Photosensitive compound, solidifying film and septum

A technology of photosensitive resin and photocurable resin, which is applied in optics, optical filters, optomechanical equipment, etc., can solve the problems of volume resistivity reduction, poor cross-linking density, and low affinity, so as to reduce volume resistance Effects of reduced reduction, excellent pattern dimensional stability, and excellent dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example A-1~A-7

[0064]

[0065]Acrylic resin particles (Nippon Paint Co., Ltd. Fainsufea), polymer dispersant, and propylene glycol monomethyl ether acetate were mixed in the ratio shown in Table 1, and dispersed with a bead mill to prepare dispersion liquid A-1 containing acrylic resin particles. ~A-4, and a-1. In addition, acrylic resin particles (Nippon Paint Co., Ltd. Fainsfea), resin-coated carbon black (Mitsubishi Chemical MS18E, particle size: 25 nm) as a light-shielding pigment (light-shielding component), and polymer dispersion were mixed in the ratio shown in Table 1 The agent and propylene glycol monomethyl ether acetate were dispersed with a bead mill to prepare a dispersion A-5 containing both acrylic resin particles and light-shielding pigments. Similarly, as a light-shielding pigment, in addition to carbon black, titanium black (manufactured by Mitsubishi Materials Co., Ltd., particle size 30 nm) or mixed organic pigment black (manufactured by Mitsubishi Chemical Co., Ltd., p...

Embodiment 1~11、 comparative example 1~4

[0070]

[0071] The dispersion liquid obtained above and the components described in Table 2 were mixed in the ratios shown in the table, and 0.30 parts of silane coupling agent S-510 (manufactured by Shin-Etsu Chemical) and propylene glycol monomethyl ether acetate were added to make the total amount It is 100 weight part, and a solid content concentration is 20 weight%. Furthermore, 0.005 parts by weight of a silicon-based surfactant SH3775M (manufactured by Toray Dow Corning) was added, and a membrane filter made of polypropylene of 2 μm was added at a rate of 0.2 kg / cm 2 Filtration was performed under pressure to prepare a photosensitive resin composition. In addition, the abbreviation of each component described in Table 2 represents the following compounds, respectively.

[0072] a-3: Nano silica dispersion liquid, NANO BYK-3650 (manufactured by Vitsukuchem Japan, particle diameter 20 to 25 nm)

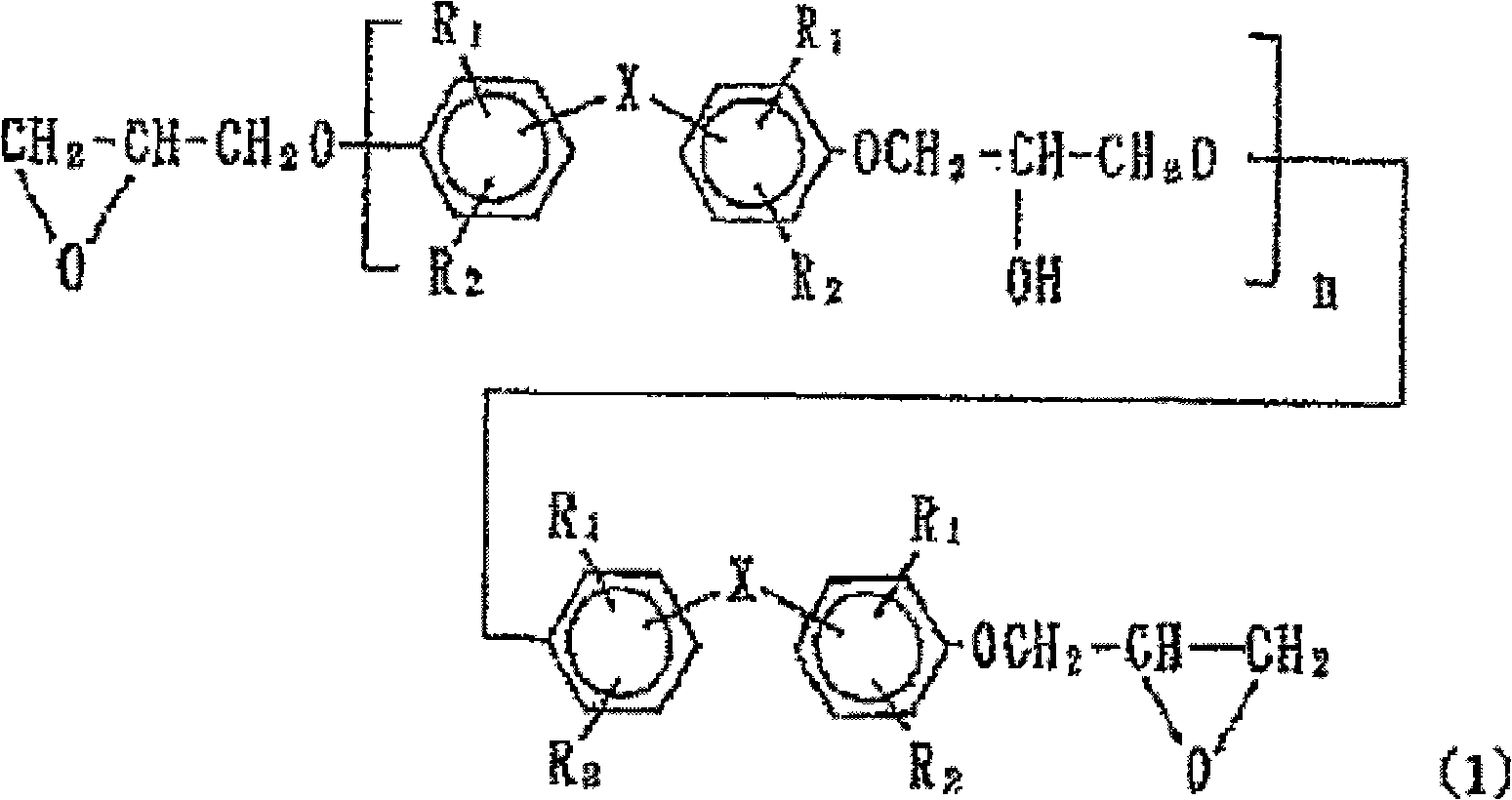

[0073] B-1: Propylene glycol monomethyl ether acetate solution of an ac...

Embodiment 12

[0100] Using the photosensitive resin composition used in Examples 6 to 11, a matrix having light-shielding barrier ribs with an opening (pixel region) of 300 μm×100 μm, a line width of 30 μm, and a film thickness (height) of 2.1 μm was formed. Subsequently, after 3 seconds of treatment with oxygen atmospheric pressure plasma, with CF 4 Atmospheric pressure plasma was performed for 3 seconds. On this light-shielding partition wall (light-shielding film), the static contact angle was measured using water or butyl carbitol acetate (BCA), and was 100° and 50°, respectively. Towards the black matrix, red, blue, and green inks with a viscosity of 9 mPa·sec and a solid content concentration of 20% were injected using an inkjet head manufactured by Toshiba Tec, and post-baked at 230°C to form a color filter. . As a result, a good color filter can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com