Glass fiber reinforced polypropylene resin powder for selective laser sintering and preparation thereof

A polypropylene resin, laser sintering technology, applied in the direction of additive processing, can solve problems such as poor physical and mechanical properties, limitations, etc., to achieve the effect of small size error, fewer holes, and suitable bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

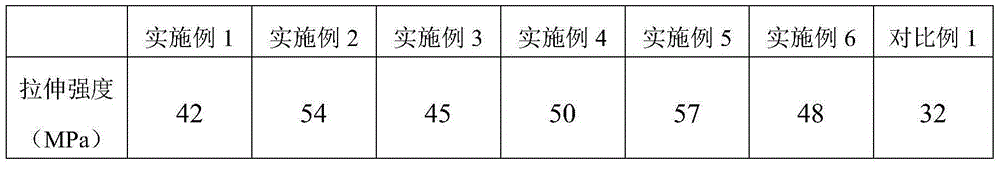

Examples

Embodiment 1

[0037] 100 parts by weight of a polypropylene resin (melt index (210° C., 2.16 kg) of 35 g / 10 min) and 1000 parts by weight of n-hexane were placed in an autoclave. Introduce high-purity nitrogen to 0.2MPa; then raise the temperature to 120°C, and keep the temperature at this temperature for 60 minutes; after the end of the constant temperature, cool down to 80°C with cooling water at a rate of 1.0°C / min, and keep the temperature at this temperature for 60 minutes; continue Decrease to 25°C at a rate of 1.0°C / min, and keep at this temperature for 60 minutes. After adding 10 weight fractions of ultra-short glass fibers with a diameter of 5 μm and a length of 150 μm, 0.25 weight fractions of antioxidant 1010 and 0.25 weight fractions of antioxidant 168, and 0.5 weight fractions of calcium stearate in the obtained solid-liquid mixture , after centrifugal separation and vacuum drying, the glass fiber reinforced polypropylene resin powder suitable for selective laser sintering is o...

Embodiment 2

[0039] 100 parts by weight of a polypropylene resin (melt index (210° C., 2.16 kg) of 55 g / 10 min) and 800 parts by weight of n-hexane were placed in an autoclave. Introduce high-purity nitrogen to 0.3MPa; then raise the temperature to 130°C, and keep the temperature at this temperature for 60 minutes; after the constant temperature is completed, cool down to 20°C with cooling water at a rate of 1.0°C / min, and keep at 20°C for 60 minutes. After adding 25 weight fractions of ultra-short glass fibers with a diameter of 10 μm and a length of 250 μm, 0.25 weight fractions of antioxidant 1010 and 0.25 weight fractions of antioxidant 168, and 1 weight fraction of zinc stearate in the obtained solid-liquid mixture , after centrifugal separation and vacuum drying, the glass fiber reinforced polypropylene resin powder suitable for selective laser sintering is obtained. The particle size of the glass fiber reinforced polypropylene resin powder is 40-130 μm, and the particle size distrib...

Embodiment 3

[0041] 100 parts by weight of a polypropylene resin (melt index (210° C., 2.16 kg) of 70 g / 10 min) and 1200 parts by weight of n-hexane were placed in an autoclave. Introduce high-purity nitrogen to 0.1MPa; then raise the temperature to 110°C, and keep the temperature at this temperature for 90 minutes; after the constant temperature is completed, cool it down to 25°C with cooling water at a rate of 0.1°C / min, and keep the temperature at this temperature for 90 minutes. After adding 10 weight fractions of ultra-short glass fibers with a diameter of 15 μm and a length of 200 μm, 0.1 weight fraction of antioxidant 1010 and 0.1 weight fraction of antioxidant 168, and 0.75 weight fraction of nano-silica in the obtained solid-liquid mixture , after centrifugal separation and vacuum drying, the glass fiber reinforced polypropylene resin powder suitable for selective laser sintering is obtained. The particle size of the glass fiber reinforced polypropylene resin powder is 30-147 μm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com