LTD

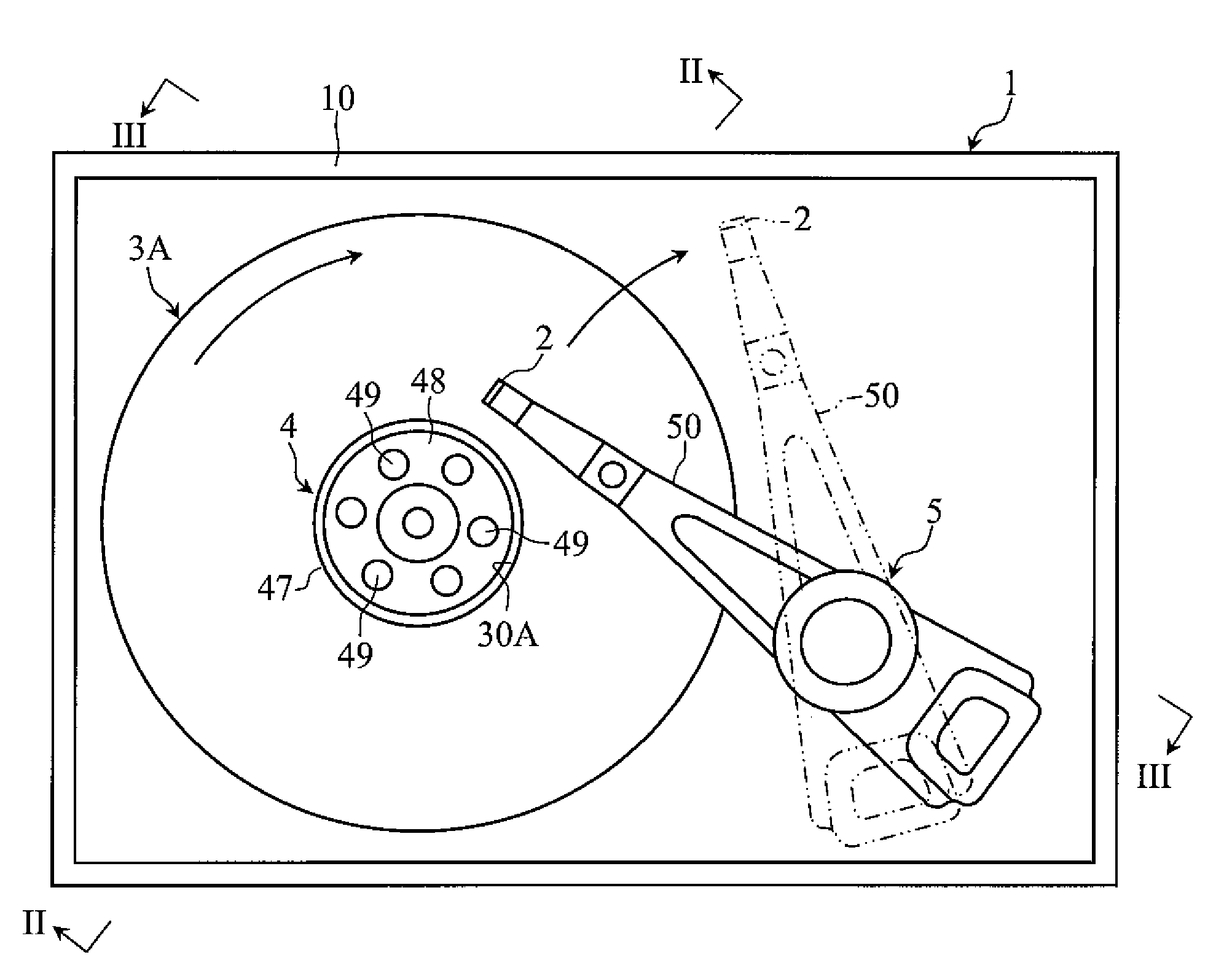

Magnetic head substrate, magnetic head and recording medium driving device

InactiveUS20090244772A1Improve flight characteristicsImprove machinabilityMaterial nanotechnologyConductive materialCarbideNitride

The present invention relates to a magnetic head substrate comprising a sintered body containing 35% by mass to 60% by mass of alumina and 40% by mass to 65% by mass of a conductive compound. The conductive compound contains at least one selected from carbide, nitride and carbonitride of tungsten. The sintered body has a maximum crystal particle size of 4 μm or less (except for 0 μm). Furthermore, the present invention provides a magnetic head provided with a slider formed of the magnetic head substrate and a recording medium driving device provided with the magnetic head.

Owner:KYOCERA CORP

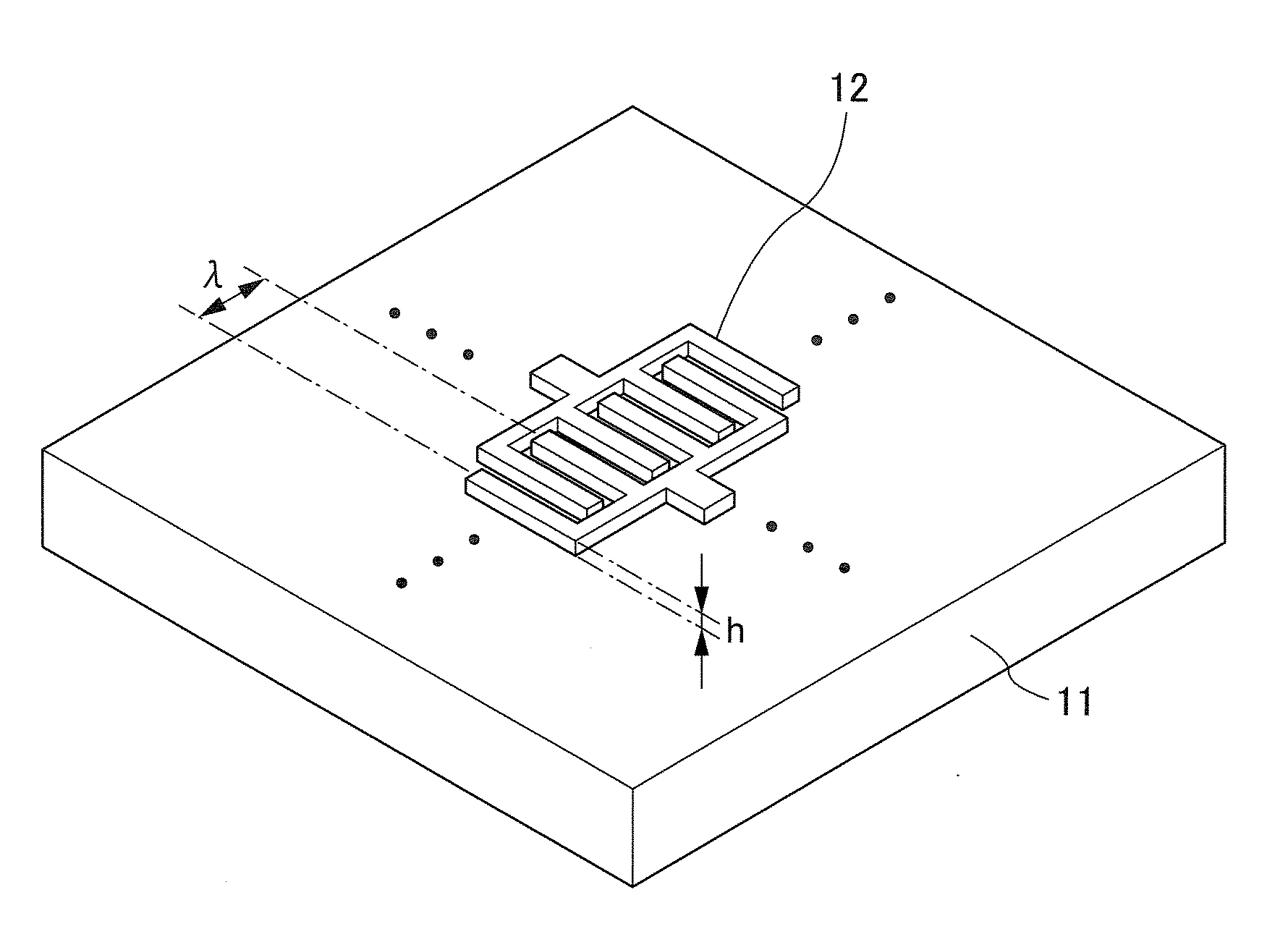

Surface acoustic wave device

ActiveUS7411333B2Lower volume resistivityAvoid charge accumulationPiezoelectric/electrostriction/magnetostriction machinesImpedence networksPiezo electricSingle crystal

Owner:SNAPTRACK

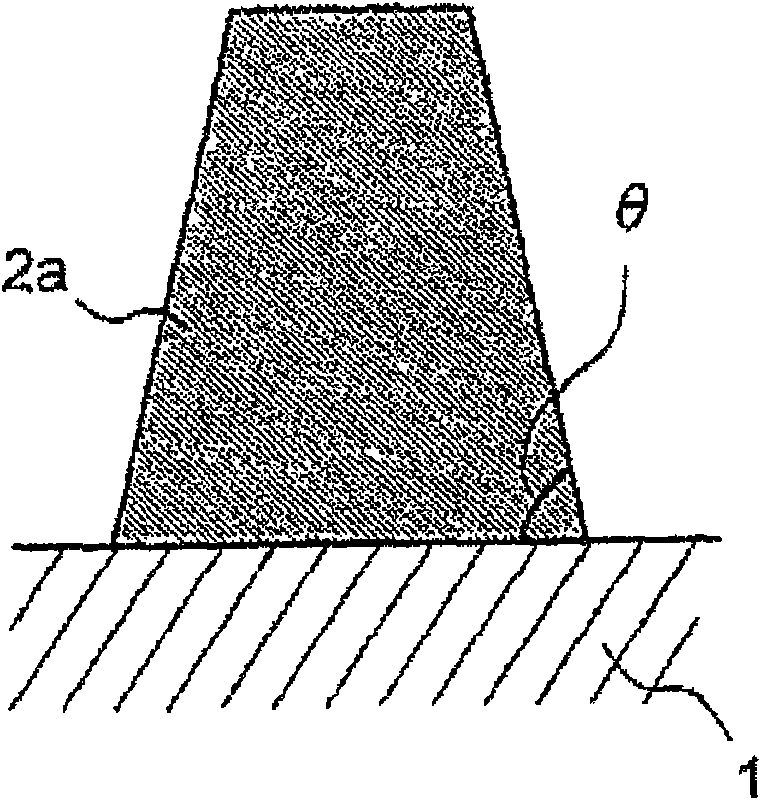

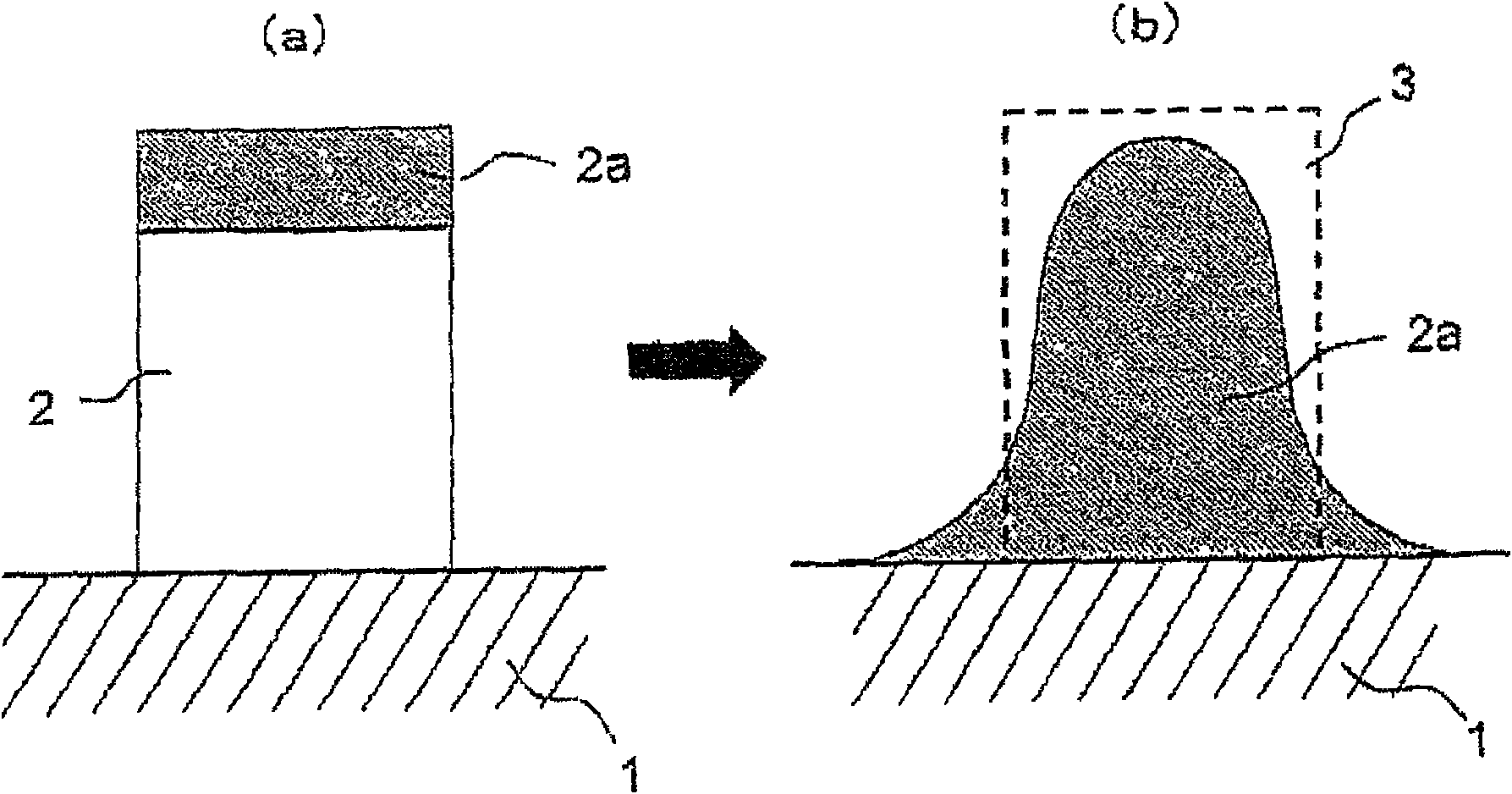

Photosensitive compound, solidifying film and septum

ActiveCN101872121AImprove dispersion stabilityImproved shape stabilityOptical filtersPolarising elementsAcrylic resinConductive materials

The invention relates to a photosensitive compound, a solidifying film and a septum, which can form excellent pattern with size stability even if a thick solidifying film is obtained and will not decrease the volume resistance even if conductive materials like carbon are used as a shielding component. The photosensitive compound is characterized in that (i) photo-curing resin and / or photo-curing monomer and (ii) acrylic resin grains are the necessary components, wherein the average once grain size of the (ii) acrylic resin grains is 50 to 200 nm and the weight ratio of the (ii) acrylic resin grains to the (i) photo-curing resin and / or photo-curing monomer is 0.1 to 2.0. Besides, the photosensitive compound is applied to making the solidifying film and the septum.

Owner:NIPPON STEEL CHEMICALL &MATERIAL CO LTD

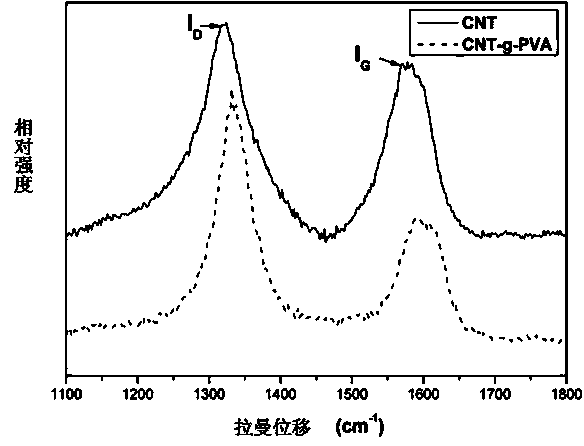

Carbon nanotube modified polyvinyl akohol nano-fiber yarn and preparing method thereof

ActiveCN103668616AHigh densityHigh strengthFilament/thread formingMonocomponent synthetic polymer artificial filamentYarnFiber

The invention relates to a carbon nanotube modified polyvinyl akohol nano-fiber yarn and a preparing method thereof. A carbon nanotube and a certain amount of polyvinyl akohol are mixed in a dissolved mode, alchlor is used as a catalyst for Friedel-Crafts alkylation reaction, residual polyvinyl akohol and aluminium ions are eliminated through post-processing, and the carbon nanotube modified in a polyvinyl akohol grafting mode is obtained; the grafted carbon nanotube is dissolved in solvent, the grafted carbon nanotube and an appropriate amount of polyvinyl akohol are prepared into spinning stock solution, a carbon nanotube modified polyvinyl akohol nano-fiber parallel array is prepared through an electrostatic spinning process, and the fiber yarn is obtained in a twisted mode. According to the carbon nanotube modified polyvinyl akohol nano-fiber yarn and the preparing method thereof, the polyvinyl akohol and the carbon nanotube are combined through chemical bonds by means of Friedel-Crafts alkylation reaction, grafting efficiency of the carbon nanotube is obviously improved, dispersibility of the carbon nanotube in the solvent and stress transfer efficiency between the carbon nanotube and a polyvinyl akohol matrix are improved, and the nano-fiber yarn having excellent mechanical performance and conductive performance is prepared.

Owner:涡阳量子信息科技有限公司

Semi-conductive mixture

InactiveCN1611535AHigh mechanical strengthReduce volume resistanceLow-density polyethyleneSemiconduction

The invention relates to a kind of semiconduction mixture. Generate basic polymer by low-density polythene with 20-70 part by weight and other polyolefin polymer with 80-30 part by weight, and then cooperate semiconduction carbon black with 30-80 part by weight in this basic polymer with 100 part by weight.

Owner:THE FUJIKURA CABLE WORKS LTD

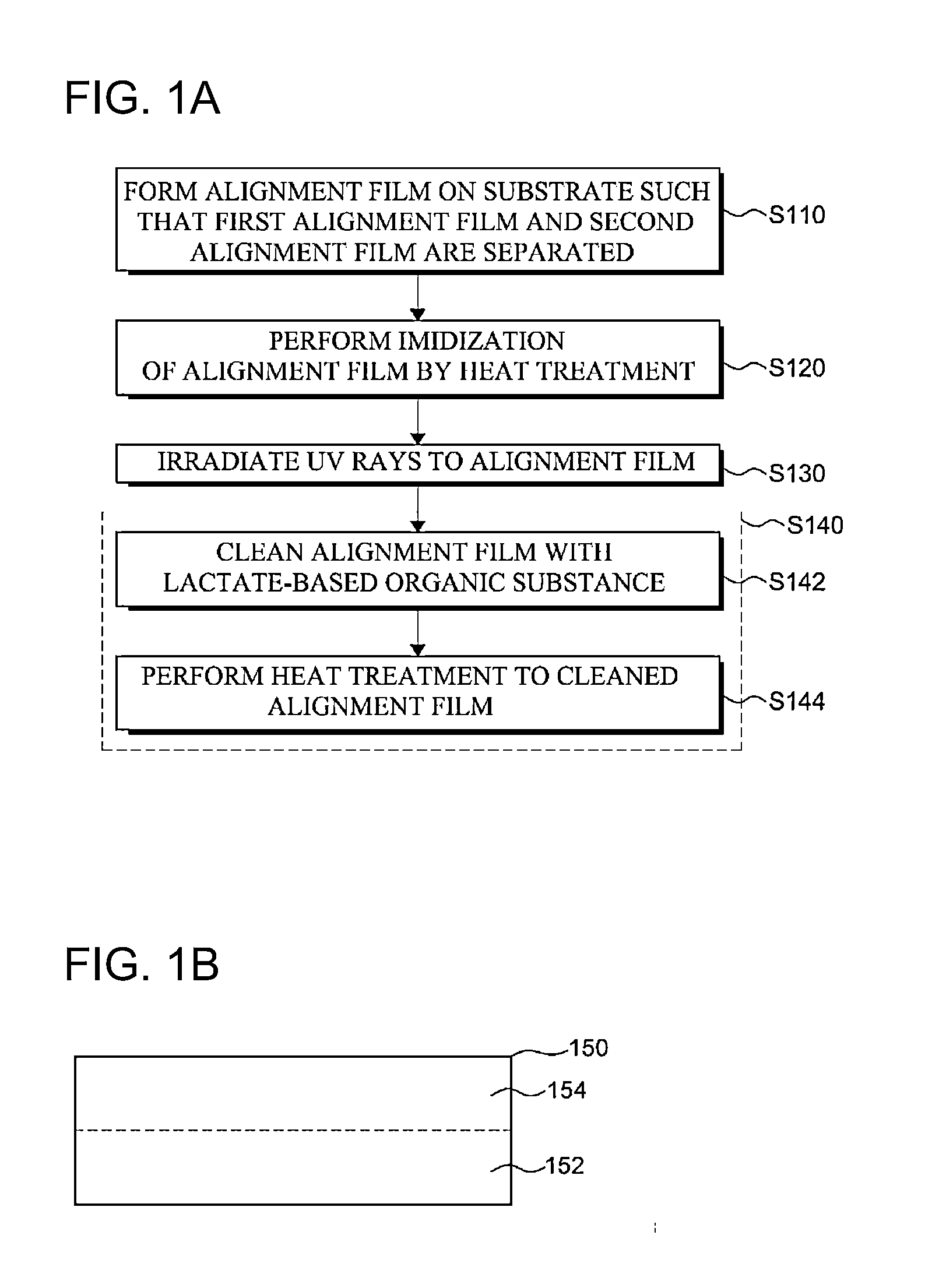

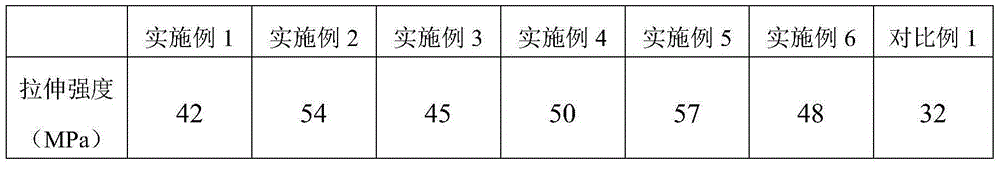

Liquid crystal display device and method of manufacturing the same

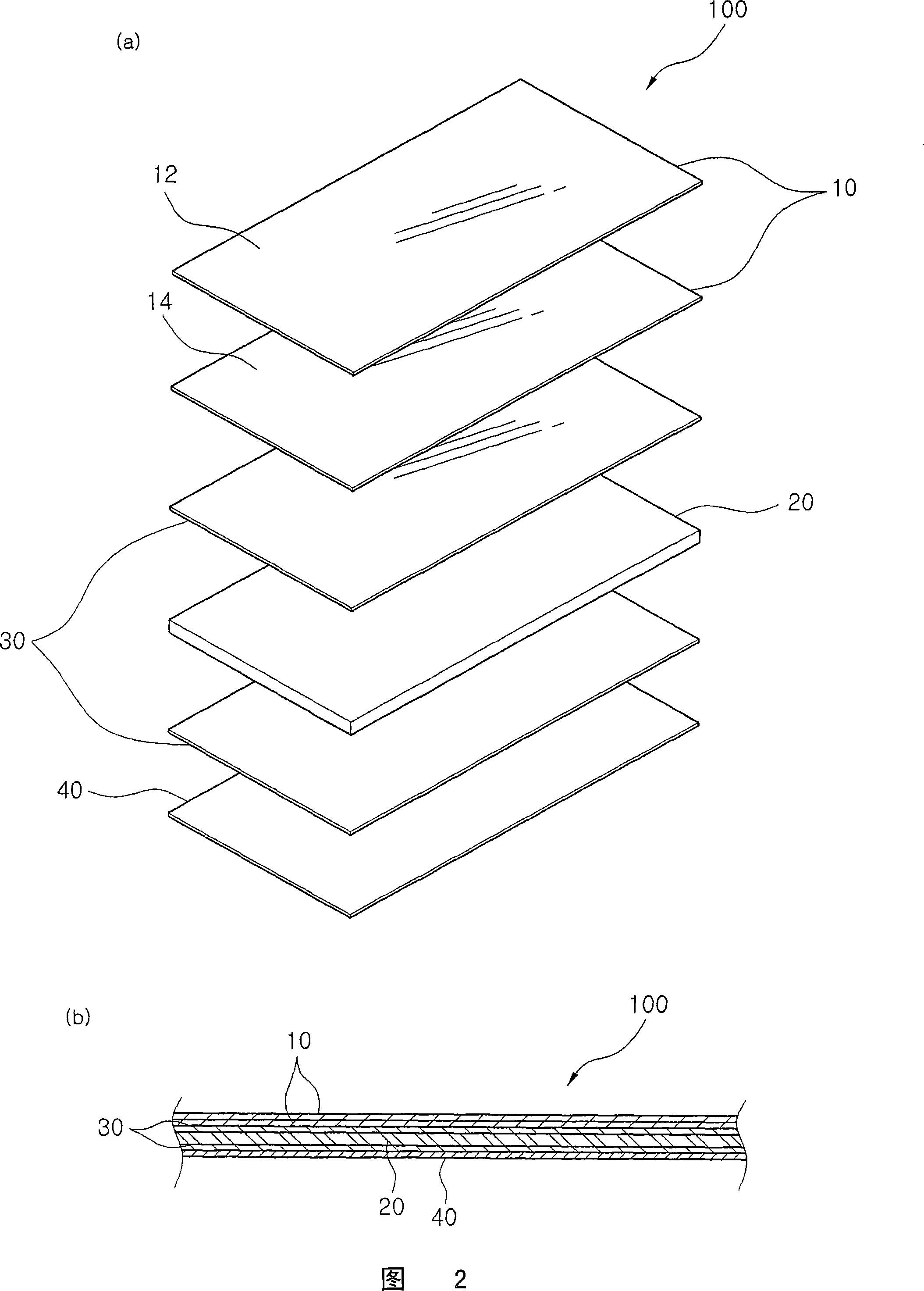

ActiveUS20140368779A1Minimize occurrenceReduce volume resistanceLamination ancillary operationsLaminationLiquid-crystal displayLiquid state

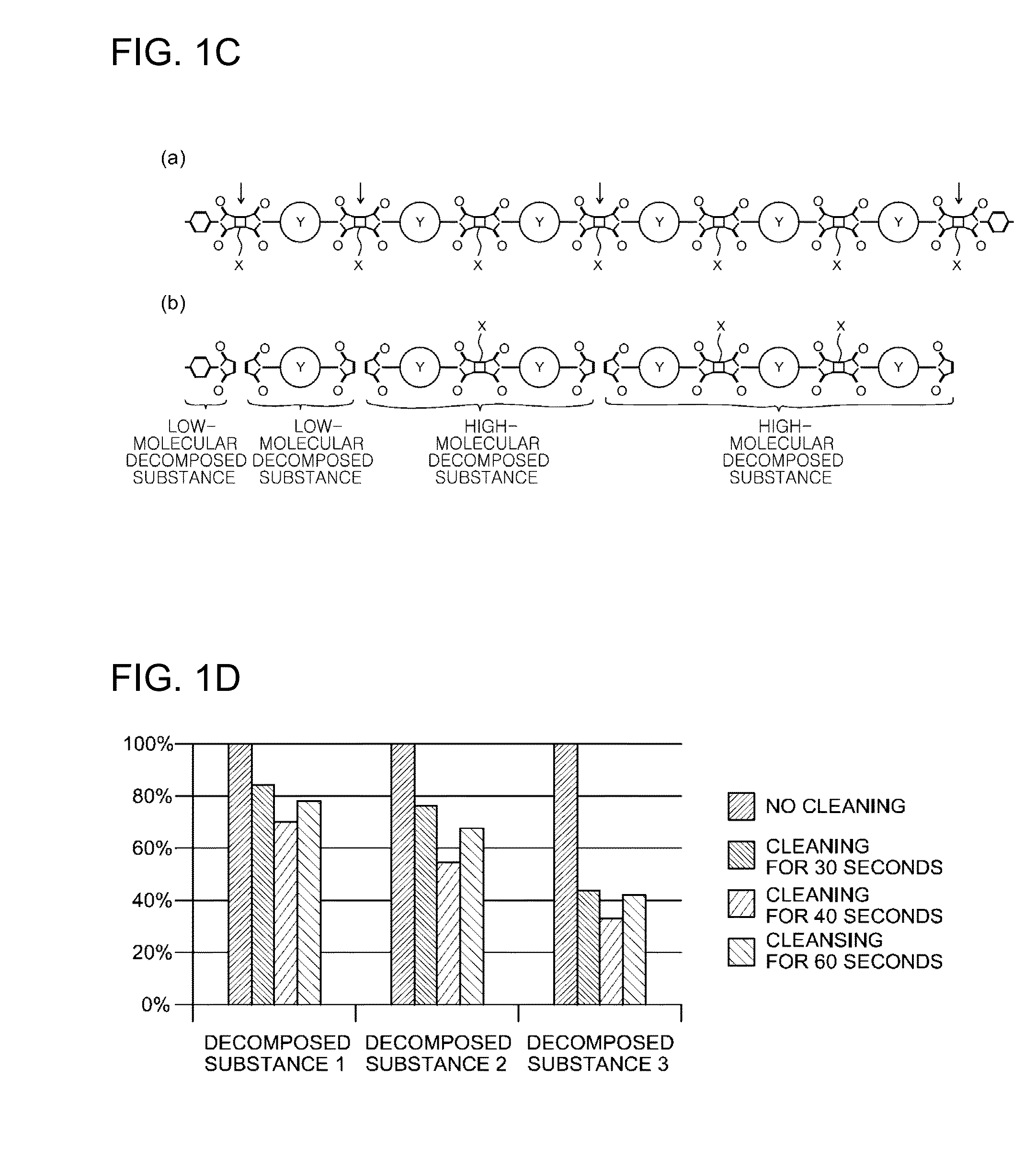

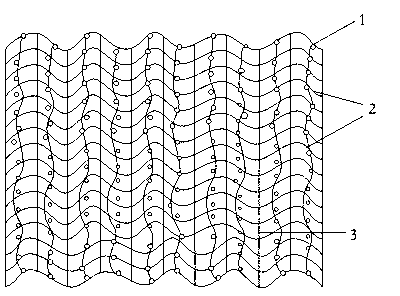

Provided is a method of manufacturing new liquid crystal display device according to an embodiment of the present invention. Firstly, an alignment film is formed on a substrate. The alignment film is divided into a first alignment film formed using, as a precursor, liquid-state polyimide that contains a photodecomposition substance and a second alignment film formed using, as a precursor, a polyamic acid that does not contain a photodecomposition substance. UV light is irradiated to the alignment film, and decomposed substances formed by irradiation of the UV light is removed by an at least two-step removing process. By the method of manufacturing a liquid crystal display device according to the exemplary embodiment of the present disclosure, bright spots are minimized in pixels and a brightness of black is lowered, so that a liquid crystal display device with a high contrast ratio can be realized.

Owner:LG DISPLAY CO LTD

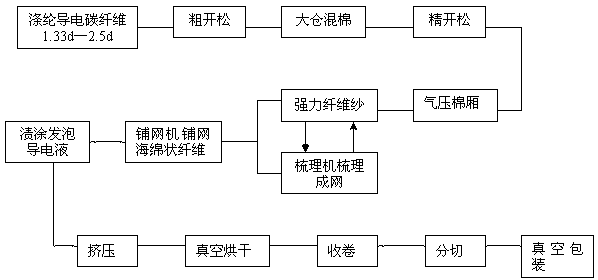

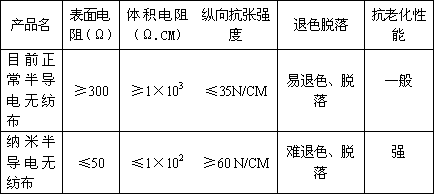

Nanometer semi-conductive non-woven fabric and processing technology thereof

InactiveCN103295704AExcellent semi-conductive propertiesHigh tensile strengthInorganic insulatorsNatural mineral layered productsYarnCopper conductor

The invention relates to a nanometer semi-conductive non-woven fabric and a processing technology of the nanometer semi-conductive non-woven fabric. The nanometer semi-conductive non-woven fabric is made of carbon fiber new materials through the advanced technologies like the high-strength spun yarn assisted net new process, the nanometer technology, the foam terylene layer technology and vacuum drying. The nanometer semi-conducive non-woven fabric has the advantages of being superior in semi-conductive performance, high in anti-tension strength, low in surface resistance and volume resistance and not prone to fading under high temperature. Besides, 'C' black on the surface cannot drop, efficiency is high, energy is saved, and environmental friendliness is achieved in a manufacturing process. The nanometer semi-conductive non-woven fabric is mainly used in cable core insulating layers of mine cables with 6KV and more than 6KV high voltage, shipboard cables with 6KV and more than 6KV high voltage and large-cross-section power cables with 10KV or more than 10KV and copper conductor surface taped coverings, capable of resisting strong electric fields and static, and semi-shielding. The nanometer semi-conductive non-woven fabric is also applicable to the development of indoor anti-static devices and anti-radiation shielding layers of medical and maternity anti-radiation clothes.

Owner:YANG ZHOU TENGFEI ELECTRIC CABLE & APPLIANCE MATERIALS CO LTD

Antistatic coating and preparation method thereof

InactiveCN106010094AReduce volume resistanceImprove shielding effectEpoxy resin coatingsElectrically-conductive paintsEpoxyPROPYLENE GLYCOL BUTYL ETHER

The invention discloses an antistatic coating and a preparation method thereof. The antistatic coating is prepared from, by weight, epoxy resin, acrylic resin, an antistatic nano-filler, polyethylene glycol, tetrabutyl orthosilicate, gelatin, dipropylene glycol butyl ether, zinc acetate, an isobutyltriethoxysilane coupling agent, a leveling agent and a solvent. The antistatic coating prepared in the invention has the advantages of low volume resistance, good shielding performance, realization of the adhesion grade being 1 grade, short curing time, wide range of the use temperature, industry standard meeting, realization of no foaming, cracking or peeling phenomena of a surface coated with the coating, and good comprehensive performances.

Owner:苏州市奎克力电子科技有限公司

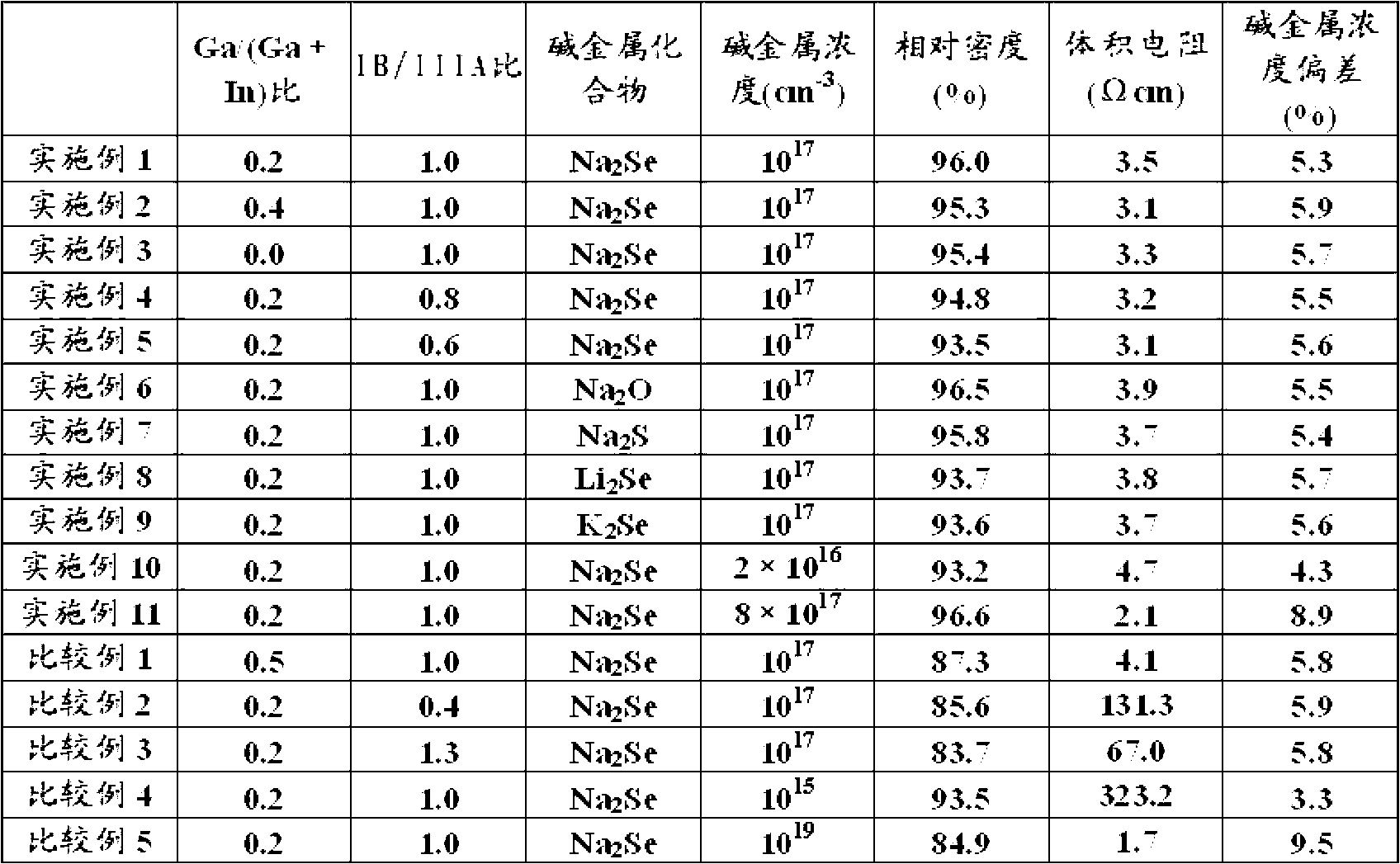

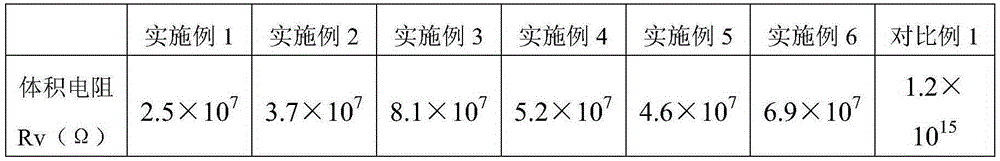

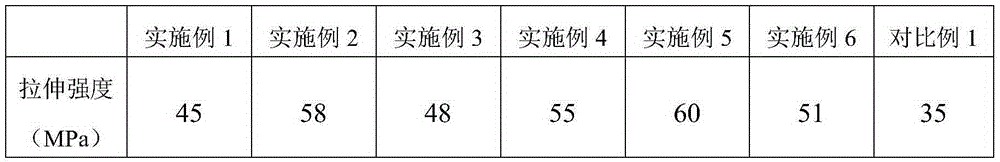

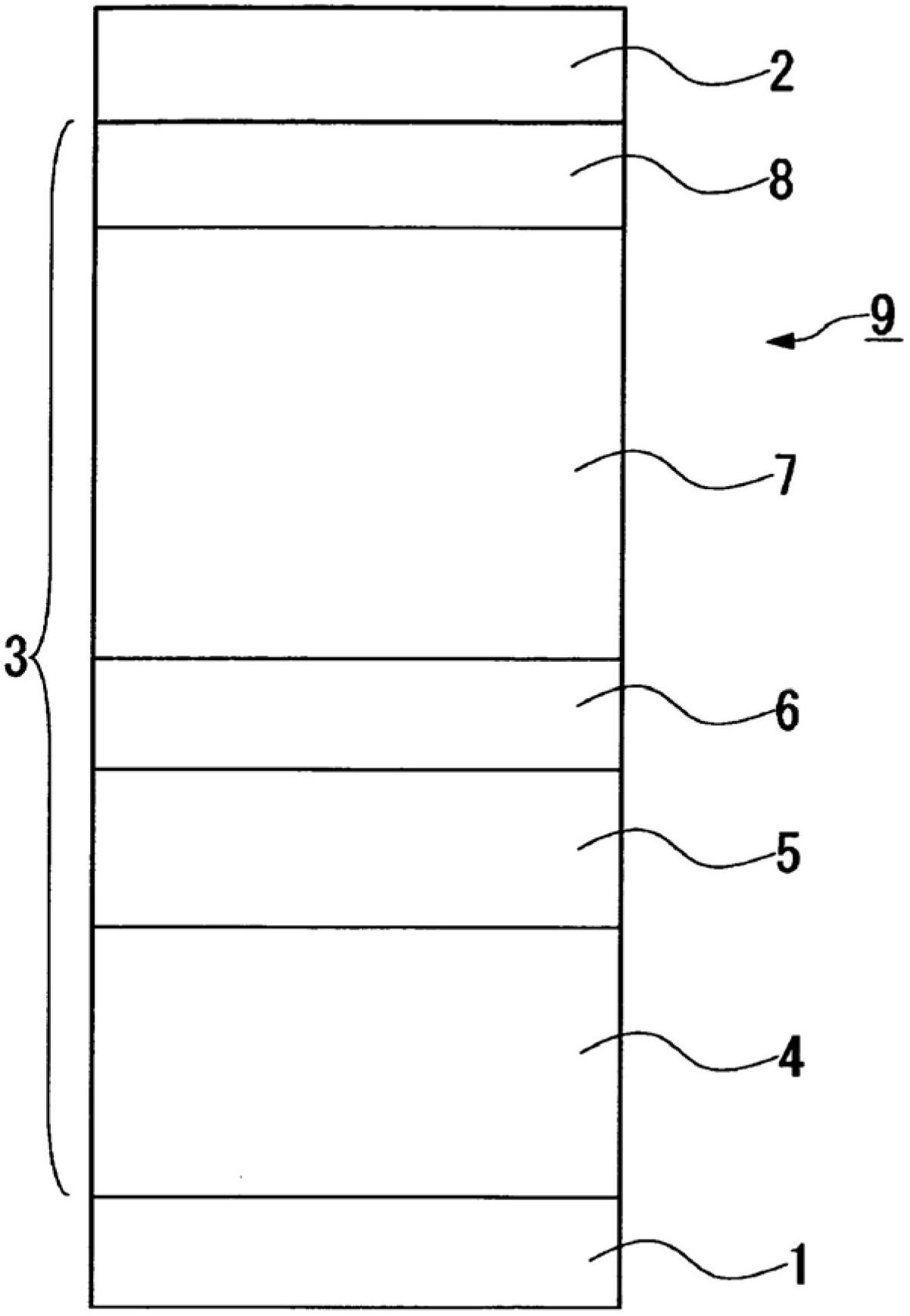

Sputtering target, compound semiconductor thin film, solar cell having compound semiconductor thin film, and method for manufacturing compound semiconductor thin film

ActiveCN102712996AReduce volume resistanceSuppress abnormal dischargeFinal product manufactureVacuum evaporation coatingSputteringCrystal structure

Disclosed is a sputtering target, which contains an alkali metal, is composed of an Ib element, IIIb element and VIb element, and has a chalcopyrite crystal structure. The sputtering target has the chalcopyrite crystal structure composed of a Ib-IIIb-VIb element, said structure being suitable for manufacturing, by sputtering one time, a light-absorbing layer having the chalcopyrite structure composed of the Ib-IIIb-VIb element.

Owner:JX NIPPON MINING & METALS CORP

Antistatic polylactic resin powder used for selective laser sintering, and preparation method thereof

The invention provides a preparation method of an antistatic polylactic resin powder used for selective laser sintering. The method comprises the following steps: 1, dissolving polylactic resin in a ketone and / or ether organic solvent at a heating temperature to obtain a polylactic resin solution; 2, cooling the polylactic resin obtained in step 1 to precipitate a solid precipitate; and 3, adding assistants to a solid-liquid mixture obtained in step 2, uniformly mixing the solid-liquid mixture and the assistants, and drying the obtained mixture to obtain the powder, wherein the assistants comprise an antistatic agent, an antioxidant and a powdery isolating agent. The method has the advantages of simplicity in operation, easiness in operation, provision of a sintering raw material with excellent processing properties for the selective laser sintering, and provision of a new direction for processing and application of functional polylactic resin. The invention further provides the antistatic polylactic resin powder prepared through the method, and a selective sintering method adopting the antistatic polylactic resin powder as a sintering powder raw material.

Owner:CHINA PETROLEUM & CHEM CORP +1

Glass fiber reinforced polylactic acid resin powder for selective laser sintering, and preparation thereof

ActiveCN106589858AEasy to operateEasy to manufactureAdditive manufacturing apparatusAdditive manufacturing with solidsSelective laser sinteringOrganic solvent

The present invention provides a preparation method of glass fiber reinforced polylactic acid resin powder for selective laser sintering. The preparation method comprises: a) dissolving a polylactic acid resin in a ketone and / or ether organic solvent at a heating temperature to obtain a polylactic acid resin solution; b) cooling the polylactic acid resin solution obtained in the step a) to precipitate the solid; and c) adding an auxiliary agent to the solid-liquid mixture obtained in the step b), uniformly mixing, and drying to obtain the powder, wherein the auxiliary agent comprises ultra-short glass fibers, an antioxidant and a powder isolation agent. According to the present invention, the method is simple and easy to operate, the sintering raw material having excellent processing performance is provided for the selective laser sintering, and the new direction is provided for the processing and application of the functional polylactic acid resin. The invention further provides the glass fiber reinforced polylactic acid resin powder prepared according to the method, and a selective laser sintering method using the glass fiber reinforced polylactic acid resin powder as the sintering powder raw material.

Owner:CHINA PETROLEUM & CHEM CORP +1

Transparent conductive film, solar cell using same, sputtering target for forming said transparent conductive film, and manufacturing method therefor

ActiveCN102666910AImprove moisture resistanceLess increase in specific resistanceConductive layers on insulating-supportsVacuum evaporation coatingElectrically conductiveLiquid-crystal display

Provided is a transparent conductive film used in liquid-crystal display devices, electroluminescent display devices, and the like, and is particularly suitable for use in solar cells. Also provided is a solar cell using said transparent conductive film and a sputtering target suited to forming said transparent conductive film. The provided transparent conductive film, which is highly moisture-resistant, comprises oxides of aluminum, magnesium, gallium, and zinc. Between 0.7% and 7% of the metal atoms in the transparent conductive film are aluminum, between 9.2% and 25% are magnesium, between 0.015% and 0.085% are gallium, and the remainder are zinc.

Owner:MITSUBISHI MATERIALS CORP

Pole seal material for lithium ion batteries and preparation method of pole seal material for lithium ion batteries

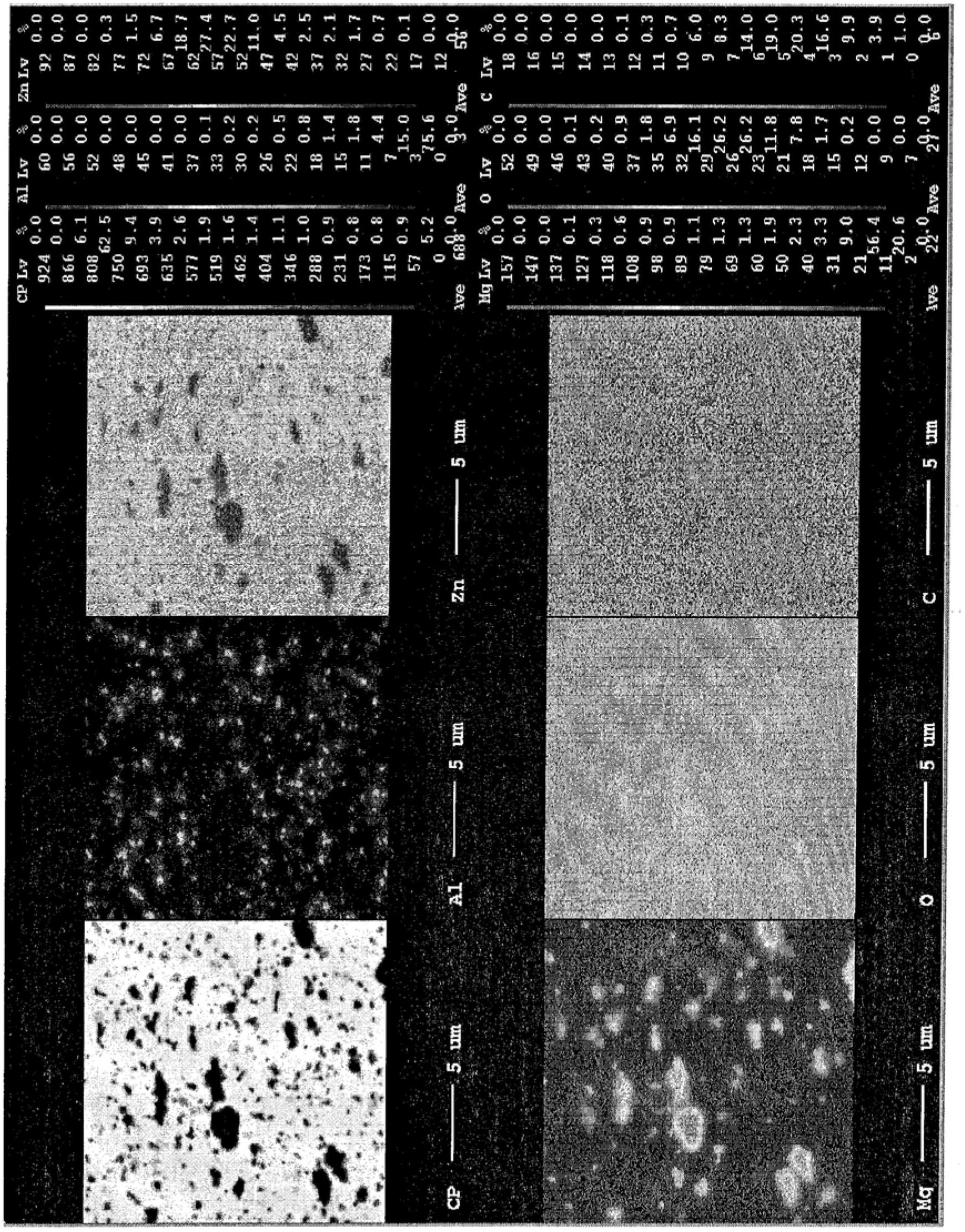

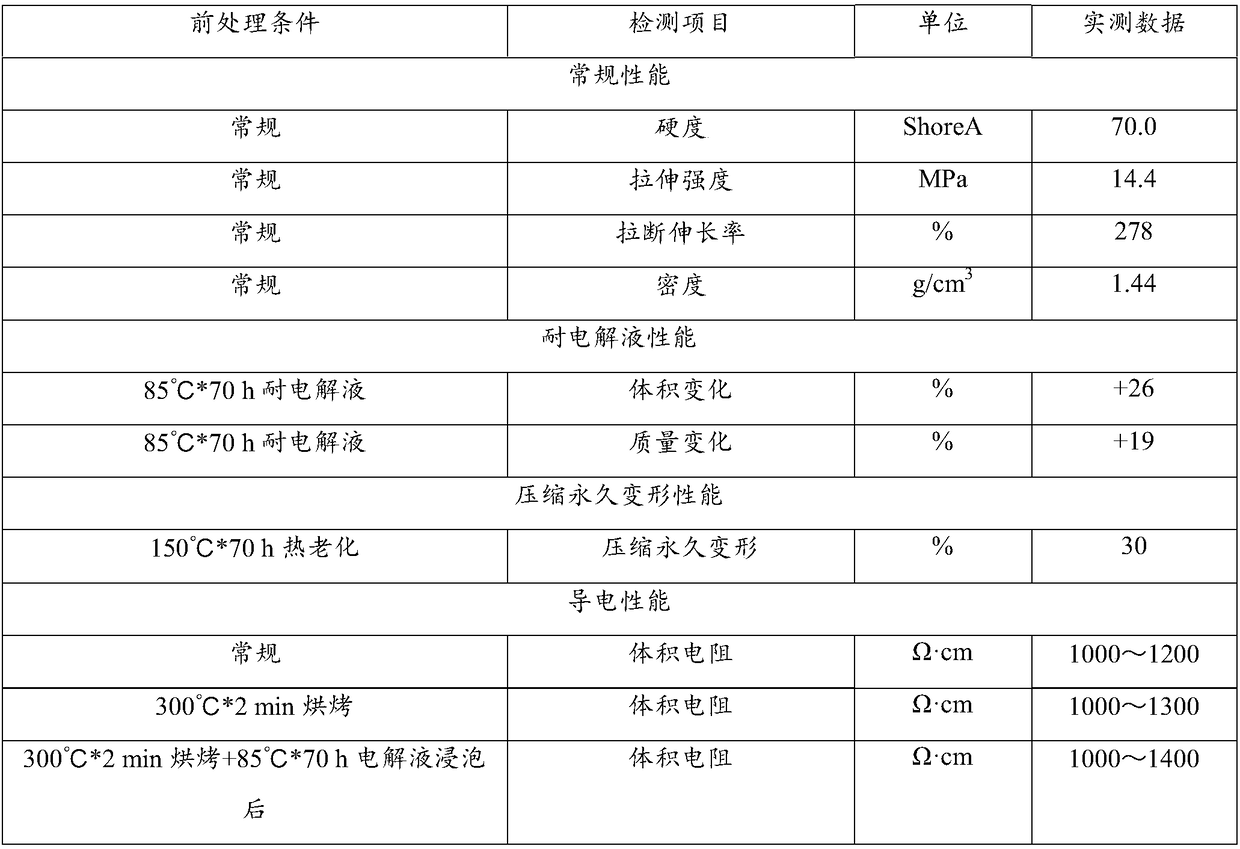

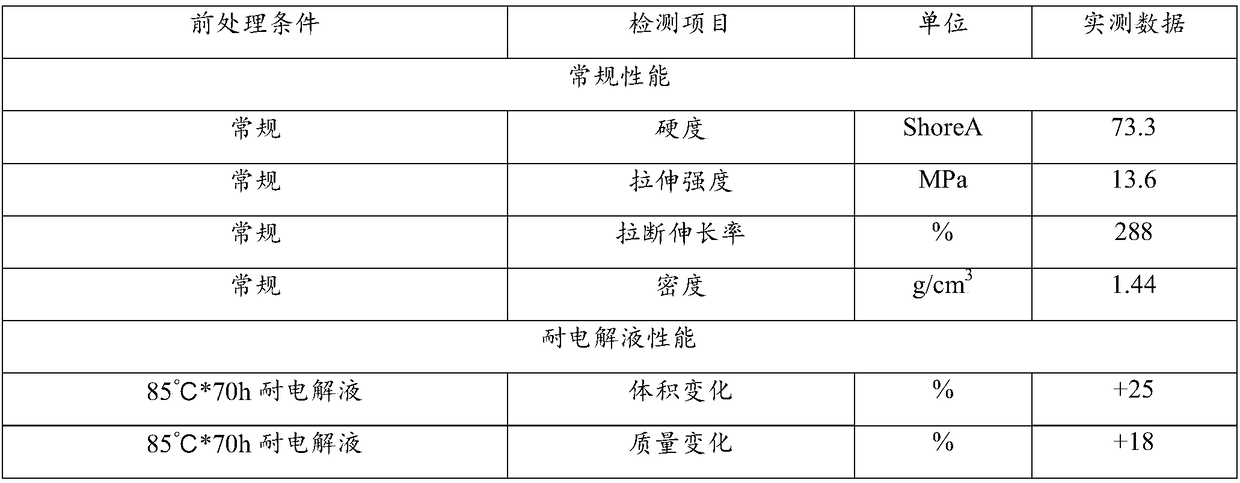

The invention discloses a pole seal material for lithium ion batteries and a preparation method of the pole seal material for the lithium ion batteries. Fluorous rubber serving as a main matrix and auxiliary materials including auxiliary rubber, conductive filler, processing auxiliary agents, a peroxide vulcanizing agent, an auxiliary cross-linking agent and the like are mixed through an open mixing mill or an internal mixing mill to obtain low-compression-set high-conductivity rubber composite material. Under the condition that low resistance and high electrolyte resistance are guaranteed, consumption of the conductive filler is decreased, and the composite material integrates low compression set and high conductivity. The material has excellent conductivity and compressive deformation characteristics, a volume resistance range is 10<2> omega cm-10<4> omega cm, and high-temperature compressive deformation is 30% or below (150 DEG C*70h). In addition, the material is excellent in physical and mechanical property, heat resistance, ageing resistance and electrolyte resistance and is quite suitable for conductive pole sealing of the lithium ion batteries.

Owner:广州国机智能橡塑密封科技有限公司 +1

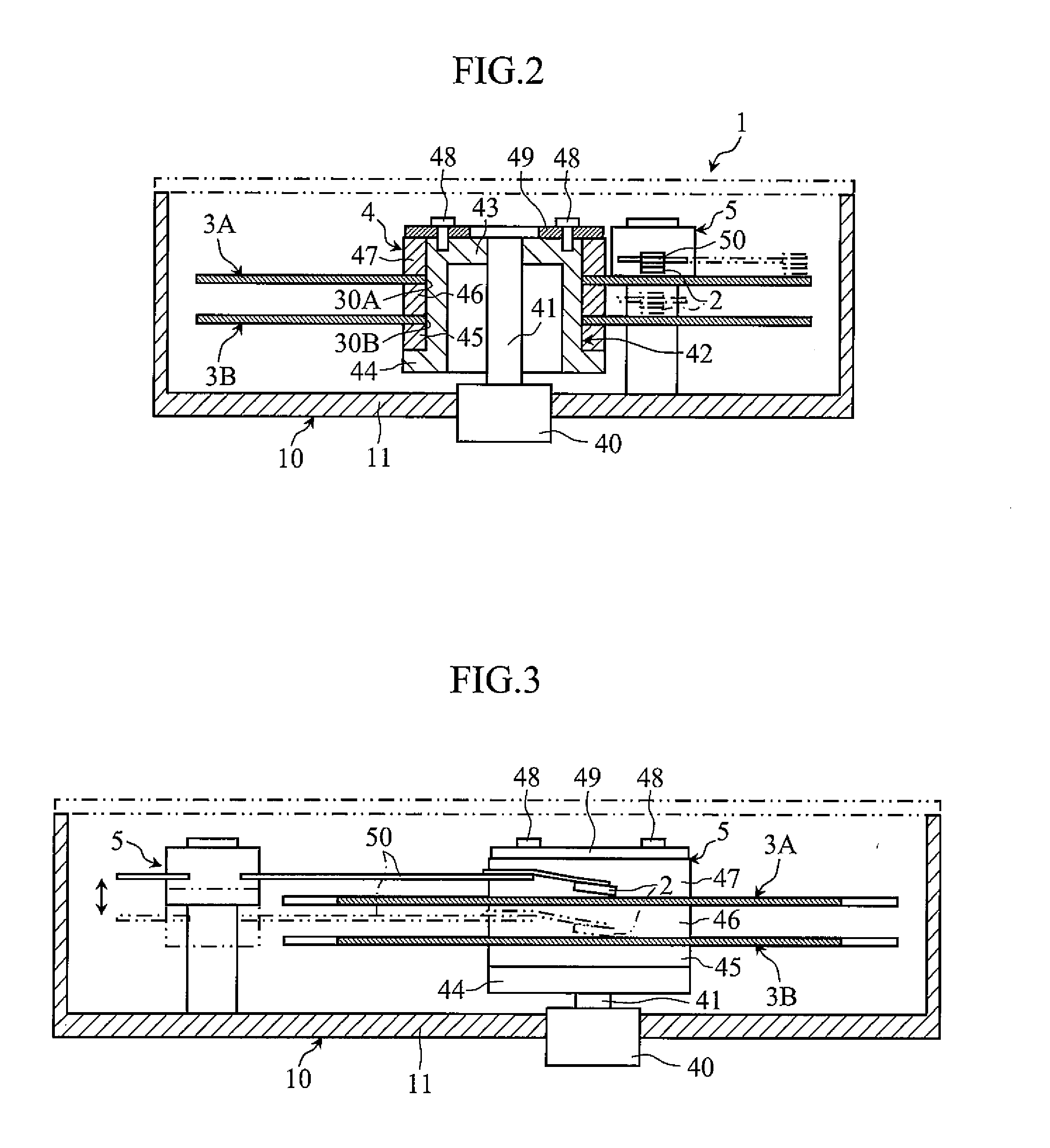

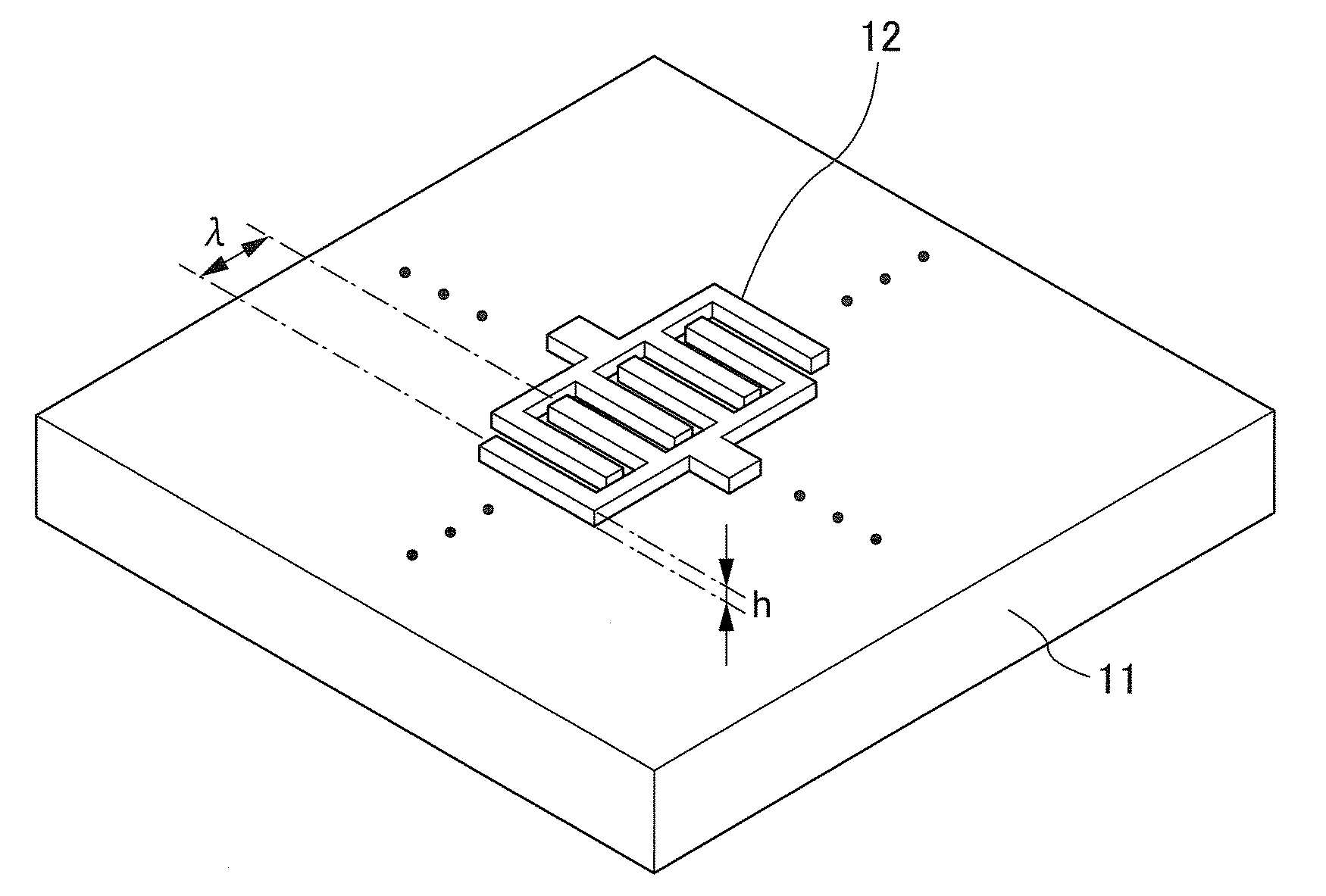

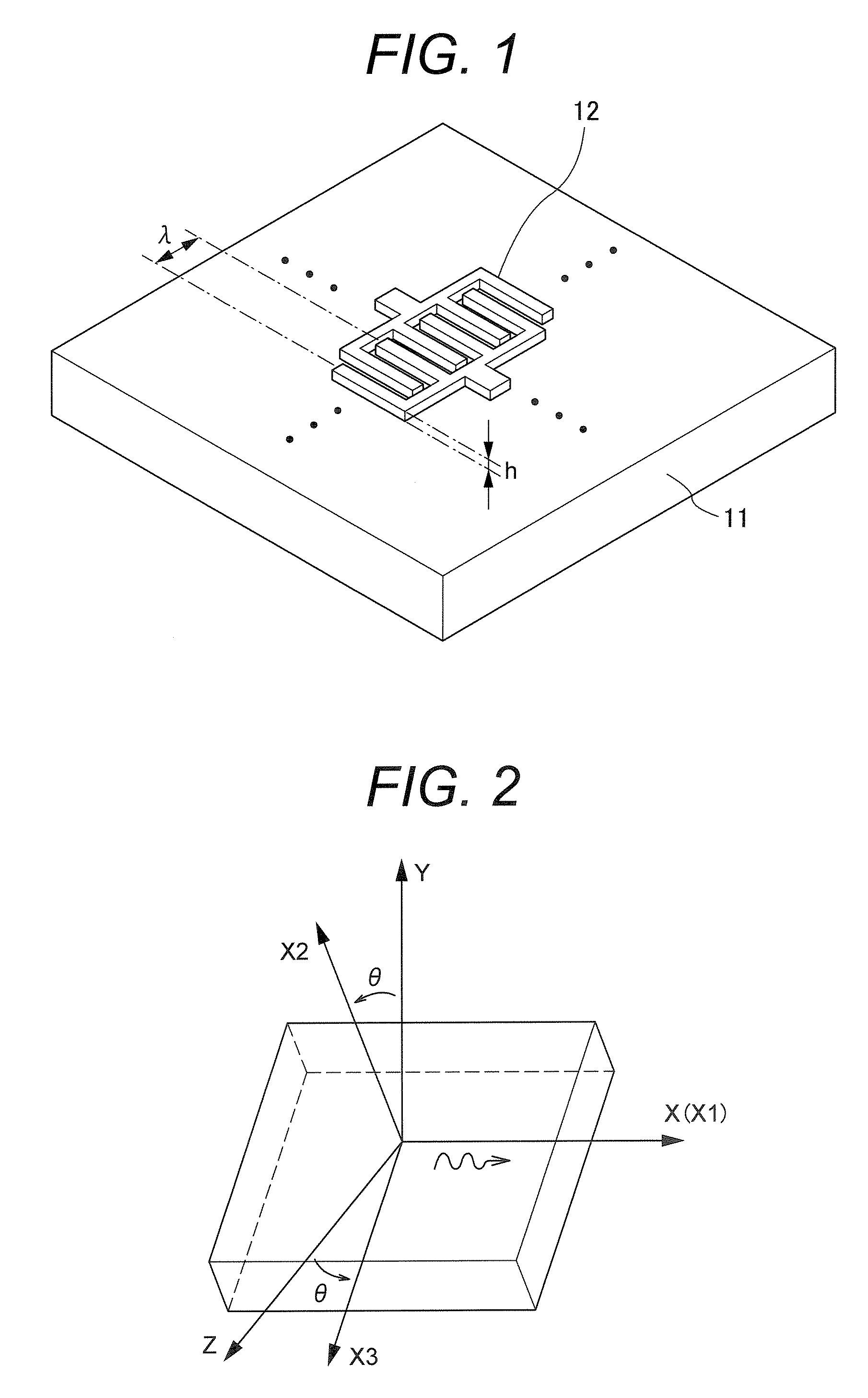

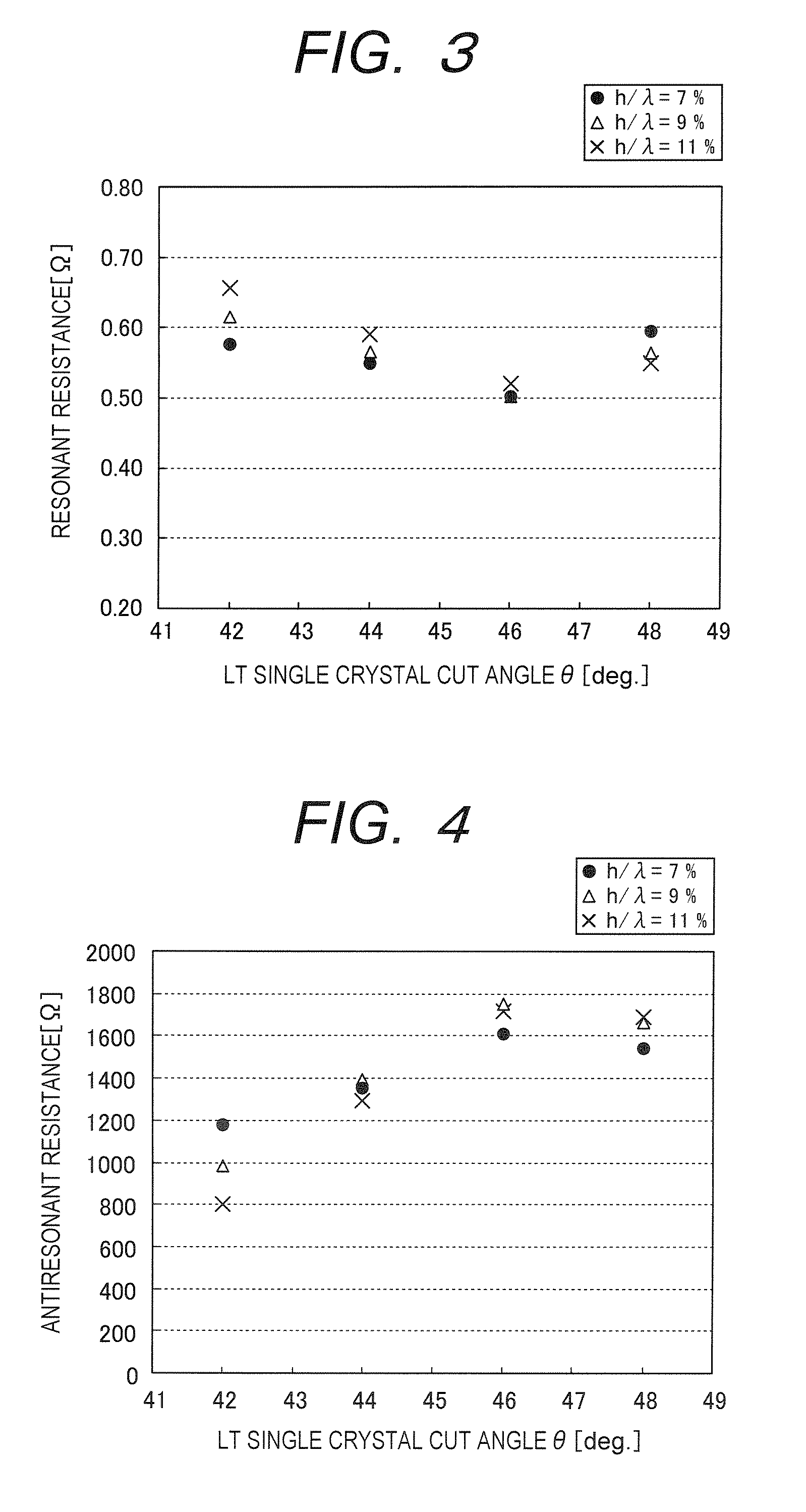

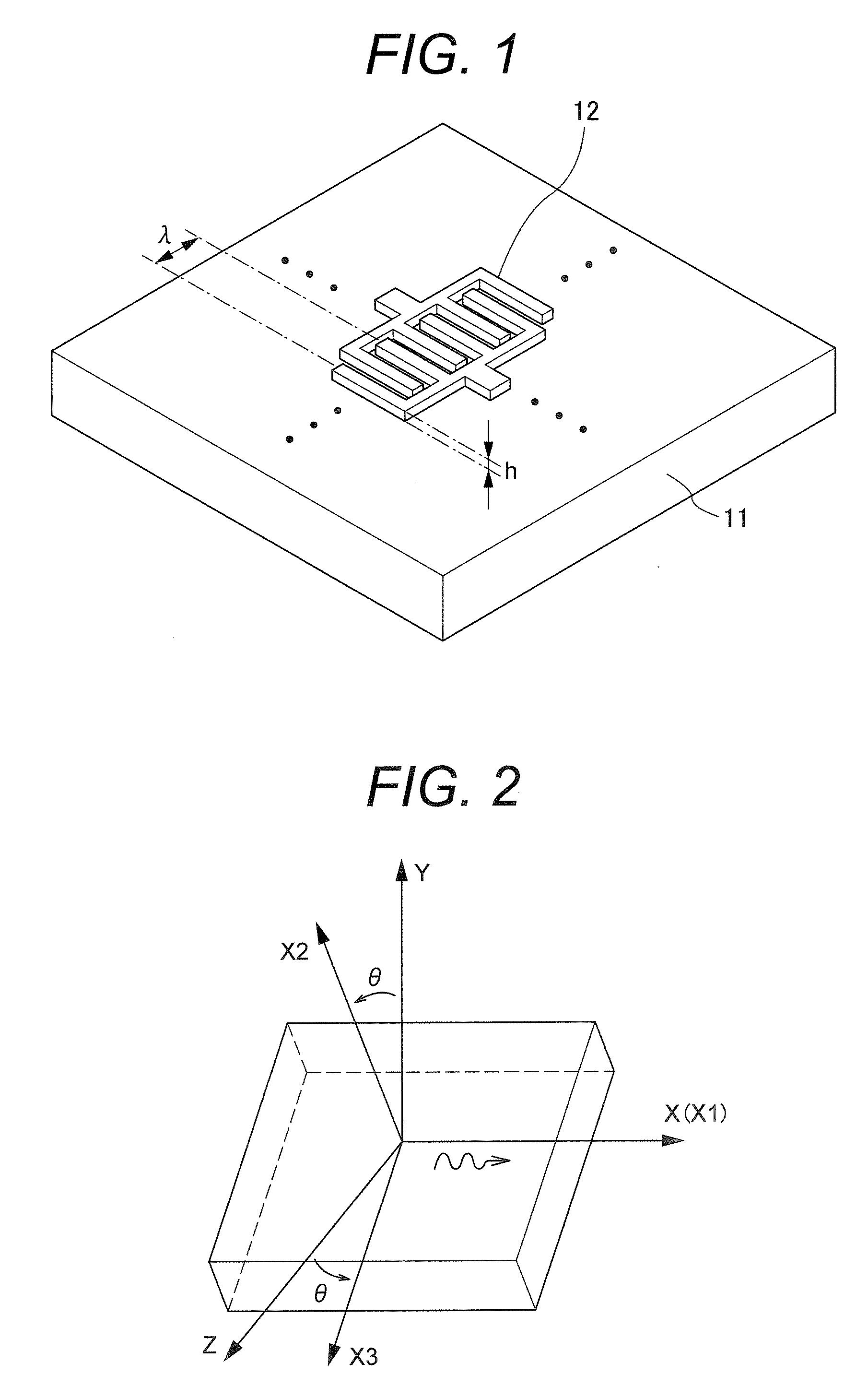

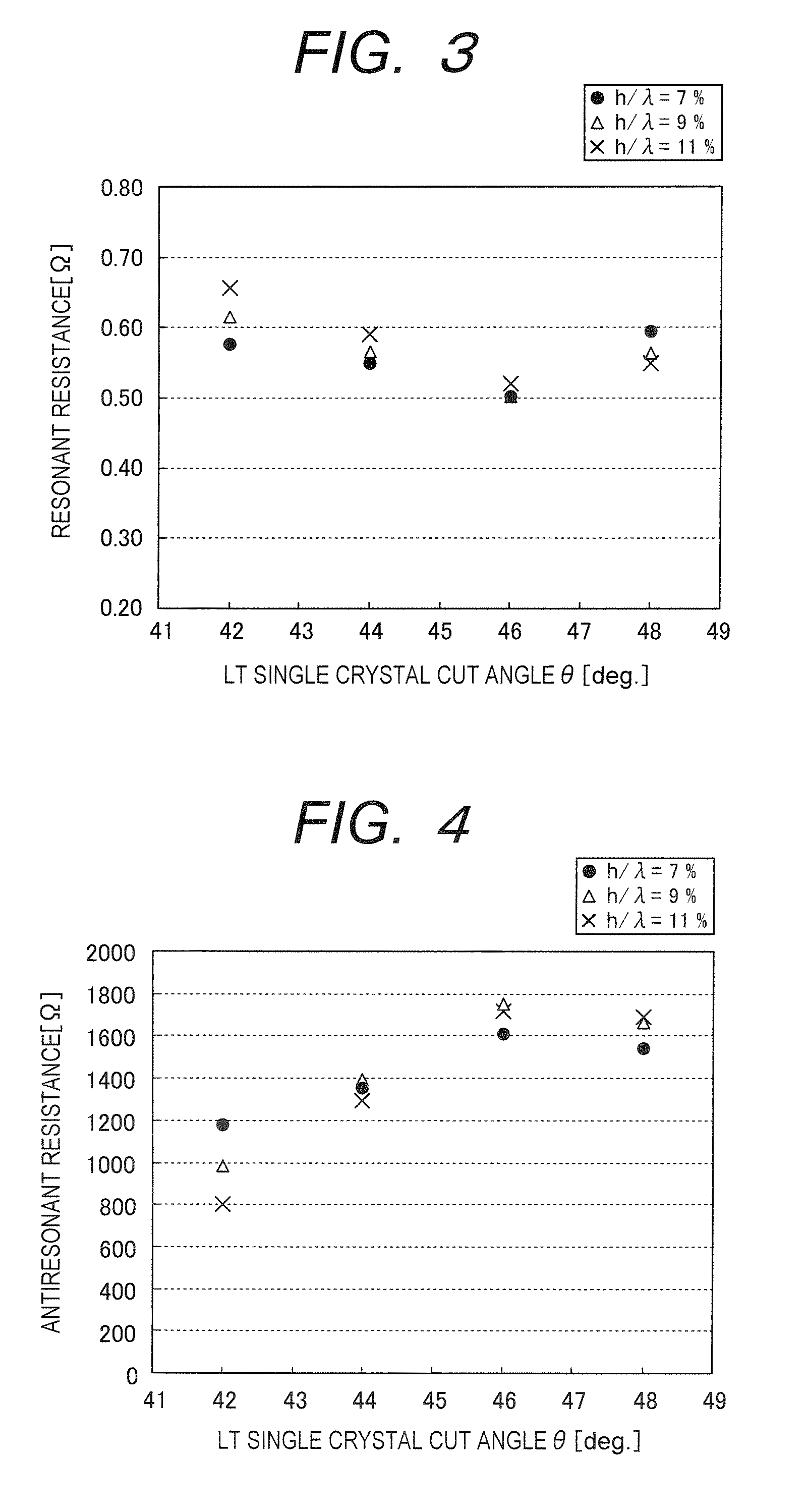

Surface acoustic wave device

ActiveUS20070018533A1Excellent electrical propertiesLower volume resistivityPiezoelectric/electrostriction/magnetostriction machinesImpedence networksSingle crystalPiezo electric

A SAW device comprises a single crystal piezo-electric strate (made, for example, of LiTaO3 or LiNbO3), and an interdigital transducer (IDT) formed of a material mainly containing Al and disposed on the piezo-electric substrate. The piezo-electric strate contains an additive (for example, Fe, Mn, Cu, Ti), and an orientation rotated by an angle in a range of 42° to 48°re preferably 46°±0.3°) from a Y-axis toward a Z-axis about an axis. The IDT presents a normalized thickness h / λ (h: thickness electrode, and λ: spacing between digits of the IDT) of 7% to 11%. A more appropriate substrate cut angle can be shown for the device which employs a piezo-electric substrate containing an additive, to improve the electric characteristics thereof.

Owner:SNAPTRACK

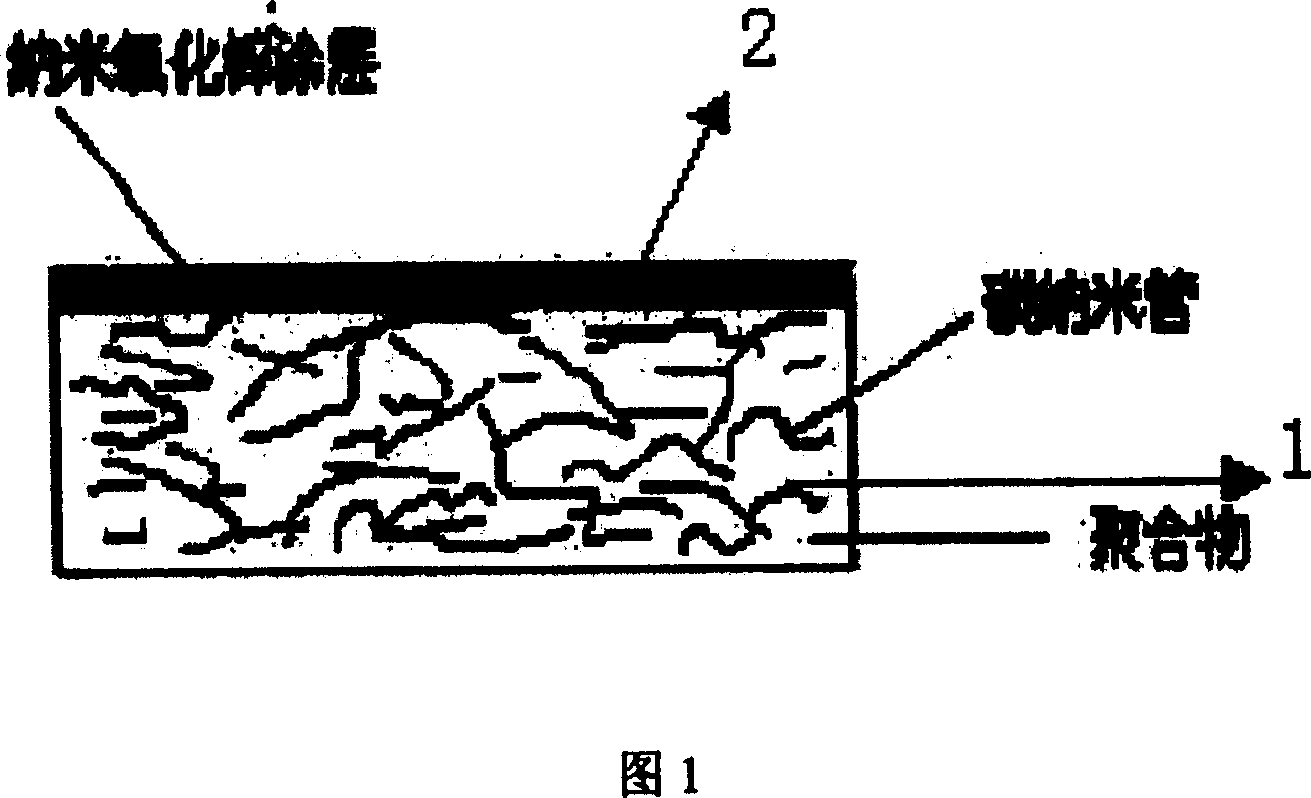

Bamboo carbon nanotube composite coating type absorbing material and preparation method thereof

InactiveCN102233695AImprove conductivityAdjust the frequency rangeLayered productsPretreated surfacesHuman healthNanotube

The invention relates to a composite coating type absorbing material and a preparation method thereof. The material comprises a carrier part and a coating part. The carrier part comprises 50-90wt% of polymer and 10-50wt% of bamboo carbon nanotube; and the coating part comprises but not be limited to the following ingredients: 30-80wt% of paint, 5-30wt% of modified nano bamboo carbon, and 5-42wt% of manganese-nickel-ferrite. The material can be used in the industries of military, communication and the like, with improving the performance of weapon and eliminating the damage of radiation (e.g. cellular radiation) to human health.

Owner:WUXI BIOX ENVIRONMENTAL MEDICINE

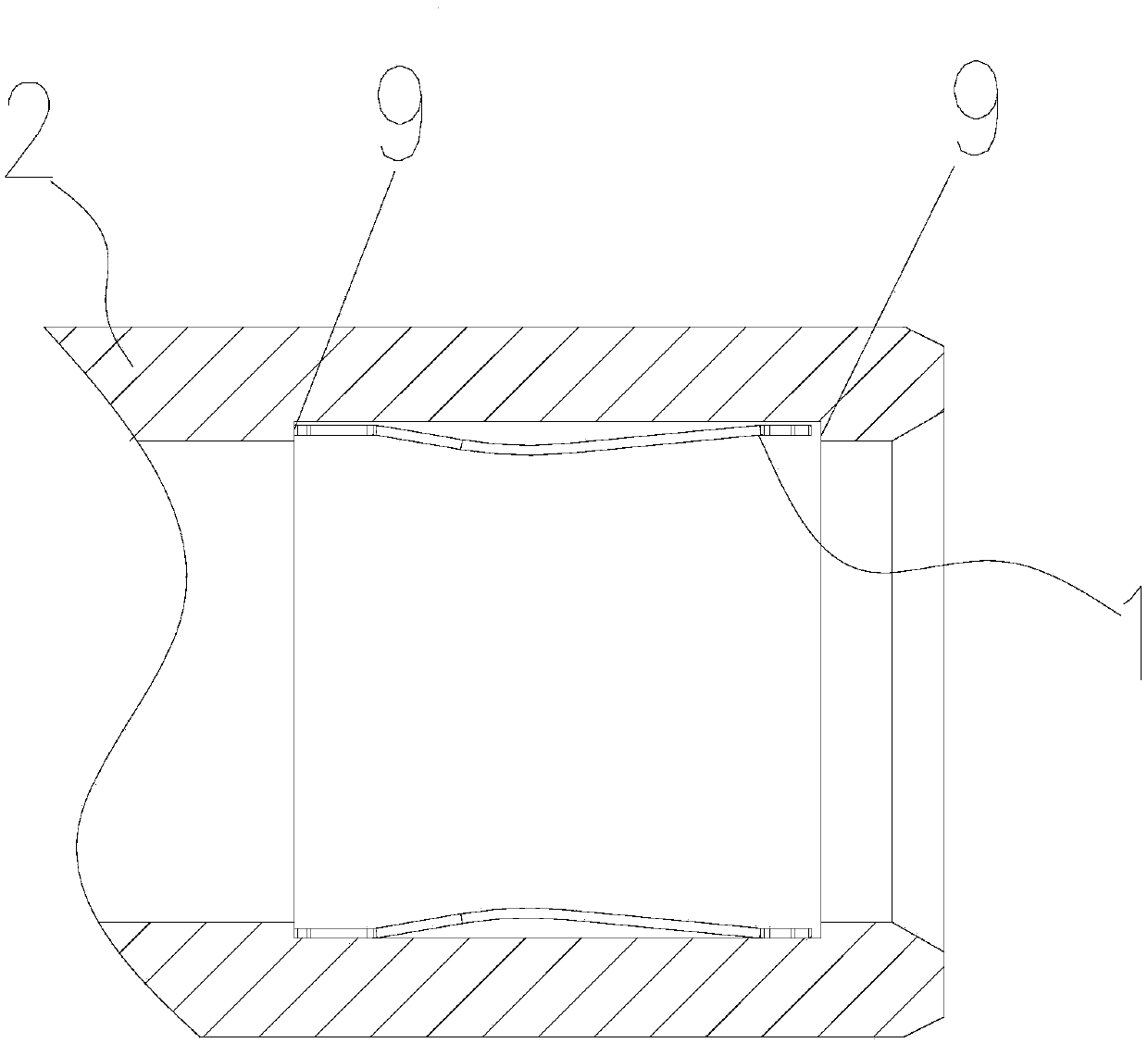

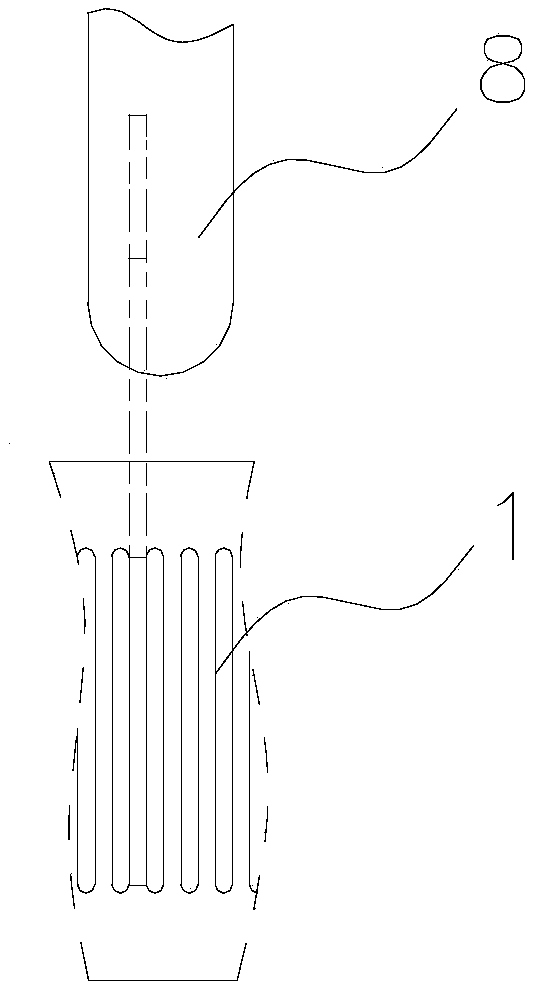

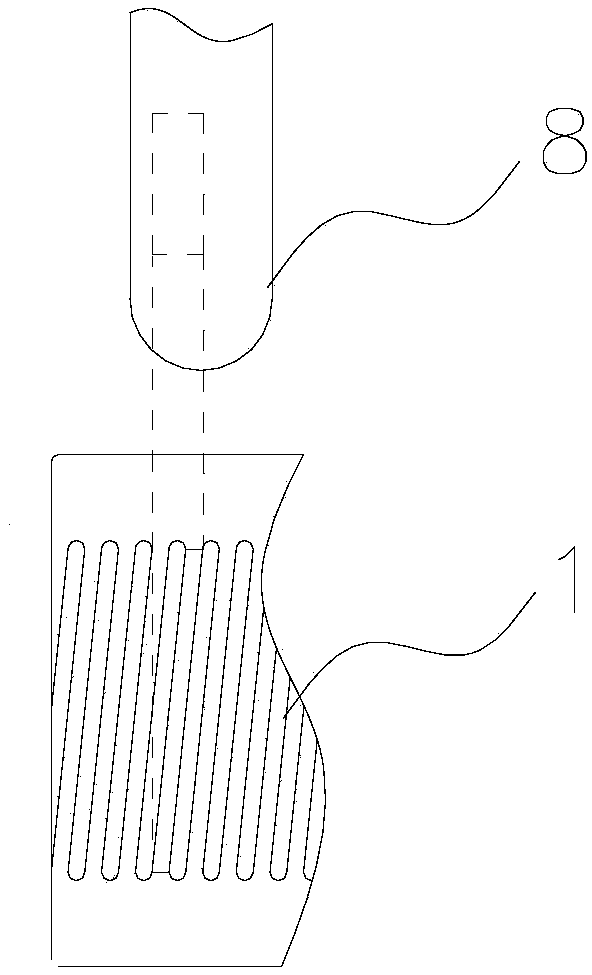

Crown spring mounting structure with good restriction and convenient disassembly

InactiveCN109638511AEasy charging connectionAvoid axial displacement and circumferential displacementSecuring/insulating coupling contact membersCoupling contact membersEngineeringAxial displacement

The invention belongs to the technical field of electric connectors and particularly relates to a crown spring mounting structure with good restriction and convenient disassembly. The crown spring mounting structure includes a crown spring and a sleeve. Elastic folding plates are uniformly distributed on the outer circumferential surfaces of the two ends of the crown spring. A plurality of throughholes are uniformly arranged on the cylinder surfaces of the two ends of the sleeve. The elastic folding plates are disposed in the through holes and have opposite folding directions. The free ends of the elastic folding plates are abutted against the walls of the through holes. The crown spring mounting structure has the beneficial effects that the axial displacement and the circumferential displacement of the crown spring in the sleeve can be avoided, the connection structure of the crown spring and the sleeve is firmly installed, which is convenient for charging connection; regardless of the diameter of the crown spring, the crown spring is convenient to disassemble and convenient to be taken out of the sleeve, thereby contributing to the maintenance of the crown spring; when the crownspring is maintained, the replacement of the connection structure of the sleeve and the crown spring can be avoided and the maintenance cost is saved.

Owner:JIANGSU WANBANG DEHE NEW ENERGY TECH CO LTD

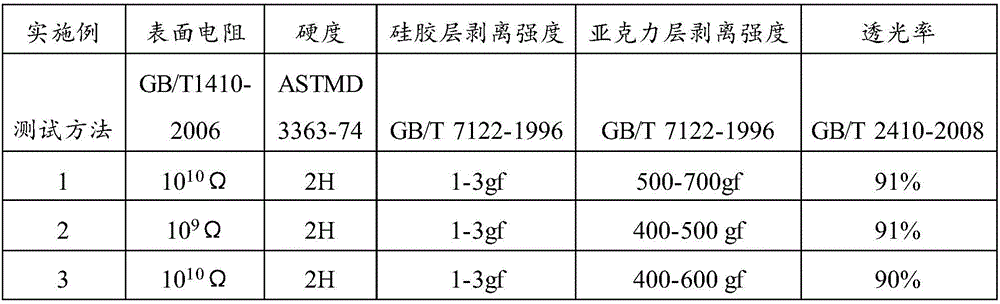

Antistatic protective film and preparation method thereof

InactiveCN106047207ALittle impact on performanceImprove antistatic performanceFilm/foil adhesivesAntistatic agentUltraviolet

The invention provides an antistatic protective film which comprises a stripping layer, a silica gel layer compounded on the stripping layer, a UV (Ultraviolet) layer compounded on the silica gel layer, a substrate layer compounded on the UV layer, an acrylic adhesive layer compounded on the substrate layer and a release layer compounded on the acrylic adhesive layer; the UV layer is made of a material comprising an acrylic monomer, a prepolymer, a photoinitiator and an antistatic agent. The UV layer is formed after the antistatic agent is mixed with a UV adhesive, can achieve an antistatic effect through reducing the volume resistance of the material, is less affected by environmental humidity and also has less influences on the performance of the protective film self. In addition, even if an outermost layer is not coated with the UV layer in the antistatic protective film, a better antistatic effect can also be achieved. Experimental results show that the surface resistance of the protective film provided by the invention can reach 109 ohms. The invention further provides a preparation meted of the antistatic protective film.

Owner:NALI OPTICAL MATERIAL DONGGUAN

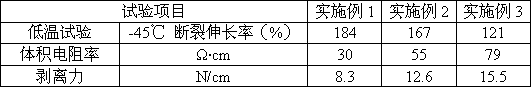

A kind of semiconductive material for ultra-low temperature resistant cable

ActiveCN107286406BReduce volume resistanceImprove flexibilityRubber insulatorsAcrylonitrileConductive materials

The invention discloses a semi-conductive material for a super low-temperature resistant cable. Raw materials related to active ingredients for preparing the semi-conductive material and weight ratios are as follows: 50 to 60 parts of butadiene-acrylonitrile rubber, 20 to 30 parts of chloroprene rubber, 10 to 30 parts of ethylene-vinylacetate rubber, 1 to 2 parts of anti-aging agent 4010NA, 3 to 5 parts of vaseline, 1 to 2 parts of TMTD (tetramethyl thiuram disulfide), 1 to 2 parts of DM, 0.2 to 0.5 part of sulphur, 1 to 2 parts of dicumyl peroxide, 3 to 6 parts of zinc oxide, 2 to 4 parts of magnesium oxide, 40 to 55 parts of carbon black N330, 20 to 40 parts of conductive carbon black and 8 to 12 parts of plasticizer.

Owner:SHANGHAI LANHAO ELECTRIC

Carbon nano-pipe composite coating layer type wave absorption material and its preparation method

ActiveCN1304497CImprove conductivityAdjust the frequency rangeConjugated diene hydrocarbon coatingsRadiation-absorbing paintsThermal energyZno nanoparticles

A coated layer type composite wave absorbing material containing carbon nanotubes is composed of the basic substrate consisting of the polymer chosen from rubber, resin and plastics and carbon nanotubes, and the coated layer consisting of paint and nano-zinc oxide. Its advantages are high effect to absorb radar waves and adjustable frequency range of wave-absorbing peak.

Owner:TSINGHUA UNIV

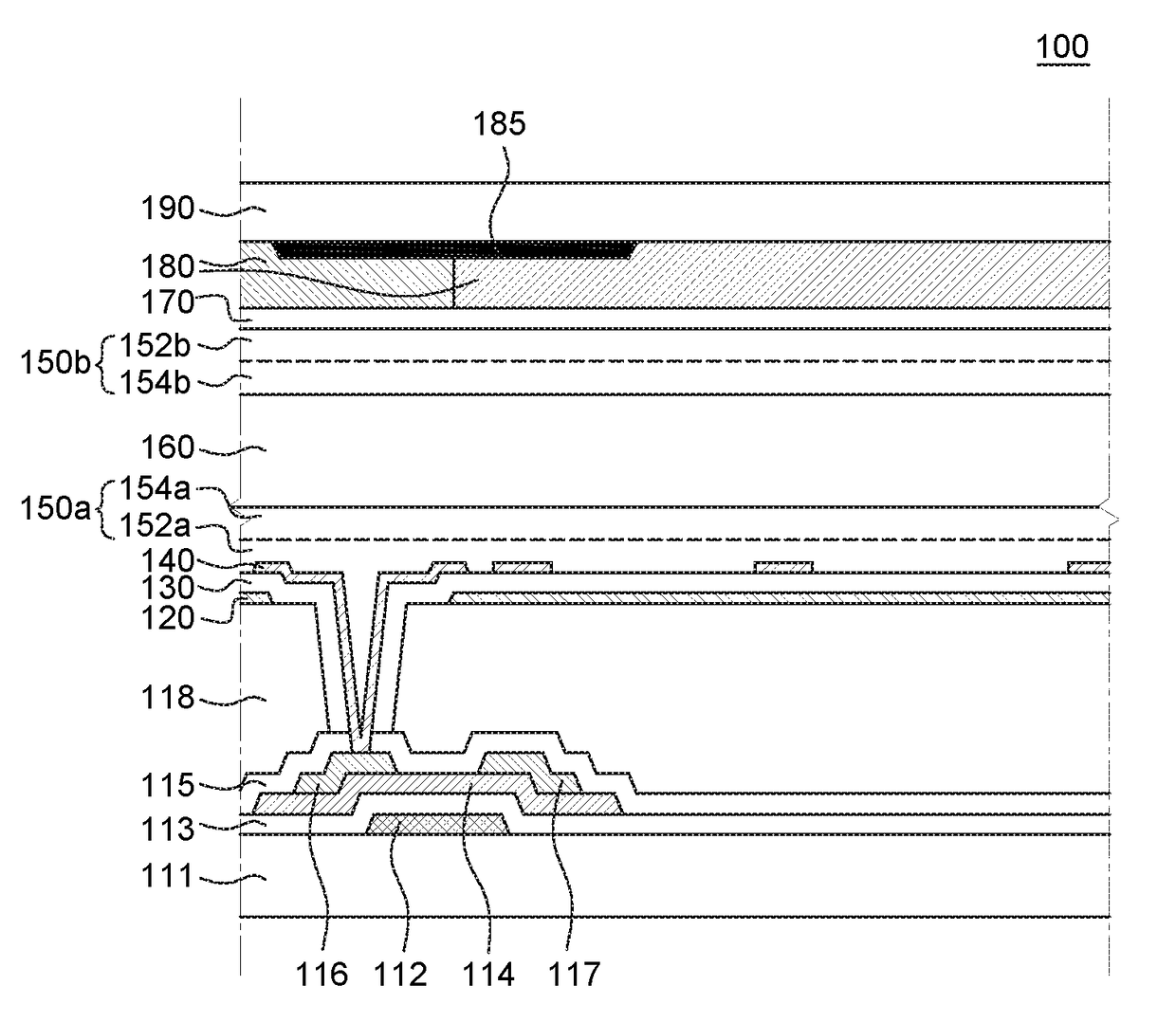

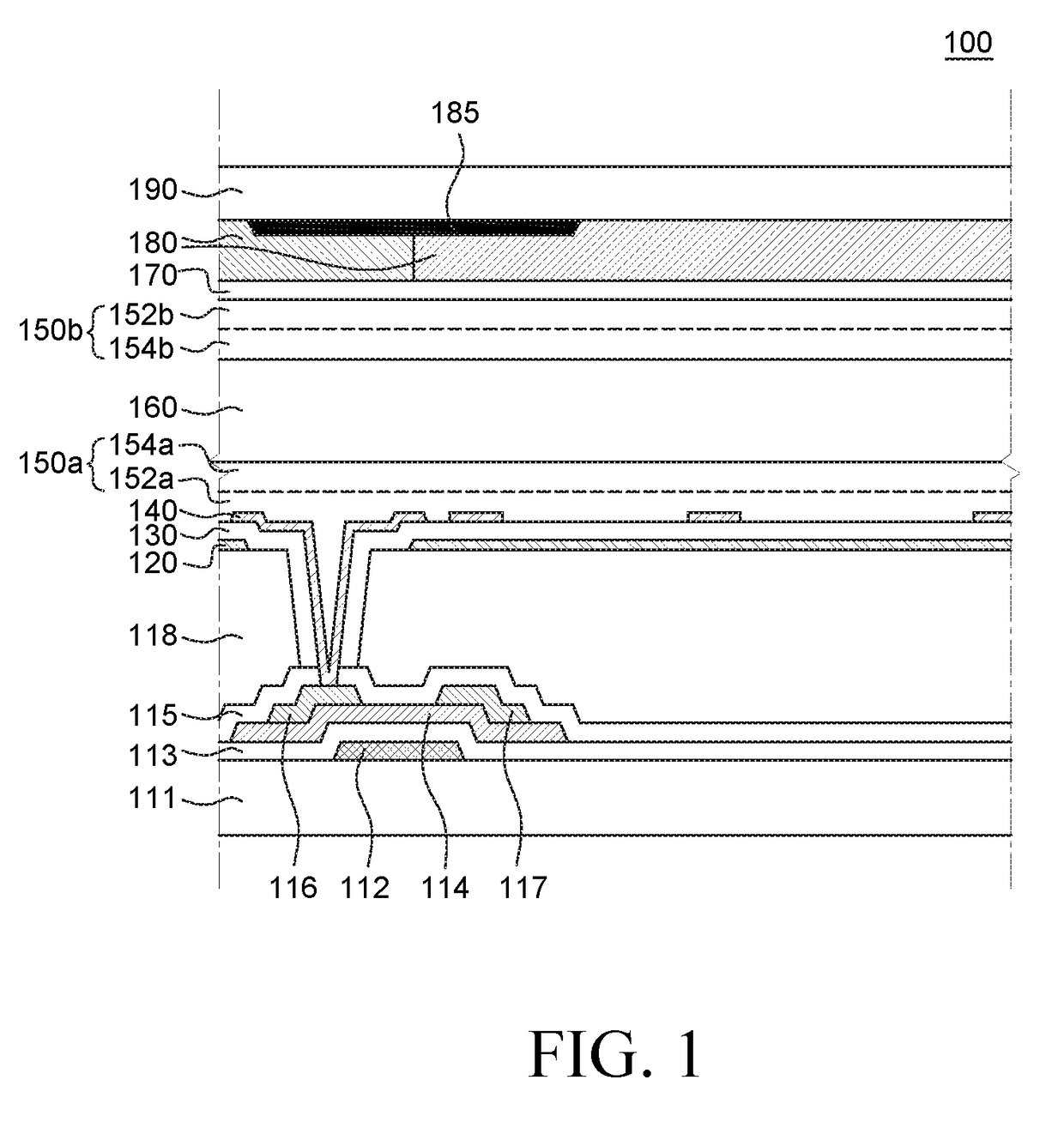

Display device and method for manufacturing the same

A display device and a method of manufacturing the same are disclosed. The display device comprises a thin film transistor on a substrate, a protective film on the thin film transistor, and an alignment film on the protective film. The protective film includes one or more protective films, and a protective film adjacent to the alignment film among the one or more protective films has a silicon content higher than a nitrogen content. Thus, it is possible to provide a display device capable of reducing image sticking or flicker.

Owner:LG DISPLAY CO LTD

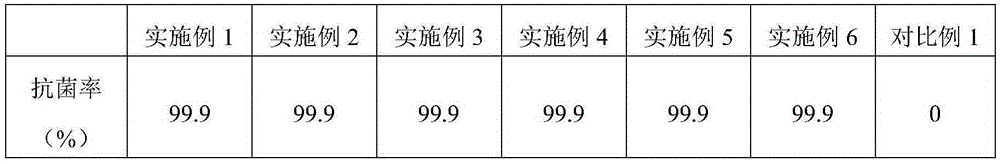

Antibacterial polypropylene resin powder used for selective laser sintering and preparation thereof

InactiveCN106565975AUniform particle size distributionGood fluidity of powderAlkaneSelective laser sintering

A preparing method of antibacterial polypropylene resin powder used for selective laser sintering is provided. The method includes a) dissolving polypropylene resin to an alkane organic solvent at a heating temperature to obtain a polypropylene resin solution, b) cooling the polypropylene resin solution prepared in the step a) to allow a solid precipitate to precipitate out, and c) adding auxiliary agents into a solid liquid mixture obtained in the step b), then fully mixing the mixture, and drying the mixture to obtain the power, wherein the auxiliary agents comprise an antibacterial agent, an antioxidant and a powder separating agent. The method is simple and easy to operate. A sintering raw material having excellent processing performance is provided for selective laser sintering, and a novel direction is provided for processing and application of functional polypropylene resin. The invention further provides the antibacterial polypropylene resin powder prepared by the method and a selective laser sintering method adopting the antibacterial polypropylene resin powder as a sintering powder raw material.

Owner:CHINA PETROLEUM & CHEM CORP +1

Glass fiber reinforced polypropylene resin powder for selective laser sintering and preparation thereof

InactiveCN106589419ASmall sizeImprove mechanical propertiesAdditive manufacturing apparatusSelective laser sinteringOrganic solvent

The invention provides a preparation method of a glass fiber reinforced polypropylene resin powder for selective laser sintering. The method includes the steps of: a) at a heating temperature, dissolving polypropylene resin in an alkane organic solvent to obtain a polypropylene resin solution; b) cooling the polypropylene resin solution obtained by step a) to make solid precipitate out; c) adding assistants into the solid-liquid mixture obtained by step b), mixing the substances evenly, and performing drying so as to obtain the powder, wherein the assistants include ultra-short glass fiber, an antioxidant and a powder separant. The method has the characteristics of simple operation and easy operation, not only provides the sintering raw material with excellent processing properties for selective laser sintering, but also provides a new direction for processing and application of functional polypropylene resin. The invention further provides the glass fiber reinforced polypropylene resin powder prepared according to the method and a selective laser sintering method adopting the glass fiber reinforced polypropylene resin powder as the sintering powder raw material.

Owner:CHINA PETROLEUM & CHEM CORP +1

Static-electricity proof tile

InactiveCN101166627AReduce volume resistancePrevent peelingCovering/liningsSynthetic resin layered productsElectrical resistance and conductanceSynthetic resin

Owner:WOOKYUNG IND +1

A kind of conductive silver glue and preparation method thereof

ActiveCN105602504BLow shrinkageReduce volume resistanceNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyAdjuvant

The invention provides a conductive silver adhesive and a preparation method thereof. The conductive silver adhesive is prepared from the following components in percentage by weight: 10-20 percent of epoxy resin, 65-75 percent of silver powder, 1-10 percent of a curing agent, 0.1-0.5 percent of a curing accelerator, 10-20 percent of a diluting agent and 0.1-1 percent of an adjuvant. Compared with a traditional conductive silver adhesive, the conductive silver adhesive has the advantages of excellent electrical performance, remarkably reduced amount of silver powder, budget cost reduction and mechanical performance improvement. The conductive silver adhesive has excellent stability and application, and the preparation method is simple, has good controllability and is suitable for industrial production.

Owner:RIZHAO ZHONGBANG ELECTRONICS CO LTD

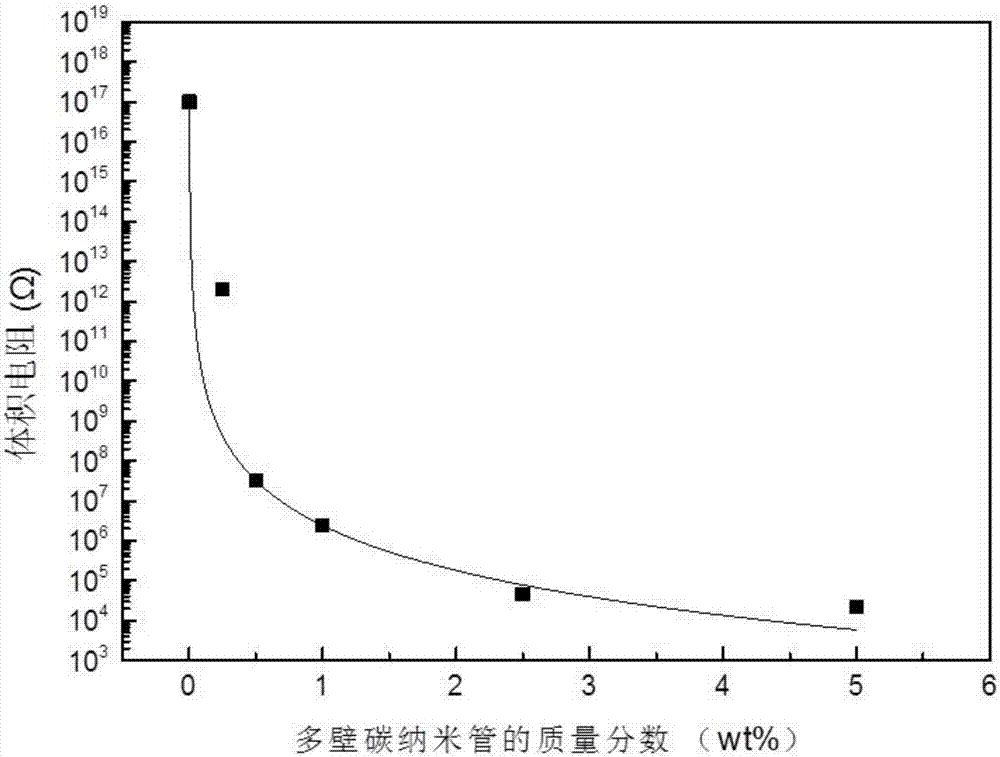

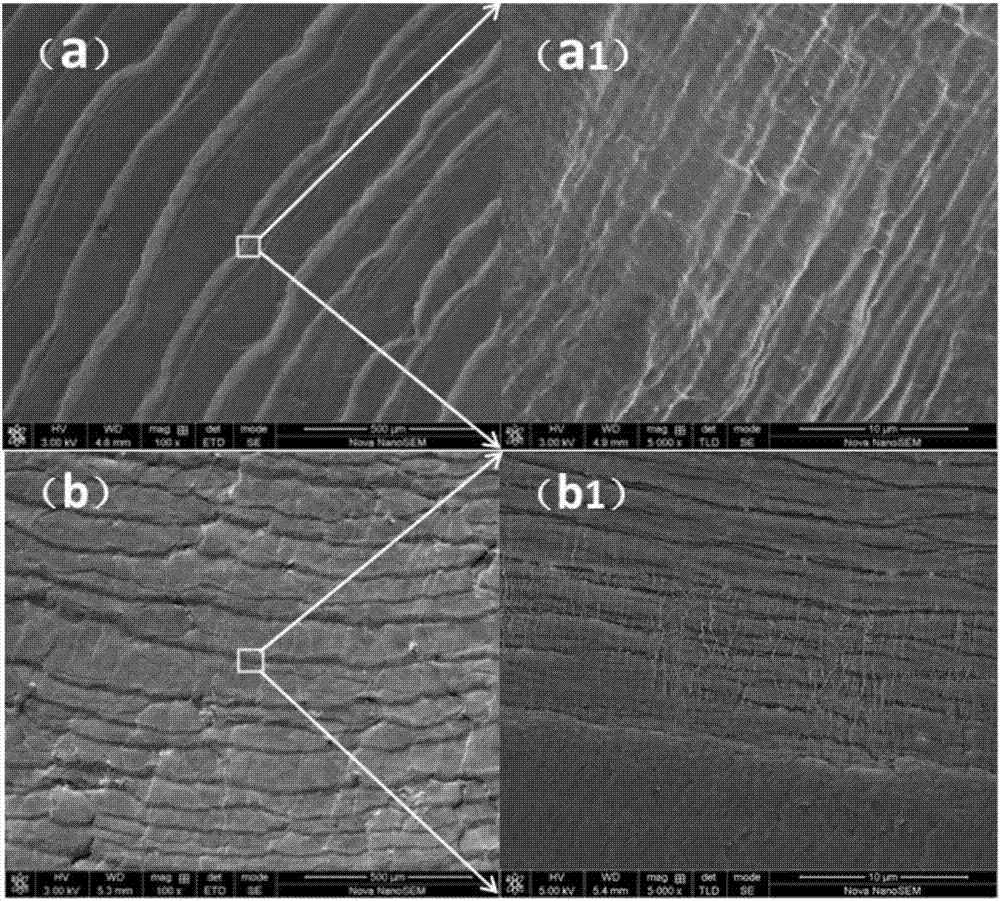

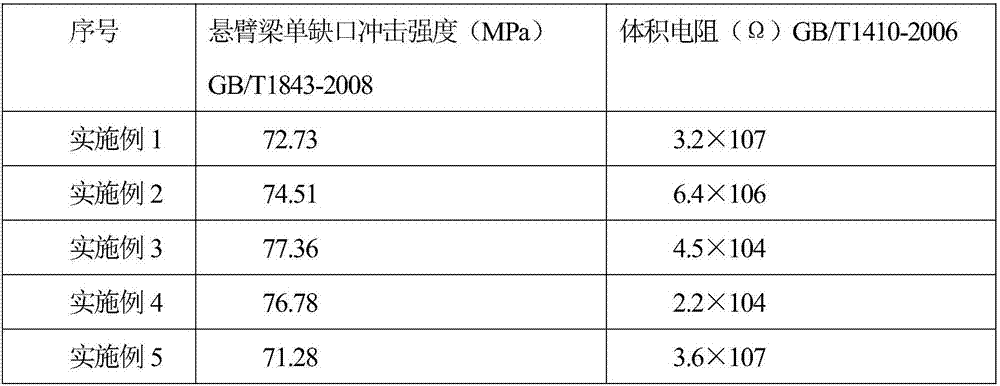

High-impact-resistance anti-static ultra-high molecular weight polyethylene composite material and preparation method thereof

InactiveCN107011561AImprove impact resistanceImprove antistatic performanceElectrical resistance and conductancePolymer science

The invention belongs to the field of high polymer materials and particularly relates to a high-impact-resistance anti-static ultra-high molecular weight polyethylene composite material and a preparation method thereof. The composite material contains a product obtained by compounding multiwalled carbon nanotubes with ultra-high molecular weight polyethylene at an ultra-high rotation speed, wherein the mass percentage content of the multiwalled carbon nanotubes in the composite material is 0.5%-5%. The ultra-high molecular weight polyethylene composite material has anti-static performance, and the volume resistance of the composite material is 103-107 ohms; the composite material has excellent impact resistance, and compared with a pure ultra-high molecular weight polyethylene composite material, the impact resistance is increased by 52.2%-73.9%. The invention further provides the preparation method of the high-impact-resistance anti-static ultra-high molecular weight polyethylene composite material. The preparation method is simple in process, environment-friendly and safe.

Owner:EAST CHINA UNIV OF SCI & TECH

Photosensitive resin composition and cured film

ActiveCN103558734AImprove dispersion stabilityImproved shape stabilityPolarising elementsPhotosensitive materials for photomechanical apparatusAcrylic resinConductive materials

The invention relates to a photosensitive compound, a solidifying film and a septum, which can form excellent pattern with size stability even if a thick solidifying film is obtained and will not decrease the volume resistance even if conductive materials like carbon are used as a shielding component. The photosensitive compound is characterized in that (i) photo-curing resin and / or photo-curing monomer and (ii) acrylic resin grains are the necessary components, wherein the average once grain size of the (ii) acrylic resin grains is 50 to 200 nm and the weight ratio of the (ii) acrylic resin grains to the (i) photo-curing resin and / or photo-curing monomer is 0.1 to 2.0. Besides, the photosensitive compound is applied to making the solidifying film and the septum.

Owner:NIPPON STEEL CHEM &MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com